John Deere X534 Parts Diagram Overview

Maintaining the efficiency of your outdoor machinery is essential for achieving optimal performance. Familiarity with the various elements that make up these machines can greatly enhance your ability to troubleshoot and ensure their longevity. By exploring the intricate relationships between each component, you can empower yourself to make informed decisions regarding maintenance and repairs.

Visual aids serve as valuable resources in this journey, offering clear representations that simplify the complexities of assembly and functionality. These illustrations can guide you through the specific features and connections, allowing you to delve into the mechanics with confidence. Whether you’re a seasoned professional or a casual user, understanding these details is crucial for effective upkeep.

In the realm of outdoor machinery, knowing the right components can lead to the ultimate efficiency. This knowledge not only aids in identifying issues but also enhances your overall experience, ensuring that your equipment operates smoothly and effectively. Explore the nuances of your machinery, and unlock the full potential of your gardening endeavors.

Understanding John Deere X534

This section explores the essential components and functionality of a specific lawn and garden machine, focusing on its design and operational features. Gaining insight into its structure enhances user experience and maintenance practices.

Key features of this equipment include:

- Robust engine performance

- Efficient cutting system

- Durable construction for longevity

Understanding the various elements contributes to effective use and troubleshooting. Notable aspects to consider include:

- Engine specifications and maintenance requirements

- Transmission types and their benefits

- Deck configurations and cutting options

- Accessories and their functionalities

By familiarizing oneself with these components, users can optimize the performance of their machine, ensuring it meets all landscaping needs efficiently.

Overview of X534 Features

This section provides a comprehensive look at the notable characteristics of a specific model in the line of outdoor machinery. With advanced engineering and user-friendly design, it stands out in its category, offering reliability and performance tailored for various tasks.

Key Characteristics

Designed for versatility, this machine excels in both efficiency and comfort. It features an intuitive interface, robust build quality, and a range of attachments to enhance its utility across different applications.

Specifications

| Feature | Description |

|---|---|

| Engine Type | Air-cooled, V-twin |

| Transmission | Hydrostatic |

| Cutting Width | 48 inches |

| Weight | Approximately 500 lbs |

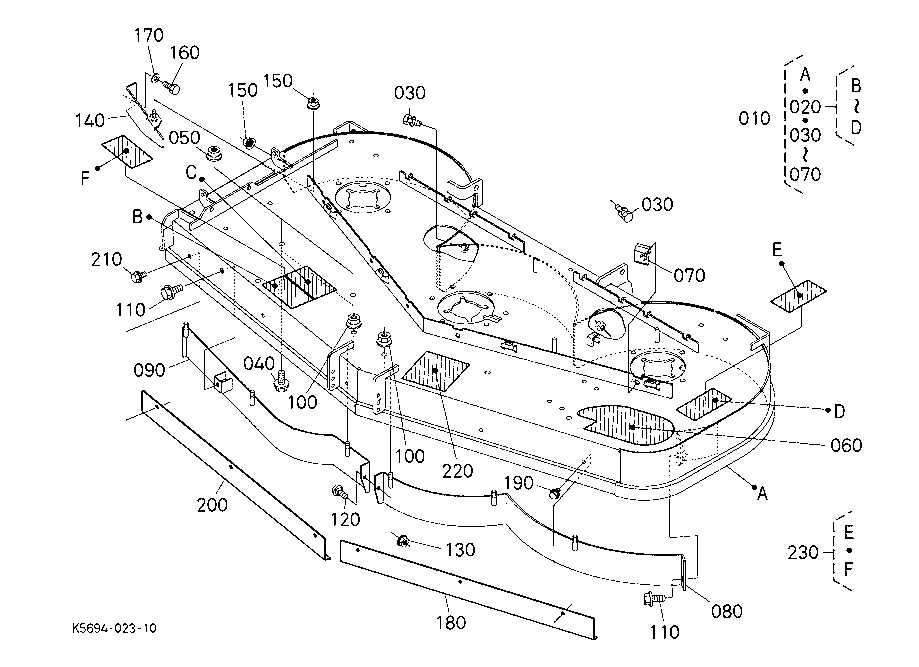

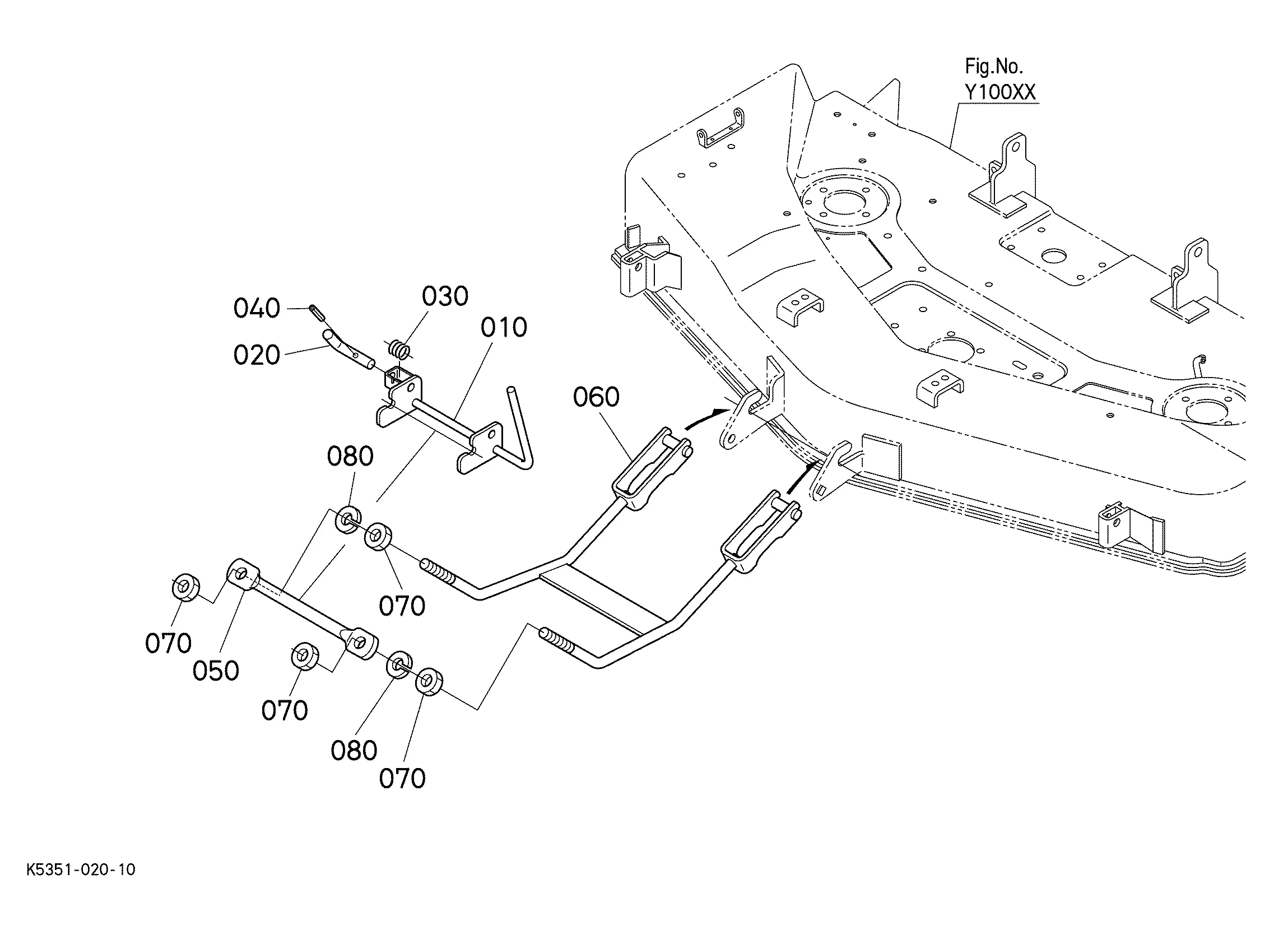

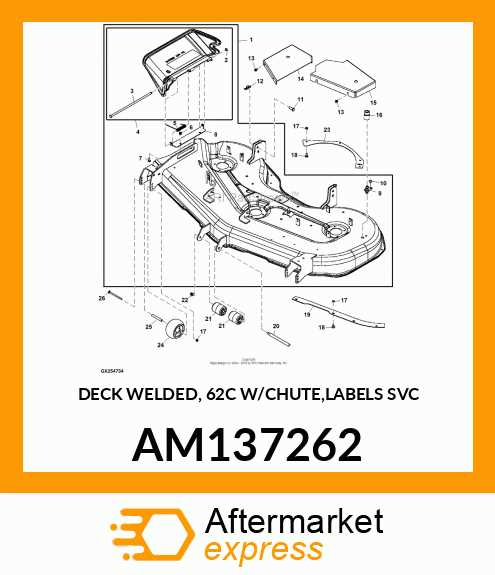

Importance of Parts Diagrams

Understanding the components of machinery is essential for effective maintenance and repair. Visual representations of individual elements serve as crucial tools, enabling users to identify and locate specific parts efficiently. This clarity not only streamlines troubleshooting but also enhances overall functionality by ensuring proper reassembly.

Facilitating Maintenance

Utilizing visual aids simplifies the process of upkeep. By providing a clear overview of each element and its relation to others, these illustrations allow technicians to follow procedures with confidence. They reduce the likelihood of errors, ensuring that all necessary components are addressed during servicing.

Enhancing Repair Efficiency

In the event of a malfunction, having access to detailed visual guides can drastically improve the speed of diagnosis and repair. When users can quickly pinpoint the problematic section, they can take prompt action, minimizing downtime. This efficiency not only saves time but also reduces costs associated with prolonged disruptions.

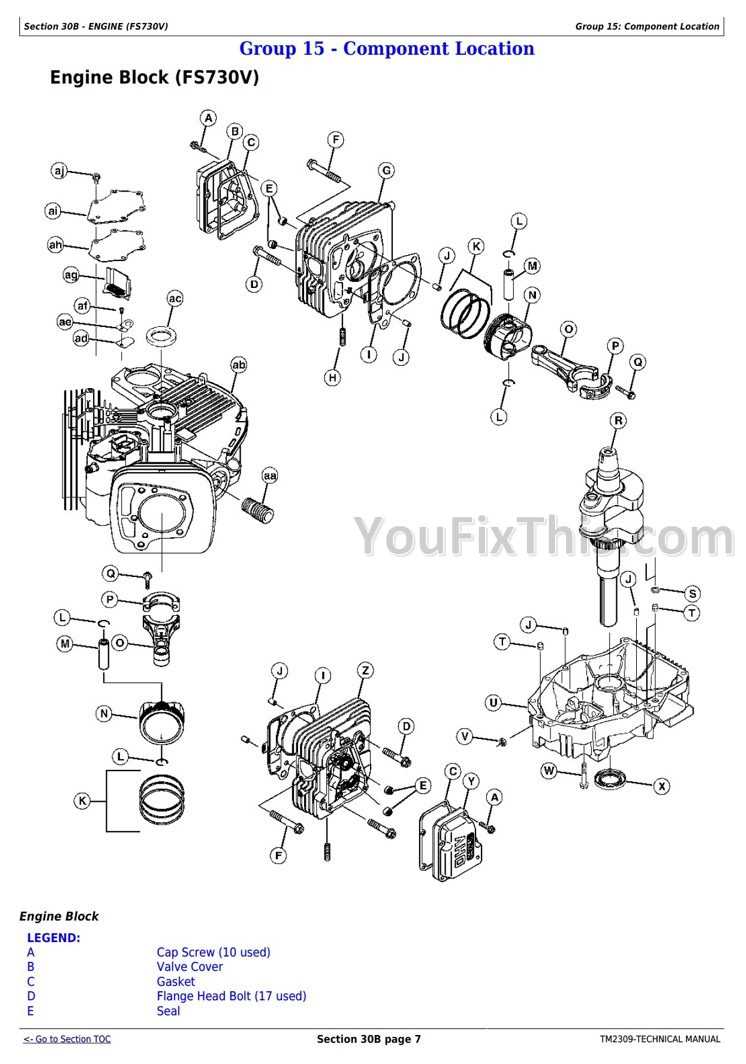

Main Components of X534

This section explores the essential elements that contribute to the functionality and efficiency of the equipment in question. Each part plays a vital role in ensuring optimal performance and durability, making them critical for maintenance and repairs.

Engine: The powerhouse of the machine, this component is responsible for providing the necessary energy to operate various functions.

Transmission: This system facilitates the transfer of power from the engine to the wheels, allowing for smooth movement and maneuverability.

Chassis: The framework supports all other components, providing stability and strength to withstand various working conditions.

Steering Mechanism: This element enables precise navigation, ensuring that the operator can control the direction effectively.

Electrical System: This network powers all electronic features, including lights and sensors, ensuring reliable operation in different environments.

Hydraulic System: Essential for powering attachments and other functions, this system enables increased versatility in operations.

Understanding these key components allows for better maintenance strategies and enhances the overall user experience.

Common Issues and Solutions

This section explores frequent challenges faced by users of outdoor equipment and offers practical remedies. Understanding these common difficulties can enhance the longevity and performance of your machine, ensuring efficient operation throughout its use.

Electrical Problems

One prevalent issue involves electrical failures, often caused by faulty connections or drained batteries. Regularly inspecting wiring and ensuring battery terminals are clean can mitigate these problems. Replacing worn-out components promptly is essential to maintain optimal functionality.

Mechanical Failures

Mechanical breakdowns, such as worn belts or blade issues, can significantly hinder performance. Routine maintenance, including belt adjustments and blade sharpening, is crucial. Keeping an eye on wear and tear helps in addressing these concerns before they escalate into major repairs.

Accessing Parts Diagrams Online

In today’s digital age, locating visual references for machinery components has become increasingly convenient. Online platforms provide a wealth of resources that allow users to view and understand the intricate assembly of equipment. These resources are essential for maintenance, repair, and enhancement of performance.

To effectively navigate these online resources, users can follow a systematic approach. Here’s a brief overview of how to access these invaluable tools:

| Step | Description |

|---|---|

| 1 | Visit a reputable website dedicated to machinery support. |

| 2 | Utilize the search function to find the specific model. |

| 3 | Access the section for visual representations and technical information. |

| 4 | Download or view the materials directly from the platform. |

This structured method allows users to find the information they need quickly and efficiently, ultimately facilitating smoother repair and maintenance processes.

How to Interpret Diagrams

Understanding technical illustrations can significantly enhance your ability to work with machinery and equipment. These visual representations provide essential information about components, their functions, and how they interact within a system. By mastering the art of interpretation, you can streamline repairs and maintenance tasks effectively.

Here are some key elements to consider when analyzing these visuals:

- Symbols and Legends: Familiarize yourself with the common symbols used in the illustration. A legend often accompanies the image, explaining what each symbol represents.

- Scale and Proportions: Pay attention to the scale of the illustration. Understanding the proportions can help you gauge the size and relationship of parts to each other.

- Connections: Look for lines that indicate how components are connected. Solid lines may represent physical connections, while dashed lines could denote electrical pathways or other relationships.

- Numbering: Many diagrams use numbers to label components. Cross-reference these numbers with accompanying documentation to understand their specific functions.

- Contextual Information: Sometimes, diagrams include additional notes or annotations that provide context. Always review this information, as it can offer insights into assembly or troubleshooting.

By keeping these factors in mind, you can develop a clearer understanding of complex systems and improve your efficiency in managing machinery and equipment.

Where to Buy Replacement Parts

Finding quality components for your machinery can significantly enhance its performance and longevity. Numerous options are available for sourcing these essential items, whether you prefer online shopping or local retailers. Understanding where to look can save you both time and money while ensuring that you receive reliable products.

Online Retailers

One of the most convenient methods to acquire necessary components is through online platforms. Websites specializing in equipment supplies often offer a vast selection, complete with detailed descriptions and customer reviews. This allows you to compare prices and find the exact match for your needs. Be sure to check for warranties and return policies to protect your purchase.

Local Dealers and Repair Shops

Another effective option is visiting local dealers or repair shops. These establishments typically stock a variety of items and can provide valuable insights based on their experience. Moreover, purchasing from a local source may expedite the process, as you can often get items immediately without waiting for shipping. Building a relationship with local suppliers can also lead to better deals and expert advice.

Maintenance Tips for X534

Regular upkeep is essential for ensuring optimal performance and longevity of your machine. Following a structured maintenance routine can prevent costly repairs and enhance efficiency. Here are some key suggestions to keep your equipment running smoothly.

- Check Fluid Levels: Regularly inspect and top off essential fluids, including engine oil, coolant, and fuel. Proper levels help maintain performance and prevent overheating.

- Inspect Belts and Hoses: Examine all belts and hoses for signs of wear or damage. Replace any that show cracks or fraying to avoid breakdowns.

- Clean or Replace Air Filters: Ensure the air intake system is clear. A clean filter allows for better airflow and engine performance.

In addition to these routine checks, consider the following practices:

- Sharpen Blades: Keeping cutting edges sharp is crucial for efficiency. Regularly sharpen or replace blades to ensure a clean cut.

- Inspect Tires: Check tire pressure and tread for any signs of wear. Properly inflated tires improve handling and reduce fuel consumption.

- Battery Maintenance: Keep terminals clean and ensure the battery is securely mounted. Regularly check the charge level and replace it if necessary.

By following these maintenance tips, you can enhance the reliability and performance of your equipment, ensuring it serves you well for years to come.

DIY Repairs with Diagrams

When tackling home maintenance tasks, having visual aids can significantly enhance the repair experience. These illustrations offer clarity, ensuring you understand the assembly and disassembly processes, making it easier to address issues independently.

Here are some advantages of using visual guides:

- Improved understanding of complex systems

- Step-by-step instructions to follow

- Increased confidence in completing repairs

To make the most of these resources, consider the following steps:

- Identify the specific issue you want to resolve.

- Locate the relevant visual guide.

- Follow each step carefully, referencing the illustration as needed.

- Test the repair to ensure functionality.

Utilizing diagrams not only simplifies repairs but also empowers you to tackle maintenance projects with ease and confidence.

Professional Repair Services

When it comes to maintaining and restoring machinery, relying on skilled technicians is essential. These services provide expertise in diagnosing issues, sourcing components, and ensuring that equipment operates efficiently. A comprehensive approach guarantees longevity and performance, enabling users to focus on their core activities without interruption.

Expert Technicians at Your Service

Qualified professionals possess the knowledge to handle various models, using advanced tools and techniques. They assess the condition of machinery, identifying potential problems before they escalate. This proactive maintenance can save time and money, ensuring that your equipment remains in optimal condition.

Quality Components and Accessories

Utilizing high-quality components is crucial for the reliability of any machine. Reputable repair services offer a range of premium parts tailored to fit specific needs. By sourcing these materials, technicians ensure that repairs are durable and effective, enhancing the overall performance and safety of your machinery.

FAQs About John Deere X534 Parts

This section aims to address common inquiries related to components for a popular model of lawn equipment, providing clarity for enthusiasts and owners alike.

Common Questions

Many individuals have concerns regarding compatibility, availability, and maintenance of various elements associated with this model. Here are some frequently asked questions:

| Question | Answer |

|---|---|

| What are the most common issues with this model’s components? | Wear and tear on belts and blades are typical, requiring periodic replacement. |

| Where can I find reliable replacements? | Authorized dealers and reputable online retailers offer a wide selection of options. |

| How often should maintenance be performed? | Regular check-ups every season are recommended to ensure optimal performance. |

Tips for Maintenance

Understanding the proper care of essential elements can extend their lifespan significantly. Always refer to the manufacturer’s guidelines for the best practices.