Comprehensive Guide to John Deere 777 Parts Diagram

The complexity of modern agricultural machinery can often be daunting for users and mechanics alike. Having a clear representation of the various elements that comprise these machines is essential for effective maintenance and repair. A comprehensive visual reference not only facilitates identification but also enhances the overall understanding of the equipment’s functionality and interconnections.

Within the realm of farm equipment, specific models stand out due to their reliability and efficiency. By examining the intricate network of components, operators can gain insights into the operational mechanics, leading to better performance and prolonged lifespan. This detailed overview serves as a valuable resource for those seeking to navigate the challenges of upkeep and troubleshooting.

As one delves deeper into the subject, it becomes evident that a systematic approach to understanding these essential components is crucial. Each segment plays a pivotal role in ensuring the machine operates smoothly. By familiarizing oneself with this layout, users can become more adept at diagnosing issues and implementing appropriate solutions.

Understanding John Deere 777 Parts

When it comes to heavy machinery, a thorough comprehension of its components is essential for effective maintenance and operation. Each element plays a pivotal role in ensuring optimal functionality, and understanding their interrelations can significantly enhance performance. This section aims to provide insights into the critical elements that contribute to the overall efficiency of these machines.

Key Components and Their Functions

Each machinery unit is equipped with various essential segments, including the engine, transmission, and hydraulic systems. The engine serves as the heart, providing the necessary power to perform tasks. The transmission ensures smooth power delivery, while the hydraulic systems enable precise control over operations. Familiarity with these components and their functions can aid operators in troubleshooting and routine maintenance.

Maintenance Tips for Longevity

Regular upkeep is vital to prolonging the lifespan of any machine. Inspecting components frequently for signs of wear can prevent unexpected breakdowns. Lubrication of moving parts is crucial to minimize friction, and replacing worn-out elements promptly can save time and resources in the long run. A proactive approach to maintenance can ensure that the equipment remains in peak condition.

Key Components of John Deere 777

The machine is composed of multiple vital systems that work together to ensure smooth and efficient operation. Understanding these elements is crucial for maintaining performance, ensuring durability, and optimizing productivity in various agricultural or industrial tasks.

Engine and Transmission

The core of the vehicle’s power lies in its engine and transmission systems. These systems are designed to provide optimal output while maintaining energy efficiency. A well-maintained engine, along with a smoothly functioning transmission, ensures the equipment can handle heavy loads and perform at its peak under demanding conditions.

- High-powered combustion engine for superior torque

- Advanced transmission system offering smooth shifting

- Fuel-efficient technology for prolonged usage

Hydraulic System

The hydraulic system is responsible for powering various attachments and enhancing the versatility of the machine. It ensures smooth operation of all hydraulic-driven parts, allowing the operator to work with precision and control in a range of environments.

- Efficient pump providing consistent hydraulic pressure

- Durable hoses designed for high-pressure conditions

- Multiple auxiliary ports for connecting additional attachments

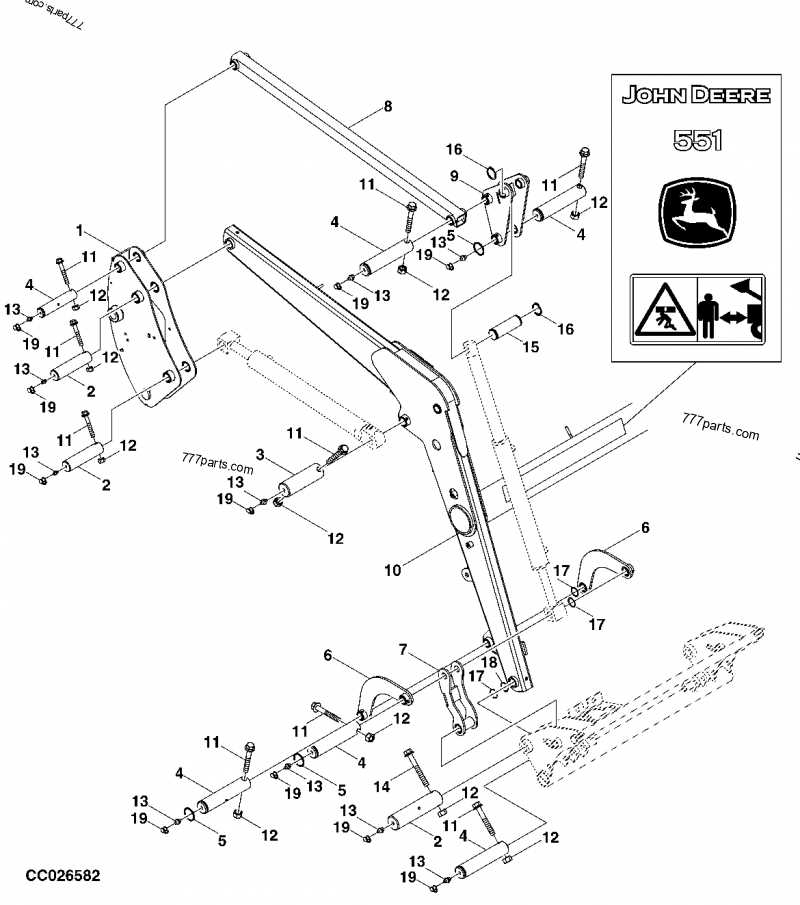

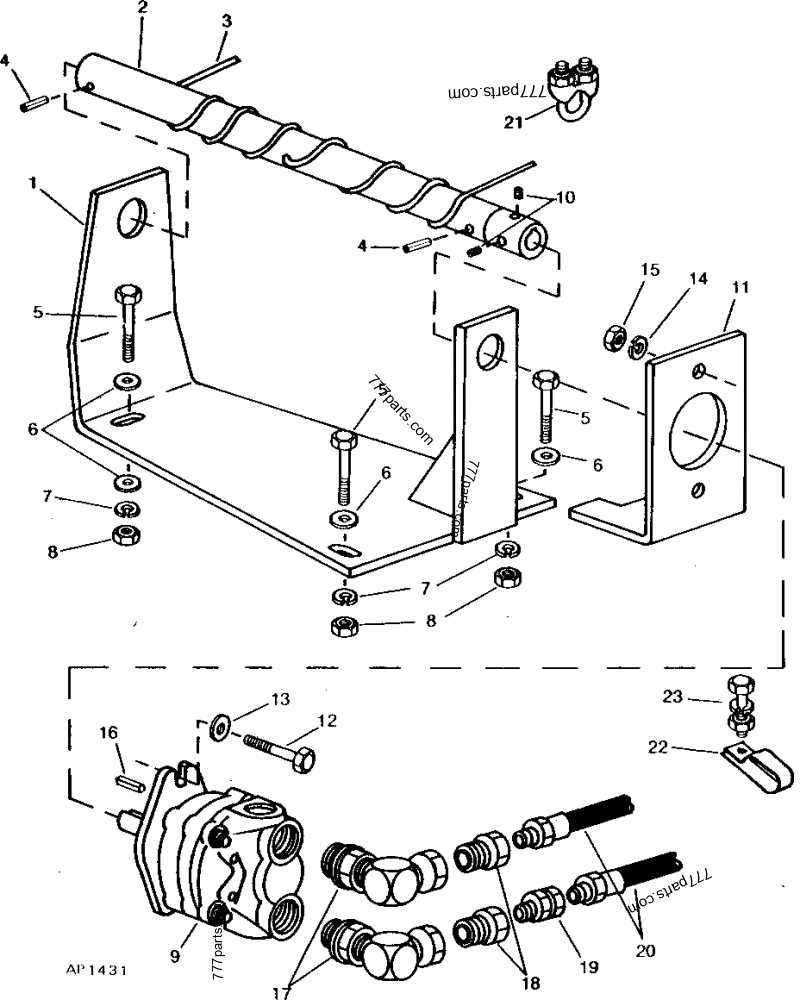

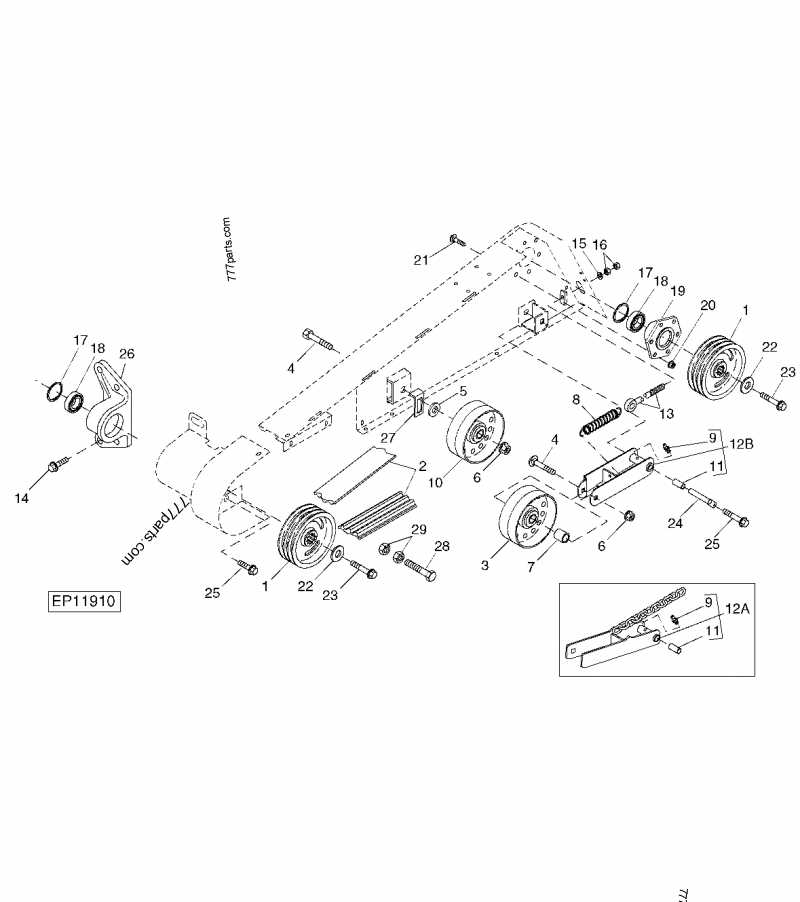

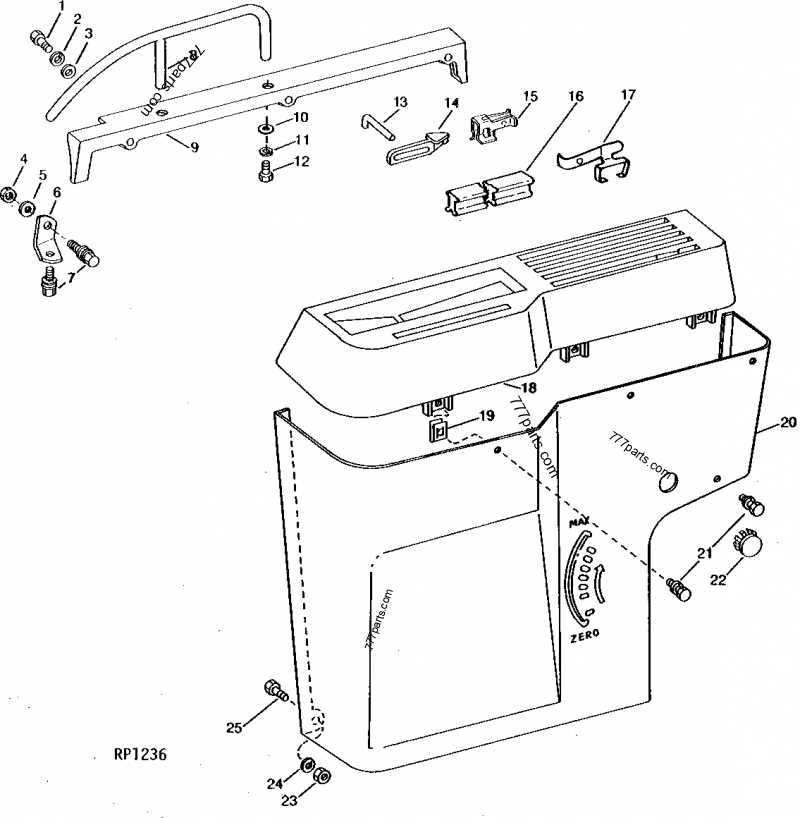

How to Read Parts Diagrams

Understanding technical illustrations is crucial for identifying and replacing mechanical components accurately. These visual guides break down complex systems, offering a clear representation of how various elements fit together, allowing users to navigate assemblies and perform maintenance efficiently.

Identifying Key Components

Each element in the illustration is typically labeled with a reference number, linking it to a corresponding list or legend. This helps locate specific parts without confusion. By following these references, users can cross-check with manuals or product listings, ensuring they have the correct replacement items.

Understanding Sectional Views

Some illustrations may present multiple angles or sectional views. These views help clarify the placement and relationship between internal and external elements. It’s essential to interpret these perspectives correctly, as they reveal hidden parts that might otherwise be overlooked during repairs.

Common Issues with John Deere 777

Machinery performance can be influenced by various factors, especially with prolonged use. Recognizing typical problems early helps ensure smooth operation and minimizes downtime. Below are some of the most frequently encountered challenges associated with this specific model of equipment.

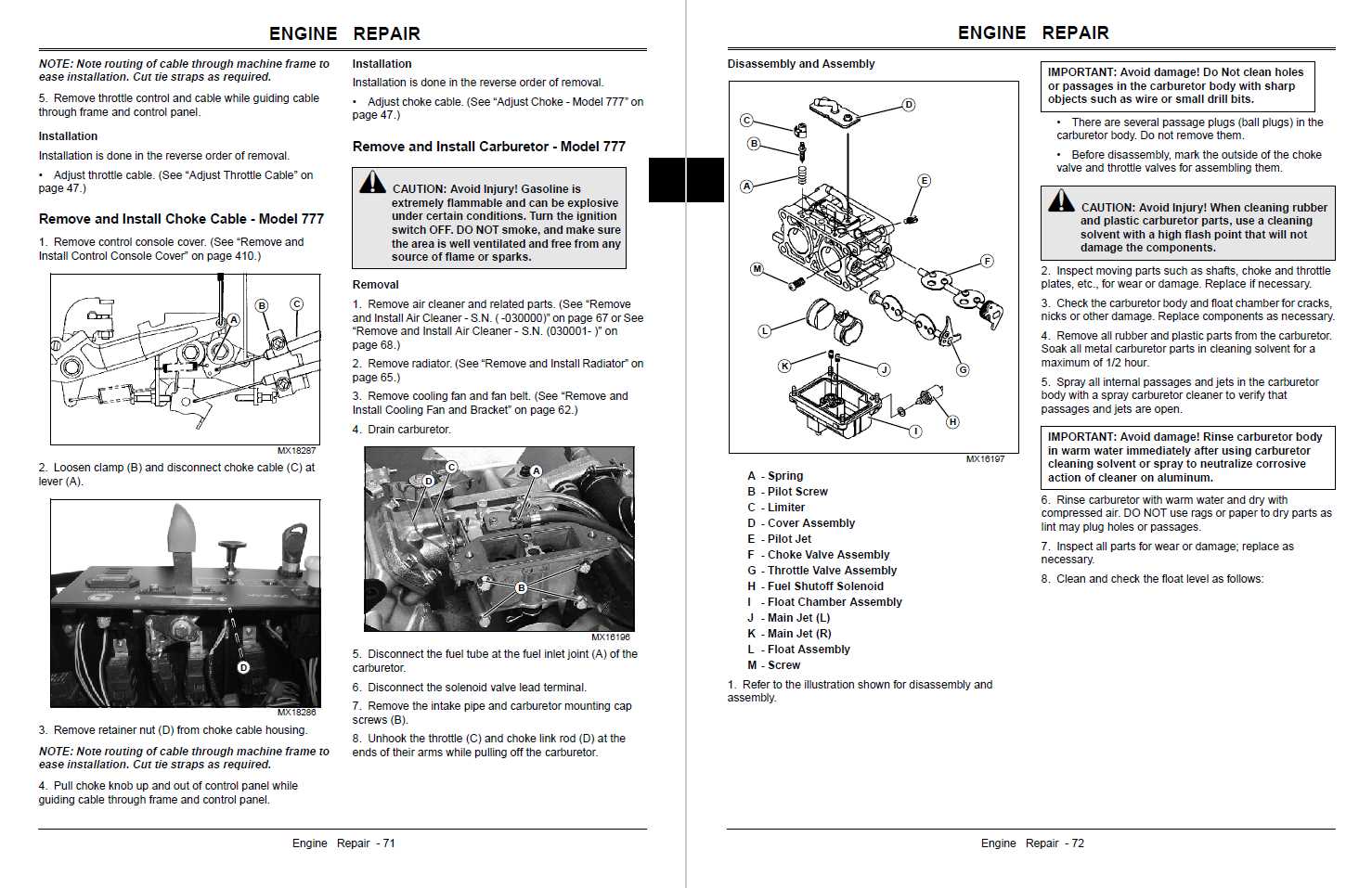

Engine Performance Problems

Engines may suffer from a loss of power, rough idling, or difficulty starting, especially in extreme weather conditions. Regular maintenance and proper fluid levels are essential in preventing these issues, but in some cases, worn-out components or clogged filters may require replacement.

Hydraulic System Failures

Hydraulic systems are prone to leaks, pressure drops, and slow response times. These issues often stem from worn seals, damaged hoses, or insufficient hydraulic fluid. Routine inspections and timely repairs can mitigate the risk of system failures and ensure that the machine remains fully functional.

Maintenance Tips for John Deere 777

Proper care of your equipment ensures its longevity and smooth operation. Regular upkeep not only prevents unexpected breakdowns but also optimizes the overall performance. This section will provide key strategies to maintain your machine effectively, ensuring that it remains in top condition for years to come.

Routine Checks: Make it a habit to inspect the machine before every use. This includes checking for any loose components, unusual wear, or fluid levels that may require attention. Early detection of minor issues can save significant time and resources in the long run.

Lubrication and Fluids: Keeping moving parts well-lubricated is essential. Regularly apply the appropriate oils and greases to prevent wear and reduce friction. Always monitor fluid levels such as oil, coolant, and hydraulic fluid, and top them off as needed to avoid overheating or mechanical failures.

Cleaning: Dirt and debris can accumulate in critical areas, leading to blockages and increased wear on components. After each use, thoroughly clean the exterior and any accessible internal sections to ensure smooth operation and prevent damage from foreign objects.

Blade and Tire Care: Inspect the blades or cutting mechanisms regularly for sharpness and integrity. Dull or damaged blades can reduce efficiency and strain the machine. Additionally, maintain proper tire pressure to ensure stability and improve fuel

Where to Find Replacement Parts

When it’s time to repair or maintain heavy machinery, locating reliable components is crucial to ensure smooth operations. Various options are available, catering to different needs, from quality and compatibility to pricing and availability. Knowing where to look for dependable items can save time and reduce downtime, making the process efficient and cost-effective.

Authorized Dealers: These suppliers often offer certified products that match the original specifications. Opting for authorized sources guarantees that the materials meet industry standards, ensuring longevity and optimal performance.

Online Marketplaces: In today’s digital age, many vendors provide an extensive range of components online. With user reviews and ratings, customers can compare different suppliers and select the most suitable options based on feedback and prices.

Salvage Yards and Reconditioned Items: For those seeking a budget-friendly solution, salvage yards can offer previously used or reconditioned components. While these might be less expensive, ensuring they are still in good working order is key to maintaining reliability.

Specialized Suppliers: Some providers focus exclusively on certain machinery types, offering custom solutions or hard-to-find components. These specialized vendors can be invaluable when sourcing rare or discontinued items.

Benefits of Using Original Parts

Maintaining the integrity and performance of machinery requires careful consideration when it comes to replacements. Using authentic components ensures that each piece fits seamlessly, enhancing both efficiency and longevity. This approach guarantees that the equipment functions as it was originally designed, avoiding unexpected breakdowns and performance issues.

Quality Assurance: Genuine components are designed and tested to meet strict standards, ensuring they perform reliably under demanding conditions. Unlike generic alternatives, they undergo rigorous quality control, minimizing the risk of premature wear and malfunctions.

Compatibility and Precision: Authentic replacements are specifically engineered to align perfectly with the machinery, reducing the chance of installation errors or mismatched parts. This precision leads to smoother operation and prevents costly damage from misfitting elements.

Longevity and Durability: Choosing original components can extend

Step-by-Step Repair Guide

This section provides a comprehensive walkthrough for repairing and maintaining machinery efficiently. By following each step carefully, you will be able to troubleshoot common issues, replace faulty components, and ensure the equipment operates smoothly. The instructions are designed to assist both beginners and experienced mechanics, making complex tasks manageable and straightforward.

Initial Inspection

Begin with a thorough inspection of the machine. Look for visible signs of wear or damage, such as leaks, unusual noises, or broken parts. Check all connections, fasteners, and seals to ensure they are intact. Identify potential problems early to avoid further complications during the repair process.

Component Replacement

If a specific part needs replacement, ensure that you have the correct tools and the new component ready. Follow safety procedures, and take care when removing old pieces. It’s important to securely fit the new part, making sure all bolts and connections are tightened properly to avoid future malfunctions.

Tools Needed for Repairs

When performing maintenance or fixing mechanical equipment, it’s crucial to have the right tools on hand. Having the appropriate gear ensures efficiency, safety, and accuracy during the repair process. Below is a list of essential items to consider before starting any repair work.

- Wrenches: Adjustable and socket wrenches come in handy for loosening and tightening various bolts and nuts.

- Screwdrivers: A full set of flathead and Phillips screwdrivers will cover most fastener types encountered during repair.

- Pliers: Different types of pliers, such as needle-nose or slip-joint, are useful for gripping, bending, and cutting wires or small parts.

- Torque Wrench: This tool ensures that nuts and bolts are tightened to the manufacturer’s specified torque levels, preventing over-tightening.

- Hammer: A solid hammer helps with minor adjustments, especially for stubborn parts that need a gentle tap.

- Lubricants and Cleaners:

Upgrading Your John Deere 777

Enhancing the performance and longevity of your equipment can significantly improve efficiency and reliability. By investing in modernized components and optimizing key systems, you ensure smoother operation and greater durability. Upgrades can be as simple as refining existing systems or as advanced as integrating new technologies for superior output. Whatever the approach, improving your machinery leads to better results in the field.

Start by assessing which elements are underperforming or could benefit from advanced technology. Mechanical enhancements, improved hydraulics, and more efficient fuel systems can all play a role in optimizing the machine’s overall functionality. These modifications reduce wear, improve efficiency, and make maintenance more manageable over time.

Mechanical adjustments often involve replacing aging components with stronger, more resilient parts. This can extend the lifespan of your equipment and improve its workload capacity. Meanwhile, incorporating cutting-edge technology such as upgraded sensors and automated systems can streamline daily tasks, providing more precise control and reducing human error.

Implementing these improvements not only enhances performance but also maximizes productivity. With proper planning and the right upgrades, you

Customer Reviews and Experiences

Users often share their insights on the performance, reliability, and overall satisfaction with their equipment. These experiences offer valuable perspectives, helping potential buyers make informed decisions. Many highlight the ease of use, durability, and the effectiveness of the machinery in various conditions. However, feedback can also include constructive criticism, where some have noted areas for improvement, such as the need for better maintenance guides or enhanced customer support.

Positive feedback frequently mentions how the machinery has exceeded expectations in terms of efficiency and longevity, especially under demanding workloads. On the other hand, occasional reports of minor malfunctions or delayed shipping times provide a balanced view, ensuring that prospective buyers get a comprehensive understanding of what to expect. Overall, user experiences tend to emphasize the product’s ability to meet a range of operational needs, with many recommending it to peers in similar industries.