Exploring the John Deere 541 Loader Parts Diagram

When it comes to heavy machinery, the intricacies of its design and functionality are crucial for efficient operation. This section delves into the various elements that make up a well-known equipment model, shedding light on their arrangement and interaction. A comprehensive overview not only enhances understanding but also aids in maintenance and troubleshooting.

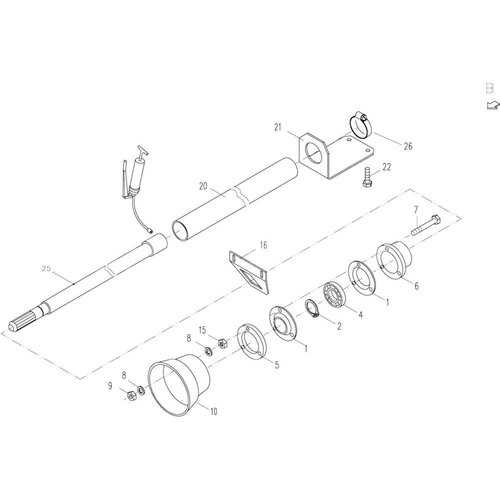

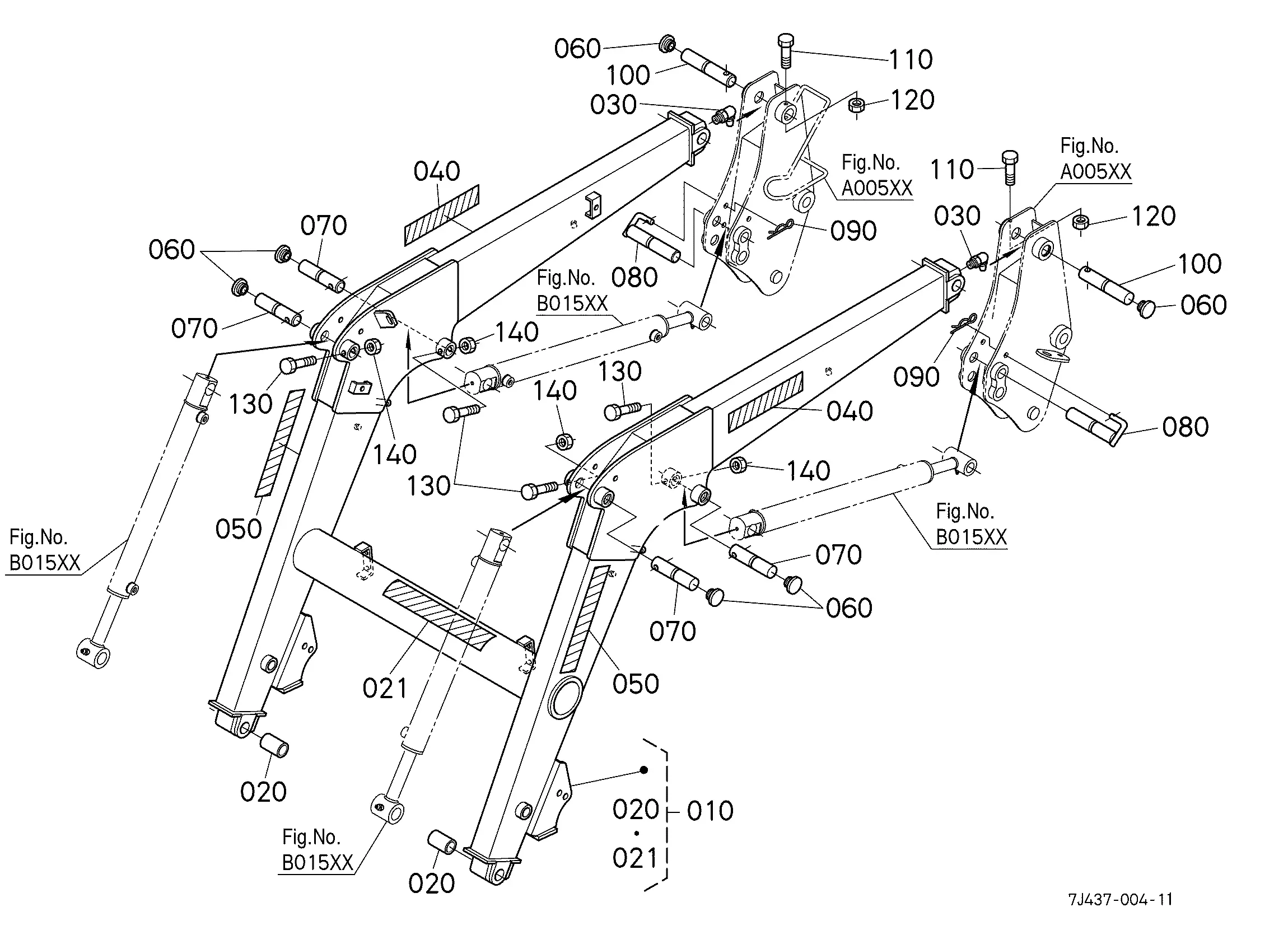

Visual representations of machinery components serve as invaluable tools for both operators and technicians. By breaking down complex systems into manageable parts, users can quickly identify specific sections and their respective roles. This knowledge is essential for ensuring optimal performance and longevity of the equipment.

Furthermore, grasping the layout of each component empowers users to tackle repairs and replacements with confidence. Whether you are a seasoned professional or a newcomer to the field, familiarizing yourself with these diagrams can significantly streamline the process, ensuring that your machine remains in top condition for years to come.

Understanding John Deere 541 Loader

This section aims to provide insights into a specific type of heavy machinery used for various agricultural and construction tasks. It is essential for operators and technicians to grasp the components and functionality of this equipment to ensure efficient operation and maintenance.

Key Features: The machine is designed to handle a variety of attachments, making it versatile for different tasks. Its robust construction allows for heavy lifting and digging, catering to demanding environments.

Maintenance and Care: Regular upkeep is vital for optimal performance. Familiarizing oneself with the various elements of the equipment can lead to improved longevity and reliability.

In summary, a comprehensive understanding of this machinery not only enhances operational efficiency but also empowers users to troubleshoot and resolve issues effectively.

Key Features of the Loader

This machinery is designed for efficiency and versatility, making it an essential tool in various industries. Its robust construction and advanced engineering allow it to perform a wide range of tasks, from lifting and transporting materials to enhancing productivity on job sites.

High Capacity: One of the standout attributes is its impressive lifting capability, which enables it to handle substantial loads with ease. This feature ensures that operators can complete tasks quickly without compromising safety.

Agility: The equipment boasts exceptional maneuverability, allowing it to navigate tight spaces effectively. This quality is particularly beneficial in urban environments or confined job sites where space is at a premium.

Durability: Built to withstand harsh conditions, this machine features high-quality materials and components that contribute to its longevity. Operators can rely on it for consistent performance even in challenging environments.

Operator Comfort: Ergonomically designed controls and spacious cabins enhance the user experience. This attention to comfort allows for longer operating hours without fatigue, improving overall productivity.

Versatility: With the ability to attach various implements, this equipment can perform multiple functions, from digging to grading. This adaptability makes it a valuable asset for any operation.

Importance of Parts Diagrams

Understanding the layout of machinery components is crucial for effective maintenance and repair. Visual representations provide clear guidance, enabling technicians to identify and source the correct elements efficiently. This ultimately enhances operational reliability and reduces downtime.

Key Benefits

- Facilitates accurate identification of components.

- Simplifies the repair process by illustrating assembly.

- Helps in inventory management and ordering supplies.

- Enhances troubleshooting efficiency.

Conclusion

Access to detailed visuals significantly streamlines the maintenance workflow, ensuring that machinery remains in optimal condition. Embracing these resources can lead to better performance and longevity of equipment.

Common Issues with Loader Components

Equipment used in agricultural and construction applications often faces various challenges that can impact performance and efficiency. Understanding these common problems can aid in preventative measures and timely maintenance, ultimately enhancing the longevity and reliability of machinery.

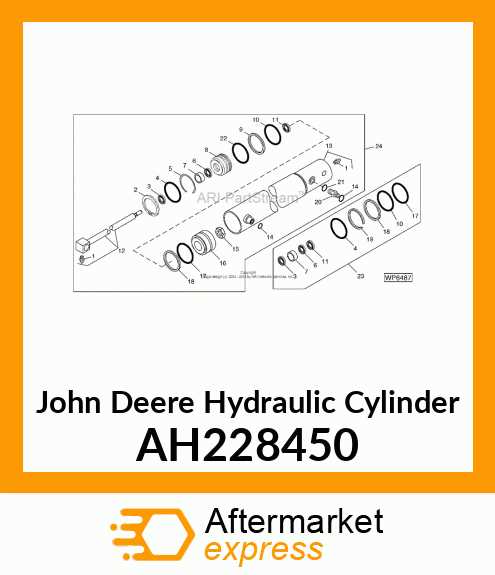

One frequent issue involves hydraulic systems, which may experience leaks or reduced pressure, leading to diminished lifting capabilities. Regular inspections of hoses and connections can help identify these faults early. Additionally, wear and tear on attachment points can result in instability, necessitating thorough checks for any signs of damage or misalignment.

Electrical malfunctions are another concern, particularly in control systems. Faulty wiring or connectors can hinder operations, making it crucial to ensure all electrical components are secure and functioning properly. Regular diagnostic tests can assist in pinpointing any underlying issues.

Lastly, general wear on moving parts, such as joints and bearings, can lead to increased friction and potential breakdowns. Implementing a consistent lubrication routine can significantly mitigate this risk, ensuring smooth operation and extending the lifespan of critical components.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations offer a clear view of each element, allowing users to identify parts and comprehend their arrangement within a system. Familiarizing yourself with the structure and symbols used can greatly enhance your ability to work with mechanical assemblies.

Key Elements to Observe

When examining these illustrations, focus on the following aspects:

| Element | Description |

|---|---|

| Symbols | Specific icons represent various components, indicating their function and connectivity. |

| Numbers | Numerical labels often correspond to a list of items, simplifying identification and ordering. |

| Lines | Connecting lines illustrate relationships between components, showing how they fit together. |

Steps to Decode the Illustration

To effectively interpret these visuals, follow a systematic approach:

- Start by reviewing the legend or key to understand symbols and terminology.

- Identify each labeled component and note its position and connection.

- Cross-reference with the accompanying list to ensure accuracy in identification.

- Utilize this understanding to inform maintenance tasks or repairs.

Essential Replacement Parts Overview

This section highlights the critical components necessary for maintaining operational efficiency and performance in heavy machinery. Understanding these elements ensures that equipment remains reliable and minimizes downtime during use.

Key Components to Consider

Focusing on essential elements such as hydraulic systems, control mechanisms, and structural reinforcements is vital. These components not only enhance functionality but also contribute to the longevity of the machinery.

Importance of Quality

Investing in high-quality replacements is crucial for optimal performance. Durability and reliability are paramount, as they directly affect the overall efficiency and safety of the equipment.

Finding Genuine John Deere Parts

When it comes to maintaining machinery, sourcing authentic components is crucial for ensuring optimal performance and longevity. Using original elements not only enhances functionality but also supports the integrity of the equipment. With the right approach, locating these high-quality replacements becomes a straightforward task.

Researching Authorized Dealers is a vital first step. Trusted vendors often have direct connections with manufacturers, ensuring that the components they offer meet rigorous quality standards. By choosing an official distributor, you can be confident in the authenticity of your purchase.

Online Resources also play a significant role in the search for legitimate components. Numerous websites provide extensive catalogs and detailed information about available items. Utilizing these platforms allows for informed decisions and can help identify specific requirements tailored to your machine.

Additionally, community forums and networks can be invaluable. Engaging with fellow enthusiasts and professionals can yield recommendations for reliable suppliers and tips on identifying genuine products. These interactions foster a supportive environment where knowledge is shared.

Finally, always keep an eye out for certifications and warranties. Genuine components typically come with assurance from the manufacturer, guaranteeing quality and performance. Investing in these verified items ultimately saves time and resources in the long run.

Tools Required for Repairs

Proper maintenance and repair of machinery necessitate a set of essential instruments. Utilizing the right tools not only enhances efficiency but also ensures safety during the repair process. Familiarizing yourself with the necessary equipment can significantly ease the task at hand and lead to better outcomes.

Essential Hand Tools

For effective repairs, a variety of hand tools is required. Wrenches, screwdrivers, and pliers are fundamental for disassembly and reassembly. Additionally, having socket sets and torque wrenches is crucial for achieving the correct tightness on bolts and screws.

Power Tools and Equipment

Incorporating power tools can greatly streamline the repair process. Drills and impact wrenches help with more demanding tasks, while grinders and cutters assist in shaping and modifying components. Investing in quality equipment can lead to the ultimate efficiency in repairs.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment requires diligent care and regular attention. By implementing a few simple maintenance practices, you can enhance performance and reduce the risk of costly repairs. A proactive approach not only keeps machinery in optimal condition but also ensures safety during operation.

Regular Inspections

Conducting routine evaluations is essential. Check for any signs of wear or damage, particularly in critical components. Lubrication is key to minimizing friction and prolonging the life of moving parts. Always follow the manufacturer’s guidelines regarding intervals and types of lubricants.

Proper Cleaning

Maintaining cleanliness is another fundamental aspect. Debris and dirt can accumulate, leading to inefficiencies and potential malfunctions. Use a soft brush or compressed air to remove contaminants, particularly from cooling systems and filters. Regular washing can prevent rust and corrosion, thereby enhancing the durability of the equipment.

Step-by-Step Repair Guide

This section provides a comprehensive approach to efficiently addressing mechanical issues. Following a systematic process ensures that repairs are conducted with precision and effectiveness.

- Assess the Situation: Start by evaluating the equipment’s condition. Identify any visible damage or irregularities.

- Gather Tools: Collect all necessary tools and replacement components to streamline the repair process.

- Refer to Diagrams: Utilize available schematics to understand the assembly and locate the components needing attention.

- Disassemble Carefully: Begin the disassembly of affected parts, noting their arrangement for reassembly.

- Inspect Components: Examine each piece for wear and damage. Replace any that are beyond repair.

- Reassemble: Follow your notes and diagrams to reassemble the equipment, ensuring all components are secure.

- Test Functionality: Once reassembled, test the equipment to confirm that it operates smoothly.

- Regular Maintenance: Implement a maintenance schedule to prevent future issues and extend equipment lifespan.

Frequently Asked Questions

This section addresses common inquiries regarding components and their configurations for various machinery. Understanding these aspects can enhance maintenance and repair efficiency.

What should I consider when looking for replacement components? It is essential to ensure compatibility with your equipment model, check for quality certifications, and confirm the supplier’s reputation.

How can I identify the right component for my machine? Referring to the service manual and utilizing online resources can help pinpoint the correct item based on specifications and visual references.

Are there any tips for maintaining these components? Regular inspection, proper cleaning, and timely lubrication can significantly extend the lifespan of your machinery parts.

Where can I find reliable sources for purchasing components? Authorized dealers, reputable online marketplaces, and specialized stores are excellent options to consider.

Online Resources for Parts Ordering

Accessing the right components for machinery has never been easier thanks to various digital platforms. These resources offer detailed catalogs, user-friendly interfaces, and secure purchasing options, streamlining the process for users seeking essential supplies.

| Resource | Description | Benefits |

|---|---|---|

| Manufacturer Website | Official site providing comprehensive catalogs of components. | Direct access to the latest products and specifications. |

| Online Marketplaces | Platforms where various sellers offer a range of items. | Competitive pricing and user reviews for informed choices. |

| Specialized Retailers | Stores focusing on specific types of machinery supplies. | Expert advice and tailored recommendations available. |

| Forums and Community Groups | Online discussions where users share experiences and sources. | Peer support and tips on where to find rare components. |

Customer Reviews and Experiences

This section highlights the insights and feedback from users who have engaged with the machinery and its components. Real-world experiences offer valuable perspectives on the functionality, durability, and overall satisfaction related to the equipment. Users often share how these tools have impacted their projects, providing potential buyers with a clearer understanding of what to expect.

User Feedback

Many users express their appreciation for the reliability and efficiency of their machines. For instance, one customer noted, “The performance has exceeded my expectations; it handles heavy loads with ease.” Others emphasize the importance of quality construction, stating, “I’ve invested in multiple units, and they have all proven to be robust and dependable.”

While experiences are predominantly positive, some users have faced challenges. A few reviews mention difficulties in sourcing specific components. One reviewer shared, “Finding the right replacements can be tricky, but once located, they fit perfectly.” This feedback serves as a reminder for potential buyers to consider support and service availability when making their choices.