Essential Guide to the John Deere 7400 Parts Diagram

In the realm of agricultural equipment, comprehending the intricate arrangement of various elements is essential for efficient maintenance and repair. The functionality of any machine hinges on the seamless interplay of its individual constituents, each serving a specific purpose to enhance overall performance. A thorough exploration of these components provides invaluable insights for operators and technicians alike.

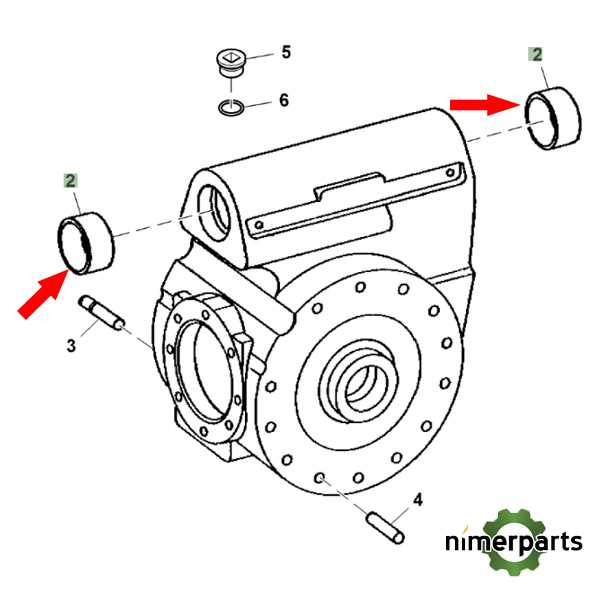

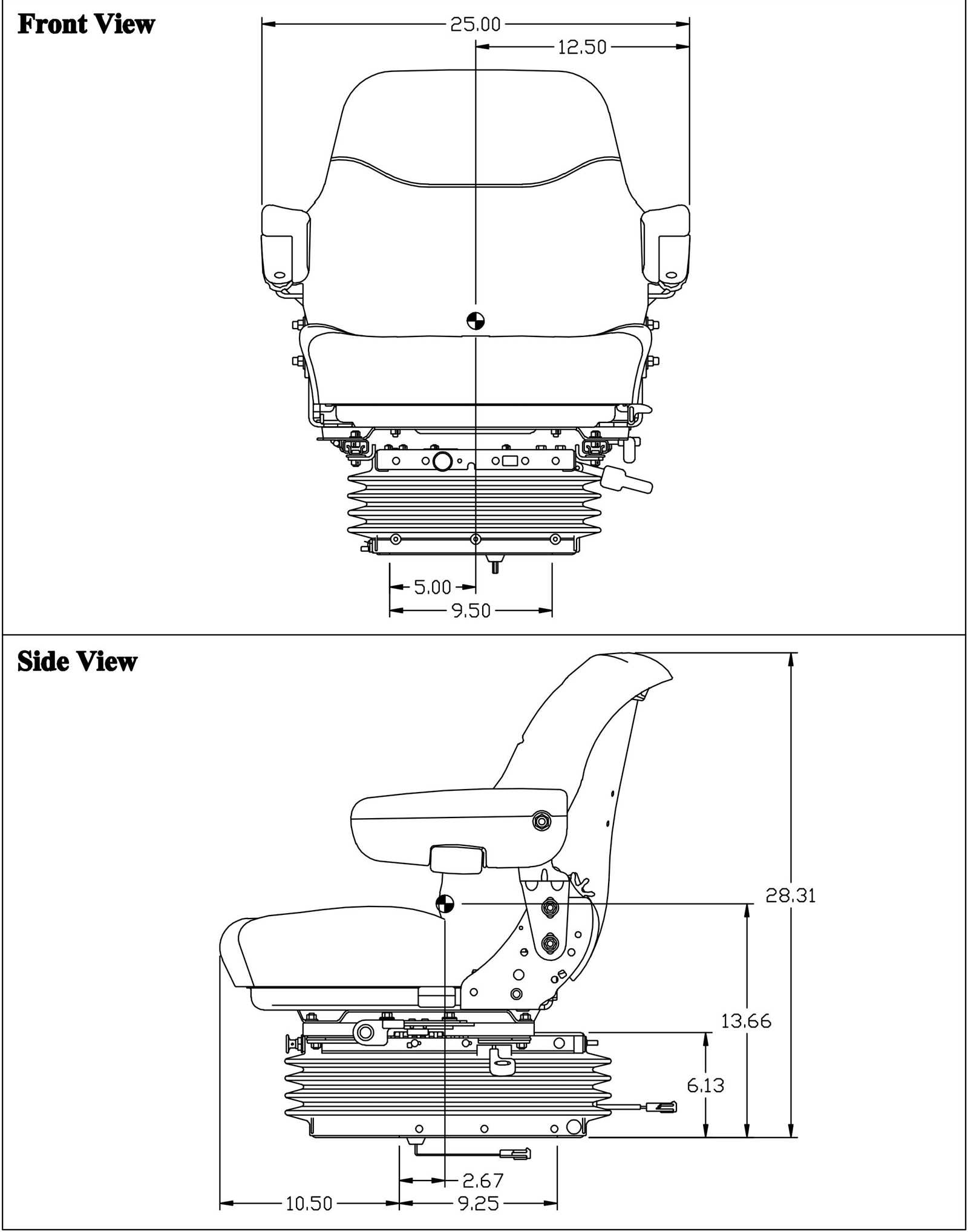

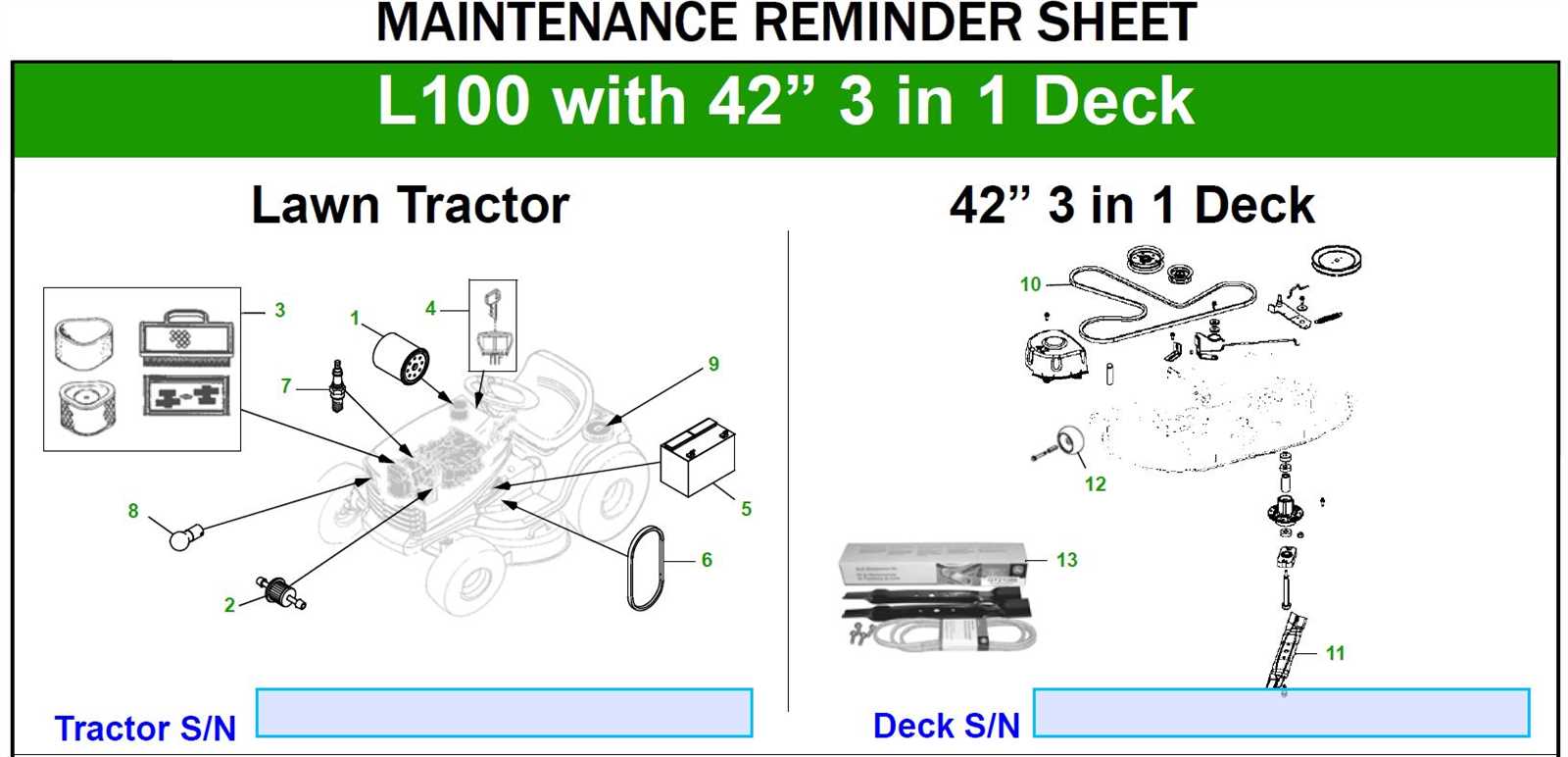

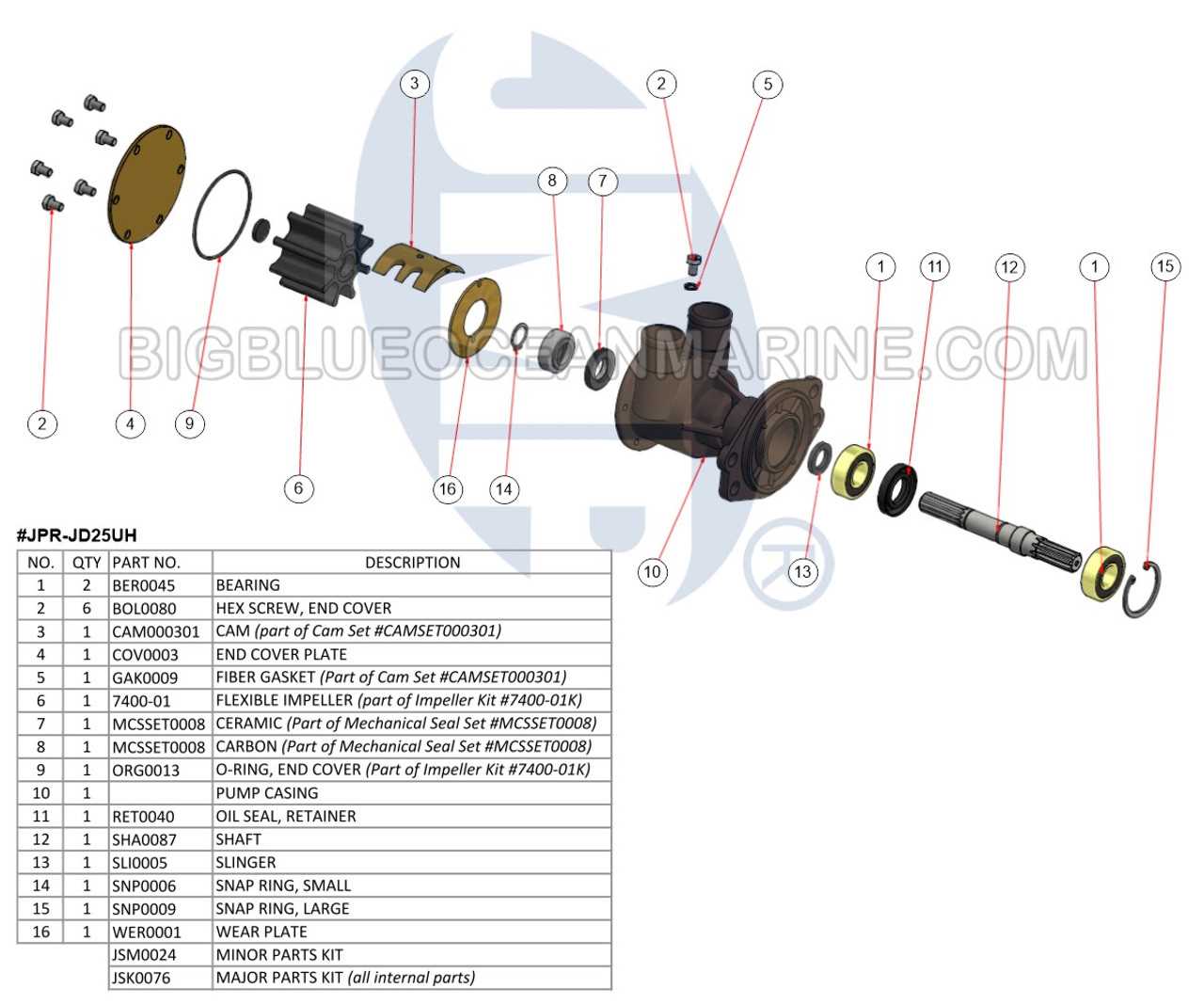

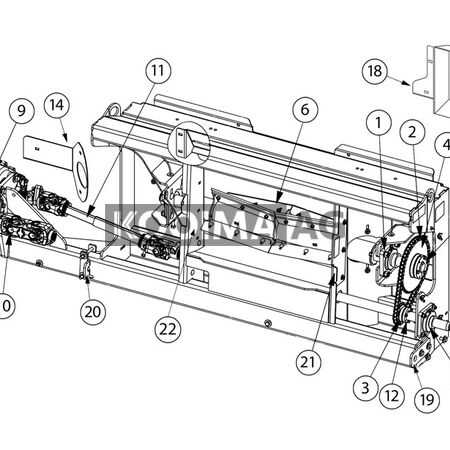

When faced with the task of servicing complex machinery, having access to detailed visual representations of the different elements becomes a significant advantage. These illustrations not only facilitate the identification of each part but also streamline the repair process by clarifying the relationships between the components. As a result, users can quickly locate and address any issues that may arise, ensuring optimal operation.

Moreover, understanding the layout and connections of machinery components aids in making informed decisions about upgrades and replacements. By familiarizing oneself with the specifics of the equipment, operators can enhance their skills and improve the longevity of their machines. This knowledge ultimately translates into greater productivity and reduced downtime in agricultural operations.

Understanding John Deere 7400 Components

Familiarity with the various elements that comprise agricultural machinery is essential for efficient operation and maintenance. This knowledge enables operators to troubleshoot issues effectively and ensure longevity in performance. Recognizing the function and interrelation of each component can significantly enhance productivity on the field.

Key Elements of the Machinery

- Engine: The powerhouse of the equipment, responsible for delivering the necessary energy for various tasks.

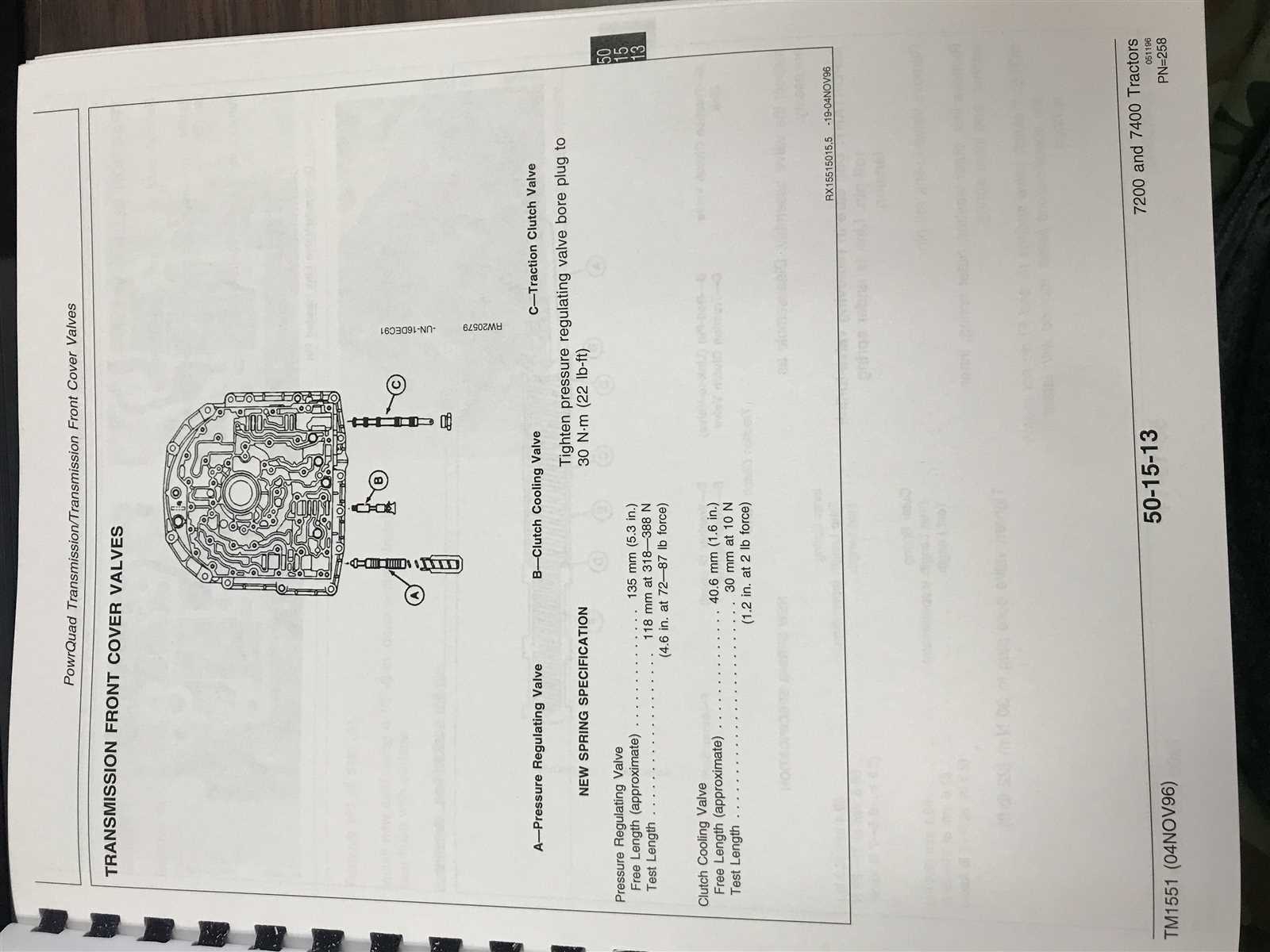

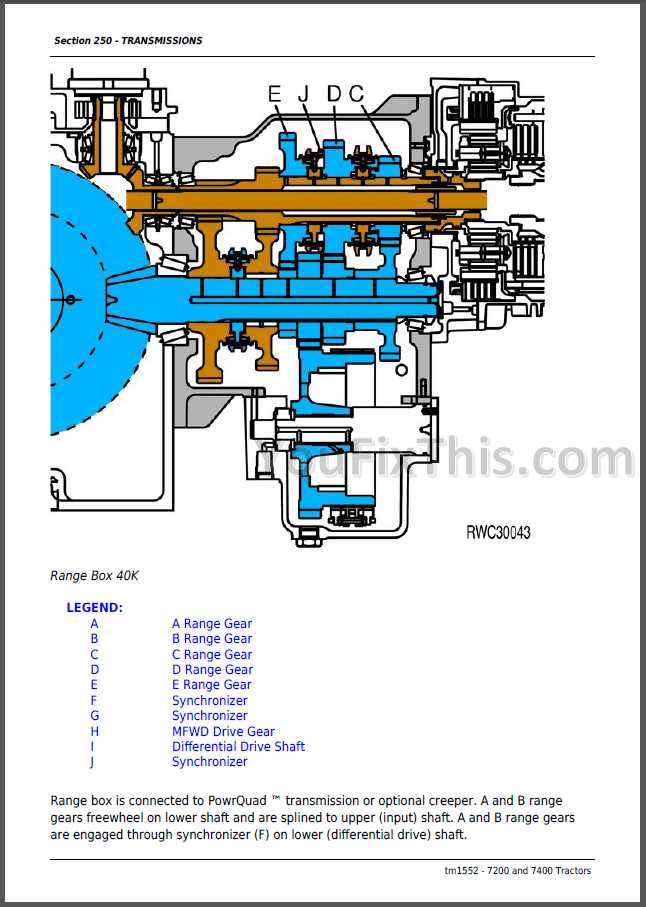

- Transmission: This system transfers power from the engine to the wheels, allowing for movement and speed adjustments.

- Hydraulic System: Vital for lifting and operating attachments, this system enhances versatility in different farming operations.

- Chassis: The framework that supports all components, ensuring stability and durability during usage.

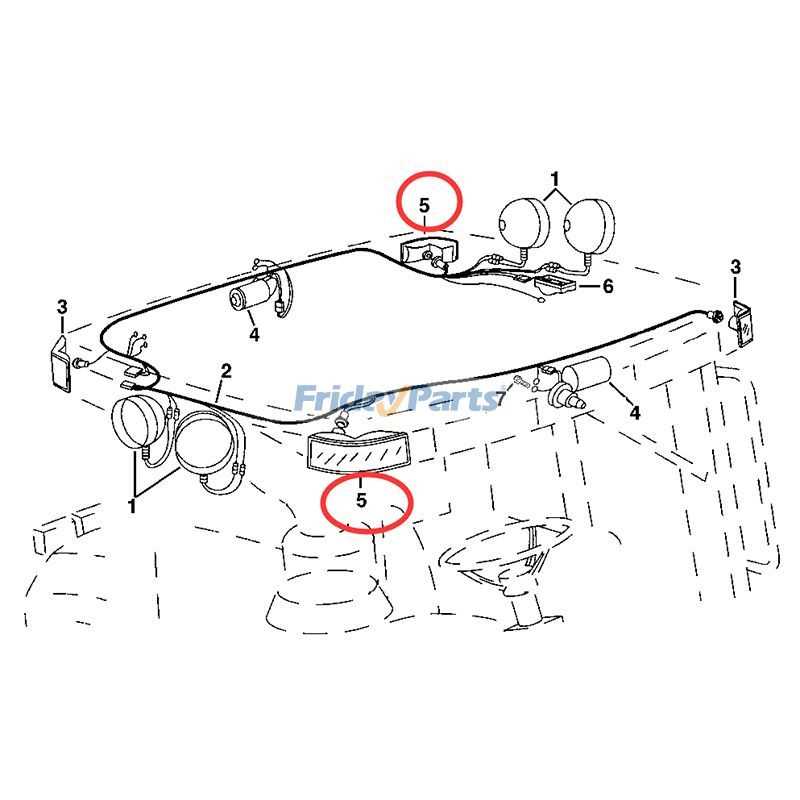

- Electrical System: Responsible for lighting and powering various electronic components, this system is crucial for operational efficiency.

Maintenance Tips

- Regularly inspect the engine and hydraulic fluid levels to avoid performance issues.

- Check the transmission fluid periodically to ensure smooth operation.

- Clean the electrical connections to prevent malfunctions.

- Monitor tire pressure and tread to ensure optimal traction and handling.

- Follow the manufacturer’s guidelines for routine servicing and repairs.

Understanding these components and their maintenance can lead to improved efficiency and reduced downtime, making the machinery more reliable for agricultural needs.

Importance of Parts Diagrams

Understanding the components of machinery is crucial for effective maintenance and repair. Visual representations of these elements provide clarity and insight, enabling users to identify individual pieces and their functions. This knowledge helps in troubleshooting issues, ensuring that every part is correctly understood and addressed during servicing.

Benefits of Visual Guides

- Enhanced Clarity: Visual aids simplify complex assemblies, making it easier to comprehend how different elements interact.

- Streamlined Repairs: Knowing the exact location and function of each piece expedites the repair process, minimizing downtime.

- Accurate Ordering: When replacement is necessary, clear illustrations ensure that the correct items are acquired, reducing the likelihood of errors.

Facilitating Maintenance

- Regular Inspections: Visual guides help users perform thorough checks by identifying wear and tear in specific components.

- Preventive Actions: Understanding component relationships allows for proactive measures to be taken before issues arise.

- Training Tools: These resources serve as effective teaching aids for new technicians, enhancing their learning experience.

How to Read the Diagram

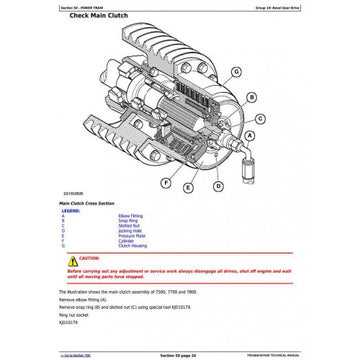

Understanding a visual representation of machinery components is essential for efficient maintenance and repair. This guide will help you navigate the schematic effectively, ensuring you can identify and locate various elements within the layout.

Key Elements to Identify

- Symbols: Familiarize yourself with the standard icons used in the schematic. Each symbol typically represents a specific part or function.

- Labels: Pay attention to the annotations next to the symbols. These will often include part numbers or descriptive text to aid identification.

- Connections: Observe how different components are interconnected. Arrows and lines will indicate relationships and flow between parts.

Steps to Follow

- Begin by reviewing the entire layout to get a general sense of the structure.

- Focus on one section at a time, starting with the most critical components.

- Cross-reference any identified parts with a manual or catalog to ensure accuracy.

- Take notes on any unclear areas, and consult additional resources if necessary.

By following these steps and paying attention to the key elements, you will enhance your ability to interpret the schematic and perform effective maintenance tasks.

Common Issues with 7400 Parts

Many users encounter frequent challenges when dealing with components of agricultural machinery. Understanding these common difficulties can help in both maintenance and repair processes. Identifying potential failures early can save time and resources in the long run.

Wear and Tear: Over time, components are subject to wear and degradation. This is particularly evident in areas exposed to high stress or harsh conditions. Regular inspection and timely replacement of these elements can mitigate major failures.

Compatibility Problems: When sourcing replacements, compatibility can often become an issue. Mismatched components may not fit correctly or function as intended, leading to inefficiencies. Ensuring that new acquisitions meet specifications is crucial.

Corrosion: Exposure to moisture and harsh chemicals can lead to corrosion, significantly impacting functionality. Regular cleaning and the use of protective coatings can help preserve metal parts.

Assembly Errors: Improper installation can result in various complications, including mechanical failures. Following manufacturer guidelines and utilizing proper tools during assembly can prevent these issues.

Lack of Maintenance: Neglecting routine maintenance is one of the most significant causes of component failures. Establishing a consistent maintenance schedule is essential for the longevity of machinery.

By being aware of these common issues, users can take proactive steps to ensure the efficiency and reliability of their equipment.

Where to Find Replacement Parts

Finding suitable components for machinery can be a daunting task, especially when precision and quality are paramount. However, various reliable sources can assist in locating the necessary items to ensure optimal performance of your equipment.

- Authorized Dealers: Start by checking with certified dealers who specialize in your specific machinery brand. They often have access to a comprehensive range of original components.

- Online Retailers: Numerous e-commerce platforms offer a vast selection of components. Websites like Amazon, eBay, and specialized equipment stores can provide both new and refurbished items.

- Local Repair Shops: Contact nearby repair facilities that focus on similar machinery. They might have spare components available or can order them directly for you.

- Salvage Yards: Consider visiting salvage yards that deal with agricultural or industrial equipment. You may find used components at a fraction of the cost.

- Manufacturer Websites: Many manufacturers have online catalogs where you can search for and order components directly. This is often the best way to ensure you receive the correct item.

By exploring these avenues, you can efficiently locate the necessary items to maintain and enhance the functionality of your machinery.

Tools Needed for Repairs

Effective maintenance and repair of machinery require the right set of tools. Having the appropriate instruments not only simplifies the process but also enhances safety and efficiency. Below is a list of essential tools that can assist in carrying out various repair tasks.

| Tool | Description |

|---|---|

| Wrenches | Used for loosening and tightening bolts and nuts of different sizes. |

| Screwdrivers | Essential for driving screws and can be found in various head types. |

| Socket Set | Provides a range of socket sizes for better torque and grip on fasteners. |

| Pliers | Helpful for gripping, bending, and cutting wire or other materials. |

| Torque Wrench | Ensures that fasteners are tightened to the manufacturer’s specifications. |

| Multimeter | Used for measuring voltage, current, and resistance in electrical systems. |

| Jack and Stands | Important for lifting machinery safely to access underneath components. |

Equipping yourself with these tools will facilitate more effective repairs and help maintain optimal performance of the equipment.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires consistent care and attention. Regular maintenance not only enhances performance but also extends the lifespan of essential components. By following a few key practices, you can avoid costly repairs and ensure your machinery remains reliable over time.

Routine Inspections

Conducting regular inspections is crucial for identifying potential issues before they escalate. Check for signs of wear and tear, and address any irregularities promptly. Pay special attention to critical systems, as they often indicate the overall health of the machinery. Routine checks can help you stay ahead of problems, ensuring your equipment operates efficiently.

Proper Lubrication and Cleaning

Keeping all moving parts well-lubricated reduces friction and prevents premature wear. Use high-quality lubricants recommended for your model, and follow the manufacturer’s guidelines for application frequency. Additionally, maintaining cleanliness is vital; remove dirt and debris that can hinder performance. Regular cleaning will protect sensitive components and promote longevity.

Comparing Models: 7400 vs. Others

When evaluating different agricultural machines, it’s essential to consider their specifications and features to determine which model best suits specific needs. Each machine offers unique advantages that cater to various farming tasks, from efficiency in fieldwork to ease of maintenance. This comparison aims to highlight the distinctions and similarities among these machines, focusing on performance, reliability, and user experience.

Performance and Efficiency

In terms of performance, many models provide robust power output and advanced technology that enhance operational efficiency. For instance, certain alternatives feature improved fuel consumption, which can lead to significant cost savings over time. Additionally, some variants may offer greater lifting capacity or enhanced traction, making them more suitable for specific agricultural applications.

Reliability and Maintenance

Reliability is a crucial factor for any machinery. Various models demonstrate different maintenance requirements, which can impact downtime and overall productivity. Some machines are designed with user-friendly maintenance features, allowing for quicker inspections and repairs. It’s vital for operators to assess these factors when choosing a model to ensure longevity and reduced operational interruptions.

Using OEM vs. Aftermarket Parts

When maintaining heavy machinery, choosing the right components can significantly impact performance and longevity. Two main categories often come into consideration: original equipment manufacturer (OEM) components and their aftermarket counterparts. Each option presents distinct advantages and drawbacks that can influence operational efficiency and maintenance costs.

OEM components are produced by the original manufacturer, ensuring a perfect fit and compatibility with the machine’s specifications. Here are some key benefits of choosing OEM:

- High quality and reliability.

- Warranty protection and support.

- Consistency in performance and longevity.

However, there are also reasons why some operators opt for aftermarket alternatives:

- Cost-effectiveness, often significantly lower than OEM.

- Availability of a wider variety of options.

- Potential for innovative designs or enhancements.

Ultimately, the decision between OEM and aftermarket options should be based on specific needs, budget constraints, and the intended use of the machinery. Understanding the trade-offs can lead to informed choices that align with operational goals.

Assembly Process Explained

The assembly process is a crucial phase in manufacturing, where individual components are meticulously brought together to create a functional unit. This stage not only demands precision but also a comprehensive understanding of the various elements involved. Each part plays a significant role in ensuring the overall efficiency and performance of the final product.

Key Steps in the Assembly Process

Understanding the key steps can enhance efficiency and minimize errors. The process typically involves the following stages:

| Step | Description |

|---|---|

| Preparation | Gathering all necessary components and tools required for assembly. |

| Inspection | Checking each part for quality and compatibility before assembly. |

| Assembly | Carefully connecting components according to specified guidelines. |

| Testing | Verifying the assembled unit functions as intended through various tests. |

| Finalization | Securing and packaging the product for delivery or storage. |

Importance of Each Stage

Every step in the assembly process is vital to achieving a high-quality outcome. Preparation ensures all resources are at hand, while inspection safeguards against defects. The assembly itself requires attention to detail, and testing verifies functionality before the product reaches the end-user. Finalization wraps up the process, ensuring the product is ready for market.

FAQs about John Deere 7400

This section aims to address common inquiries related to a specific agricultural machinery model, focusing on its features, maintenance, and usability. Understanding these aspects can help users make informed decisions and enhance their operational efficiency.

General Questions

- What are the key specifications of this model?

- How does this machine compare to newer models?

- What type of fuel does it require?

- What is the average lifespan of this equipment?

Maintenance and Repairs

- What regular maintenance tasks should be performed?

- Where can I find replacement components?

- How often should oil changes be conducted?

- Are there common issues that owners should be aware of?

Community Resources and Support

Accessing a wealth of resources and support from the community can significantly enhance your understanding and maintenance of agricultural machinery. Enthusiasts and professionals often gather to share valuable insights, experiences, and practical solutions, fostering a collaborative environment for troubleshooting and repairs.

Online Forums and Discussion Groups

Participating in online forums and discussion groups can provide instant access to a diverse pool of knowledge. Members frequently share their expertise, answer questions, and post detailed guides or tutorials. These platforms can be instrumental in helping users navigate complex issues or identify specific components that require attention.

Local Workshops and Meetups

Attending local workshops or meetups offers hands-on learning opportunities and allows for networking with fellow enthusiasts. Engaging in these events can lead to valuable partnerships, where individuals can exchange tips and advice on machinery upkeep and enhancements. Additionally, local experts often provide demonstrations that can deepen your practical skills.

Embracing community resources can empower users to tackle maintenance tasks with confidence, ensuring that machinery operates efficiently for years to come. By leveraging collective knowledge, you not only enhance your own skills but also contribute to the shared expertise of the community.