Understanding the John Deere MX5 Parts Diagram for Efficient Maintenance

The intricate design of agricultural equipment plays a crucial role in enhancing productivity and efficiency on the field. Each machine comprises various elements that work in harmony to ensure optimal performance. Gaining insight into these individual components can significantly aid in maintenance and troubleshooting.

In this section, we will explore a detailed overview of the specific units involved in a popular model of farming machinery. By dissecting these elements, users can better appreciate their functions and interrelations, leading to more informed decisions regarding upkeep and repairs.

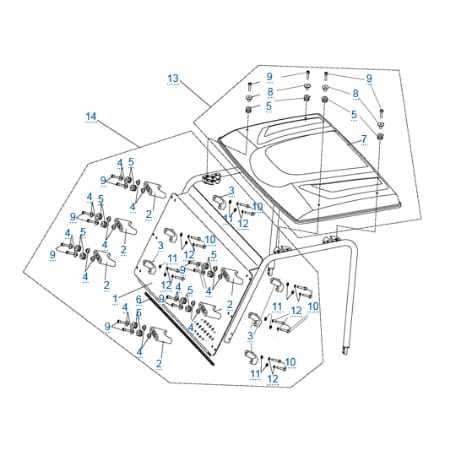

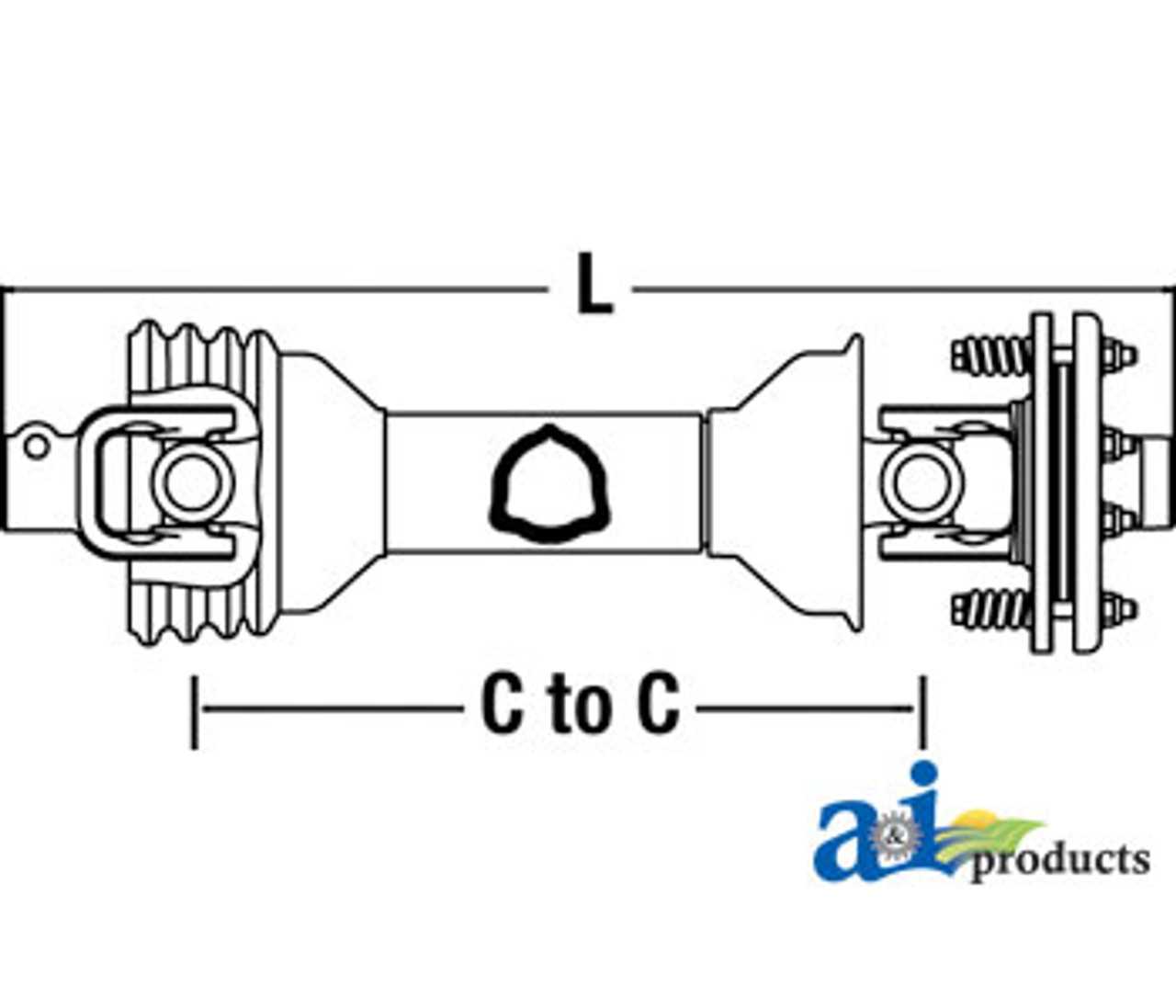

Furthermore, having access to a visual representation of these components not only simplifies the understanding of their layout but also serves as a valuable reference for anyone looking to enhance their knowledge or perform maintenance tasks. Let’s delve into the essentials that make up this vital equipment.

Understanding the MX5 Parts Diagram

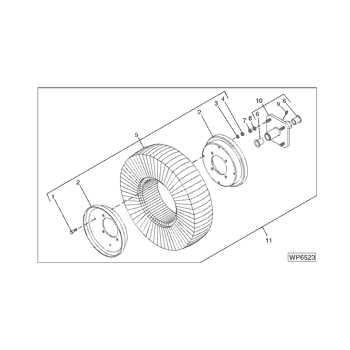

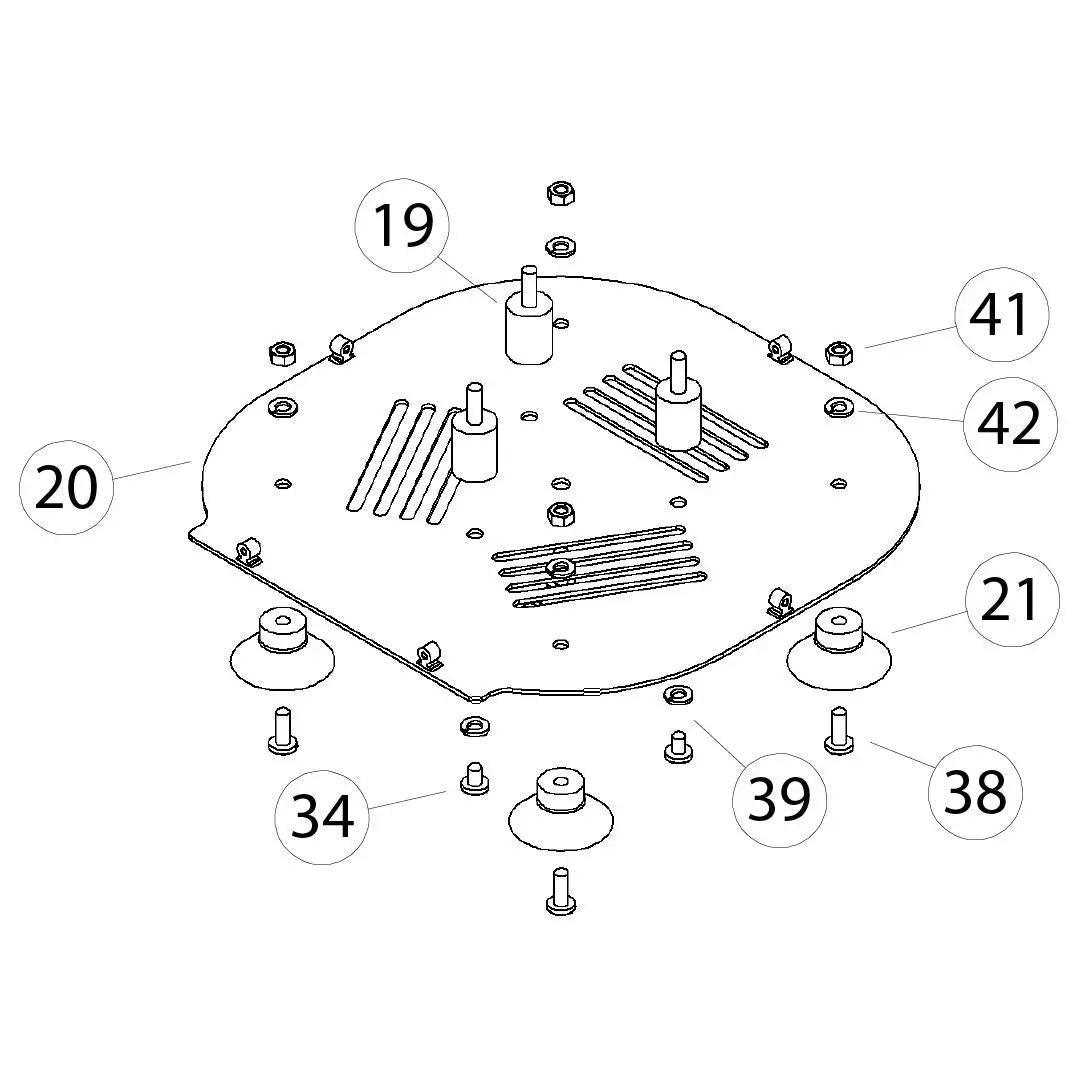

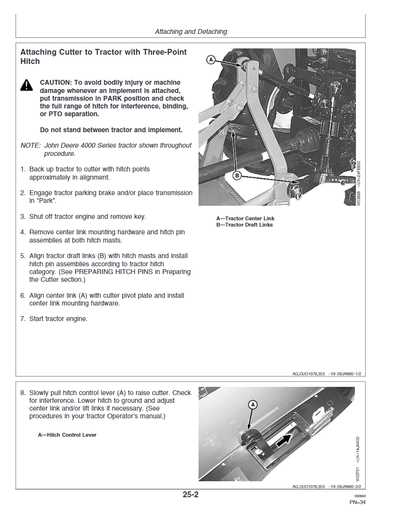

Grasping the layout of components is essential for effective maintenance and troubleshooting of agricultural machinery. A comprehensive visual representation serves as a guide, simplifying the process of identifying each element and its function within the system.

Importance of Visual References

A well-structured illustration helps users quickly locate specific elements, ensuring that repairs and replacements are executed accurately. This clarity reduces downtime and enhances overall efficiency in operations.

Key Components to Recognize

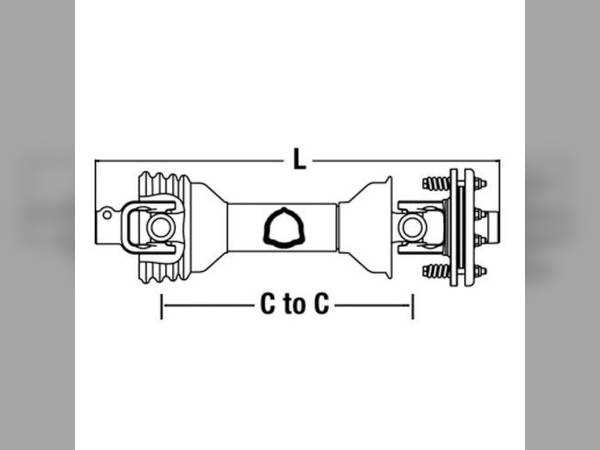

Familiarizing oneself with crucial elements like the drive system and attachment points is vital. Understanding how these components interact can lead to better performance and longevity of the equipment.

Key Components of the MX5

This section explores the essential elements that contribute to the efficiency and functionality of the machine, focusing on their roles and significance. Understanding these components allows for better maintenance and optimal performance in various applications.

Cutting Mechanism

The cutting mechanism plays a crucial role in ensuring precise operation. It consists of blades designed for effective grass management, enabling clean cuts and promoting healthy growth.

Drive System

A reliable drive system powers the equipment, providing the necessary torque and speed. This system ensures smooth movement and enhances overall productivity during use.

Maintenance Tips for MX5 Parts

Proper upkeep of your equipment components ensures optimal performance and longevity. Regular attention to details can prevent unexpected breakdowns and costly repairs. Below are essential practices to maintain the integrity of your machinery.

| Tip | Description |

|---|---|

| Regular Inspections | Conduct routine checks to identify wear and tear. Look for cracks, rust, or any irregularities that could affect functionality. |

| Lubrication | Apply appropriate lubricants to moving parts to reduce friction and enhance performance. Ensure you use the recommended types for your equipment. |

| Cleanliness | Keep all components clean from dirt and debris. Regular cleaning prevents buildup that can hinder operation. |

| Proper Storage | When not in use, store equipment in a dry, sheltered area to protect it from the elements and reduce wear. |

| Follow Manufacturer Guidelines | Adhere to the maintenance schedule and recommendations provided by the manufacturer to ensure all aspects of your machinery are properly cared for. |

Common Issues with MX5 Components

When it comes to machinery components, several common problems can arise that affect overall performance and longevity. Understanding these issues is crucial for effective maintenance and optimal functioning. From wear and tear to alignment discrepancies, recognizing the signs early can prevent more significant complications down the line.

One frequent challenge is excessive wear on moving parts, often caused by inadequate lubrication or poor quality materials. This can lead to decreased efficiency and increased energy consumption. Regular inspections and timely replacements are essential to mitigate these effects.

Another common issue is misalignment, which can result in uneven stress distribution across components. This not only shortens the lifespan of parts but also affects the overall operation. Ensuring proper alignment during installation and routine checks can help maintain harmony within the system.

Corrosion is yet another concern, particularly in environments exposed to moisture and chemicals. Protective coatings and regular cleaning can minimize the risk of rust and deterioration, thus extending the life of the machinery.

Lastly, issues with electrical connections can lead to malfunctioning systems. Loose or damaged wiring often results in intermittent operation or complete failures. Routine maintenance and thorough inspections of electrical systems are vital to ensure consistent performance.

Benefits of Using Genuine Parts

Opting for authentic components in machinery maintenance and repair offers numerous advantages that contribute to enhanced performance and longevity. Utilizing original replacements ensures compatibility with the equipment, reducing the risk of malfunctions and promoting seamless operation.

Reliability and Quality

Genuine components are designed to meet specific manufacturing standards, which guarantees their reliability. By choosing these authentic pieces, operators can rest assured that they are investing in quality that has been rigorously tested, leading to improved efficiency and reduced downtime.

Long-Term Cost Savings

While counterfeit alternatives may seem like a cost-effective solution initially, they often lead to higher expenses over time. Authentic replacements minimize the likelihood of breakdowns and costly repairs, ultimately providing better value and ensuring that the machinery operates at its best for years to come.

How to Read the Diagram Effectively

Understanding a visual representation of components is essential for anyone involved in maintenance or assembly tasks. This section provides valuable insights on how to interpret these illustrations efficiently, ensuring you can identify and work with various elements with confidence.

Here are some key strategies to enhance your comprehension:

- Familiarize Yourself with Symbols: Each illustration may use specific symbols to denote various parts. Take time to learn these icons to avoid confusion.

- Follow the Flow: Many illustrations are designed to show the relationship and sequence of components. Trace the lines connecting elements to understand their interactions.

- Pay Attention to Labels: Descriptive text accompanying the visuals can provide essential information about each part’s function and specifications.

By applying these techniques, you will be better equipped to interpret complex visual guides and streamline your repair or assembly processes.

Additionally, consider the following tips:

- Break It Down: Instead of trying to understand the entire illustration at once, focus on one section at a time.

- Refer to the Manual: Use the accompanying documentation for further context on each component and its role.

- Practice Regularly: The more you work with these representations, the more intuitive they will become.

Mastering these skills will significantly enhance your ability to work effectively with technical illustrations and improve your overall efficiency in tasks related to machinery and equipment.

Replacement Parts for MX5 Models

When maintaining and repairing agricultural machinery, finding suitable components is essential for optimal performance. This section highlights the vital elements needed for efficient operation and longevity of your equipment.

Identifying Components is the first step in ensuring your machinery runs smoothly. Key elements include blades, belts, and bearings, each playing a crucial role in functionality. Regular checks can prevent costly downtimes and extend the life of your machine.

Quality Assurance should never be overlooked. Opting for original or high-quality aftermarket alternatives ensures reliability and durability. It’s advisable to consult trusted suppliers who provide detailed descriptions and specifications for every element.

Maintenance Tips can further enhance your machinery’s performance. Regular lubrication, timely replacements, and thorough inspections are practices that help avoid unexpected failures and maintain productivity.

By focusing on these critical components, users can ensure their equipment remains in excellent working condition, ultimately leading to more efficient and effective operations.

MX5 Parts Availability and Sourcing

When it comes to acquiring components for specialized machinery, understanding the channels and resources available is crucial. Ensuring that the necessary items can be sourced efficiently can greatly enhance operational efficiency and minimize downtime.

Online Retailers: Numerous e-commerce platforms offer a wide selection of components, catering to both OEM and aftermarket options. Browsing these sites can provide competitive pricing and convenience in ordering.

Local Dealers: Engaging with authorized dealers can yield benefits such as warranty assurances and access to genuine components. Building a relationship with a local supplier can also facilitate faster service and expert advice.

Salvage Yards: For those looking to save costs, salvage yards can be a treasure trove of usable items. Exploring these facilities may uncover rare finds that are still in good condition, ideal for budget-conscious operators.

Online Forums and Communities: Participating in specialized forums can connect enthusiasts and professionals alike. Sharing experiences and recommendations can lead to valuable insights regarding sourcing and availability.

Manufacturer Websites: Directly visiting manufacturer websites can provide detailed information on available components and even facilitate direct purchasing options, ensuring authenticity and quality.

By exploring these various avenues, users can ensure they have access to the necessary components, thereby maintaining their machinery in optimal condition.

Upgrading Your MX5 Components

Enhancing the functionality of your agricultural machinery can significantly improve performance and efficiency. By focusing on key elements that require attention, you can ensure that your equipment operates at its best. Upgrading components not only extends the life of your machinery but also enhances productivity, making it essential to consider the various options available for improvement.

When looking to enhance your equipment, start by assessing the current state of each part. Identifying areas that are worn or outdated can guide you toward the most beneficial upgrades. High-quality replacements can lead to improved operation, reduced maintenance costs, and an overall better user experience.

Researching compatible enhancements is crucial. Consider features that add versatility, such as adjustable settings or advanced technology integrations. These upgrades can tailor your machinery to specific tasks, allowing for greater adaptability in diverse working conditions.

Finally, consult with professionals or trusted sources to ensure that the chosen components are reliable and suited for your needs. Proper installation and maintenance of upgraded features will maximize their effectiveness, ultimately contributing to the longevity and success of your equipment.

Illustrative Examples from the Diagram

This section aims to provide a clearer understanding of the various components represented in the schematic. By examining specific examples, users can gain insights into the functionality and interaction of each element within the overall assembly.

Component A: This part plays a crucial role in the operational efficiency of the machine. Its design is optimized to ensure durability and reliability during use, which ultimately contributes to enhanced performance.

Component B: This element serves as a vital connection between several key sections, facilitating seamless operation. Its strategic placement within the configuration ensures that all parts work harmoniously together, minimizing potential disruptions.

Component C: Recognized for its adaptability, this feature allows for various adjustments depending on the specific requirements of the task. Users can customize its settings to achieve optimal results based on differing conditions.

Through these examples, it becomes evident how each piece contributes to the functionality of the system as a whole, highlighting the importance of understanding these relationships for effective maintenance and operation.

Expert Insights on MX5 Repairs

Understanding the intricacies of equipment maintenance can significantly enhance longevity and performance. Knowledgeable technicians emphasize the importance of routine inspections and proper repairs to ensure seamless operation. Here are some key aspects to consider when addressing issues with your machinery:

- Regular Maintenance: Implementing a schedule for check-ups can prevent minor issues from escalating.

- Quality Components: Using high-grade replacements ensures better durability and reliability.

- Technical Manuals: Consulting detailed guides can provide essential information on assembly and disassembly processes.

- Professional Assistance: Engaging with experienced mechanics can offer insights that improve repair outcomes.

Moreover, it’s crucial to stay updated on any technical advancements or recalls related to your equipment. Understanding the common failure points can lead to preemptive actions that mitigate risks. The following strategies can further enhance repair efficacy:

- Conduct thorough inspections to identify wear and tear.

- Document all repairs and maintenance actions for future reference.

- Utilize diagnostic tools to pinpoint underlying problems accurately.

- Stay informed about manufacturer updates and recommended practices.

By adopting a proactive approach and leveraging expert insights, users can achieve optimal performance and extend the lifespan of their machinery.