Comprehensive Guide to John Deere LTR180 Parts Diagram

Understanding the structure and organization of machinery elements is essential for proper maintenance and efficient repairs. Each component has its specific place and function, which contributes to the overall performance of the equipment. Knowing where these elements are located and how they interconnect can greatly simplify troubleshooting and upgrades.

This guide will walk you through the detailed layout of crucial assemblies, helping you identify the individual units and their respective connections. By examining each section carefully, you will gain insights into the intricate setup, making it easier to handle complex tasks involving replacements or adjustments.

Whether you’re looking to optimize functionality or perform necessary fixes, this resource provides valuable information on the internal arrangement of essential mechanical systems, ensuring smooth operation and longevity of your equipment.

Overview of the John Deere LTR180 Model

This popular machine is known for its reliability and efficiency, making it a top choice for those needing dependable performance. It’s designed to handle various tasks with ease, offering a versatile solution for users looking to maintain their outdoor spaces effectively. The structure and build are crafted with longevity in mind, ensuring that it can withstand regular use while delivering consistent results.

Key Features and Capabilities

The model comes equipped with a powerful engine that provides sufficient strength to tackle even challenging conditions. Its cutting system is engineered to offer precision and cleanliness, allowing for a smooth and professional finish. The compact design also makes maneuvering through tight spaces more manageable, enhancing its overall user experience.

Durability and Maintenance

Built with high-quality materials, this machine is designed for long-term use, resisting wear and tear over extended periods. Regular upkeep is simplified through accessible components, ensuring that routine servicing can be conducted efficiently. This attention to detail in both design and maintenance helps extend its life, ensuring reliable performance for years to come.

Main Components and Their Functions

This section highlights the key mechanical and operational elements of the equipment, providing an overview of their essential roles and how they contribute to the overall functionality. Each part is designed to work in harmony, ensuring efficient performance and long-term reliability.

Engine and Power Transmission

- Engine: The heart of the machine, it generates the necessary power to drive all mechanical functions. With proper maintenance, it ensures consistent performance.

- Transmission: Transmits the engine’s power to the wheels, allowing smooth movement and control. It plays a crucial role in managing speed and torque, adapting to various operating conditions.

Cutting and Maneuvering Mechanisms

- Mowing Deck: The component responsible for cutting, featuring adjustable height settings for varied grass lengths. It ensures even trimming across large surfaces.

- Steering System: Provides precise control over the machine’s d

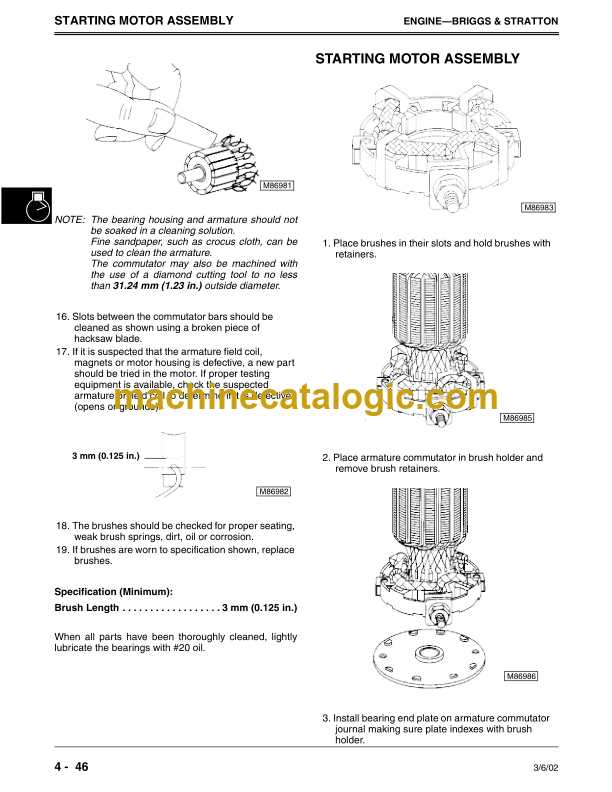

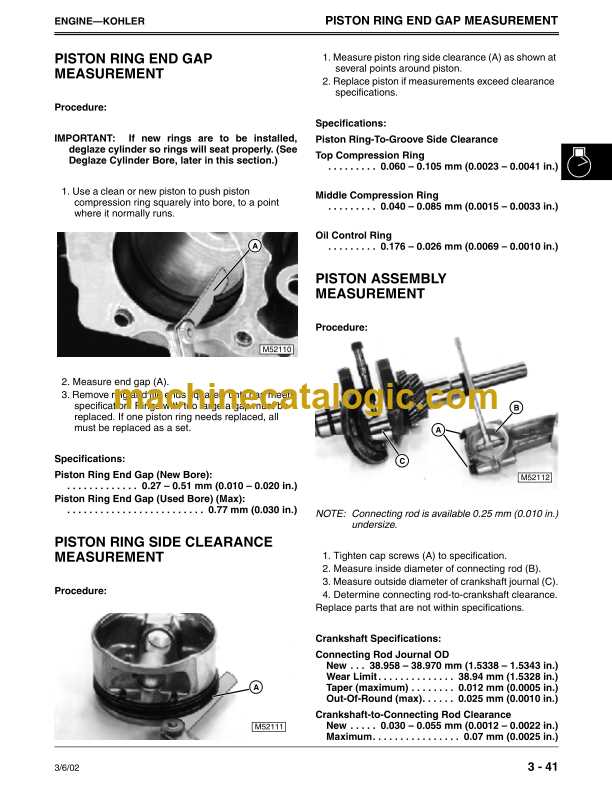

Engine Parts Breakdown for LTR180

Understanding the key components of the motor system is essential for maintaining optimal performance. This section provides a comprehensive overview of the internal mechanisms, detailing the various elements that work together to ensure efficient operation. By familiarizing yourself with these elements, you can better troubleshoot potential issues and keep everything running smoothly.

The heart of the system consists of several critical elements, including the cylinder head, which houses crucial components like valves and spark plugs. The crankshaft ensures the conversion of linear motion into rotational force, allowing the machine to operate. Additionally, the piston moves within the cylinder to generate the necessary compression for ignition.

Other essential elements include the camshaft, which controls the timing of valve movements, and the carburetor, responsible for mixing air and fuel. Keeping these parts well-maintained and understanding their individual functions is vital for long-term reliability and performance.

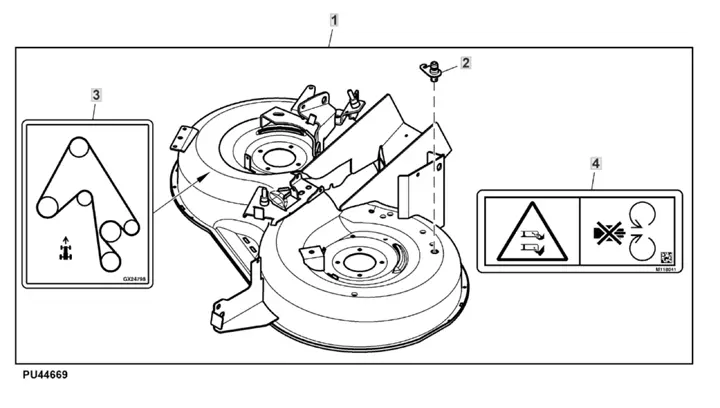

Understanding the Mower Deck Assembly

The mowing platform plays a crucial role in ensuring efficient grass cutting and overall machine performance. Proper understanding of how each component works together can extend the lifespan of the equipment and ensure smoother operation during heavy use. Let’s break down the key elements that contribute to a functional and reliable cutting system.

- Blades: These are central to achieving a clean cut. Positioned strategically beneath the platform, they rotate rapidly to slice through the grass evenly.

- Belt System: The belt connects the motor to the blade mechanism, transferring power to allow the blades to rotate at high speeds.

- Spindles: Mounted to hold the blades in place, these components are vital for keeping the cutting surfaces at the correct height and angle.

- Discharge Chute: This directs the clippings away from the machine, preventing clogging and ensuring the material is spread out evenly.

- Height Adjustment Lever: Allows the operator to control how hi

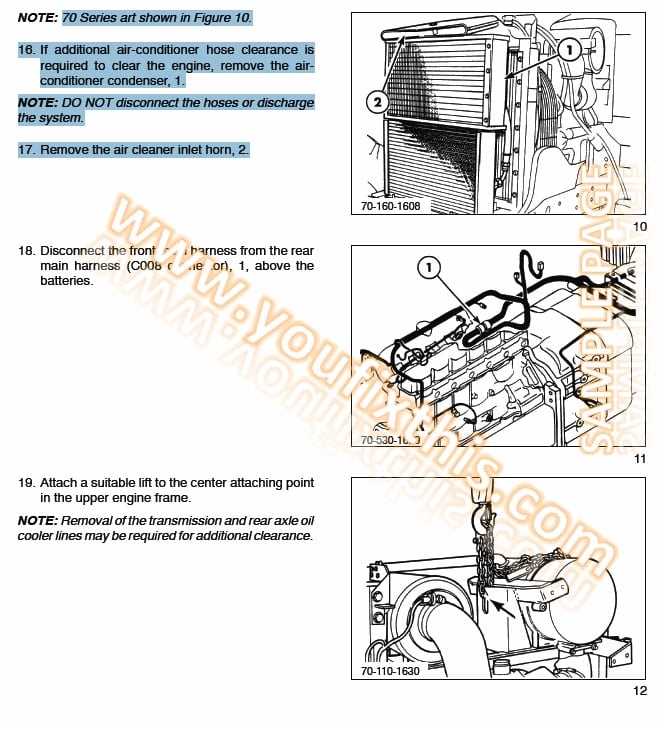

Hydraulic System Components Explained

The hydraulic system is a vital part of many mechanical devices, ensuring the smooth transfer of energy through fluid motion. Understanding the individual elements that work together in this system is crucial for maintaining and troubleshooting hydraulic machinery. This section will cover the key components that enable the system to function efficiently, focusing on their roles and interactions.

- Pump: The pump generates the necessary force to move fluid through the system, creating the pressure needed for operation.

- Valves: These control the direction, flow rate, and pressure of the hydraulic fluid, allowing for precise adjustments and regulation of the system.

- Cylinders: Hydraulic cylinders convert fluid power into mechanical energy, providing the movement required for various tasks.

- Reservoir: This component stores the hydraulic fluid, ensuring that there is a sufficient supply available to the pump.

- Filters: Filters are responsible for keeping the hydraulic fluid clean, preventing contaminants from entering and damaging the system.

- Hoses and Pipes: These serve as the conduit through which the hy

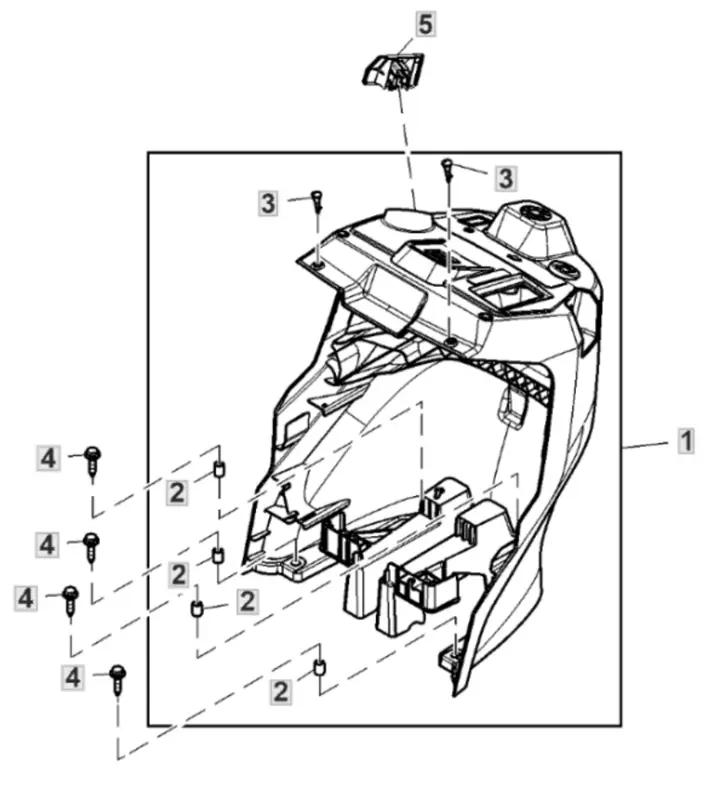

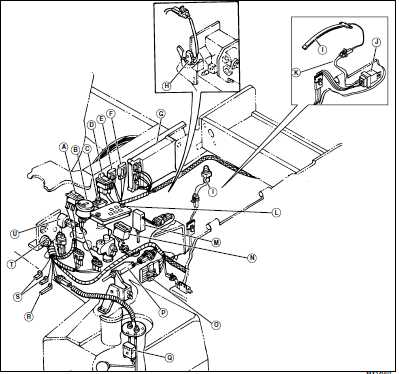

Electrical System and Key Parts

The electrical framework of a compact utility machine plays a crucial role in its overall functionality and efficiency. Understanding the essential components and their interactions can significantly enhance maintenance practices and operational performance. This section outlines the primary elements that constitute the electrical network, ensuring optimal operation and longevity of the equipment.

Core Components

At the heart of the electrical assembly is the battery, which serves as the primary power source for various functions, including ignition and lighting. The alternator, another vital component, ensures that the battery remains charged while the engine runs, providing a steady power supply to electrical systems. Additionally, fuses and relays protect circuits from overloads, enhancing safety and reliability.

Wiring and Connectors

Wiring harnesses form the intricate pathways through which electrical signals travel, linking all essential components. High-quality connectors are equally important, as they ensure secure and efficient connections between different parts of the system. Regular inspection of these elements can prevent electrical failures and ensure consistent performance, ultimately leading to a more dependable operational experience.

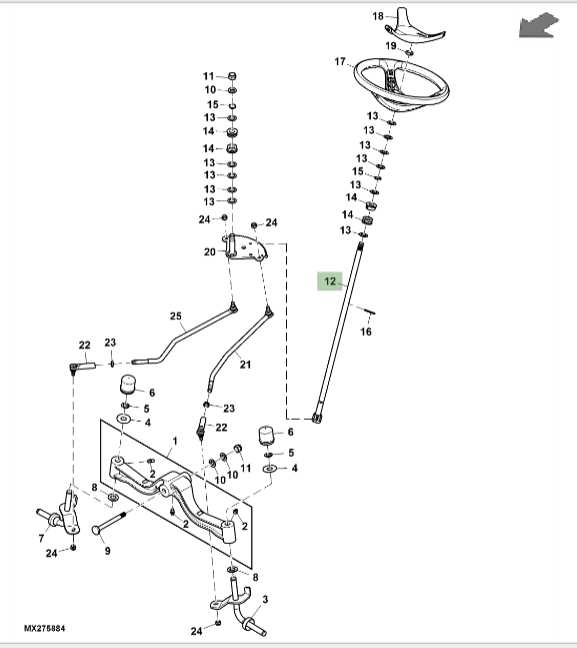

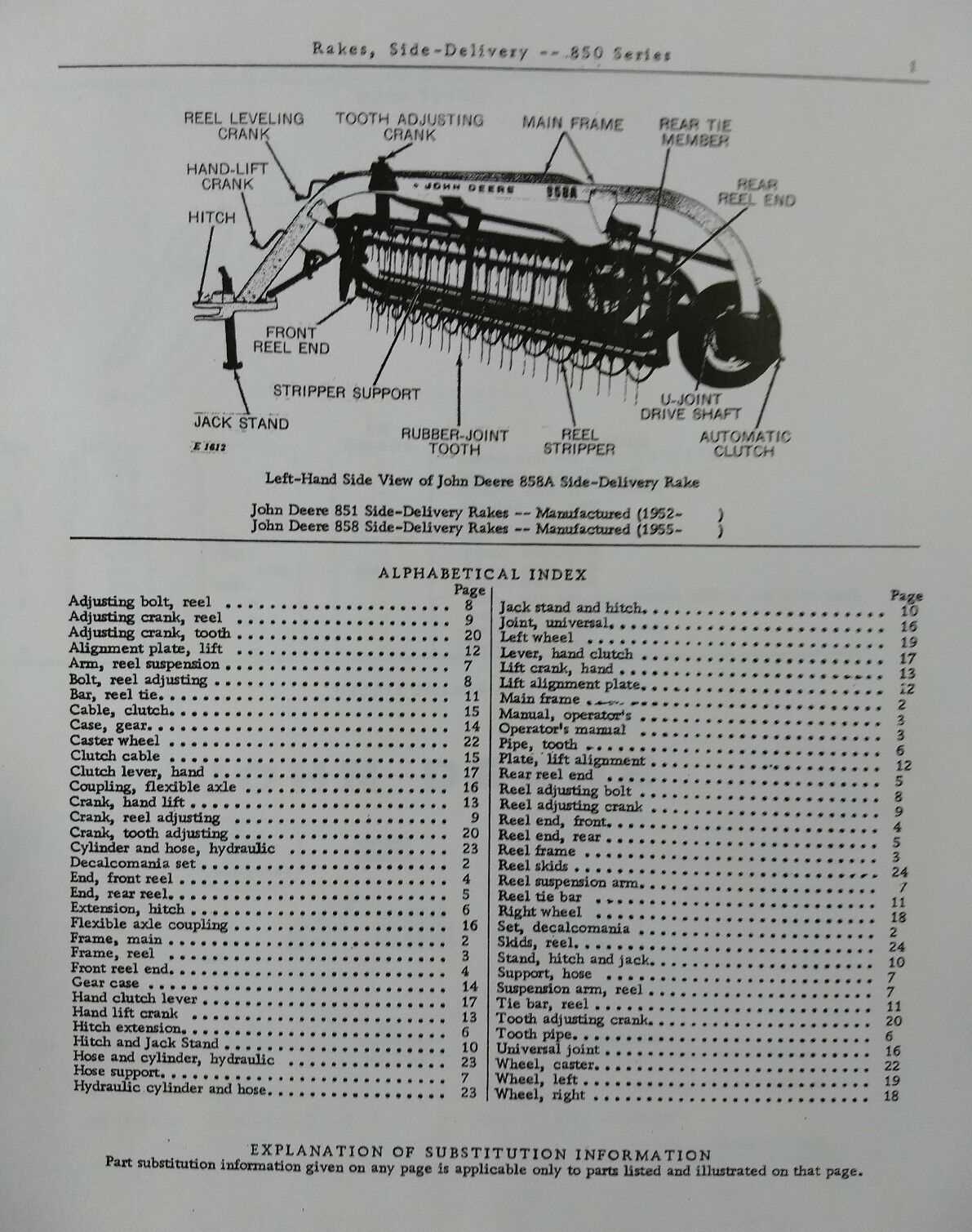

Steering and Transmission Parts Guide

This section provides an overview of the essential components involved in steering and transmission systems. Understanding the various elements and their functions is crucial for maintaining optimal performance and ensuring smooth operation in any vehicle. By familiarizing yourself with these components, you can better address maintenance needs and troubleshoot any issues that may arise.

Key Steering Components

The steering mechanism is vital for directional control and stability. Key elements include the steering wheel, column, and linkage. The steering wheel allows the operator to guide the vehicle, while the column connects the wheel to the linkage system, translating the driver’s inputs into movement. Regular inspection and maintenance of these components are essential for safe operation.

Transmission System Essentials

The transmission system is responsible for transferring power from the engine to the wheels. Important parts include the gearbox, drive shafts, and clutch. The gearbox enables the selection of different speed ranges, while the drive shafts transmit torque to the wheels. The clutch allows for smooth engagement and disengagement of power, ensuring efficient performance during operation.

How to Maintain the Cutting Blades

Regular upkeep of the cutting components is crucial for ensuring optimal performance and longevity of your equipment. Proper maintenance not only enhances the efficiency of the cutting action but also helps to avoid unnecessary wear and tear. This section provides guidelines to keep these essential parts in prime condition.

Routine Inspection

Conducting frequent checks on the cutting elements is vital. Look for signs of damage, such as nicks or dents, which can impact cutting efficiency. Make sure to clean any debris that may have accumulated during operation. A thorough inspection helps identify issues before they escalate into more significant problems.

Sharpening Techniques

Keeping the cutting edges sharp is essential for achieving a clean cut. Dull blades can strain the engine and lead to uneven results. Use a sharpening tool specifically designed for this purpose, and follow the manufacturer’s instructions for the best results. Sharpening should be done periodically, based on usage frequency.

Maintenance Task Frequency Inspection for damage Before each use Cleaning debris After each use Sharpening blades Every 20 hours of use By following these simple maintenance practices, you can ensure that your cutting apparatus operates efficiently and lasts for many seasons. A little attention to these details can make a significant difference in performance.

Diagram of the Fuel System Parts

This section explores the essential components involved in the fuel delivery mechanism of the equipment. Understanding how these elements interact is crucial for maintaining optimal performance and ensuring the longevity of the engine.

The fuel delivery mechanism consists of several key components that work in harmony. The fuel tank serves as the primary reservoir, storing the liquid energy source until it is needed. From there, the fuel pump draws the fuel and transports it to the engine. This process is aided by a fuel filter, which ensures that any contaminants are removed before the fuel reaches the engine, protecting its internal workings.

Additionally, the fuel lines connect these parts, allowing for the efficient flow of fuel. The carburetor plays a vital role in mixing the fuel with air, creating a combustible mixture that powers the engine. Understanding the function and importance of each component helps in troubleshooting issues and performing necessary maintenance.

Regular inspection of the fuel system is essential. Keeping the tank clean and ensuring that filters are replaced as needed will contribute to the overall health of the engine. Knowledge of the individual components allows for informed decisions during repairs and replacements, leading to a smoother operation and enhanced efficiency.

Troubleshooting Common Mechanical Issues

Mechanical systems can occasionally encounter various problems that hinder their performance. Identifying and addressing these issues promptly is crucial for maintaining efficiency and prolonging the lifespan of the equipment. This section will outline common mechanical challenges, their symptoms, and potential solutions to help ensure optimal functionality.

Issue Symptoms Possible Solutions Engine Overheating High temperature readings, unusual noises, loss of power Check coolant levels, inspect radiator for blockages, examine water pump operation Unresponsive Controls Difficulty operating, erratic movement, inconsistent response Inspect control linkage, check for fluid leaks, verify cable connections Excessive Vibration Shaking during operation, abnormal sounds, uneven wear on components Check for loose or damaged parts, balance rotating elements, lubricate moving parts Poor Performance Reduced power, increased fuel consumption, sluggish response Inspect air filters, check fuel quality, clean or replace spark plugs By understanding these common issues and their solutions, users can effectively troubleshoot mechanical problems, ensuring the equipment remains in good working order.

Tips for Replacing Worn-Out Components

Maintaining the efficiency of machinery is crucial for optimal performance and longevity. When components begin to show signs of wear, it is essential to address these issues promptly to prevent further damage. This section offers practical advice for effectively replacing deteriorated elements to ensure the smooth operation of your equipment.

Identifying the Right Components

Before starting the replacement process, accurately identifying the required items is vital. Consult the manufacturer’s resources or trusted manuals to ensure you choose the correct specifications. Double-checking compatibility with your machinery will save time and reduce the risk of errors.

Tools and Preparation

Gathering the appropriate tools ahead of time can streamline the replacement procedure. Having everything organized not only enhances efficiency but also minimizes the chance of mishaps. Ensure you follow safety protocols during the replacement to protect yourself and your equipment from potential hazards.