Comprehensive Guide to John Deere 950 Parts Diagram

In the realm of agricultural machinery, having a clear understanding of the individual elements that comprise a machine is essential for effective maintenance and repair. Each component plays a crucial role in ensuring the overall functionality and efficiency of the equipment.

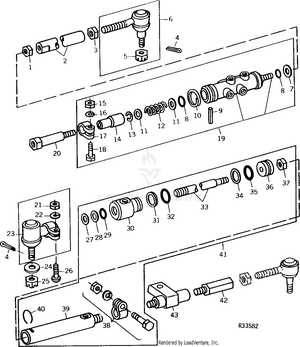

Utilizing visual representations can significantly aid in grasping the intricate relationships between different pieces. These illustrations serve as a valuable resource for both seasoned professionals and newcomers, allowing for a more comprehensive approach to equipment management.

Whether you are seeking to enhance your knowledge or streamline your repair processes, delving into the specifics of each segment can lead to improved performance and longevity of your machinery. The ultimate goal is to ensure optimal operation and reliability, enabling users to tackle their tasks with confidence.

Understanding John Deere 950 Components

Grasping the intricacies of machinery requires a deep dive into its various elements. Each component plays a vital role in ensuring optimal performance and efficiency. A comprehensive understanding of these elements is essential for maintenance and repair.

Essential Elements of this machinery include the engine, transmission, and hydraulic systems, all of which work in harmony to deliver power and functionality. Familiarity with these parts can greatly enhance troubleshooting skills and operational knowledge.

Recognizing the importance of each segment allows operators to make informed decisions regarding service and upgrades. This knowledge ultimately leads to improved longevity and productivity of the machine.

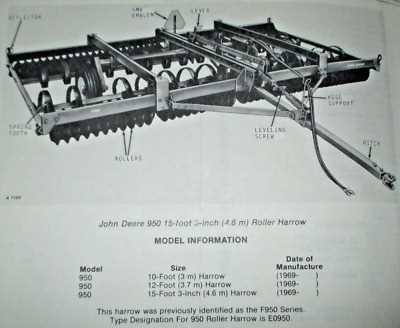

Overview of John Deere 950

This section provides an in-depth look at a particular model known for its durability and versatility in agricultural applications. Designed for efficiency, it serves a wide range of tasks, making it a popular choice among farmers and operators.

Equipped with robust features, this machinery excels in various environments. Its engine performance and ergonomic design contribute to an enhanced user experience, allowing for prolonged operation with minimal fatigue. The integration of advanced technology aids in precision and productivity, ensuring that users can tackle different challenges effectively.

Maintenance is simplified through accessible components, promoting longevity and reliable performance over time. Understanding the specifications and layout of this model can significantly aid in optimizing its use, ensuring that operators can achieve the best results on their fields.

Overall, this model represents a blend of power and functionality, making it a vital asset in modern agricultural practices.

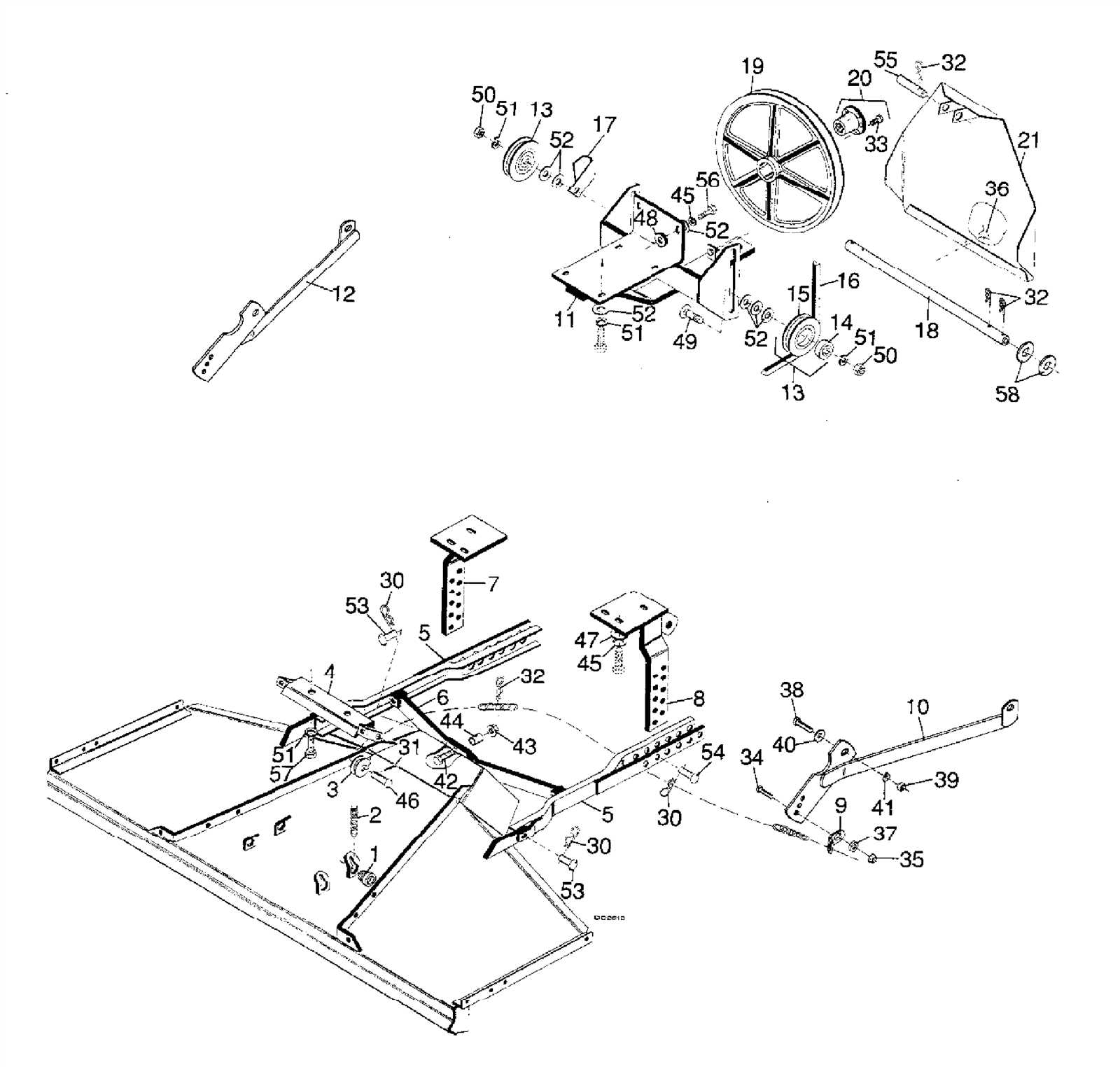

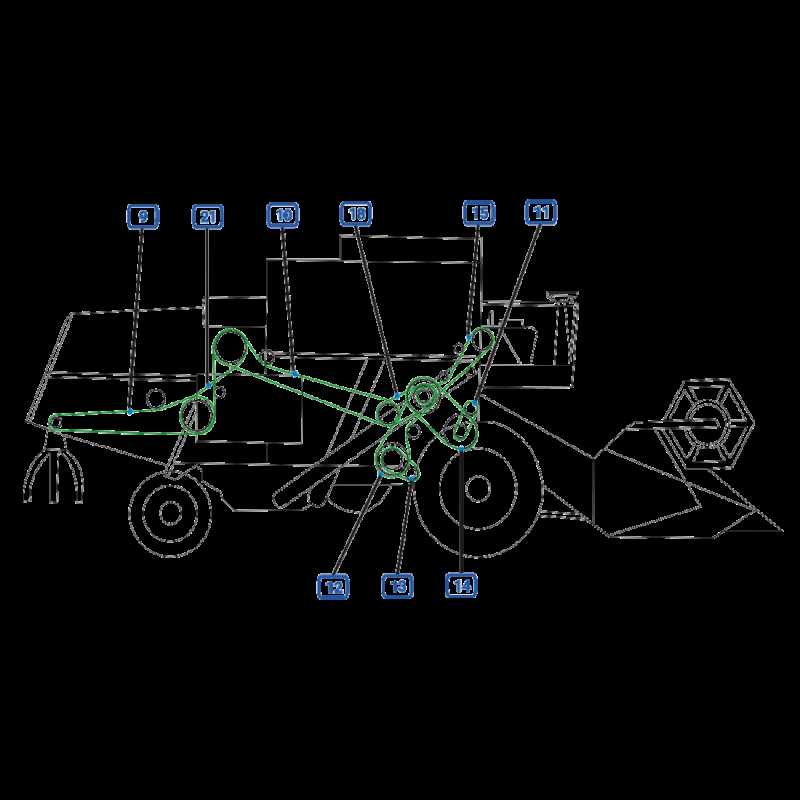

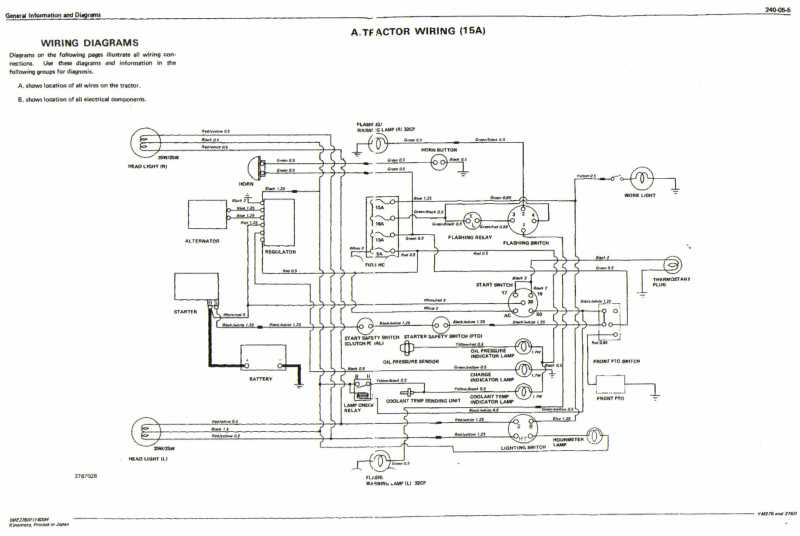

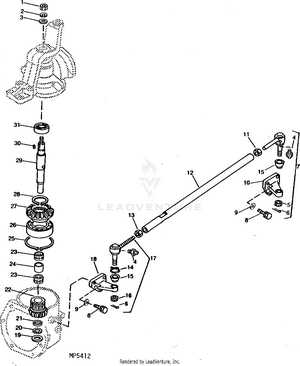

Importance of Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair of machinery. They serve as essential tools that enhance understanding of how individual elements interact within complex systems. By utilizing these illustrations, technicians can quickly identify and address issues, ensuring efficient repairs and minimizing downtime.

Furthermore, such representations provide clarity during disassembly and reassembly, reducing the risk of errors. They can also facilitate communication among team members, enabling a shared understanding of the mechanical layout. Ultimately, leveraging these resources not only streamlines processes but also contributes to the longevity and reliability of equipment.

Key Features of the 950 Model

This model stands out in its category due to several innovative characteristics that enhance functionality and user experience. From its robust design to efficient performance, it caters to various agricultural needs.

- Durability: Engineered to withstand tough conditions, ensuring longevity and reliability.

- Performance: Equipped with a powerful engine that delivers exceptional torque and efficiency.

- Versatility: Compatible with a range of attachments, making it suitable for diverse tasks.

- User-friendly Controls: Intuitive control layout that simplifies operation for users of all skill levels.

- Maintenance Accessibility: Designed for easy access to key components, facilitating quicker service and repairs.

Overall, these attributes contribute to a superior agricultural tool that meets the demands of modern farming.

Common Parts of John Deere 950

This section explores essential components of a popular agricultural machine, highlighting their significance and functionality in ensuring optimal performance. Understanding these elements can enhance maintenance and operational efficiency, ultimately leading to improved productivity in various farming tasks.

Engine Components

The heart of the machinery includes key elements such as the crankshaft, pistons, and fuel injectors. Each part plays a critical role in the power generation and overall operation of the unit, contributing to its reliability during demanding tasks.

Transmission and Drive System

Vital to the movement and control of the equipment, the transmission includes gears, clutches, and driveshafts. Proper maintenance of these components ensures smooth operation and extends the lifespan of the machinery, making it essential for any operator.

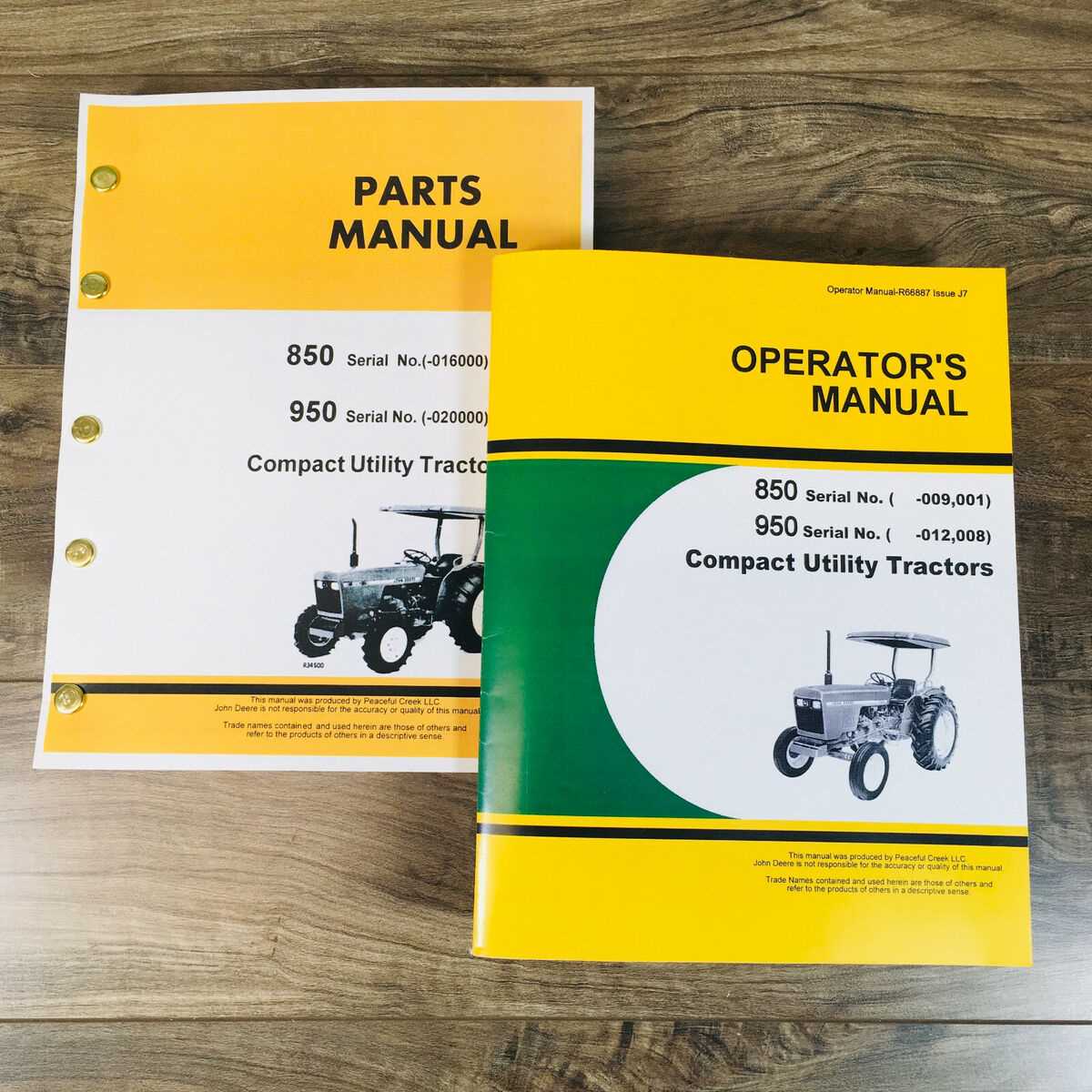

How to Access Parts Diagrams

Finding detailed illustrations for machinery components can be crucial for effective maintenance and repairs. Various resources are available to help you locate these essential visuals, ensuring you have the right information at your fingertips.

Online Resources: Many manufacturers offer digital platforms where users can easily navigate through comprehensive catalogs. Utilizing these websites allows for quick access to visual aids.

Manuals and Guides: Printed materials often contain relevant images and schematics. Checking the owner’s manual can provide insights into the layout and assembly of different elements.

Community Forums: Engaging with other enthusiasts and professionals in online communities can yield valuable recommendations on where to find specific visuals. Members often share links or personal resources that can be beneficial.

Technical Support: Reaching out to customer service or technical support can lead to personalized assistance. They may provide access to exclusive resources tailored to your machinery.

By exploring these avenues, you can ensure that you have the ultimate tools needed for efficient upkeep and repair of your equipment.

Interpreting the Diagram Symbols

Understanding the various icons and symbols in machinery schematics is crucial for effective maintenance and repair. These graphical representations simplify complex components and their relationships, allowing users to quickly identify parts and their functions. Mastering these symbols enhances both comprehension and efficiency during troubleshooting.

Common Symbol Types

In technical illustrations, several standard symbols are frequently employed. Recognizing these can facilitate a smoother navigation of the schematic.

| Symbol | Meaning |

|---|---|

| ⚙️ | Gear or Mechanical Part |

| Battery or Power Source | |

| Tool or Adjustment Component | |

| Rotating Mechanism | |

| Control System or Circuit |

Tips for Decoding Schematics

To effectively interpret the illustrations, familiarize yourself with the legend or key provided alongside the drawing. Each symbol typically has a designated meaning, which can vary by manufacturer. Pay close attention to the context in which a symbol appears, as its interpretation can depend on adjacent elements and overall system design.

Replacement Parts for John Deere 950

Maintaining machinery requires an understanding of its essential components and their replacements. Whether you are performing routine maintenance or addressing unexpected failures, knowing the right substitutes can enhance performance and longevity.

Quality Components: When sourcing new elements, prioritize high-quality options to ensure compatibility and durability. Reliable suppliers often provide detailed specifications that help in identifying suitable alternatives.

Maintenance Tips: Regular inspections can help you catch wear and tear early. Keeping a log of replacements and service history can also facilitate better decision-making for future repairs.

Where to Find: Various online retailers and local dealerships offer extensive catalogs. Consulting with experts can provide insights into the most effective replacements for specific needs.

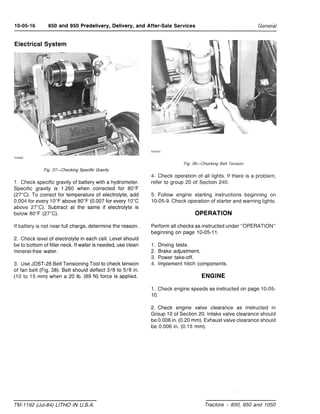

Maintenance Tips for 950 Owners

Ensuring the longevity and efficiency of your machinery involves regular upkeep and attention to detail. By following a structured maintenance routine, you can enhance performance and prevent costly repairs in the long run.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Oil Change | Every 100 hours | Use high-quality lubricant for optimal engine performance. |

| Filter Replacement | Every 200 hours | Check air and fuel filters to ensure clean operation. |

| Tire Inspection | Monthly | Check for wear and proper inflation to avoid handling issues. |

| Battery Check | Monthly | Ensure terminals are clean and connections are tight. |

| Belts and Cables | Every 50 hours | Inspect for wear and tension to maintain functionality. |

Finding Genuine Parts Online

Locating authentic components for machinery can be a challenging task. With numerous options available on the internet, distinguishing between quality and counterfeit products is crucial for maintaining optimal performance and longevity. This guide aims to help you navigate the online marketplace effectively to secure reliable replacements.

Researching Reliable Suppliers

Begin by identifying reputable vendors with a proven track record. Look for companies that specialize in heavy equipment and have positive reviews from customers. Check for certifications or affiliations with recognized manufacturers, as these can indicate a commitment to quality and customer service.

Understanding Product Specifications

When searching for replacements, it’s essential to familiarize yourself with the specific requirements of your equipment. Consult manuals and technical resources to grasp the exact specifications needed. This knowledge will empower you to make informed decisions and avoid incompatible items.

Always prioritize quality over price when shopping online. While it may be tempting to opt for cheaper alternatives, investing in genuine components will ultimately save you time and money by ensuring the reliability and efficiency of your machinery.

Remember, your equipment deserves the best. Proper maintenance and the use of authentic components are key to achieving longevity and optimal performance.

Compatibility with Other John Deere Models

This section explores how certain machinery components can interchange with various models from the same manufacturer, ensuring versatility and efficiency in maintenance. Understanding compatibility can enhance operational efficiency and reduce downtime by allowing users to utilize available resources effectively.

Several models within the same series share similar characteristics, making it possible to substitute specific components without compromising functionality. For instance, certain transmission parts or engine components may fit seamlessly across different units, providing a cost-effective solution for repairs and upgrades.

It’s essential to consult the manufacturer’s specifications or a comprehensive cross-reference guide to ensure that replacements meet the required standards for performance and reliability. This practice not only fosters a streamlined approach to maintenance but also supports the longevity of the equipment.

Frequently Asked Questions about Parts

This section aims to address common inquiries related to components and their functionalities, ensuring users are well-informed about their options and maintenance needs.

- What should I consider when choosing components?

Evaluate compatibility, quality, and warranty options.

- How can I identify a faulty component?

Look for signs such as unusual noises, leaks, or performance drops.

- Where can I find reliable replacements?

Authorized dealers, online marketplaces, and specialized retailers are good sources.

- What maintenance is needed for my equipment?

Regular inspections, cleaning, and timely replacements are essential.

- How do I know if a component is genuine?

Check for certification marks and purchase from reputable sources.

- Can I install components myself?

Many users can manage basic installations, but consulting a professional is recommended for complex tasks.