Comprehensive Guide to John Deere JS63 Parts Diagram

Maintaining and repairing agricultural machinery requires a comprehensive understanding of its various elements. Familiarity with each component and its function can significantly enhance performance and extend the lifespan of the equipment. This knowledge empowers operators to make informed decisions during maintenance and troubleshooting processes.

In this section, we will explore a detailed breakdown of a specific model, highlighting the key parts that contribute to its efficient operation. By examining this intricate network of components, users will gain valuable insights into how their machinery works, enabling them to identify issues more readily and streamline repair efforts.

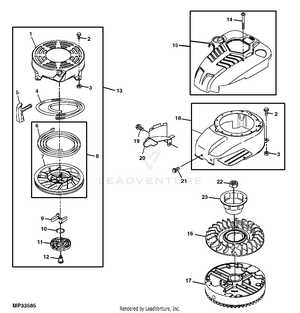

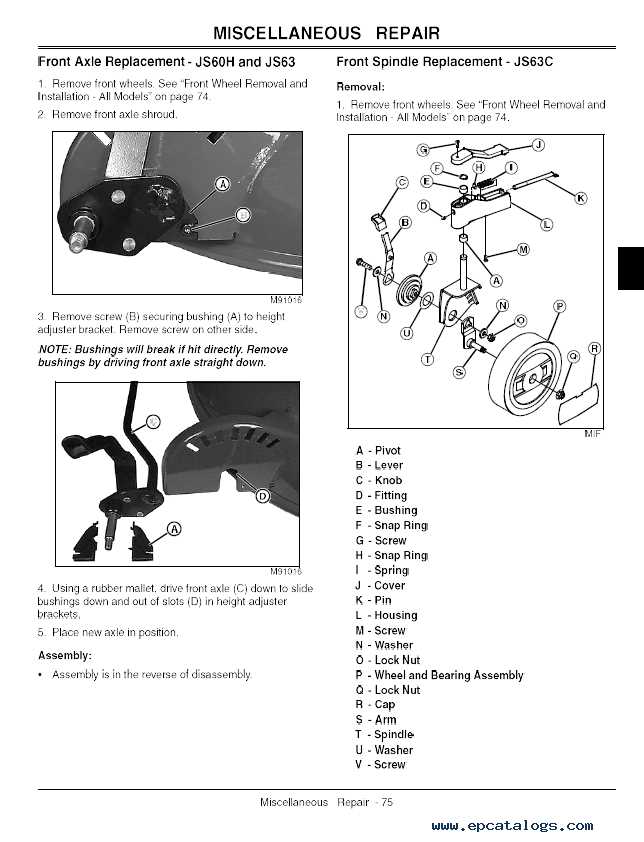

Additionally, we will provide visual references that illustrate the arrangement and relationships between different elements. Such diagrams serve as essential tools for anyone looking to deepen their understanding of machinery and enhance their technical skills.

Understanding John Deere JS63 Components

Comprehending the individual elements of a lawn care machine is essential for effective maintenance and optimal performance. Each component plays a critical role in the overall functionality, ensuring a smooth operation. This section will explore the vital parts and their significance in achieving a well-manicured lawn.

Main Components Overview

- Engine: Powers the equipment, providing the necessary energy for operation.

- Blade Assembly: Responsible for cutting grass efficiently.

- Deck: Houses the blade assembly and supports the overall structure.

Maintenance Tips

- Regularly check the engine oil and air filter for optimal performance.

- Sharpen or replace blades as needed to ensure clean cuts.

- Inspect the deck for any debris or damage after use.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding machinery. They provide clear guidance, allowing users to identify and locate essential elements quickly and efficiently. This clarity enhances both maintenance and repair processes.

Effective communication is another significant advantage. Such illustrations bridge the gap between complex technical jargon and practical application, making it easier for technicians and enthusiasts alike to comprehend intricate systems.

Moreover, accurate references reduce the risk of errors during assembly or disassembly, ensuring that each element is handled appropriately. This accuracy is vital for maintaining optimal performance and longevity of equipment.

In summary, visual aids not only facilitate better understanding but also promote efficiency and safety in mechanical operations.

Common Issues with JS63 Lawn Mower

Owners of this specific lawn maintenance machine often encounter a variety of challenges that can impact its performance and reliability. Understanding these frequent problems can help users maintain their equipment more effectively and extend its lifespan.

One prevalent issue is the mower’s engine failure to start, which can stem from fuel contamination, battery problems, or issues with the ignition system. Additionally, users may experience uneven cutting, usually caused by dull blades or improper deck height adjustment. Overheating can also occur, often due to a clogged air filter or inadequate oil levels.

Another common concern is the malfunction of the drive system, which might be linked to worn belts or faulty transmission components. Regular maintenance and inspections can help mitigate these issues and ensure optimal functionality.

How to Access Parts Diagrams

Finding the right illustrations for components can significantly enhance maintenance and repair tasks. Understanding how to navigate these resources effectively is crucial for anyone working with machinery.

Utilizing Manufacturer Resources

Most manufacturers provide online portals where you can search for specific models and retrieve relevant visuals. Look for sections dedicated to service or support for streamlined access.

Consulting User Manuals

User manuals often include references to component schematics. Checking these documents can provide valuable insights into assembly and disassembly processes.

Key Parts for Maintenance

Ensuring optimal performance of your equipment requires regular attention to essential components. Understanding the critical elements involved in upkeep can significantly enhance longevity and efficiency.

| Component | Description | Function |

|---|---|---|

| Air Filter | Prevents dirt and debris from entering the engine. | Maintains airflow and engine efficiency. |

| Oil Filter | Filters impurities from engine oil. | Ensures clean oil circulation for lubrication. |

| Spark Plug | Ignites the air-fuel mixture in the engine. | Ensures reliable starting and combustion. |

| Blades | Cutting elements that require sharpness for effective performance. | Provides a clean cut for optimal results. |

Tools Needed for Repairs

Proper maintenance and repair of outdoor equipment require a selection of essential implements to ensure efficient and effective service. Having the right tools on hand not only facilitates the repair process but also helps to maintain the longevity and performance of the machinery.

Basic Hand Tools: A comprehensive toolkit typically includes a variety of wrenches, screwdrivers, and pliers. These basic hand tools are crucial for tackling various fasteners and components that may require adjustment or replacement.

Socket Set: A high-quality socket set is indispensable for working with nuts and bolts. Different sizes and types of sockets allow for versatile use across various tasks, making them a valuable addition to any repair kit.

Torque Wrench: To ensure that fasteners are tightened to the correct specifications, a torque wrench is essential. This tool prevents over-tightening, which can lead to damage, and ensures that repairs meet safety standards.

Diagnostic Tools: For troubleshooting issues effectively, diagnostic equipment such as multimeters or specialized testers can help identify electrical problems and other malfunctions that may not be immediately visible.

Safety Gear: Safety should never be overlooked. Equip yourself with gloves, goggles, and ear protection to minimize the risk of injury while performing repairs.

In summary, having a well-stocked toolkit equipped with essential implements can significantly enhance the repair process, ensuring that equipment operates smoothly and efficiently.

Replacing Blades on JS63

Maintaining sharp cutting implements is essential for optimal performance in any mowing device. Over time, these components can wear down, leading to inefficient grass cutting and uneven results. This section will guide you through the process of replacing these crucial elements, ensuring your equipment runs smoothly and effectively.

Tools Required

Before beginning the replacement process, gather the necessary tools. You will typically need a wrench set, a socket set, and possibly a flathead screwdriver. Ensuring you have all tools at hand will streamline the replacement and reduce downtime.

Step-by-Step Replacement Process

1. First, ensure the machine is powered off and disconnected from any power source for safety.

2. Next, tilt the device to access the underside where the cutting implements are mounted.

3. Use the appropriate wrench to remove the bolts securing the existing blades. Carefully detach them and inspect for any additional wear on other components.

4. Align the new blades with the mounting points and secure them tightly with the bolts.

5. Finally, return the equipment to its upright position and conduct a safety check before use.

Identifying Wear and Tear

Recognizing signs of degradation is essential for maintaining optimal performance and longevity of machinery. Regular inspection allows operators to detect issues early, preventing costly repairs and downtime. Understanding the common indicators of wear can significantly enhance the efficiency of equipment operations.

Common Signs of Degradation

Visual cues such as cracks, rust, or fraying materials are often the first signs of deterioration. Additionally, unusual noises or changes in performance can signal underlying problems that require immediate attention.

Maintenance Tips

To mitigate wear, implement a routine maintenance schedule that includes cleaning, lubrication, and replacement of worn components. Keeping an eye on these factors can ensure your equipment remains in peak condition, ultimately prolonging its lifespan.

Where to Purchase Parts

Finding reliable components for your equipment can be a challenge, but there are several avenues to explore. It’s essential to identify trustworthy sources that offer quality replacements at competitive prices. By leveraging both online and local resources, you can ensure that your machinery remains in optimal working condition.

Here are some common options for acquiring the necessary components:

| Source Type | Description |

|---|---|

| Authorized Dealers | These retailers provide original components with manufacturer warranties and expert guidance. |

| Online Marketplaces | Websites like Amazon and eBay offer a wide selection, often at discounted prices. |

| Local Repair Shops | Neighborhood mechanics may have access to quality alternatives and can assist with installation. |

| Salvage Yards | These facilities can be a treasure trove for used but functional items at lower costs. |

| Manufacturer’s Website | Purchasing directly from the source often guarantees authenticity and the latest versions. |

Upgrading Your Lawn Mower

Enhancing your lawn care equipment can significantly improve performance and efficiency. By incorporating modern upgrades, you can ensure that your machine operates smoothly and effectively tackles grass cutting tasks.

Benefits of Upgrading

- Improved cutting precision

- Increased durability

- Enhanced fuel efficiency

- Better comfort and control

Key Areas for Improvement

- Blades: Consider switching to high-quality, sharper blades for cleaner cuts.

- Engine: Upgrading to a more powerful engine can boost performance.

- Wheels: Larger, sturdier wheels can improve maneuverability on uneven terrain.

- Comfort Features: Adding ergonomic handles can enhance user experience during operation.

Tips for Long-lasting Performance

Ensuring optimal functionality and durability of your machinery requires consistent maintenance and mindful usage. By implementing a few strategic practices, you can significantly enhance the longevity of your equipment and reduce the likelihood of costly repairs.

Regular Maintenance Checks

Routine inspections are essential. Check for wear and tear, lubricate moving parts, and replace any worn components promptly. This proactive approach prevents minor issues from escalating into major failures.

Proper Usage Techniques

Utilizing equipment according to the manufacturer’s guidelines is crucial. Avoid overloading and always use the correct settings for different tasks. This not only maximizes efficiency but also extends the life of your machinery.