Comprehensive John Deere F525 Parts Diagram Guide

In the realm of outdoor equipment, comprehending the intricate assembly of various elements is crucial for maintenance and repair. This guide explores the essential organization of components, enabling users to identify and manage each section effectively.

For enthusiasts and professionals alike, having a clear visual representation of mechanical structures can significantly enhance the repair process. By examining these configurations, individuals can delve into the ultimate functionality of their machinery, ensuring optimal performance.

Whether you are an experienced technician or a passionate hobbyist, mastering the intricacies of these assemblies will empower you to tackle any challenges that arise. Understanding how each piece interconnects is vital for maintaining the longevity and efficiency of your equipment.

Understanding John Deere F525

This section delves into the intricacies of a well-regarded model known for its robust performance and reliability in outdoor tasks. Designed for versatility, this equipment has garnered attention among enthusiasts and professionals alike, thanks to its efficient operation and user-friendly features.

Equipped with a powerful engine, this machine excels in various applications, making it a popular choice for both residential and commercial use. Its design promotes ease of maintenance, allowing operators to keep it in optimal condition with minimal effort. Understanding its components and functionality can significantly enhance the user experience and longevity of the equipment.

Moreover, this model’s adaptability to different attachments and accessories expands its utility, catering to a wide range of gardening and landscaping needs. Familiarity with the operational mechanics and available upgrades empowers users to maximize the potential of their machinery.

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for maintenance and repair tasks. Visual representations of these elements provide clarity, ensuring that users can easily identify each section and its function. This familiarity not only streamlines repairs but also enhances the overall efficiency of the equipment.

Facilitating Repairs

When addressing issues with machinery, having a clear visual guide can significantly reduce troubleshooting time. By consulting these illustrations, technicians can pinpoint malfunctioning elements quickly, allowing for faster and more accurate resolutions. This reduces downtime and keeps operations running smoothly.

Enhancing User Knowledge

These visual aids serve as excellent educational tools. Users can familiarize themselves with the structure and operation of their equipment, leading to better handling and care. Moreover, understanding how each component interrelates fosters a greater appreciation for the machinery’s design and function.

In summary, visual schematics play an essential role in maintenance, repair, and user education. Their clarity and detail empower individuals to manage their equipment more effectively.

Overview of F525 Components

This section provides a comprehensive look at the various elements that make up the equipment in question. Understanding these components is essential for effective maintenance and operation, ensuring optimal performance and longevity.

Main Assembly

The primary structure consists of a robust framework that supports the entire mechanism. Key sections include the chassis, engine housing, and attachment points for different implements, each designed for durability and functionality.

Finding OEM Replacement Parts

Locating original equipment manufacturer components is essential for maintaining the efficiency and longevity of your machinery. Ensuring compatibility and quality can enhance performance and reliability.

Here are some effective strategies to find the right replacements:

- Consult the owner’s manual for specifications and recommendations.

- Visit manufacturer websites to access resources and online catalogs.

- Contact authorized dealers for expert guidance and availability.

- Utilize online marketplaces dedicated to machinery components.

- Join forums or communities where enthusiasts share advice and experiences.

By exploring these avenues, you can delve deeper into securing the ultimate components for your equipment, ensuring it operates at peak performance.

Benefits of Using Diagrams

Visual representations are essential tools that enhance understanding and communication in various fields. They allow individuals to quickly grasp complex information by breaking it down into easily digestible elements.

Clarity and Precision: Utilizing visual aids minimizes ambiguity, ensuring that all users interpret information consistently. This leads to more effective collaboration and reduces the chances of errors.

Enhanced Retention: Research shows that visual information is more easily remembered than text alone. By incorporating diagrams, users can recall details more effectively, ultimately improving knowledge retention.

Efficient Problem Solving: Visual representations enable users to identify relationships and patterns within data quickly. This can lead to faster decision-making and more efficient troubleshooting.

Accessible Learning: Diagrams cater to different learning styles, making information accessible to a wider audience. They serve as a bridge for those who may struggle with traditional text-based formats.

Common Issues with F525 Models

Many owners of this popular lawn care equipment encounter specific challenges over time. Understanding these common problems can help in effective maintenance and enhance the longevity of the machinery. Regular attention to these issues can prevent more significant failures and ensure optimal performance.

Engine Troubles

One frequent issue involves the engine not starting or stalling unexpectedly. This can be attributed to fuel delivery problems, clogged filters, or ignition system failures. Regular checks and timely replacements can mitigate these concerns.

Transmission Problems

Another prevalent challenge is related to the transmission system. Users may experience difficulty in shifting gears or a complete loss of movement. Often, this results from worn-out belts or low fluid levels. Regular inspections are crucial for maintaining functionality.

Steps to Access the Diagram

Gaining access to the schematic representation of machinery components is essential for effective maintenance and repair. This guide outlines the necessary steps to locate and view these valuable resources, ensuring you can efficiently address any issues with your equipment.

| Step | Description |

|---|---|

| 1 | Identify the Model: Start by confirming the specific model of your equipment to ensure you retrieve the correct information. |

| 2 | Visit the Official Website: Navigate to the manufacturer’s website, where technical resources are often available for public access. |

| 3 | Access the Support Section: Look for a section dedicated to customer support, manuals, or technical documents that might house the information you need. |

| 4 | Search for Documentation: Utilize search functions to find specific technical documents related to your model, including schematics. |

| 5 | Download or View Online: Once located, you can either download the document for offline use or view it directly in your browser. |

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of any machinery. By following systematic care guidelines, users can ensure optimal performance and reduce the risk of unexpected breakdowns.

| Tip | Description |

|---|---|

| Regular Cleaning | Remove debris and dirt to prevent corrosion and mechanical issues. |

| Oil Changes | Frequent oil replacements keep the engine running smoothly and enhance efficiency. |

| Check Fluid Levels | Maintain proper levels of all fluids to avoid overheating and wear. |

| Tire Maintenance | Inspect and maintain tire pressure for better traction and fuel efficiency. |

| Inspect Belts and Cables | Regularly check for wear and replace as needed to ensure reliability. |

Tools Required for Repairs

When undertaking maintenance tasks, having the right instruments is crucial for ensuring efficiency and accuracy. Proper tools not only streamline the process but also enhance safety and longevity of the equipment.

Essential Tools

Below is a list of indispensable instruments commonly required for effective repairs:

| Tool | Description |

|---|---|

| Wrenches | Used for gripping, fastening, and turning nuts and bolts. |

| Screwdrivers | Essential for driving screws into various materials. |

| Socket Set | Allows for better leverage and ease when working with fasteners. |

| Pliers | Useful for gripping, bending, and cutting wires or small components. |

| Torque Wrench | Ensures fasteners are tightened to the correct specifications. |

Safety Equipment

In addition to standard tools, safety gear is vital to protect oneself during repair work:

| Equipment | Purpose |

|---|---|

| Gloves | Protects hands from sharp edges and chemical exposure. |

| Safety Glasses | Prevents eye injury from debris and dust. |

| Ear Protection | Reduces noise exposure during operation. |

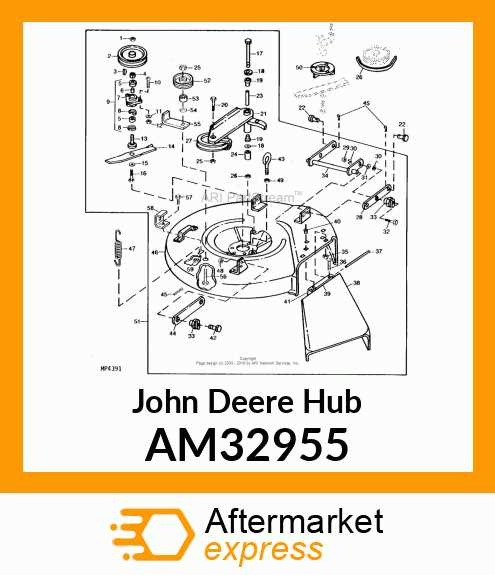

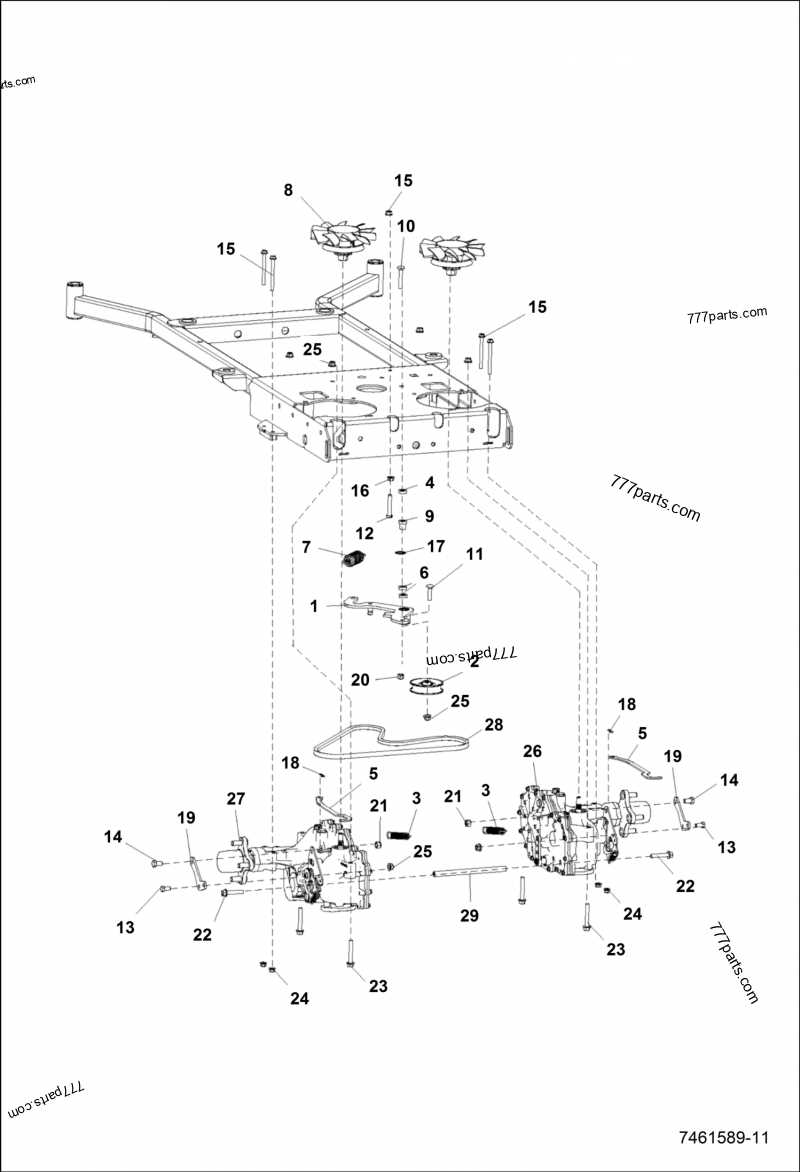

Identifying Parts by Diagram

Understanding the components of a machine through visual representations is essential for effective maintenance and repair. Diagrams serve as valuable tools that simplify the process of locating and recognizing individual elements within complex machinery. By interpreting these visual guides, users can enhance their troubleshooting skills and ensure their equipment operates efficiently.

Benefits of Visual Guides

Utilizing illustrations allows for quicker identification of specific elements. This method minimizes confusion, especially for those who may not be familiar with the technical terminology associated with machinery. Furthermore, these visual aids can facilitate a more streamlined repair process, saving time and effort.

Effective Use of Illustrations

To maximize the benefits of these visual references, users should approach them with an organized mindset. Carefully cross-referencing illustrations with the physical components can lead to more accurate assessments. Additionally, noting the arrangement and connections depicted in the visuals can provide insights into the overall functionality of the machine.

Aftermarket vs. Original Parts

When it comes to maintaining machinery, the choice between standard and alternative components can greatly influence performance and longevity. Each option presents unique benefits and potential drawbacks that users must consider.

- Original Components:

- Designed specifically for the equipment.

- Often come with a warranty, ensuring quality and reliability.

- Higher cost, but potentially better fit and performance.

- Alternative Components:

- Generally more affordable, appealing to budget-conscious users.

- Availability may vary, leading to quicker sourcing options.

- Quality can be inconsistent; careful selection is essential.

Ultimately, evaluating these options requires consideration of individual needs, preferences, and the specific demands of the machinery in question.

Where to Buy F525 Parts

Finding the right components for your equipment can significantly enhance its performance and longevity. Whether you’re looking for replacement items or upgrades, it’s essential to know where to source quality options.

Here are some reliable avenues to consider:

- Authorized Dealers: These locations often have a comprehensive selection of official components, ensuring compatibility and reliability.

- Online Retailers: Websites specializing in equipment supplies frequently offer a wide range of options, often at competitive prices. Be sure to read reviews for assurance on quality.

- Local Repair Shops: Many local mechanics and repair shops can order specific items for you or may have them in stock.

- Salvage Yards: For those on a budget, visiting a salvage yard can yield affordable alternatives, often in good condition.

Consider your needs and preferences when selecting a source, and always verify the return policy and warranty options to safeguard your purchase.

Frequently Asked Questions

This section aims to address common inquiries related to maintenance and repair components for a specific type of equipment. Here, you will find helpful answers that can enhance your understanding and assist you in troubleshooting or upgrading your machinery.

| Question | Answer |

|---|---|

| What should I do if I can’t find the specific components I need? | Check various online retailers and forums; many enthusiasts share resources and alternatives. |

| How often should I replace certain components? | It depends on usage, but regular checks every season are advisable to ensure optimal performance. |

| Are there any common upgrades recommended? | Upgrading the engine or adding improved tires can significantly enhance efficiency. |

| Where can I find detailed assembly instructions? | User manuals and online resources are great places to start for detailed assembly guidance. |