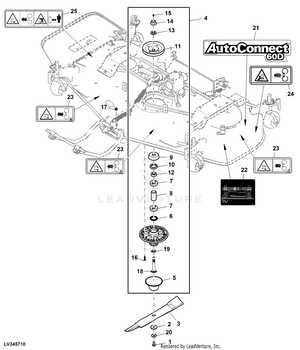

John Deere Auto Connect 60D Parts Diagram Overview

The intricate machinery used in contemporary farming plays a crucial role in enhancing productivity and efficiency. As technology continues to evolve, understanding the various elements that comprise these machines becomes increasingly important for operators and enthusiasts alike. This knowledge not only aids in maintenance but also ensures optimal performance during operations.

In this exploration, we delve into a specific model known for its innovative design and functionality. By examining the individual components, we aim to provide a clearer picture of how each part contributes to the overall effectiveness of the equipment. This understanding empowers users to make informed decisions regarding repairs and upgrades, ultimately leading to improved operational outcomes.

Furthermore, having access to a detailed visual representation of these components allows for a better grasp of their arrangement and interconnectivity. This insight is invaluable for anyone looking to enhance their expertise in agricultural machinery. By breaking down the structure and functionality, we can appreciate the engineering behind these essential tools that drive modern farming.

Understanding John Deere Auto Connect 60D

This section delves into the innovative system designed for seamless integration with agricultural machinery. It emphasizes the efficiency and convenience offered to users, highlighting how modern technology enhances functionality and reduces operational time.

Benefits of the Integration System

The advanced setup allows for quick attachment and detachment of implements, minimizing downtime and streamlining workflows. Users can experience enhanced productivity, as the mechanism is designed for ease of use, even in challenging conditions.

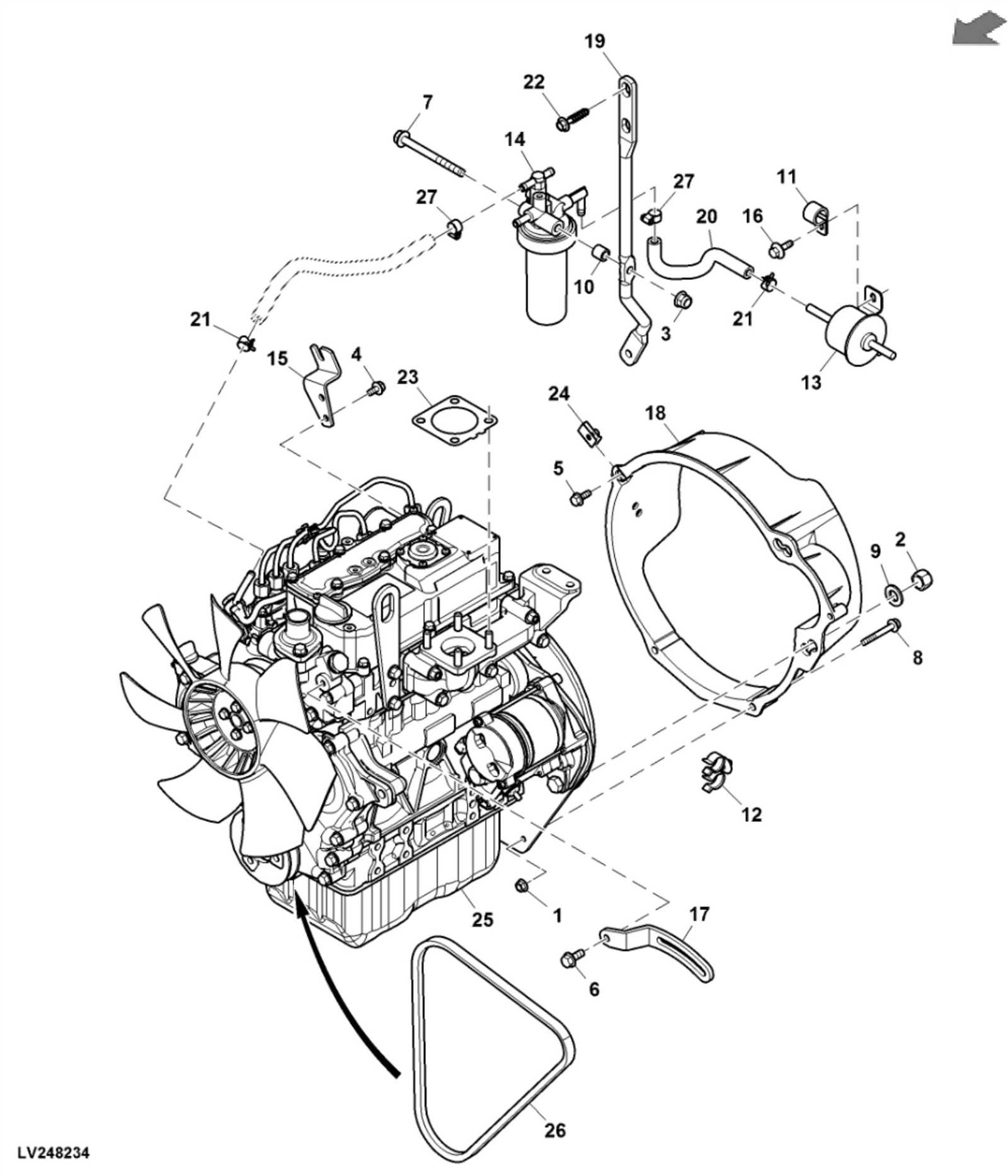

Components of the Mechanism

Key elements of this system work together to facilitate smooth operation. Understanding each component’s role can help users maintain their equipment effectively. Regular maintenance and awareness of potential issues can ensure longevity and optimal performance of the entire assembly.

By familiarizing oneself with this technology, operators can maximize the efficiency of their machinery, leading to improved results in their agricultural endeavors.

Key Features of Auto Connect 60D

This innovative implement offers several standout attributes that enhance usability and efficiency for operators. Designed with precision, it simplifies the attachment process, ensuring a seamless experience whether you are an experienced user or a beginner.

| Feature | Description |

|---|---|

| Quick Attachment | Facilitates rapid connection to the host machine, minimizing downtime and maximizing productivity. |

| Sturdy Construction | Built from high-quality materials, ensuring durability and reliability in various operating conditions. |

| Enhanced Maneuverability | Designed for easy handling, allowing operators to navigate tight spaces with confidence. |

| Integrated Safety Features | Equipped with safety mechanisms that prevent accidental disengagement during operation. |

| Versatile Compatibility | Compatible with a range of machines, making it a flexible option for diverse tasks. |

Benefits of Auto Connect Technology

This innovative mechanism transforms the way attachments are engaged and disengaged, streamlining operations for users. By simplifying this process, it enhances efficiency and minimizes physical strain, making tasks more manageable and productive.

Enhanced Efficiency

- Quick attachment changes save time during operations.

- Reduced need for manual adjustments allows for smoother transitions between tasks.

- Less downtime means more work completed in a shorter period.

Improved User Experience

- Intuitive design facilitates easier usage for operators of all skill levels.

- Minimized physical effort decreases fatigue and risk of injury.

- Enhanced visibility and access promote safer handling during attachment changes.

Overall, this technology not only boosts productivity but also significantly enhances the overall experience for users, making their work more enjoyable and efficient.

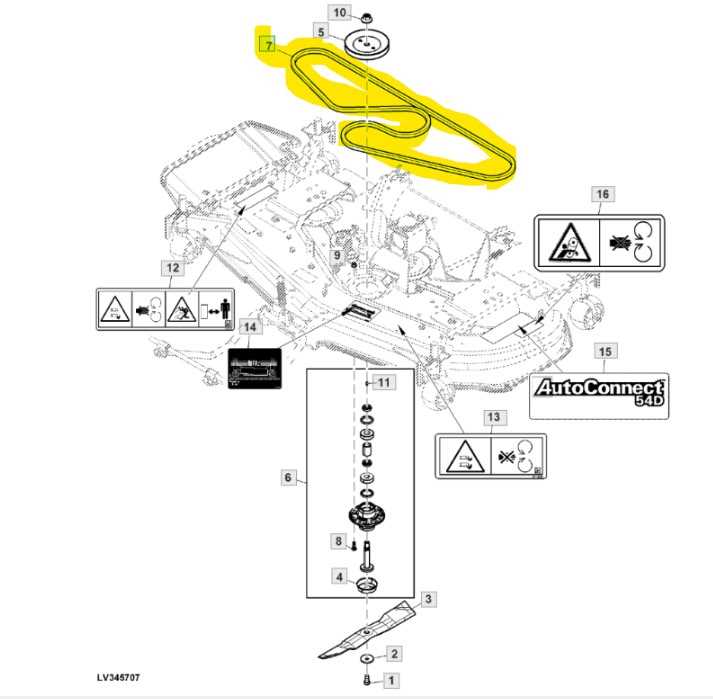

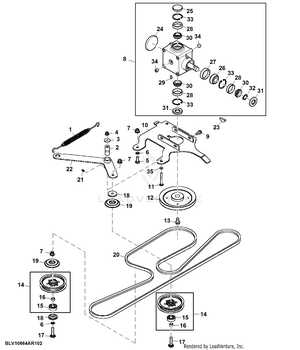

Components of the 60D Mower Deck

The mower deck is a vital assembly that contributes significantly to the overall performance of lawn care equipment. Understanding its various elements is essential for maintenance and optimal functioning. Each component plays a unique role, working in harmony to achieve a precise cut and effective grass management.

Main Elements

At the core of the mower deck, the cutting blades are crucial for delivering a clean and even cut. These sharp, rotating blades are designed to slice through grass efficiently. Surrounding the blades, the deck housing provides structural support and protects the operator from debris. This durable casing ensures that the mower operates safely and effectively.

Additional Features

Another important feature is the belt system, which transfers power from the engine to the blades. This mechanism is essential for maintaining consistent blade speed and performance. Additionally, the height adjustment system allows users to modify the cutting height, enabling customization for different grass types and seasonal conditions. Regular inspection of these components is vital to ensure longevity and efficiency, highlighting the importance of understanding each part of the mower deck.

How to Read Parts Diagrams

Understanding visual representations of components is essential for efficient maintenance and repair. These illustrations provide a wealth of information, allowing users to identify and locate various elements, ensuring that any necessary replacements or repairs can be carried out accurately.

Key Components of Visual Representations

- Symbols: Familiarize yourself with the symbols used, as each often represents specific items or tools.

- Labels: Pay attention to labels that indicate part names, numbers, and additional details.

- Connections: Observe how components are linked, which can provide insight into their function and installation.

Steps for Effective Interpretation

- Identify the Sections: Break down the illustration into sections for easier analysis.

- Match with Lists: Cross-reference the visual with any accompanying lists or indexes for clarification.

- Use Reference Guides: Consult user manuals or online resources for more in-depth explanations of specific components.

By mastering these techniques, you can navigate these visual tools with confidence, streamlining your repair processes and ensuring a thorough understanding of the assembly.

Common Challenges in Operating the Automatic Linkage System

In the realm of mechanized agricultural equipment, the integration of automated coupling mechanisms has presented both conveniences and challenges to operators. This section examines several recurrent difficulties encountered during the operation and maintenance of these sophisticated linkages.

Intermittent Connection Failures

One prevalent issue experienced by users involves sporadic failures in establishing a secure connection between components. This disruption can stem from various factors, such as misalignment of linkage elements or inadequate engagement due to environmental debris.

Mechanical Misalignment Issues

Another common challenge observed pertains to mechanical misalignments within the linkage assembly. These deviations from optimal alignment can result in inefficiencies during connection attempts and may necessitate manual adjustments or realignments.

Maintenance Tips for 60D Parts

Proper upkeep of your machinery components is essential for optimal performance and longevity. By following a few simple guidelines, you can ensure that each element functions smoothly and efficiently, reducing the risk of breakdowns and enhancing overall productivity.

Regular Inspection

- Check for any signs of wear or damage on the equipment.

- Look for loose connections or bolts that may need tightening.

- Inspect hoses and belts for cracks or fraying.

Cleaning and Lubrication

- Clean all moving parts regularly to prevent buildup of dirt and debris.

- Apply appropriate lubricants to ensure smooth operation.

- Remove any excess grease to avoid attracting more dirt.

Following these maintenance tips will help in extending the life of your machinery and enhancing its performance. Make these practices a part of your routine to enjoy reliable and efficient operation.

Replacing Parts on the 60D Mower

Maintaining and renewing components on your mower is essential for ensuring optimal performance and longevity. Understanding the procedure for swapping out these elements can significantly enhance your mowing experience, allowing for smoother operation and improved efficiency. Proper attention to detail during replacements will contribute to the machine’s overall health.

Common Components to Replace

Among the frequently replaced elements are the blades, belts, and filters. Blades should be inspected regularly for wear and sharpened as needed. Dull or damaged blades can lead to uneven cuts and increased strain on the engine. Belts are also crucial, as they transfer power and enable movement. Any signs of fraying or cracking indicate it’s time for a replacement. Lastly, filters play a vital role in maintaining engine cleanliness and efficiency; replacing them at recommended intervals helps ensure the mower runs smoothly.

Steps for Efficient Replacement

To start the replacement process, ensure the mower is powered off and safely secured. Begin by consulting the manual for specific guidelines regarding the components. Carefully remove the worn or damaged part, taking note of the configuration for reinstallation. When placing the new component, confirm that it is aligned correctly and securely fastened. After replacements are complete, perform a quick inspection to guarantee everything is in order before using the mower again.

By following these steps, you can effectively maintain your mower, ensuring it operates at its best throughout the season.

Tools Needed for Repairs

When undertaking maintenance tasks, having the right equipment is crucial for ensuring efficient and effective work. A well-equipped workspace not only enhances productivity but also contributes to achieving high-quality results. This section outlines the essential implements required for various repair activities.

Basic Hand Tools: A sturdy set of hand tools is fundamental. This includes wrenches, screwdrivers, and pliers, which allow for easy adjustments and disassembly of components. Having different sizes ensures compatibility with various fasteners.

Power Tools: For more demanding tasks, power tools such as drills and impact wrenches can significantly speed up the process. These tools provide the necessary force to handle tougher materials and fastenings.

Measuring Instruments: Accurate measurements are vital in any repair job. Tools such as tape measures, calipers, and levels ensure that every component is fitted correctly, preventing issues down the line.

Safety Gear: Prioritizing safety is essential. Protective eyewear, gloves, and masks help shield against potential hazards, ensuring a safe working environment while performing repairs.

Cleaning Supplies: Maintaining cleanliness is important during repairs. Brushes, cloths, and solvents help remove debris and contaminants, allowing for a clear view of the work area and ensuring all components are properly serviced.

Equipping yourself with these tools not only prepares you for repair tasks but also instills confidence in your ability to handle various maintenance challenges efficiently.

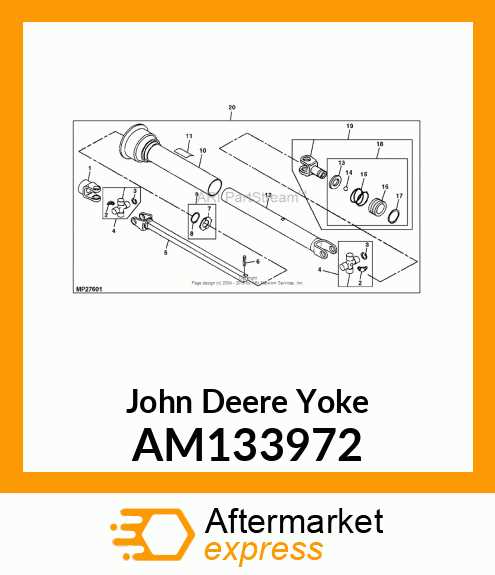

Where to Find Replacement Parts

Locating suitable components for your machinery is essential for maintaining optimal performance and longevity. With a variety of sources available, users can explore options that cater to both quality and budget considerations.

One of the most reliable avenues is the official website of the manufacturer. Here, you can often find a comprehensive catalog of components specifically designed for your model. Additionally, many authorized dealers provide genuine items, ensuring compatibility and quality assurance.

For those seeking alternative solutions, aftermarket suppliers are worth considering. These vendors frequently offer a broad range of products at competitive prices. However, it’s crucial to verify the reputation of these sources to ensure you receive durable and effective replacements.

Online marketplaces also present a convenient option for sourcing various items. Platforms such as e-commerce sites enable users to compare prices and read customer reviews, which can guide informed purchasing decisions. Always check seller ratings and return policies before committing to a purchase.

Finally, local repair shops and equipment rental businesses can be valuable resources. They often have an array of components on hand or can recommend trusted suppliers. Building relationships with these professionals may lead to better insights and potential discounts.

Step-by-Step Assembly Guide

In this comprehensive guide, we will walk you through the meticulous process of putting together the components required for the device. Our aim is to provide a clear and structured approach, ensuring that each step flows logically into the next without unnecessary complications.

Preparation

- Gather all necessary components and tools before beginning.

- Ensure you have a well-lit and organized workspace to facilitate assembly.

- Refer to the accompanying documentation for any specific instructions or safety precautions.

Assembly Steps

- Start by identifying each part according to its unique characteristics.

- Follow the sequence outlined in the assembly manual to avoid confusion.

- Connect components securely using the appropriate fasteners and techniques.

- Test each connection and alignment as you proceed to maintain accuracy.

- Refer to diagrams or illustrations provided to verify correct placement and orientation.

- Double-check all connections and alignments before moving to the next step.

By following these systematic steps, you will ensure a smooth and efficient assembly process, culminating in a functional and reliable end product.

Comparing 60D with Other Models

When evaluating different mowing implements, it’s essential to consider various models to determine which best meets specific agricultural needs. Each model offers unique features, dimensions, and functionalities that cater to different types of terrain and grass conditions. This comparison aims to highlight the strengths and weaknesses of the 60D in relation to its counterparts.

One of the key distinctions lies in the cutting width and design. While some models may prioritize compactness for maneuverability, the 60D typically provides a wider cutting area, allowing for increased efficiency in larger fields. This can significantly reduce the time spent mowing, which is a crucial factor for commercial operations.

Another important aspect to consider is the ease of attachment and detachment. Certain alternatives might offer quicker connection mechanisms, making them more user-friendly for those who frequently switch between implements. In contrast, the 60D’s design may require a bit more time for setup but compensates with stability and performance during operation.

Durability and maintenance also play a vital role in this comparison. The materials and construction techniques used in various models can impact their longevity and the frequency of necessary repairs. The 60D is often praised for its robust build, making it a reliable choice for those seeking longevity in challenging conditions.

Lastly, price and value for money are crucial considerations. While the initial investment in the 60D may be higher than some competing models, its efficiency and durability can lead to cost savings in the long run, making it a worthwhile consideration for budget-conscious buyers.

Customer Reviews and Experiences

Feedback from users plays a crucial role in understanding the efficiency and reliability of any equipment. Experiences shared by customers provide insights into functionality, ease of use, and overall satisfaction. This section delves into various opinions and evaluations regarding a specific model of machinery, highlighting both positive and negative aspects.

Positive Experiences: Many users commend the seamless integration and user-friendly design. They appreciate how effortlessly the equipment operates, often noting significant improvements in productivity. Several reviews emphasize the durable construction and dependable performance, making it a favored choice among professionals and hobbyists alike.

Challenges Faced: While most feedback is favorable, some users have encountered issues. A few reviews mention difficulties with setup or adjustments, suggesting that clearer instructions could enhance the overall experience. Additionally, concerns about maintenance requirements have been raised, indicating that prospective buyers should be aware of the care involved.

Overall, the shared experiences paint a comprehensive picture of user satisfaction, guiding potential buyers in their decision-making process. The insights gathered here reflect a blend of reliability and areas for improvement, contributing to a well-rounded understanding of the product.