Understanding the Parts Diagram of John Deere 535 Round Baler

In the world of farming machinery, maintaining optimal functionality is crucial for productivity. Every machine is composed of various elements that work in harmony to perform specific tasks efficiently. Grasping the arrangement and interaction of these components is essential for operators and technicians alike.

Focusing on a particular model, one can delve into the intricate layout of its essential mechanisms. By examining a visual representation of its structure, users can gain insights into the various sections and their respective roles. This knowledge not only aids in troubleshooting but also enhances overall performance and longevity.

By familiarizing oneself with the intricate details of machinery layouts, one can make informed decisions regarding maintenance and repairs. Understanding how each part contributes to the whole empowers operators to optimize their equipment’s use and ensure it meets the demands of the field.

Understanding John Deere 535 Baler

The machine in focus is essential for agricultural operations, especially in hay and forage management. Its efficiency in compressing and forming biomass into manageable units makes it invaluable for farmers seeking to optimize their workflow. By exploring its components and functionality, one can appreciate how it contributes to increased productivity on the field.

Key features of this equipment include its advanced mechanism for gathering materials, as well as its ability to produce consistently shaped bundles. These qualities not only enhance the usability of the output but also facilitate easier transportation and storage. Understanding these aspects helps users maximize the machine’s potential.

Maintenance is crucial for ensuring longevity and performance. Regular checks and replacements of worn elements can prevent costly breakdowns. Familiarizing oneself with the internal workings and the arrangement of its components can significantly aid in troubleshooting and repairs.

Ultimately, mastery of this machinery, including knowledge of its operation and upkeep, can lead to more efficient farming practices, allowing for better resource management and improved crop yield.

Key Components of the Baler

The efficiency of a baling machine hinges on its essential elements, each contributing to the overall functionality and performance. Understanding these crucial components helps operators maintain and troubleshoot effectively, ensuring optimal operation during hay or forage collection.

- Feeding System: This mechanism is responsible for directing the material into the machine, ensuring a consistent flow for processing.

- Compression Chamber: A vital area where the material is compacted into bales, the design of this chamber significantly affects the density and shape of the finished product.

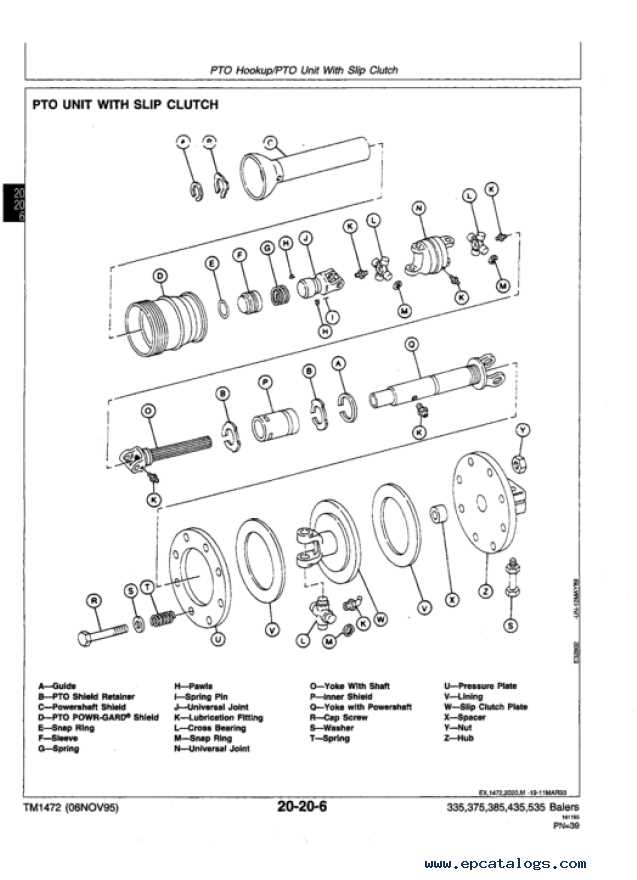

- Wrapping Mechanism: This component secures the bales, often utilizing twine or netting, to keep them intact for transport and storage.

- Drive System: Comprising various gears and belts, this system powers the movement of internal parts and the overall operation of the unit.

- Control Panel: The interface that allows the operator to manage settings and monitor performance, crucial for efficient machine operation.

Each of these components plays a significant role in the successful execution of the baling process. Proper maintenance and understanding of their functions can lead to enhanced productivity and reduced downtime.

Importance of Proper Maintenance

Regular upkeep of machinery is crucial for optimal performance and longevity. Neglecting maintenance can lead to reduced efficiency, increased downtime, and costly repairs. Ensuring that all components are in good working condition not only enhances productivity but also minimizes the risk of unexpected failures.

Enhancing Performance

Proper maintenance directly impacts the effectiveness of equipment. When all parts are functioning as intended, operators can expect smoother operation and better results. Regular inspections and timely replacements of worn-out components help maintain peak performance levels.

Cost Efficiency

Investing time and resources in maintenance can lead to significant savings in the long run. By preventing major breakdowns through routine checks, operators can avoid hefty repair bills and unplanned downtime. A proactive approach ensures that machinery runs efficiently, leading to lower operational costs.

Common Issues and Solutions

When operating large agricultural machinery, various challenges may arise that can hinder efficiency and productivity. Identifying these frequent problems and understanding their solutions is essential for maintaining optimal performance.

Frequent Malfunctions

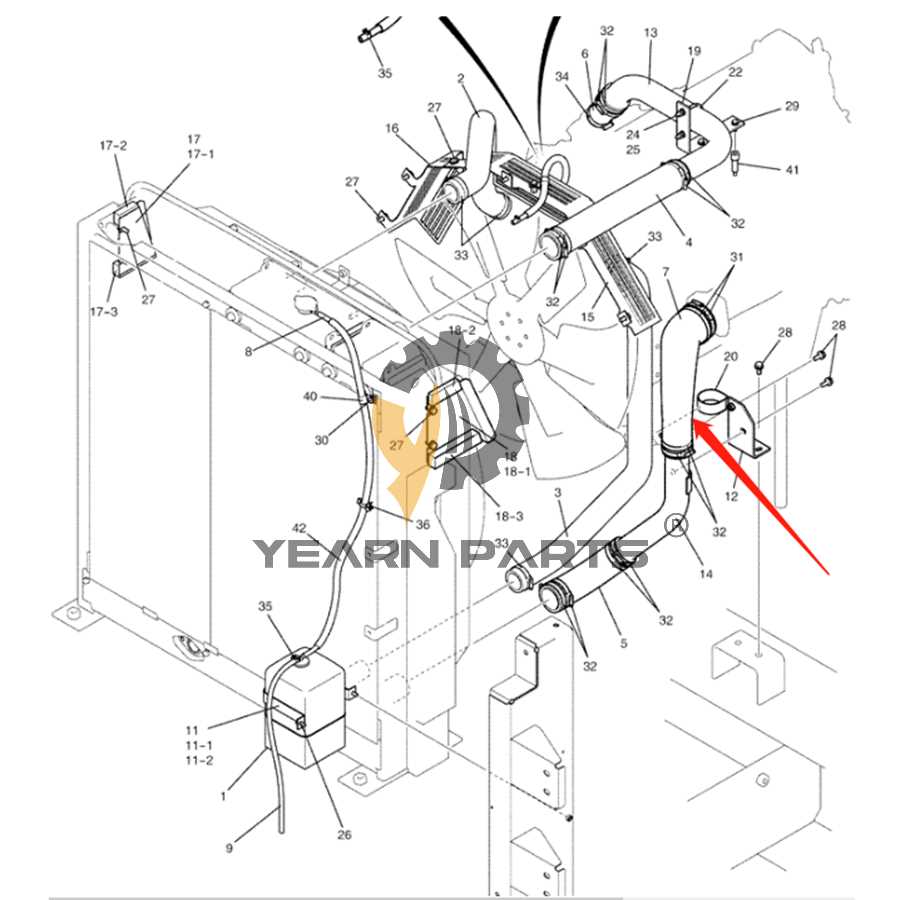

One common issue involves blockages within the system, which can occur due to uneven material flow. Regularly inspecting and clearing these areas can prevent downtime and ensure smooth operation.

Wear and Tear

Another prevalent concern is the deterioration of components over time, which can lead to reduced functionality. Routine maintenance, including lubrication and timely replacement of worn parts, is crucial to extend the lifespan of the equipment.

Where to Find Replacement Parts

Locating the necessary components for agricultural machinery can significantly enhance its efficiency and longevity. There are several avenues to explore when searching for quality replacements, each offering unique benefits and accessibility options.

Online Retailers

The internet hosts a variety of online vendors specializing in equipment components. Websites dedicated to agricultural supplies often provide extensive catalogs, allowing you to compare prices and availability. Customer reviews can guide your purchasing decisions, ensuring that you select reliable products. Additionally, many sites offer detailed specifications, making it easier to find compatible items.

Local Dealerships and Repair Shops

Visiting nearby dealerships or repair shops can yield immediate results. These establishments typically stock essential components and may even provide expert advice on installation and maintenance. Establishing a relationship with local suppliers can be advantageous, as they often offer personalized service and can order specific items if they are not readily available. Networking with local farmers can also provide insights into reputable sources in your area.

Operating the John Deere 535

Efficiently managing this agricultural implement requires understanding its functionality and features. Proper operation ensures optimal performance and longevity, maximizing productivity during hay or forage collection.

Familiarization with Controls: Begin by getting acquainted with the various controls. Each lever and button is designed to streamline processes such as adjusting tension, monitoring baling cycles, and engaging the pickup mechanism.

Pre-Operation Checks: Prior to use, conduct a thorough inspection. Verify that all components are in good condition, including belts, chains, and the pick-up head. Lubrication of moving parts is crucial to prevent wear and tear.

Setting the Machine: Adjust the settings based on the specific type of material being processed. This may involve changing the density settings or modifying the width of the pickup. Proper calibration is essential for achieving desired results.

Operating Procedures: During operation, maintain a consistent speed to ensure even compression and formation of bales. Monitor indicators for any abnormalities, and be ready to adjust as necessary to maintain efficiency.

Post-Operation Maintenance: After use, clean the implement thoroughly to remove any residual material. Inspect for any damage or wear that may have occurred during operation. Regular maintenance extends the lifespan of the machine and enhances reliability.

Benefits of Round Baling Technology

Modern baling techniques offer numerous advantages that significantly enhance agricultural efficiency and productivity. These innovations enable farmers to optimize their processes, ensuring that harvested materials are managed effectively and economically.

Increased Efficiency: The use of advanced baling systems allows for quicker processing of crops, reducing the time between harvesting and storage. This leads to better preservation of feed quality.

Cost-Effectiveness: By minimizing labor and fuel requirements, contemporary baling solutions can lower operational costs. This is especially beneficial for large-scale operations aiming for profitability.

Space Optimization: The compact shape of bales facilitates easier stacking and storage, maximizing available space on farms and reducing the risk of spoilage.

Versatility: These machines can handle a variety of materials, making them suitable for different types of crops and conditions. This flexibility allows farmers to adapt to changing market demands.

Overall, embracing modern baling technology can lead to substantial improvements in agricultural practices, ultimately driving success and sustainability in the industry.

Comparing Different Baler Models

When evaluating various machinery options for hay and forage processing, it is essential to consider the unique features and capabilities of each model. Different machines cater to specific needs and preferences, influencing efficiency and output quality.

Size and Capacity: Some machines are designed for larger operations, offering higher capacity and efficiency, while others are more suited for smaller farms, providing flexibility and ease of use.

Technology and Features: Advanced models may include enhanced technology, such as precision monitoring systems, which can optimize performance. Conversely, simpler versions might focus on reliability and straightforward operation.

Maintenance and Durability: It’s vital to assess the longevity and maintenance requirements of each option. Some machines are built for rugged use, requiring less frequent servicing, while others might need regular attention to maintain optimal function.

Ultimately, making an informed choice involves delving into each model’s specifications, ensuring the selected equipment aligns with operational goals and farming practices.

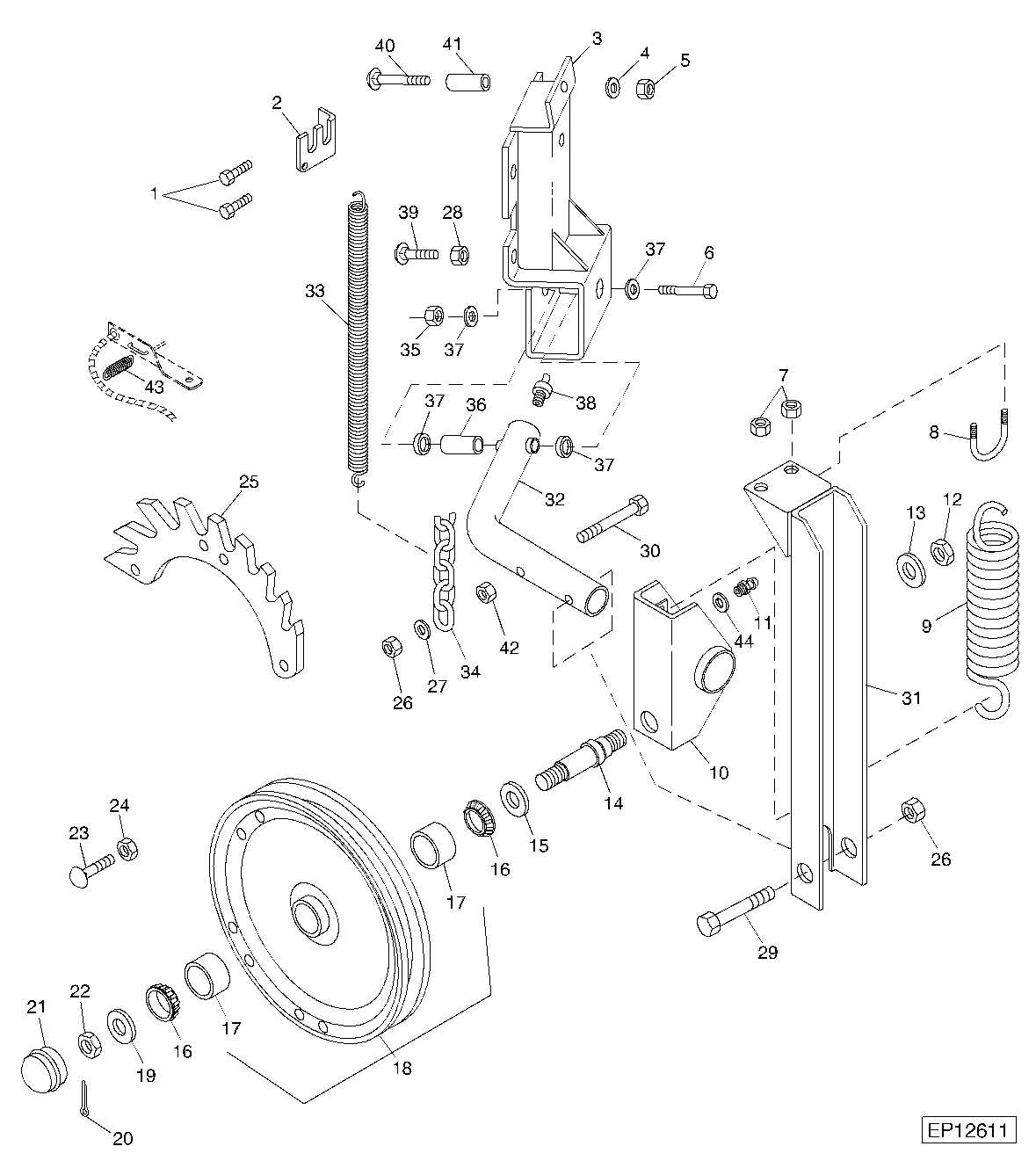

Assembly Instructions for Parts

This section provides a comprehensive guide for assembling various components of your equipment. Proper assembly is crucial for optimal performance and longevity. Follow these instructions carefully to ensure a successful setup.

Essential Tools Required

- Wrenches

- Screwdrivers

- Pliers

- Socket set

- Torque wrench

Step-by-Step Assembly Process

- Begin by laying out all components for easy access.

- Refer to the user manual for specific assembly sequences.

- Secure all connections tightly to avoid any loose fittings.

- Double-check alignment of all parts before finalizing the assembly.

- Test the assembled unit for any unusual noises or movements.

Upgrades and Accessories Available

Enhancing the functionality and efficiency of agricultural equipment can significantly improve productivity. A variety of upgrades and accessories are designed to optimize performance, ensure durability, and make operations more convenient for users. Below are some popular options that can elevate your machine’s capabilities.

Performance Enhancements

- Advanced Hydraulic Systems

- High-Performance Gearboxes

- Improved Pickup Mechanisms

- Enhanced Tensioning Systems

Convenience Accessories

- Automatic Lubrication Kits

- LED Lighting Packages

- Integrated Monitoring Systems

- Custom Hitch Options

Investing in these enhancements not only boosts the efficiency of your equipment but also extends its lifespan, ensuring a valuable return on investment for years to come.

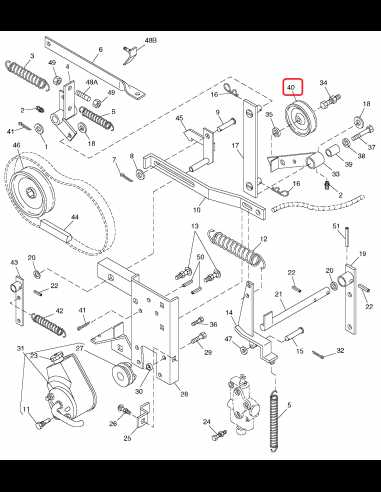

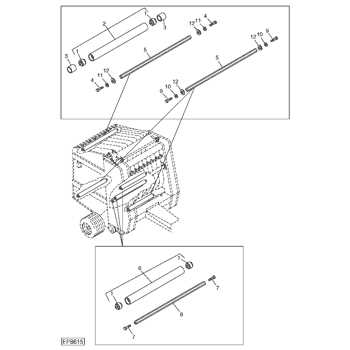

Visual Guide to Parts Diagram

This section provides a comprehensive overview of the components involved in the machinery used for agricultural processes. Understanding the intricate details of each element is crucial for efficient maintenance and operation. A well-illustrated guide can enhance familiarity and streamline troubleshooting efforts.

Key Components Overview

Familiarize yourself with the essential elements, such as the feeding system, tensioning mechanisms, and wrapping units. Each part plays a vital role in ensuring optimal functionality, and recognizing their positions can aid in effective repairs and upgrades.

Maintenance Tips

Expert Tips for Efficient Use

Maximizing productivity and ensuring longevity of your agricultural machinery involves strategic practices and careful attention to detail. By implementing expert recommendations, you can enhance performance and reduce downtime, leading to a more efficient operation overall.

1. Regular Maintenance: Schedule consistent inspections and maintenance to identify wear and tear early. This proactive approach can prevent costly repairs and extend the lifespan of your equipment.

2. Proper Adjustment: Ensure that all components are correctly calibrated for optimal functionality. Incorrect settings can lead to inefficiencies and increased fuel consumption.

3. Quality Materials: Always use high-quality materials and consumables to avoid frequent replacements. Investing in premium components can save time and money in the long run.

4. Training and Familiarization: Educate operators on the proper use and handling of the machinery. Well-trained personnel are less likely to make errors that could result in damage or decreased efficiency.

5. Monitor Performance: Keep track of operational metrics and adjust practices as necessary. Analyzing performance data can reveal patterns that help in optimizing workflows.

6. Optimize Timing: Plan operations around weather conditions and seasonal factors to achieve the best results. Proper timing can significantly impact the quality and efficiency of your work.

By following these expert tips, you can ensure that your agricultural machinery operates at peak efficiency, delivering the best possible outcomes for your farming endeavors.