Comprehensive Guide to John Deere S100 Parts Diagram PDF

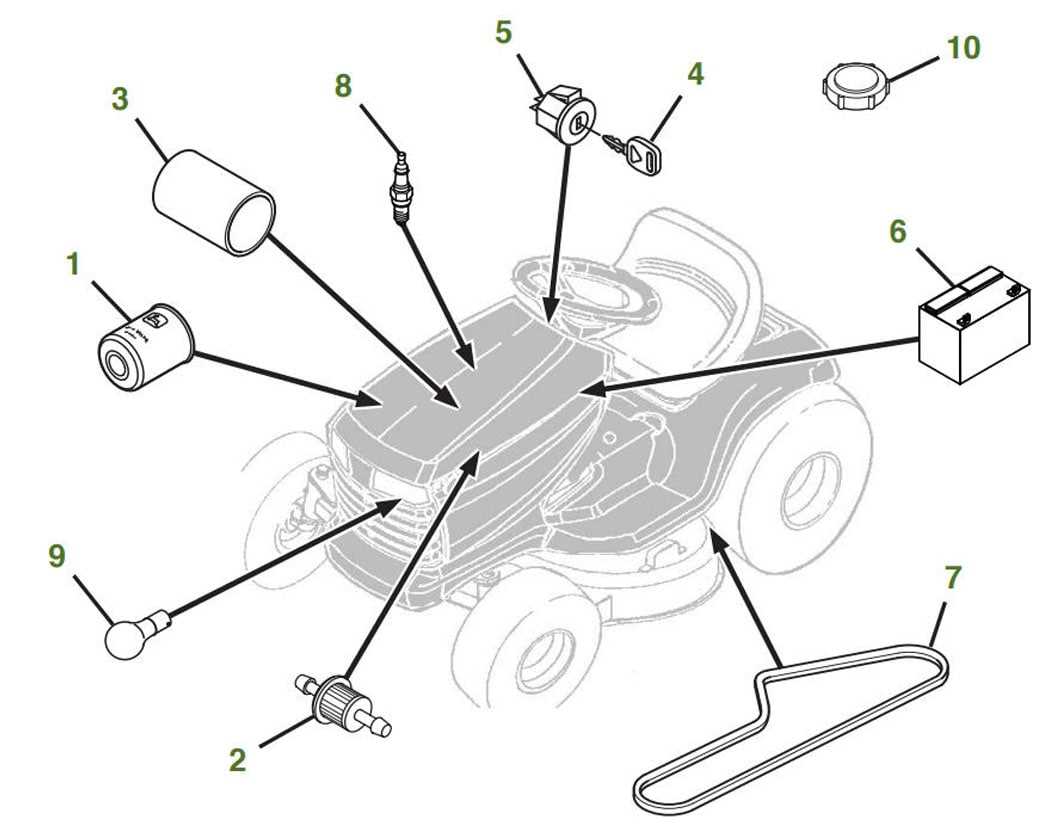

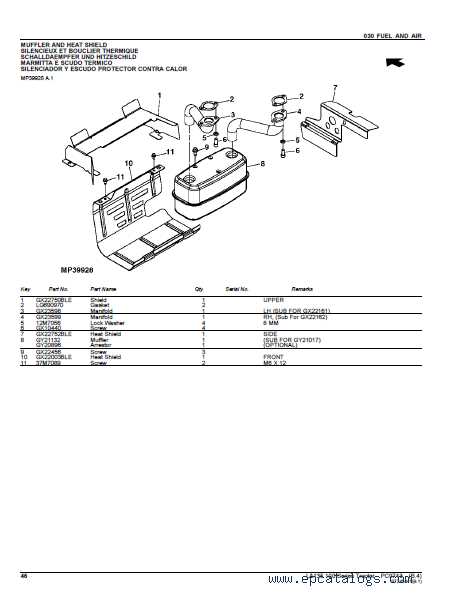

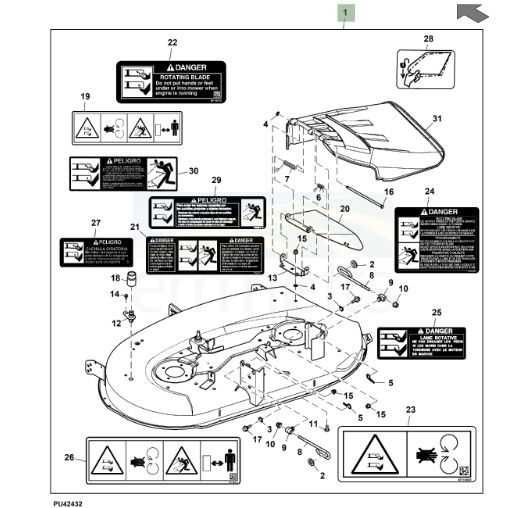

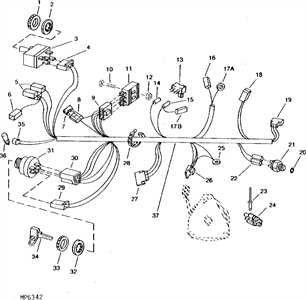

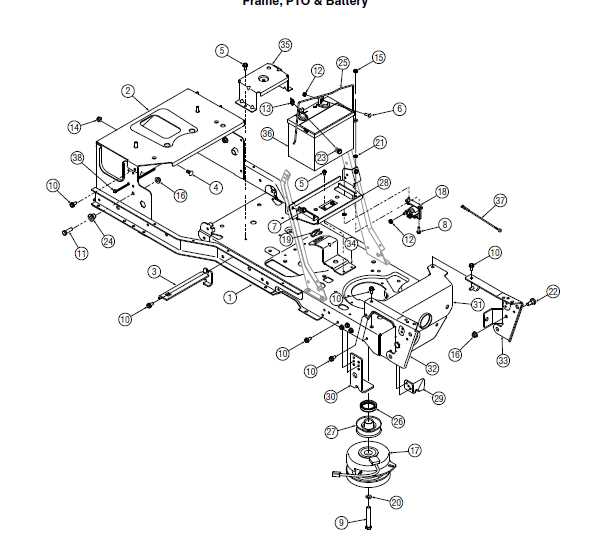

The intricate relationship between machinery and its individual elements is crucial for effective maintenance and repair. Having a clear visual representation of these components can significantly enhance the troubleshooting process. This section delves into the various segments that make up a specific model, providing invaluable insight for users and technicians alike.

Visual aids play a vital role in comprehending complex systems. By utilizing schematic representations, one can easily identify where each component resides and how they interconnect. This clarity not only simplifies repairs but also promotes a deeper understanding of the equipment’s functionality.

For those engaged in the upkeep or restoration of their machinery, accessing detailed illustrations and references is essential. Such resources empower users to undertake maintenance tasks with confidence, ensuring optimal performance and longevity of their equipment. By familiarizing oneself with the arrangement of these crucial elements, operators can enhance their technical skills and knowledge base.

Understanding John Deere S100 Components

Exploring the intricacies of a lawn care machine involves examining its essential elements and how they interact to ensure optimal performance. Each component plays a crucial role in the overall functionality, contributing to the efficiency and reliability of the equipment.

Key Elements of the Machine

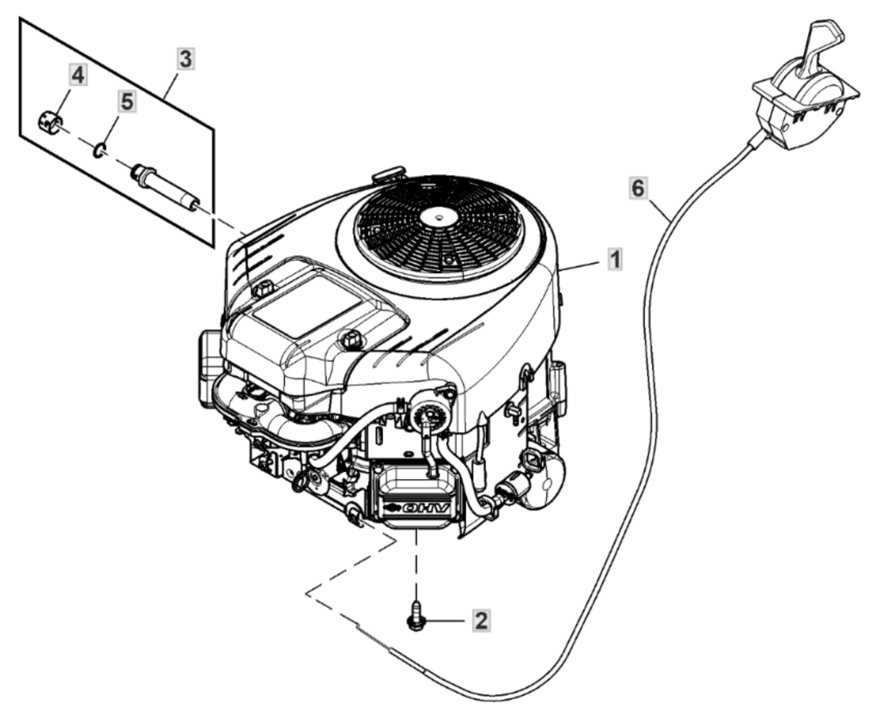

- Engine: Powers the entire unit, providing necessary torque and horsepower.

- Transmission: Facilitates movement and speed adjustments, enhancing maneuverability.

- Cutting Deck: Responsible for the quality of the cut, influencing the machine’s effectiveness.

- Wheels: Affect traction and stability, crucial for various terrains.

Maintenance and Care

- Regularly inspect components for wear and tear.

- Keep the engine clean and well-lubricated.

- Check the cutting deck for sharpness and damage.

- Ensure proper tire pressure for optimal performance.

Understanding these elements allows for better maintenance and enhances the longevity of the machine, ensuring it serves effectively for years to come.

Importance of Parts Diagrams

Understanding the various components of machinery is essential for maintenance and repairs. Visual representations of these elements serve as crucial tools, enabling users to identify and locate specific sections easily. This clarity promotes efficient troubleshooting and fosters a deeper comprehension of the equipment’s structure and functionality.

Enhancing Maintenance Efficiency

Clear illustrations allow for quick reference during maintenance tasks. When users can pinpoint the exact location of a component, it minimizes the time spent searching for parts and reduces the likelihood of errors during assembly or disassembly. This efficiency not only saves time but also contributes to overall productivity.

Facilitating Accurate Repairs

Detailed visuals support users in making informed decisions regarding repairs. By providing a comprehensive view of all necessary components, these resources empower users to gather the right tools and materials before starting work. This preparedness is essential for ensuring that repairs are conducted smoothly and effectively, ultimately prolonging the life of the machinery.

How to Access PDF Diagrams

Accessing visual guides and technical blueprints is essential for efficient maintenance and repairs. These resources provide crucial information, allowing users to understand the structure and components of machinery effectively. In this section, we will explore various methods to locate and download these valuable documents.

Online Resources

Many manufacturers offer official websites where users can find comprehensive visual resources. Typically, these platforms include sections dedicated to support or documentation, where you can search by model or category. Additionally, forums and community websites often share links to these essential files, providing a collaborative approach to resource sharing.

Using Search Engines

Utilizing search engines can be an efficient way to find specific guides. Enter relevant keywords along with terms such as “manual,” “guide,” or “schematic” to narrow down results. Filters can also be applied to refine your search by file type, ensuring you retrieve only the necessary documents in your preferred format.

Common Issues with S100 Parts

In any machinery, certain components are prone to wear and tear, leading to various operational challenges. Understanding these common issues can help in maintaining optimal performance and extending the lifespan of the equipment.

Frequent Challenges

- Wear and Tear: Regular use can lead to degradation of essential components, affecting overall efficiency.

- Misalignment: Improper installation or usage can result in parts not fitting together correctly, leading to operational failures.

- Corrosion: Exposure to moisture and environmental factors can cause rust, compromising the integrity of metal components.

Prevention Tips

- Regular Maintenance: Schedule routine inspections to identify and address issues before they escalate.

- Proper Storage: Keep machinery in a dry, sheltered area to minimize exposure to harmful elements.

- Quality Replacement: Use high-quality substitutes to ensure reliability and compatibility with existing components.

Maintenance Tips for S100 Models

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. Implementing a consistent maintenance routine can help prevent breakdowns and enhance performance. By following a few key practices, you can keep your machine in optimal condition and ready for use at any time.

First and foremost, regularly check and change the oil. Clean oil is vital for the smooth operation of the engine, and changing it at recommended intervals can significantly extend its lifespan. Be sure to use the appropriate type and grade as specified in the user manual.

Another crucial aspect is the air filter. A clean air filter promotes better airflow, which is essential for optimal combustion. Inspect it frequently and replace it as needed to maintain peak performance.

Additionally, pay attention to the blades. Keeping them sharp not only improves cutting efficiency but also reduces strain on the engine. Regularly inspect for wear and sharpen or replace as necessary.

Finally, ensure that all belts and cables are in good condition. Worn or frayed components can lead to malfunctions and should be addressed promptly. Regular inspections will help identify any potential issues before they escalate.

Identifying Genuine John Deere Parts

When it comes to maintaining machinery, recognizing authentic components is crucial for optimal performance and longevity. High-quality replacements ensure reliability and efficiency, making it essential for operators to differentiate between genuine and counterfeit options.

Check the Packaging: Authentic items typically come in branded packaging, complete with labels and barcodes. Look for signs of quality in the materials used.

Examine the Markings: Genuine components often have distinct markings or serial numbers. Research these identifiers to confirm authenticity.

Purchase from Authorized Dealers: Acquiring items through recognized retailers significantly reduces the risk of counterfeit goods. Authorized sellers maintain a standard for quality assurance.

Research Reviews: Seek feedback from other users. Genuine components usually receive positive reviews regarding performance and durability.

Consult the Manual: The owner’s manual often includes specifications for original components. Cross-reference these details when shopping for replacements.

By being vigilant and informed, operators can ensure they select the best components for their machinery, ultimately enhancing its performance and lifespan.

Comparing S100 Parts with Other Models

In the realm of lawn care machinery, understanding the differences in components across various models is essential for optimal maintenance and performance. Each model brings unique features that cater to specific needs, and recognizing these distinctions can enhance user experience.

Comparative Analysis reveals that certain machines may offer superior durability or efficiency, while others might excel in ease of use or accessibility of replacement elements. By examining these variations, users can make informed decisions about upgrades or repairs.

Moreover, compatibility with accessories and attachments is another crucial aspect to consider. Some machines are designed to work seamlessly with a broader range of tools, thereby providing greater versatility for different tasks.

Ultimately, delving into the specifics of each model not only aids in identifying the right fit but also promotes longevity and reliability in operation.

Resources for S100 Repairs

When it comes to maintaining and fixing your lawn equipment, having access to reliable resources is essential. Whether you are looking for replacement components or detailed guides, knowing where to find the right information can make all the difference in ensuring your machinery operates smoothly.

Where to Find Information

Numerous platforms offer valuable insights and resources for repairs. Online forums and community groups dedicated to outdoor equipment can provide firsthand experiences and tips from fellow enthusiasts. Additionally, many websites specialize in selling components and often feature comprehensive guides on repairs and maintenance.

Recommended Tools and Supplies

Having the right tools is crucial for effective repairs. Below is a table summarizing essential tools and supplies you may need:

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening bolts and nuts. |

| Screwdriver Set | Essential for various screws found in machinery. |

| Multimeter | Useful for diagnosing electrical issues. |

| Oil and Lubricants | To keep moving parts functioning smoothly. |

| Cleaning Supplies | For regular maintenance and keeping equipment in good condition. |

Safety Precautions When Repairing

Ensuring safety during maintenance and repair activities is paramount. Proper precautions help prevent accidents and ensure a smooth workflow. Understanding potential hazards and employing protective measures can significantly reduce risks associated with mechanical tasks.

Essential Safety Measures

- Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and steel-toed boots.

- Work in a well-ventilated area to avoid inhalation of fumes and dust.

- Keep a first aid kit readily accessible for emergencies.

- Ensure all tools and equipment are in good working condition before use.

Handling Equipment Safely

- Disconnect power sources before beginning any repairs.

- Follow manufacturer instructions carefully for any disassembly or reassembly tasks.

- Be cautious of sharp edges and moving parts during maintenance.

- Always use tools as intended to avoid injury.

Upgrading Your S100 Equipment

Enhancing your machinery can significantly improve performance and efficiency. Whether you aim to boost productivity or extend the lifespan of your equipment, understanding the available enhancements is crucial. From simple modifications to comprehensive upgrades, the right choices can make a substantial difference in your operation.

Performance Enhancements

One of the primary focuses when upgrading is enhancing performance. Consider investing in advanced attachments that improve functionality and versatility. Upgrading to a more powerful engine can also provide a noticeable boost in speed and capability. Additionally, regular maintenance and timely replacements of worn components can lead to smoother operation and reduced downtime.

Comfort and Usability Features

Improving comfort and usability can greatly affect your overall experience. Features such as ergonomic seating, intuitive controls, and advanced technology interfaces can make your time spent operating the machine much more pleasant. Implementing modern safety features and visibility enhancements will not only ensure a better working environment but also promote efficiency and productivity.

FAQs About S100 Parts and Diagrams

This section addresses common questions regarding components and schematics for a specific model. Understanding these elements can enhance maintenance, repair, and overall functionality, ensuring optimal performance and longevity of your equipment.

What resources are available for locating component information?

Numerous online platforms provide detailed resources, including manuals and schematics. These materials are invaluable for identifying specific elements and their corresponding locations, which can aid in both troubleshooting and repairs.

How can I ensure I am purchasing the correct components?

To guarantee the right components are acquired, refer to the model specifications and consult authorized retailers or official documentation. Verifying compatibility with your specific model will help prevent issues and enhance the effectiveness of replacements.