John Deere L120 Parts Diagram PDF Guide

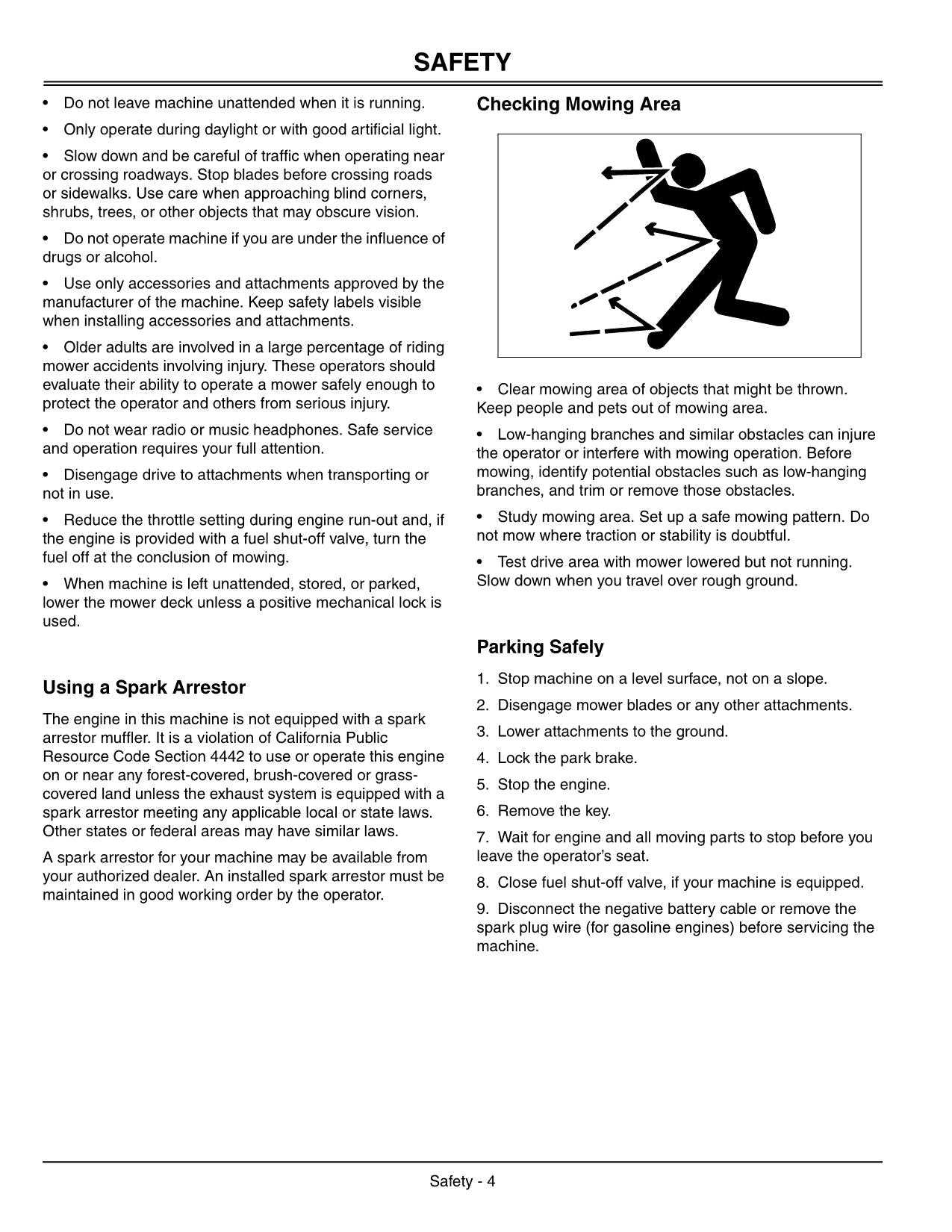

Understanding the intricate design and functionality of lawn equipment is essential for proper maintenance and repair. This section delves into the various elements that make up these machines, focusing on how each part contributes to overall performance. Whether for troubleshooting, replacing worn-out components, or simply gaining a deeper understanding, having a clear breakdown of these crucial elements is invaluable.

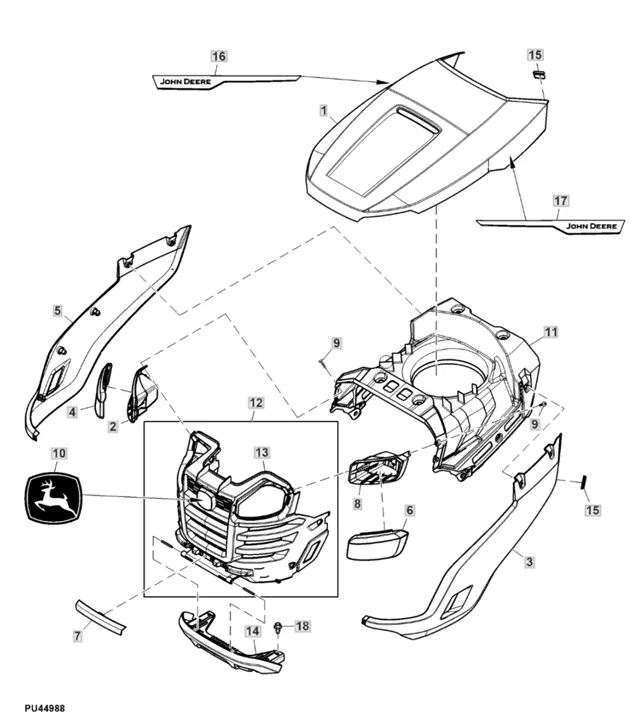

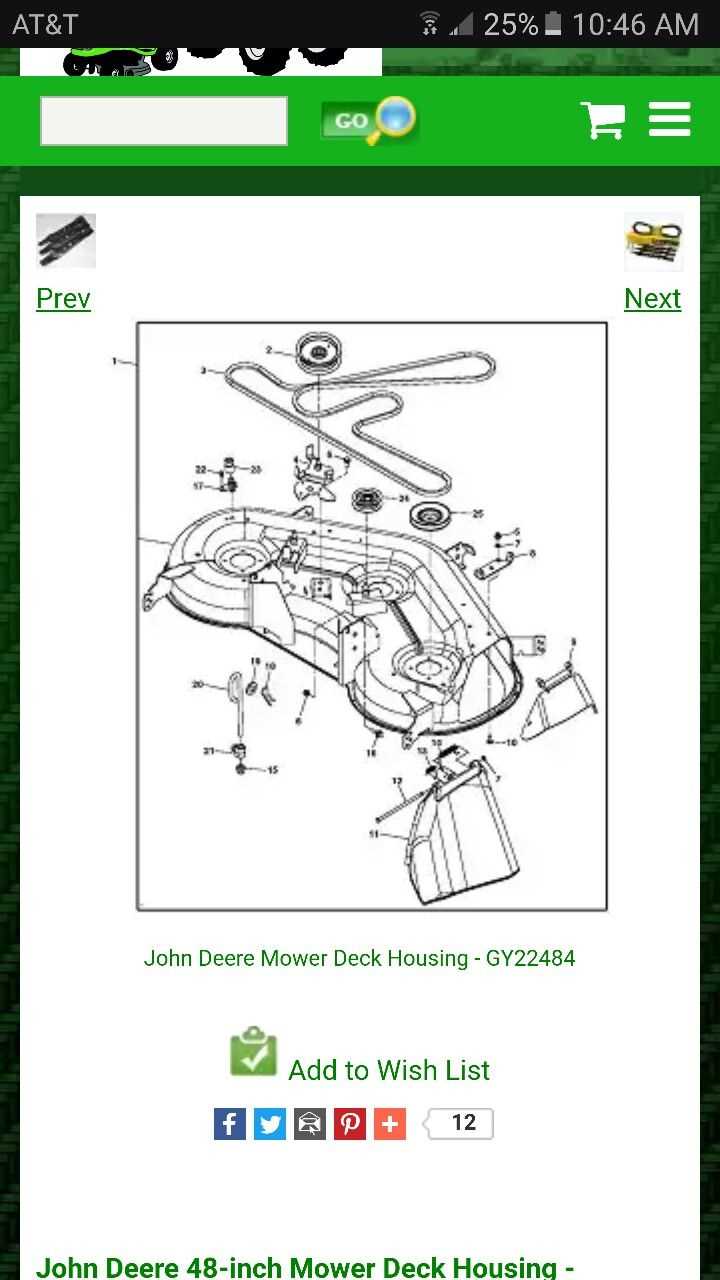

For those seeking clarity on individual components, visual aids can offer significant assistance. A detailed representation of the equipment’s structure allows users to easily identify the necessary parts, enhancing the repair or maintenance process. Knowing where each component fits ensures that repairs are carried out effectively and in a timely manner.

In this guide, we will provide a comprehensive resource that offers a structured overview of the components, aiding you in identifying, replacing, and maintaining the parts required for optimal functioning. This resource aims to simplify the complexity of machinery by offering an accessible reference point for all users.

Exploring John Deere L120 Components

This section delves into the various elements that make up a well-designed machine. Understanding the key elements of any device is crucial for ensuring proper maintenance and functionality. By examining each piece and its role, users can achieve smoother operation and troubleshoot effectively when issues arise.

Key Operational Elements

The critical operational parts of this equipment ensure its performance across diverse tasks. These components work together to provide power, stability, and control during use, allowing the machine to meet specific demands efficiently. Understanding each part’s function within the system can simplify repairs and enhance overall performance.

Maintenance Considerations

Key Features of the L120 Model

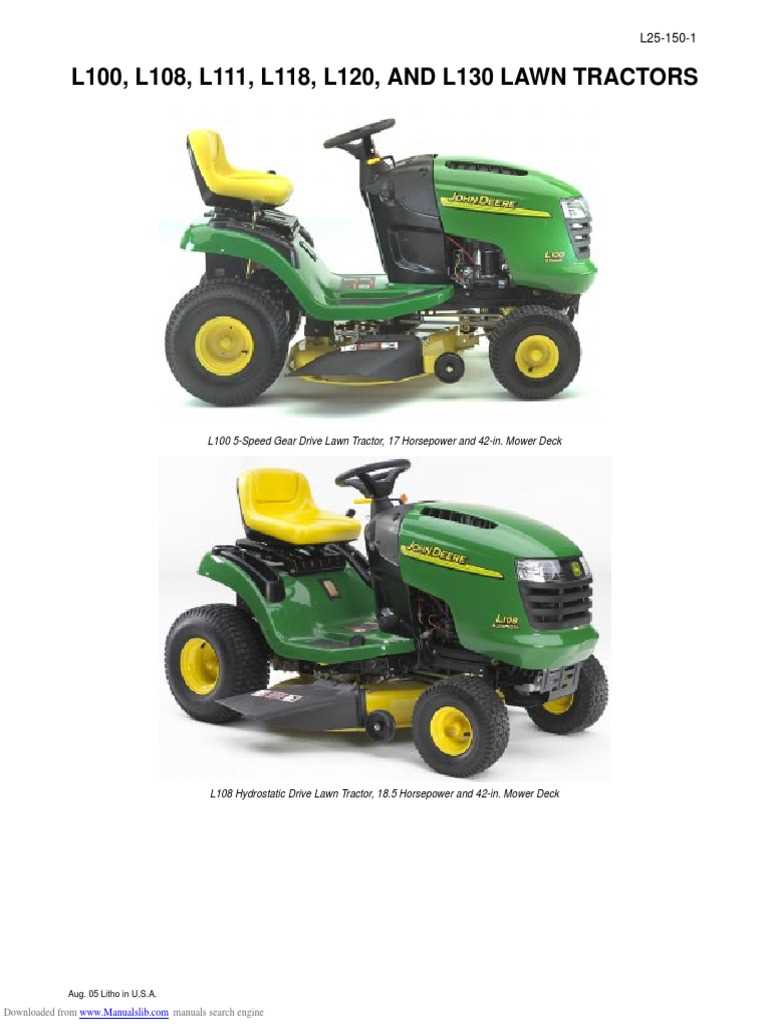

The L120 model stands out in the world of outdoor machinery, showcasing a blend of functionality and innovation. Its design emphasizes user convenience, making it suitable for various tasks around the yard.

One of the most notable aspects is its powerful engine, which provides ample torque and efficiency. This ensures smooth operation, even in challenging conditions. Additionally, the model features an ergonomic design, allowing users to navigate with ease and comfort during prolonged use.

Another significant characteristic is the cutting system, which offers adjustable heights for precision and adaptability to different grass types. This versatility is complemented by a spacious cutting deck that minimizes the number of passes required to achieve a well-manicured lawn.

Moreover, the model is equipped with an easy-to-use control panel, simplifying operation for both seasoned users and newcomers. This user-friendly approach enhances the overall experience, making yard maintenance a more enjoyable task.

Finally, the model’s durable construction ensures longevity, standing up to the rigors of regular use while maintaining performance. This combination of features positions it as a reliable choice for anyone seeking efficiency in outdoor tasks.

Detailed Parts Breakdown for Efficient Maintenance

Understanding the intricate components of your equipment is essential for optimal performance and longevity. A comprehensive analysis of each element allows for better planning of maintenance tasks, ensuring that all parts function harmoniously. By familiarizing yourself with these components, you can identify potential issues before they escalate, ultimately saving time and resources.

Key Components to Monitor

Focus on critical areas such as the engine assembly, transmission, and cutting mechanisms. Regular inspections of these sections can prevent unexpected breakdowns and enhance overall efficiency. Additionally, attention to belts, filters, and blades will contribute significantly to the smooth operation of your machinery.

Benefits of Detailed Knowledge

Acquiring in-depth knowledge of your machine’s structure not only aids in timely repairs but also empowers you to make informed decisions about upgrades or replacements. This proactive approach fosters a reliable working environment and maximizes productivity.

Understanding the Power System Configuration

Grasping the intricacies of a machinery’s energy management framework is essential for optimal performance and longevity. This framework encompasses various components that work in synergy to generate, distribute, and utilize power efficiently. By comprehending how these elements interact, operators can ensure that their equipment operates smoothly and effectively.

The core of this configuration typically includes an engine, a transmission system, and electrical components, all of which are designed to convert fuel into mechanical energy. Understanding the role of each element allows for better maintenance practices and troubleshooting when issues arise. Moreover, a well-designed energy system not only enhances productivity but also contributes to fuel efficiency, reducing operational costs.

Additionally, the integration of modern technology in power systems, such as sensors and control units, provides real-time data that can be invaluable for performance monitoring. This technological advancement aids in diagnosing potential problems before they escalate, ultimately extending the lifespan of the machinery. Awareness of these systems and their configurations is crucial for any operator aiming to maximize efficiency and reliability.

Critical Engine Components and Their Roles

Understanding the essential elements that constitute an engine is vital for both performance and longevity. Each component plays a specific role in ensuring that the engine operates efficiently, contributes to power generation, and maintains overall functionality. A thorough comprehension of these parts can aid in diagnostics and maintenance, ultimately enhancing the machine’s reliability.

Key Components

Several critical elements work in harmony to facilitate the operation of an engine. Below is a brief overview of some of these essential components and their primary functions:

| Component | Role |

|---|---|

| Cylinder Block | Forms the core structure of the engine and houses various components such as pistons. |

| Pistons | Convert fuel combustion energy into mechanical motion. |

| Crankshaft | Transforms linear motion from the pistons into rotational motion to drive the machinery. |

| Camshaft | Regulates the timing of valve openings and closings, ensuring optimal air-fuel mixture flow. |

| Valves | Control the intake of air and fuel as well as the exhaust of combustion gases. |

Importance of Regular Maintenance

Maintaining these crucial components is essential for optimal performance. Regular inspections and timely replacements of worn parts can prevent more extensive damage and ensure the engine remains in peak condition. Understanding the roles of these elements empowers users to make informed decisions regarding maintenance and repairs.

Wheels and Tires: Choosing the Right Fit

Selecting the appropriate wheels and tires is crucial for ensuring optimal performance and safety in outdoor machinery. The right combination can significantly enhance traction, stability, and maneuverability, making your tasks easier and more efficient.

When considering options, it’s important to evaluate several key factors:

- Size: The dimensions of the wheels and tires affect overall handling and comfort. Ensure compatibility with your equipment’s specifications.

- Type: Different terrains require different types of tires. Choose between turf, all-terrain, or specialized options based on where you’ll be operating.

- Load Capacity: Assess the weight your machinery will carry to prevent tire wear and potential failures.

- Tread Pattern: The design of the tread can influence grip and drainage. Select a pattern that suits your typical ground conditions.

- Material: Consider the durability and flexibility of the materials used, as they impact performance and longevity.

By carefully weighing these factors, you can select the right wheels and tires that not only enhance performance but also extend the lifespan of your equipment.

Transmission and Drive System Overview

The transmission and drive system is a critical component that ensures effective power transfer from the engine to the wheels, facilitating smooth movement and control. This system is designed to optimize performance while maintaining reliability under various operating conditions. Understanding its structure and functionality is essential for maintenance and troubleshooting.

Key Components

At the heart of the transmission and drive system are several essential elements that work in unison. These components include the gearbox, drive belts, pulleys, and axles. Each part plays a specific role in delivering the necessary torque and speed to propel the machine efficiently.

| Component | Function |

|---|---|

| Gearbox | Adjusts the engine’s output to achieve desired speeds. |

| Drive Belts | Transmits power from the engine to the wheels. |

| Pulleys | Change the direction of the drive belts and adjust speed ratios. |

| Axles | Connect wheels to the transmission and facilitate movement. |

Maintenance Considerations

Regular inspection and maintenance of the transmission and drive system are crucial for optimal performance. Checking fluid levels, inspecting belts for wear, and ensuring all connections are secure can help prevent costly repairs and extend the lifespan of the equipment. Understanding these aspects will aid operators in achieving maximum efficiency.

How to Locate Replacement Parts

Finding the right components for your equipment can be a straightforward process if you know where to look. Whether you’re performing routine maintenance or making necessary repairs, understanding how to source the right items is crucial for ensuring your machinery operates effectively. This guide outlines the essential steps to help you track down the necessary replacements efficiently.

Utilize Online Resources

The internet offers a wealth of information and resources. Start by visiting official manufacturer websites where you can often find detailed catalogs. Many of these platforms provide search functions to help you narrow down your options by model and type. Additionally, reputable online retailers specialize in providing quality components for various machinery, complete with customer reviews and ratings to assist in your decision-making.

Consult Local Dealers and Repair Shops

Another effective method is to reach out to local dealers or repair shops. These professionals have extensive knowledge of the equipment and can offer personalized assistance. They may also stock the specific items you need or be able to order them for you. Furthermore, engaging with local experts can provide insights into compatibility and alternative options that might not be readily apparent online.

In summary, whether you choose to explore online resources or consult local specialists, ensuring you have accurate information and the right connections will simplify the process of finding replacement items for your machinery.

Electrical System Diagrams and Troubleshooting

The electrical system in machinery plays a crucial role in its overall functionality and performance. Understanding the layout and connections within this system can significantly aid in diagnosing issues and ensuring optimal operation. This section delves into the intricacies of electrical schematics, providing valuable insights for effective troubleshooting and maintenance.

Understanding Electrical Layouts

Electrical layouts serve as blueprints, illustrating how components are interconnected. Familiarizing oneself with these layouts helps in identifying potential problem areas. Common elements include batteries, switches, relays, and wiring harnesses, each contributing to the overall efficiency of the system. Recognizing the role of each component allows for more targeted diagnostics.

Troubleshooting Techniques

When faced with electrical malfunctions, systematic troubleshooting is essential. Start by checking power sources and connections for signs of wear or damage. Utilize a multimeter to measure voltage levels, ensuring that each part is functioning within its specified range. Documenting findings throughout the process can provide clarity and assist in identifying recurring issues. In many cases, replacing faulty components or reestablishing connections can resolve problems effectively.

In conclusion, mastering the fundamentals of electrical systems not only enhances operational reliability but also empowers users to address issues proactively.

Decoding the Fuel System Layout

Understanding the configuration of the fuel mechanism is essential for optimal performance and maintenance of any small engine machinery. A well-designed fuel system ensures efficient fuel delivery, proper combustion, and overall reliability. Familiarizing oneself with its components and their interconnections can help diagnose issues and facilitate effective repairs.

Key components of the fuel system typically include:

- Fuel Tank: Stores the gasoline and maintains pressure.

- Fuel Pump: Delivers fuel from the tank to the engine.

- Fuel Filter: Cleans the fuel before it reaches the engine to prevent clogs.

- Carburetor or Fuel Injector: Mixes fuel with air for combustion.

- Fuel Lines: Transport fuel between components.

When analyzing the layout, it is beneficial to focus on:

- Flow Direction: Understand how fuel moves through the system, starting from the tank and ending at the combustion chamber.

- Component Placement: Identify where each part is located and how it connects to others for seamless operation.

- Potential Issues: Look for common failure points such as leaks, clogs, or malfunctions in the pump and filters.

By grasping the fuel system’s architecture, operators can enhance troubleshooting capabilities, ensure timely maintenance, and prolong the lifespan of their equipment.

Chassis and Frame Assembly Insights

The foundation of any mechanical system relies heavily on the integrity of its framework. A robust chassis not only supports various components but also ensures stability and performance during operation. Understanding the intricacies of frame assembly is crucial for maintenance and enhancements.

Components of the Chassis play a vital role in determining the overall strength and durability. These include the main frame, cross members, and support brackets, each contributing to the overall structure. It is essential to select high-quality materials to prevent wear and enhance longevity.

Assembly Techniques significantly impact the performance of the chassis. Proper alignment and secure fastening are critical to avoid misalignment that can lead to premature wear or failure. Utilizing specialized tools and techniques can facilitate a smoother assembly process.

Incorporating regular inspections and maintenance routines can identify potential issues early, preserving the functionality of the assembly. Understanding how each component interacts within the framework allows for more effective troubleshooting and repairs.

Identifying Components for Smooth Operation

Understanding the various elements of machinery is crucial for ensuring efficient functionality and longevity. Each component plays a specific role, and recognizing these parts aids in maintenance and troubleshooting. Proper identification helps in avoiding potential issues and enhances overall performance.

Key Components to Recognize

- Engine: The heart of the machine, responsible for power generation.

- Transmission: Facilitates the transfer of power from the engine to the wheels.

- Deck: The cutting area that determines the effectiveness of grass trimming.

- Wheels: Essential for mobility and stability on different terrains.

- Controls: User interface that allows for maneuvering and adjustments.

Maintenance Tips for Each Component

- Regularly inspect the engine for signs of wear or leaks.

- Ensure the transmission fluid is at appropriate levels.

- Keep the deck clean and sharp for optimal cutting performance.

- Check tire pressure and tread for safe operation.

- Familiarize yourself with the controls to ensure proper use.

By knowing these vital parts and their maintenance needs, users can promote a seamless experience and prolong the life of their equipment.

Maintenance Tips for Long-Term Performance

Ensuring optimal performance of your equipment over time requires regular attention and care. Implementing a consistent maintenance routine not only prolongs the lifespan of the machinery but also enhances its efficiency. Below are some essential practices to keep your equipment running smoothly.

Regular Cleaning and Inspection

Keeping the machinery clean is crucial for preventing dirt and debris buildup, which can lead to mechanical issues. Regularly inspect all components for signs of wear or damage. Pay special attention to areas that are prone to accumulating grime, as these can significantly impact performance if neglected.

Lubrication and Fluid Checks

Routine lubrication of moving parts is essential to minimize friction and reduce wear. Ensure that all necessary fluids, such as oil and coolant, are at optimal levels and replace them as recommended by the manufacturer. A well-lubricated machine operates more efficiently and is less likely to encounter problems over time.