Understanding the John Deere 544J Parts Diagram for Efficient Maintenance

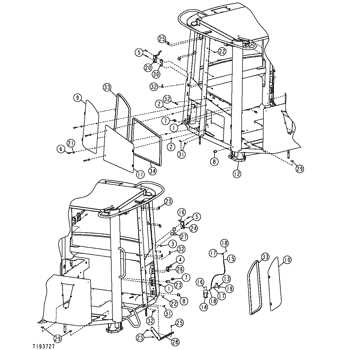

When operating heavy machinery, a comprehensive understanding of the various components and their interrelationships is essential for effective maintenance and repair. These layouts serve as a visual guide, enabling operators and technicians to quickly identify parts, understand their functions, and streamline the servicing process. Such diagrams are invaluable for ensuring that equipment runs smoothly and efficiently.

With a focus on enhancing operational efficiency, detailed representations of machinery components can greatly assist in troubleshooting and parts replacement. They offer a clear view of how each piece fits into the overall system, making it easier to pinpoint issues and undertake repairs. This is particularly crucial in preventing prolonged downtime, which can be costly for any operation.

By familiarizing oneself with these illustrative guides, users can cultivate a deeper knowledge of their machinery, leading to more informed decisions regarding maintenance schedules and repairs. Ultimately, this expertise not only extends the lifespan of the equipment but also enhances overall productivity on the job site.

Understanding the John Deere 544J

This section aims to provide insights into a specific model of heavy machinery, focusing on its key components and functionalities. Knowing how these machines operate and the parts involved is essential for effective maintenance and operation.

Key Features of the Machine

This particular piece of equipment is renowned for its robust performance and versatility. Its powerful engine, combined with advanced hydraulic systems, enables it to handle a variety of tasks efficiently. Operators appreciate its ease of use, allowing for both precision and power in different working conditions.

Maintenance and Care

Proper upkeep is crucial for ensuring longevity and optimal performance. Regular inspections and timely replacements of essential components can prevent costly breakdowns. Understanding the layout of internal systems and how they interact is vital for any operator or technician aiming to keep this machinery in peak condition.

Key Features of the 544J Model

The 544J model is renowned for its exceptional capabilities and robust design, making it a favored choice among operators in various industries. This machinery combines power and efficiency, providing outstanding performance in demanding environments.

Powerful Engine: Equipped with a high-performance engine, this model delivers impressive horsepower, ensuring optimal productivity during heavy tasks. The engine’s design promotes fuel efficiency, allowing for extended operation without frequent refueling.

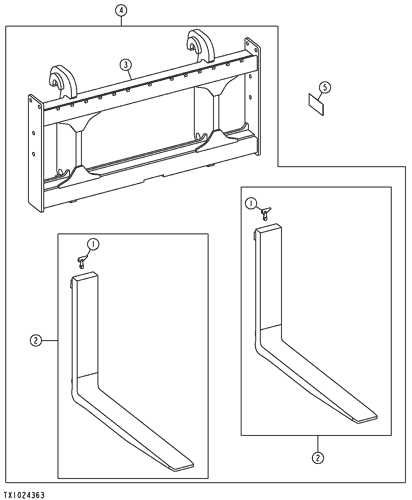

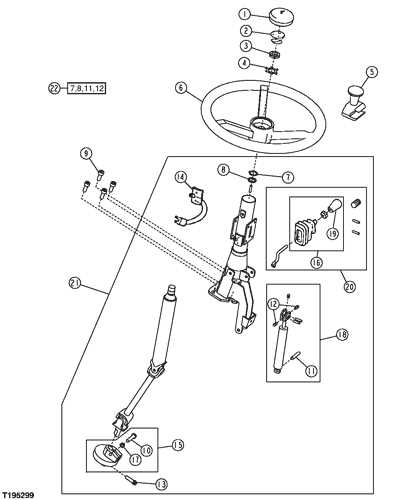

Advanced Hydraulics: The hydraulic system is designed to enhance lifting and digging capabilities, providing operators with precision control and responsiveness. This feature significantly boosts overall efficiency, enabling seamless handling of various attachments.

Operator Comfort: An ergonomic cab design prioritizes user comfort, offering adjustable seating and intuitive controls. This thoughtful design reduces operator fatigue during long shifts, contributing to improved safety and productivity.

Durability: Constructed with high-quality materials, this model is built to withstand the rigors of tough job sites. Its robust chassis and reinforced components ensure longevity and reliable performance under heavy loads.

Versatility: The 544J is compatible with a wide range of attachments, making it adaptable to numerous applications. Whether for construction, landscaping, or agriculture, this versatility enhances its utility and value.

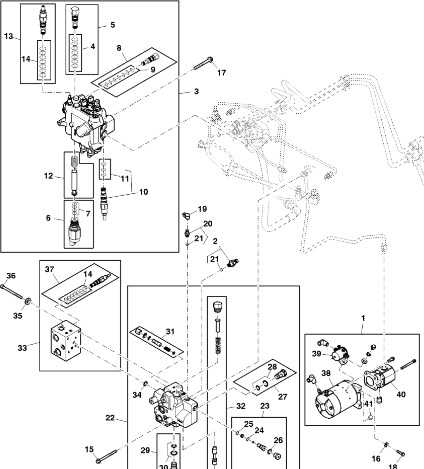

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations serve as invaluable tools that enhance comprehension of complex systems, ensuring that operators and technicians can identify and address issues efficiently.

Facilitating Repairs

Accurate visual guides allow for quicker diagnosis of malfunctions. By clearly illustrating each component, these aids help users pinpoint problems without unnecessary guesswork, leading to faster resolution and reduced downtime.

Streamlining Maintenance

Regular upkeep becomes simpler when users can reference detailed schematics. These resources provide insight into the interconnections between elements, promoting thorough inspections and proactive measures that extend the lifespan of equipment.

Common Issues with 544J Components

When working with heavy machinery, certain components may exhibit common problems that can affect performance and reliability. Understanding these issues can help operators and maintenance personnel address them promptly, ensuring smooth operation and extending the lifespan of the equipment.

Frequent Component Failures

- Hydraulic leaks: Over time, seals and hoses can wear out, leading to fluid loss and reduced efficiency.

- Electrical malfunctions: Wiring can become damaged or corroded, resulting in intermittent functionality or complete failure of electrical systems.

- Wear on moving parts: Continuous use can lead to abrasion and degradation, particularly in joints and bearings.

Signs of Mechanical Issues

- Unusual noises: Grinding or clunking sounds may indicate problems with gears or bearings.

- Decreased performance: A noticeable reduction in power or speed can signal issues within the engine or transmission.

- Fluid contamination: Discoloration or particulates in fluids can suggest internal wear or damage.

By recognizing these common challenges, operators can take proactive measures to maintain their machinery and minimize downtime.

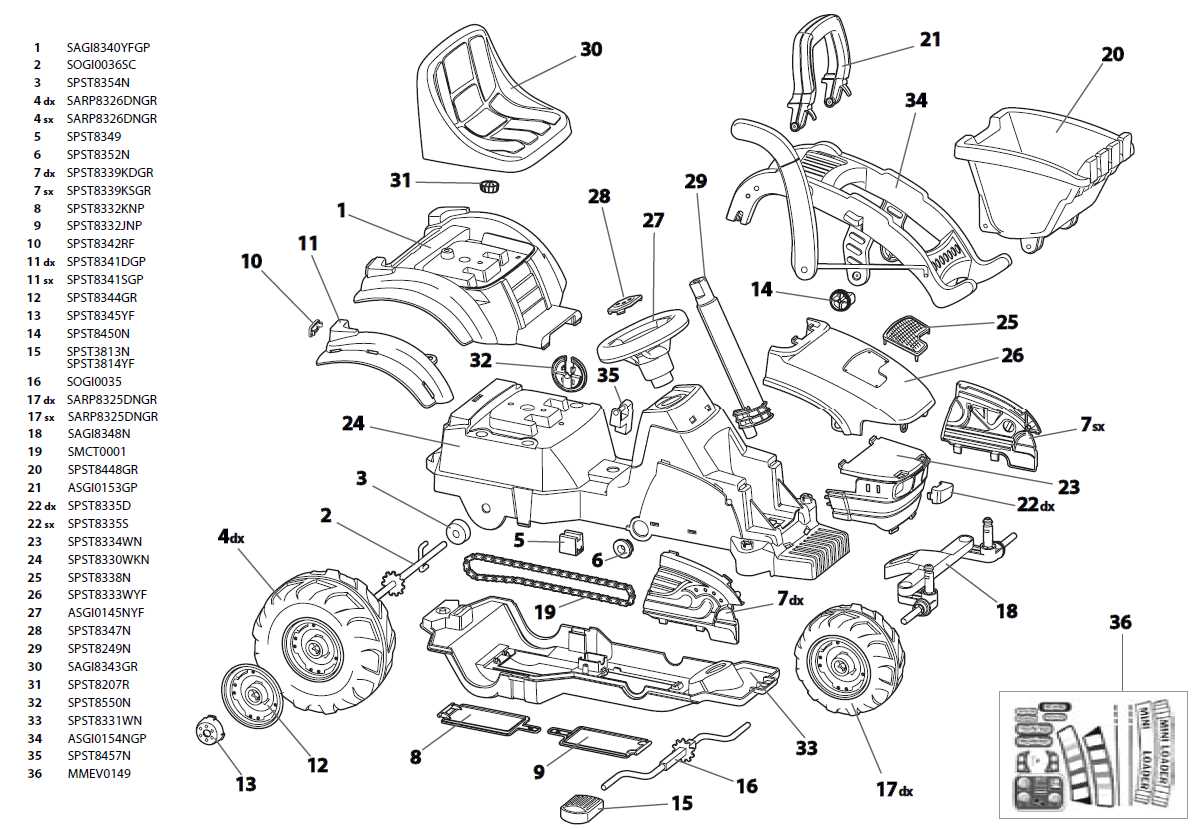

Identifying Replacement Parts

Understanding how to locate suitable components for machinery is essential for maintaining optimal performance and prolonging lifespan. Recognizing the right elements can significantly enhance efficiency and reduce downtime. This section delves into strategies and tips for identifying the necessary replacements for your equipment.

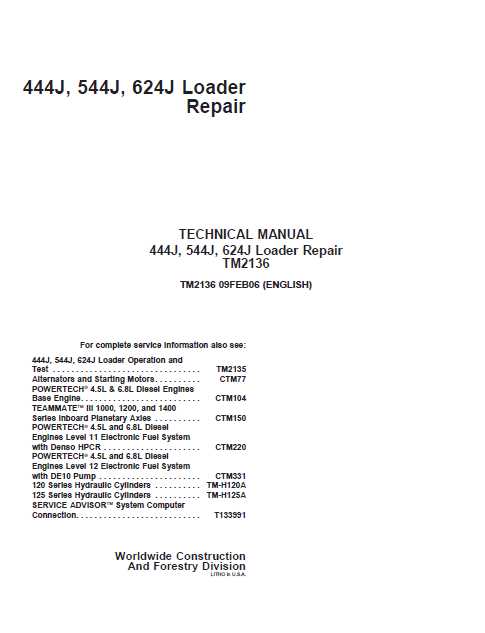

Utilizing Manufacturer Resources

One of the most effective ways to ensure compatibility is to reference official resources provided by the manufacturer. These include detailed manuals and catalogs that outline specifications for each component. By consulting these documents, you can confirm the exact features and dimensions required, minimizing the risk of incorrect replacements.

Consulting with Experts

Engaging with professionals who specialize in machinery can provide valuable insights. Whether through forums, repair shops, or direct consultation, these experts often possess extensive knowledge about various models and their corresponding elements. Their experience can guide you toward the most reliable options available.

Incorporating these approaches will streamline the process of finding appropriate replacements, ensuring your machinery operates smoothly and efficiently.

Where to Find Diagrams Online

Locating technical illustrations for machinery can significantly enhance maintenance and repair processes. Various online resources provide access to these valuable references, ensuring users can find the specific visuals needed to understand their equipment better.

Manufacturer Websites

Official sites often offer extensive libraries of technical resources, including visuals that detail components and assembly. These platforms are reliable, as they typically provide accurate and up-to-date information directly from the source.

Online Forums and Communities

Engaging with specialized online communities can yield valuable insights. Users often share resources, including links to illustrations and personal experiences. Participating in discussions can help users discover uncommon references that may not be widely known.

In summary, utilizing a combination of manufacturer resources and community input can streamline the search for essential technical illustrations, ultimately supporting effective equipment management.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components ensures optimal performance and longevity for machinery. These elements are specifically designed to meet the exact specifications and quality standards set by the manufacturer, leading to enhanced reliability and efficiency in operation.

Enhanced Compatibility

OEM components are crafted to fit seamlessly into existing systems, minimizing the risk of malfunctions or compatibility issues. This precision leads to smoother functionality and reduces the likelihood of costly repairs caused by mismatched alternatives.

Improved Durability

Components sourced directly from the manufacturer are built using high-quality materials and advanced engineering practices. This results in superior durability and performance, ensuring that machinery operates at its best for a longer period. Investing in these authentic parts ultimately saves time and resources in the long run.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of heavy machinery requires a proactive approach to maintenance. Regular attention to various components not only extends the life of the equipment but also enhances its efficiency. Implementing systematic checks and balances can prevent minor issues from escalating into major problems, ultimately saving time and costs associated with repairs.

Start by establishing a consistent maintenance schedule that includes routine inspections of critical systems. Focus on fluid levels, filters, and any signs of wear or damage. Cleanliness plays a vital role; keeping the machinery free from dirt and debris can significantly reduce the risk of corrosion and mechanical failures.

Regularly lubricate moving parts to minimize friction and wear. This simple practice can improve performance and decrease the likelihood of breakdowns. Additionally, pay attention to tire pressure and track alignment, as these factors greatly influence operational efficiency and safety.

Stay informed about the latest updates and recommendations from the manufacturer. Utilize high-quality replacement components when necessary, as they contribute to the overall reliability of the machinery. Investing in preventive measures today will ensure that your equipment continues to perform effectively for years to come.

Comparing 544J to Other Models

When evaluating different equipment models, it is essential to analyze their features, performance, and usability. This section provides a comparative overview of one specific model against its peers, highlighting key similarities and differences.

Performance Metrics

- Power Output: Assessing the horsepower can reveal the capabilities of each machine.

- Load Capacity: Comparing the maximum load each model can handle is crucial for operational efficiency.

- Fuel Efficiency: Understanding consumption rates helps in long-term operational cost analysis.

Design Features

- Operator Comfort: Cabin design and ergonomics can significantly impact productivity.

- Durability: The materials and build quality used in different models determine their longevity in various conditions.

- Maintenance Access: Ease of servicing and part replacement can affect downtime and repair costs.

In conclusion, understanding the distinctions and advantages of various equipment models aids users in making informed decisions that best suit their operational needs.

Getting Help from Professionals

When facing challenges with machinery, seeking assistance from experienced specialists can significantly enhance efficiency and reduce downtime. Professionals possess in-depth knowledge and expertise that can help identify issues quickly, ensuring your equipment operates at peak performance.

Consulting with experts not only provides valuable insights but also ensures that repairs and maintenance are carried out correctly. This minimizes the risk of further complications and extends the lifespan of your machinery. Here are some key advantages of relying on professionals:

| Advantage | Description |

|---|---|

| Expert Knowledge | Professionals have extensive training and experience, allowing them to diagnose problems accurately. |

| Quality Repairs | They use high-quality components and techniques, ensuring reliable repairs. |

| Time Efficiency | Expert help can save time by resolving issues more quickly than a novice might. |

| Long-term Support | Professionals often provide ongoing maintenance services, promoting equipment longevity. |

Ultimately, leveraging professional expertise not only addresses immediate concerns but also contributes to a more sustainable operational strategy for your machinery.