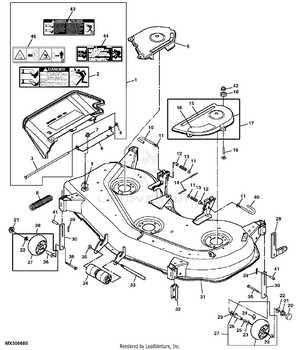

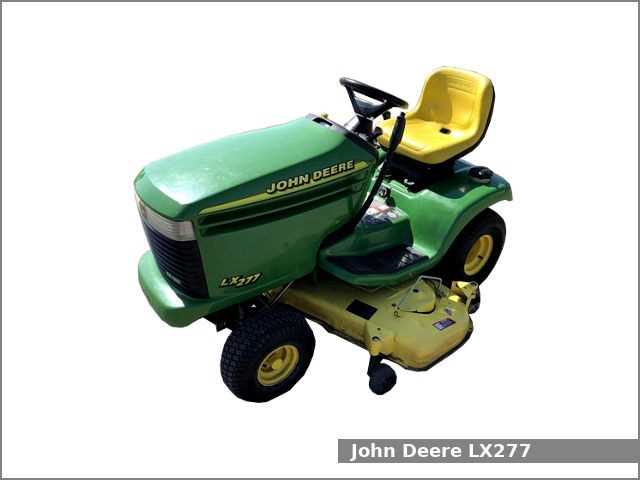

John Deere LX277 AWS Parts Diagram Overview

In the realm of outdoor machinery, comprehending the arrangement of various elements is crucial for maintenance and repair. An effective layout representation serves as a vital tool for users, enabling them to identify and address potential issues with their equipment efficiently. This knowledge empowers owners to ensure their devices operate at peak performance.

Detailed illustrations that depict the configuration of mechanical components not only assist in troubleshooting but also facilitate a deeper understanding of how different parts interact. By familiarizing oneself with these visuals, users can enhance their ability to perform repairs and replacements with confidence.

Moreover, grasping the specifics of each section fosters better care practices, ultimately extending the longevity of the equipment. Armed with this information, individuals can take proactive steps towards maintaining their machinery, ensuring it remains a reliable ally in their gardening endeavors.

This model stands out in its category due to its exceptional design and advanced capabilities. It is engineered to provide users with a seamless experience, combining efficiency with versatility, making it suitable for various tasks around the yard or garden.

Among the notable characteristics are its robust performance and user-friendly controls, which enhance maneuverability and overall operation. The compact design allows for easy navigation in tight spaces, while the durable construction ensures long-lasting use.

| Feature | Description |

|---|---|

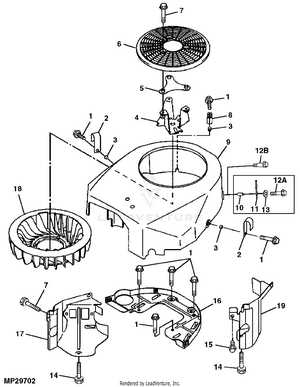

| Engine | Powerful engine designed for high efficiency and reliability. |

| Transmission | Smooth automatic transmission that allows for effortless speed adjustments. |

| Deck | Sturdy mowing deck that delivers an even cut for a pristine lawn finish. |

| Handling | Ergonomically designed controls for enhanced operator comfort and ease of use. |

| Versatility | Compatibility with a range of attachments for different gardening tasks. |

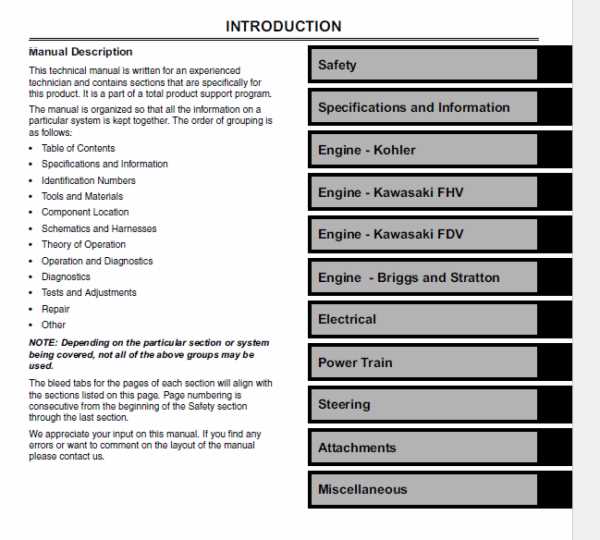

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the assembly and functionality of machinery. They provide an accessible way to identify individual elements and their relationships, ensuring clarity in maintenance and repair processes.

Utilizing these illustrations can enhance the efficiency of troubleshooting and replacement tasks. Technicians can quickly locate necessary items, minimizing downtime and streamlining operations.

Moreover, these visuals serve as essential tools for training new personnel, offering clear guidance on the structure and organization of machinery. As a result, they promote safer practices and reduce the likelihood of errors during service.

| Benefits | Description |

|---|---|

| Enhanced Understanding | Facilitates comprehension of complex systems. |

| Efficiency | Speeds up identification and replacement of components. |

| Training Aid | Supports the onboarding process for new technicians. |

| Safety | Promotes safer handling and maintenance procedures. |

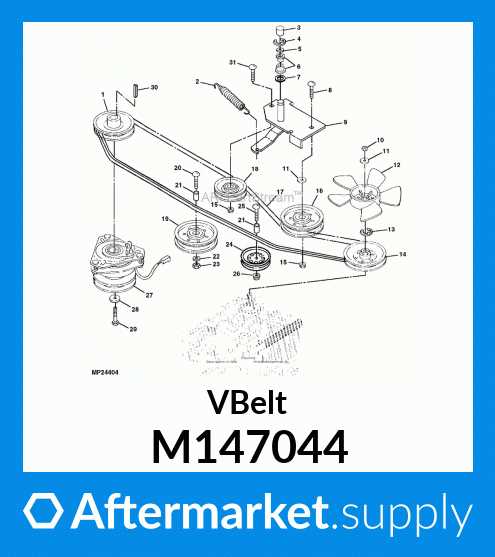

Common Replacement Parts for LX277

Maintaining equipment in optimal condition often involves replacing worn components. Understanding the typical elements that may require replacement can help ensure continued performance and reliability. Below are some frequently needed replacements that owners might consider.

Essential Components

Various essential components contribute to the smooth operation of the machinery. Here are some commonly replaced items:

| Component Name | Description | Function |

|---|---|---|

| Fuel Filter | Filters impurities from the fuel | Ensures clean fuel reaches the engine |

| Air Filter | Cleans incoming air | Protects the engine from dust and debris |

| Blades | Cutting blades for mowing | Ensures a clean cut of grass |

| Batteries | Power source for the machinery | Starts the engine and powers electrical systems |

| Belts | Drive belts for various functions | Transmits power to different components |

Maintenance Tips

Regular inspections and timely replacements can extend the lifespan of the equipment. Keeping track of wear and tear on these components helps maintain efficiency and performance during use.

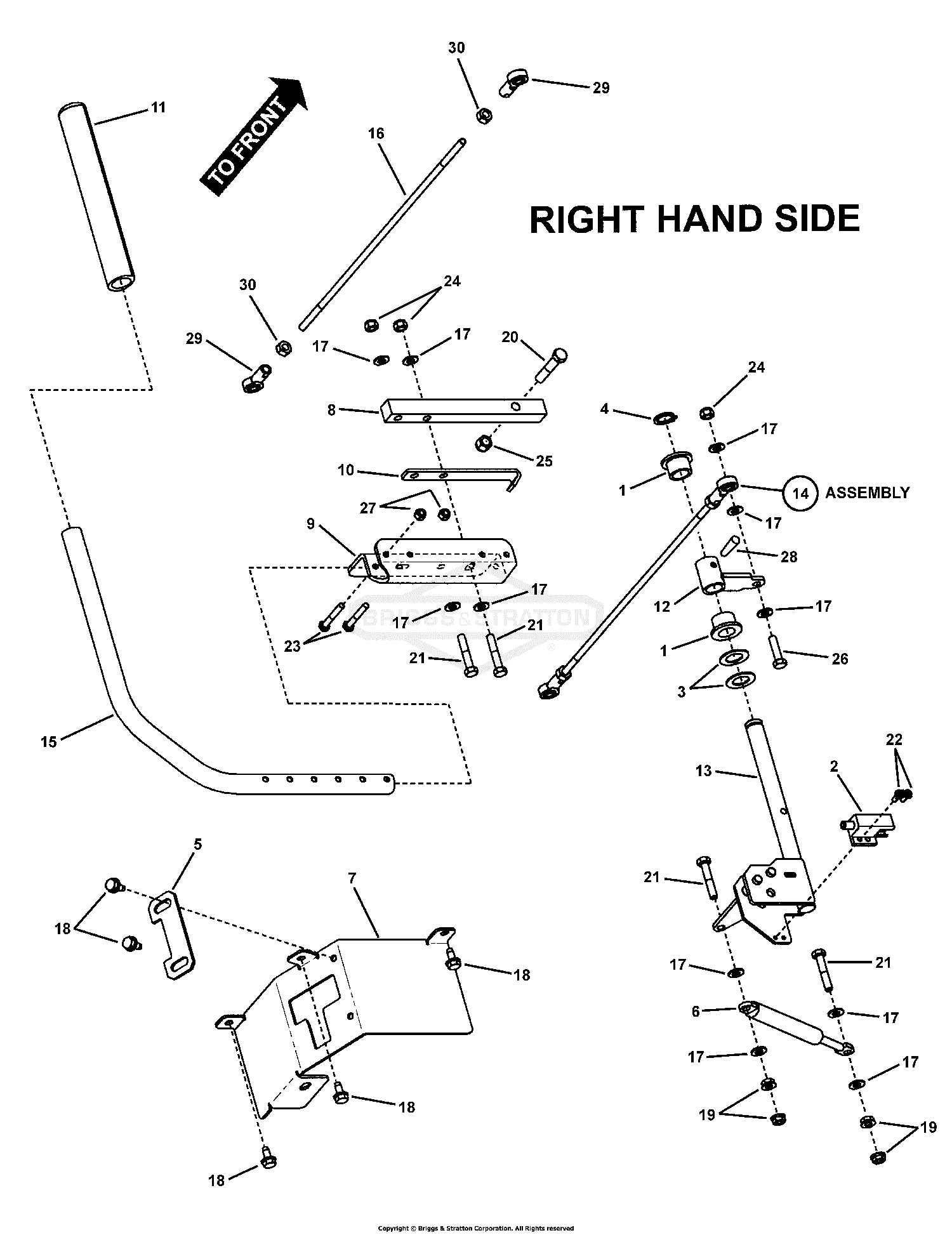

Understanding the Parts Breakdown

The examination of a machinery assembly is crucial for maintaining optimal functionality and performance. A thorough comprehension of the various components and their interconnections allows for more effective troubleshooting and repair. This section delves into the essential elements of the system, illustrating how each contributes to the overall operation.

Key aspects to consider include:

- Component Identification: Recognizing each part and its specific role enhances the efficiency of maintenance tasks.

- Functional Relationships: Understanding how different pieces interact helps diagnose issues more accurately.

- Replacement Protocols: Familiarity with the standard procedures for replacing components can prevent operational downtime.

By grasping the breakdown of each element, users can ensure their equipment operates smoothly and efficiently, reducing the likelihood of unexpected failures.

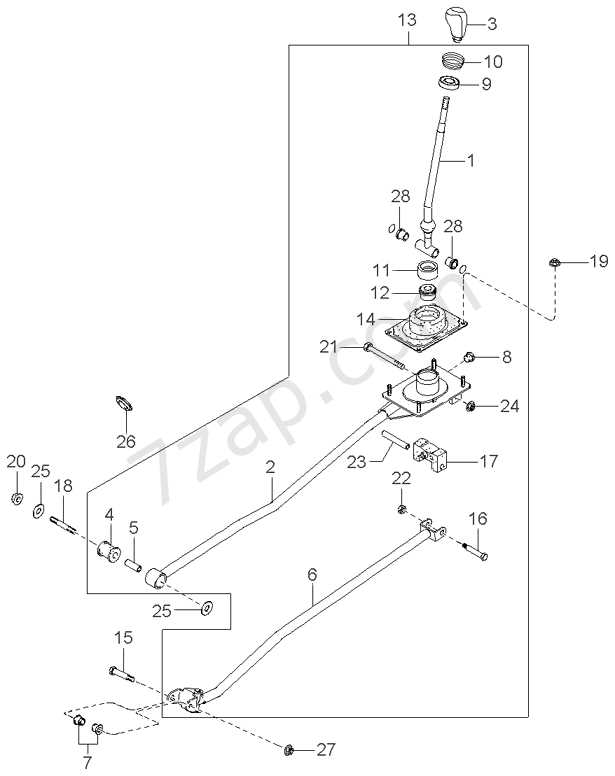

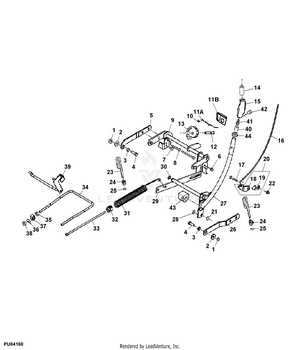

Identifying Components in Diagrams

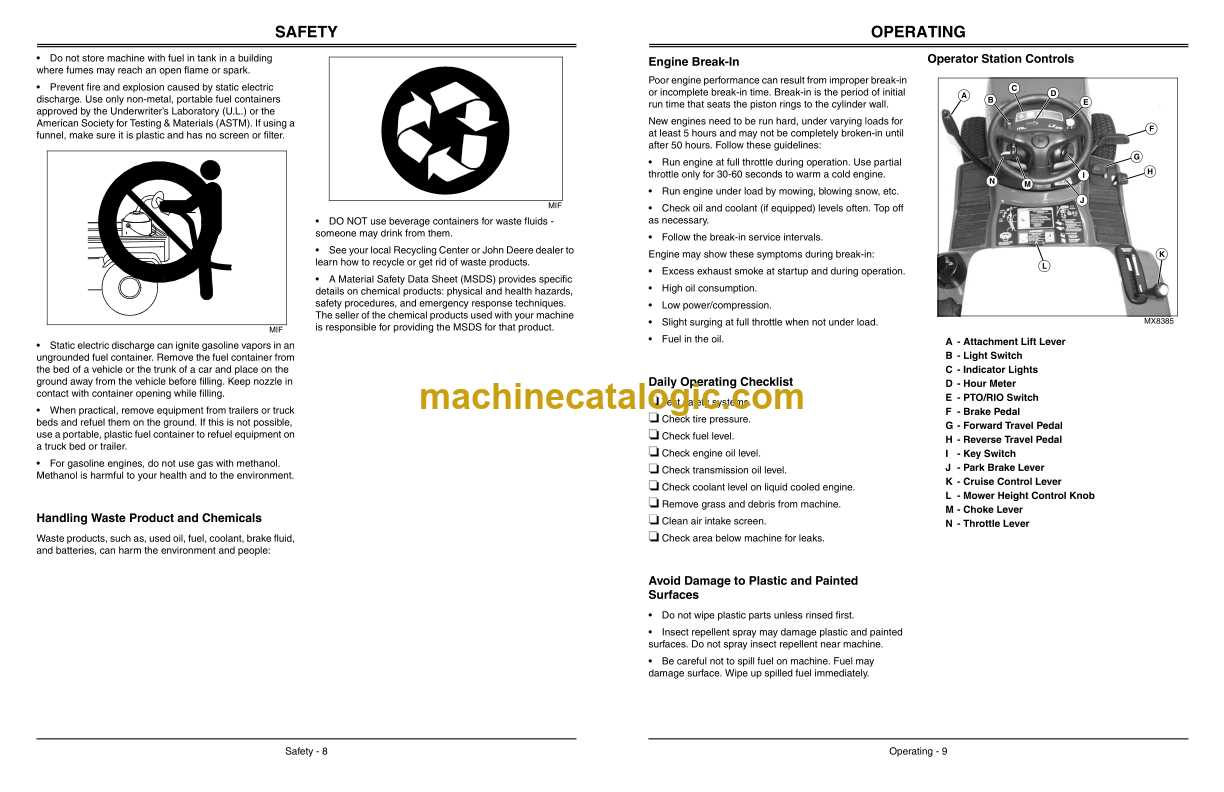

Understanding the various elements in schematics is crucial for effective maintenance and repair. These illustrations serve as a visual guide, allowing users to comprehend the layout and function of different parts within a system. By familiarizing oneself with the symbols and notations used, one can easily navigate through complex structures.

Each component typically has a designated label or symbol that signifies its role. For instance, connectors may be represented by specific shapes, while mechanical parts might have distinct outlines. Recognizing these representations enhances one’s ability to troubleshoot issues and replace items when necessary.

In addition to symbols, the arrangement of elements can provide insights into their interrelations. Understanding how different parts connect and interact can lead to a deeper comprehension of overall functionality. By mastering these visual cues, individuals can increase their proficiency in operating and maintaining equipment effectively.

Maintenance Tips for LX277

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. By following a few straightforward guidelines, you can enhance its efficiency and prevent potential issues. Proper maintenance not only prolongs the lifespan of your machine but also contributes to a safer and more enjoyable operation.

1. Routine Inspections: Regularly check all critical components to identify signs of wear or damage. Inspect belts, blades, and tires to ensure they are in good condition.

2. Fluid Checks: Keep an eye on fluid levels, including oil, coolant, and fuel. Regularly change the oil and replace filters as recommended to maintain engine health.

3. Cleaning: Clean the exterior and undercarriage to remove dirt and debris that can affect performance. Ensure that air filters are clean to optimize airflow.

4. Lubrication: Apply lubricant to moving parts as specified in the user manual. Proper lubrication reduces friction and wear, extending the life of components.

5. Seasonal Preparations: Before seasonal changes, perform a thorough inspection and service to prepare the machine for different operating conditions, ensuring it is ready for use when needed.

By incorporating these maintenance practices, you can ensure your equipment runs smoothly and efficiently, ultimately enhancing its performance and reliability.

Where to Find Genuine Parts

When it comes to maintaining and repairing outdoor equipment, sourcing authentic components is crucial for ensuring optimal performance and longevity. Various options are available for individuals seeking high-quality replacements that fit their machinery seamlessly.

Authorized Dealers

One of the most reliable sources for original components is authorized dealers. These establishments specialize in specific equipment brands and carry a wide range of genuine items. Customers can expect expert advice and assistance in selecting the right components for their machinery.

Online Retailers

In the digital age, many online retailers offer a vast selection of authentic components. Shopping online provides convenience and access to numerous options, often at competitive prices. It’s essential to choose reputable websites that guarantee the authenticity of their products.

| Source | Advantages | Considerations |

|---|---|---|

| Authorized Dealers | Expert assistance, genuine items | Potentially higher prices |

| Online Retailers | Convenience, wide selection | Need to verify authenticity |

Troubleshooting Common Issues

When operating a lawn maintenance machine, various challenges may arise that can hinder performance. Understanding these typical problems and their solutions can greatly enhance efficiency and prolong the lifespan of your equipment. Below are some frequent issues encountered and the recommended approaches to resolve them.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Engine Won’t Start | Empty fuel tank, faulty spark plug, dead battery | Refill fuel, replace spark plug, charge or replace battery |

| Poor Cutting Performance | Dull blades, incorrect cutting height, debris buildup | Sharpen or replace blades, adjust cutting height, clean the deck |

| Overheating | Low oil levels, blocked air intake, worn-out cooling fan | Check and refill oil, clear air intake, replace cooling fan |

| Unusual Noises | Loose parts, damaged belts, worn bearings | Tighten loose components, inspect and replace belts, lubricate or replace bearings |

Upgrades and Enhancements Available

For enthusiasts looking to enhance their equipment’s performance and efficiency, numerous upgrades are accessible. These modifications can improve functionality, extend longevity, and provide a more enjoyable user experience.

Some notable enhancements include:

- Engine Performance Tuning: Optimizing the engine can lead to increased power and improved fuel efficiency.

- Transmission Upgrades: Upgrading the transmission can enhance shifting smoothness and responsiveness, resulting in a better driving experience.

- Suspension Modifications: Improved suspension components can offer better stability and handling, especially on uneven terrain.

- Accessory Add-Ons: Additional attachments such as snow blades, trailers, or baggers can increase versatility and functionality for various tasks.

Implementing these improvements not only boosts performance but also enhances the overall operational capabilities of the machine.

Connecting with Support Resources

When working with complex equipment, it’s important to know where to find reliable assistance. Whether you’re troubleshooting an issue or looking for guidance on routine maintenance, connecting with support resources can save you time and frustration.

Online help portals provide quick access to a variety of materials, including technical manuals, guides, and frequently asked questions. These platforms allow users to easily search for the information they need without having to sift through irrelevant content.

If online sources aren’t enough, customer service hotlines or live chat options can provide more personalized assistance. Reaching out to trained professionals ensures that you’re getting accurate advice tailored to your specific situation.