Understanding the John Deere X740 Parts Diagram

In the realm of farming and landscaping, efficiency hinges on the intricate interplay of various machine elements. A comprehensive grasp of these components can significantly enhance maintenance practices and operational effectiveness. Each section of machinery plays a vital role, and recognizing these functions empowers operators to make informed decisions.

Familiarity with schematics is essential for troubleshooting and repairs. By analyzing the arrangement and connectivity of each piece, one can swiftly identify potential issues and streamline the maintenance process. This knowledge not only prolongs the lifespan of equipment but also minimizes downtime, ensuring that work proceeds smoothly.

Furthermore, understanding the various elements involved can lead to better customization and upgrades. As technology advances, operators have the opportunity to enhance their machines, adapting them to specific tasks and improving overall productivity. Thus, a detailed look at component layouts serves as a foundation for both effective management and innovative enhancements in agricultural practices.

Understanding John Deere X740 Parts

When it comes to maintaining and repairing outdoor machinery, familiarity with essential components is crucial for optimal performance. Each element plays a vital role in ensuring that the equipment operates smoothly and efficiently. Gaining insights into these components not only aids in troubleshooting but also enhances overall functionality.

Exploring the key elements allows users to pinpoint specific areas that may require attention. From the engine assembly to the transmission system, understanding how each piece interacts can lead to improved longevity and effectiveness. Investing time in this knowledge not only simplifies repairs but also elevates the user’s experience with the machinery.

Overview of X740 Model Features

This section provides an in-depth look at the key attributes and capabilities of a renowned lawn and garden equipment model. Known for its robust performance and versatility, this machine is designed to meet the diverse needs of users, from homeowners to professionals. Its innovative engineering and thoughtful design make it a reliable choice for various landscaping tasks.

| Feature | Description |

|---|---|

| Engine Power | Equipped with a powerful engine, this model ensures efficient operation, even in challenging conditions. |

| Cutting Width | Offers a generous cutting width, enabling quick and thorough mowing, saving time and effort. |

| Transmission | Features an advanced transmission system for smooth and responsive handling, enhancing maneuverability. |

| Comfort Features | Designed with user comfort in mind, it includes ergonomic seating and intuitive controls for a pleasant experience. |

| Attachments | Compatible with a wide range of attachments, allowing for versatile use across different tasks and seasons. |

Importance of Parts Diagrams

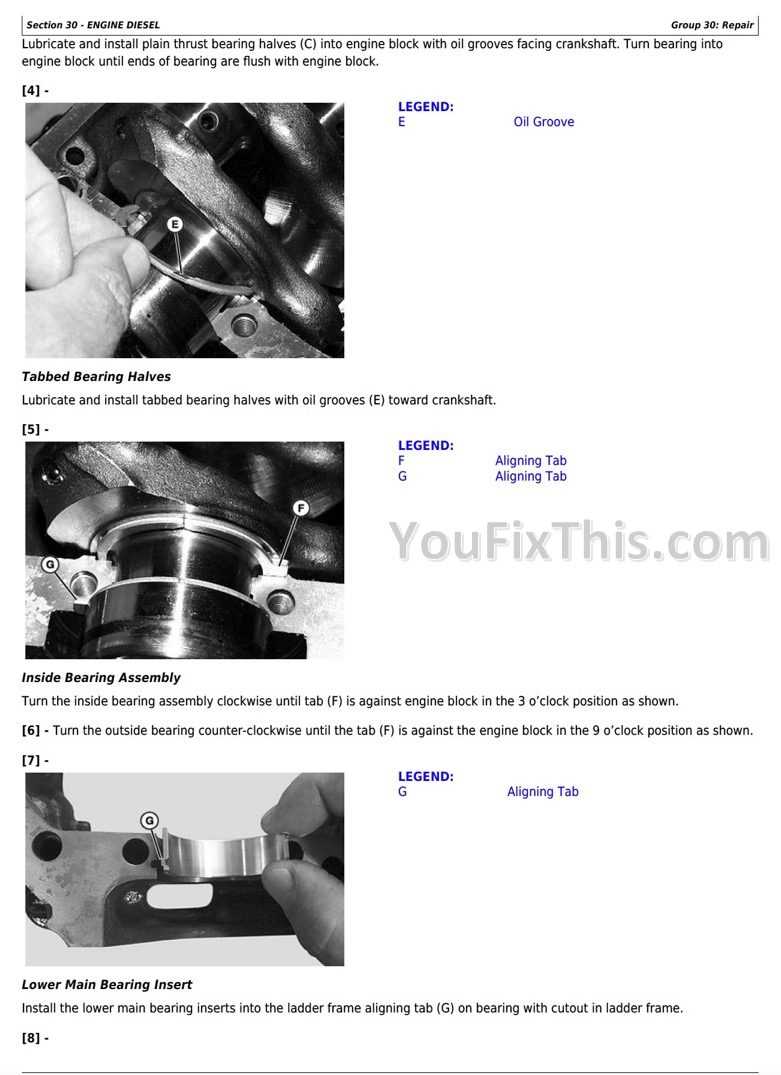

Visual representations of components play a crucial role in understanding complex machinery. These illustrations serve as essential tools for both maintenance and assembly, enabling users to identify various elements and their interconnections. By providing a clear overview, they enhance comprehension and facilitate efficient repairs.

Utilizing such visuals can significantly reduce the time spent troubleshooting issues. When users can easily locate specific items, they can quickly ascertain what needs replacement or adjustment. This not only improves workflow but also minimizes the risk of errors during the repair process.

Furthermore, these schematics are invaluable resources for training and educational purposes. They help newcomers grasp the intricacies of machinery, fostering a deeper understanding of operational mechanics. With well-organized visuals, even complex systems become more accessible, allowing users to build their expertise with confidence.

In summary, comprehensive visual aids are indispensable for anyone involved in machinery maintenance and repair. They streamline processes, enhance learning, and ultimately contribute to the longevity and efficiency of equipment.

Identifying Key Components

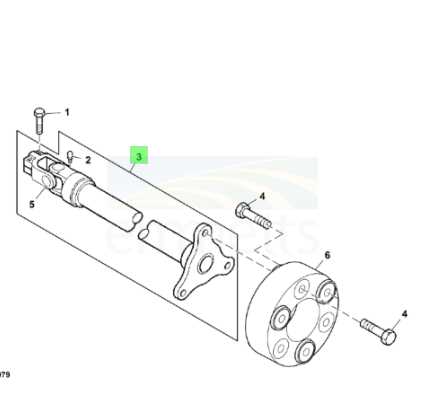

Understanding the essential elements of a machine is crucial for effective maintenance and repair. Each component plays a specific role, contributing to the overall functionality and efficiency of the equipment. Familiarity with these parts helps users diagnose issues, perform upgrades, and ensure smooth operation.

Here are some of the primary components to consider:

- Engine: The heart of the machine, responsible for generating power.

- Transmission: This system transfers power from the engine to the wheels, influencing speed and torque.

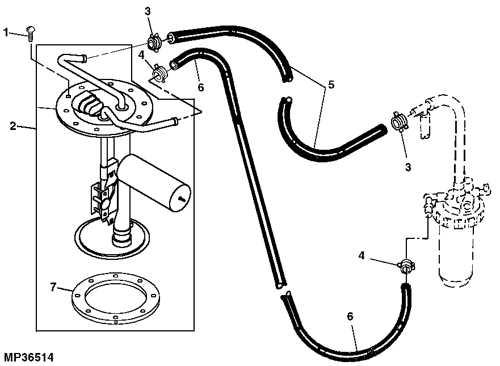

- Hydraulics: Vital for various functions, such as lifting and tilting, these systems use fluid power for efficient operation.

- Chassis: The framework that supports all other components, ensuring stability and durability.

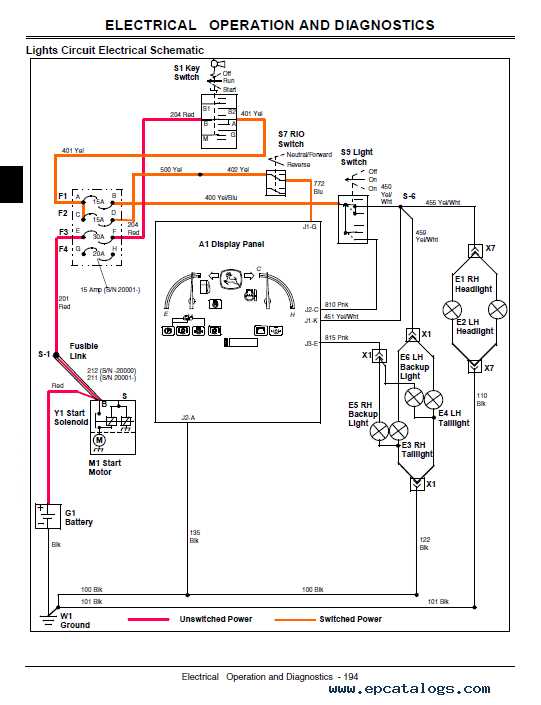

- Electrical System: Powers lights, controls, and other essential features, integrating safety and performance.

Focusing on these key areas can enhance your understanding of the equipment’s operation and assist in troubleshooting common problems.

Common Replacement Parts for X740

Maintaining outdoor equipment is essential for optimal performance and longevity. Understanding the key components that often require attention can greatly enhance the user experience. Regular replacement of certain elements not only ensures smooth operation but also minimizes downtime during crucial tasks.

Among the frequently needed components are belts, which play a vital role in power transmission. Worn or damaged belts can lead to decreased efficiency and may cause additional strain on the engine. It’s advisable to inspect these regularly and replace them when signs of wear are evident.

Another critical element includes filters. Air and oil filters should be replaced periodically to maintain proper airflow and lubrication, which are crucial for the equipment’s performance. Neglecting these can result in reduced engine efficiency and potential damage.

Blades are essential for cutting tasks and should be checked frequently. Dull or damaged blades can compromise cutting quality and lead to excessive fuel consumption. Replacing them at the first sign of wear ensures clean and efficient operation.

Finally, consider the importance of spark plugs. These components are integral for starting the engine and ensuring smooth operation. Regular checks and timely replacements can prevent starting issues and enhance overall performance.

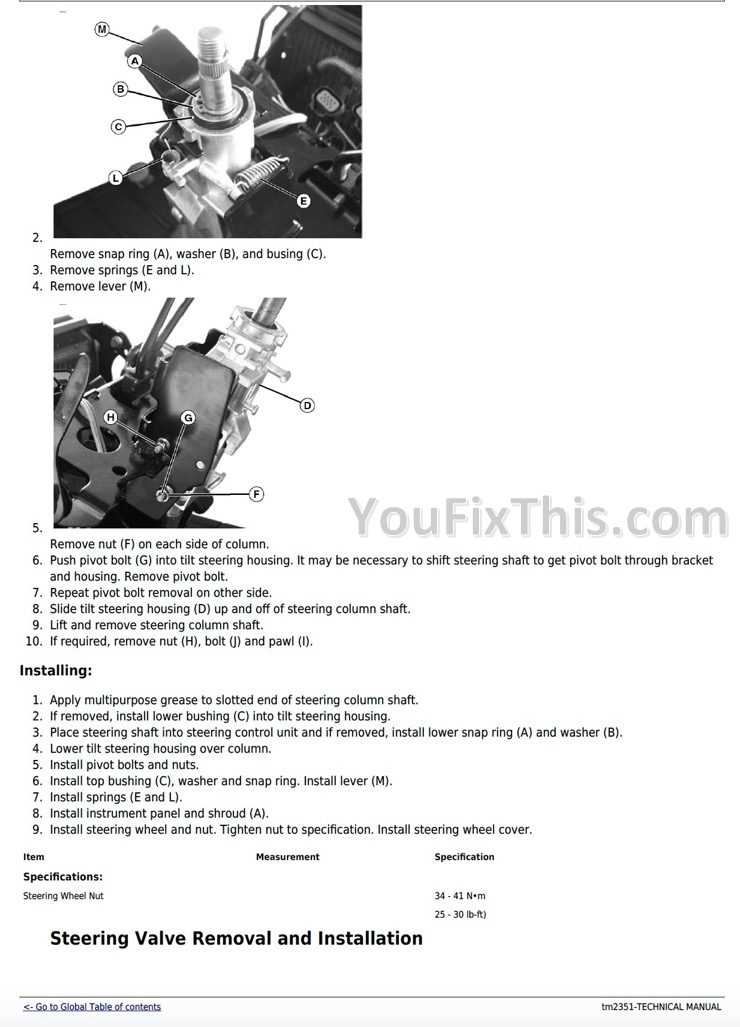

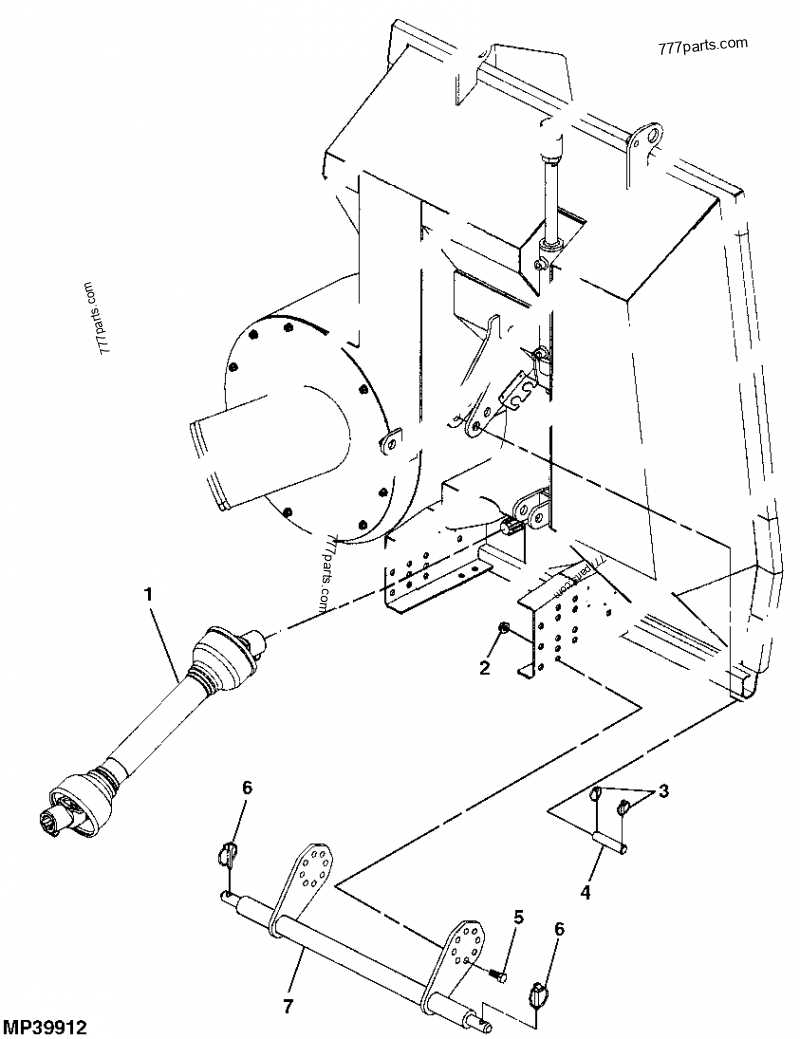

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. Such illustrations provide a clear overview of how various elements are arranged and interact, helping users identify the necessary components for specific tasks.

| Step | Description |

|---|---|

| 1 | Start by examining the overall layout, noting the major assemblies and their relationships. |

| 2 | Identify individual components by referring to the labels and numbers associated with each item. |

| 3 | Cross-reference with a list or catalog for detailed specifications and part numbers. |

| 4 | Pay attention to any notes or legends that provide additional context or instructions. |

By following these steps, one can effectively navigate and interpret visual component representations for efficient repairs and enhancements.

Tools Needed for Repairs

When undertaking maintenance or repair tasks, having the right tools is essential for ensuring efficiency and accuracy. Proper equipment not only simplifies the process but also enhances safety and prolongs the lifespan of the machinery.

Essential Tools

- Wrenches

- Screwdrivers

- Pliers

- Socket set

- Torque wrench

- Multimeter

Additional Supplies

- Lubricants

- Cleaning solvents

- Replacement seals

- Safety gloves

- Protective eyewear

Equipping yourself with these tools ensures a smoother repair experience, allowing for thorough inspection and precise adjustments as needed.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the extended lifespan of your equipment. By implementing a consistent maintenance routine, you can prevent common issues and enhance performance, ultimately saving time and resources in the long run.

Routine Inspections

Conducting periodic checks is vital. Look for signs of wear and tear, such as frayed belts or leaking fluids. Addressing these minor issues early can prevent them from escalating into major repairs. Always consult the manufacturer’s guidelines for specific inspection points relevant to your machinery.

Proper Cleaning

Keeping your equipment clean not only improves its appearance but also promotes efficient operation. Remove dirt and debris from vital components regularly. Using the right cleaning agents will ensure that you don’t damage sensitive parts, allowing your machinery to perform optimally.

Ordering Parts Online Effectively

Acquiring components through online platforms can streamline maintenance and repairs, ensuring timely service and optimal performance. Understanding the nuances of this process enhances efficiency and satisfaction. Here are some essential strategies to navigate the digital marketplace successfully.

Research and Verify Sources

Before making a purchase, it is crucial to identify reliable vendors. Check reviews, ratings, and feedback from other customers to gauge the credibility of the seller. Opting for well-established platforms or authorized dealers minimizes the risk of counterfeit items and ensures quality. Additionally, confirm that the website provides clear contact information and customer support options.

Utilize Clear Specifications

When searching for components, use precise terminology and specifications. Gather all necessary information regarding model numbers, compatibility, and required features. This approach helps in filtering results effectively and reduces the likelihood of ordering incorrect items. Always double-check compatibility with your machinery before finalizing any order to avoid unnecessary returns.

By implementing these strategies, individuals can enhance their online shopping experience, ensuring they receive the correct components efficiently and reliably.

Comparing OEM vs Aftermarket Parts

When maintaining machinery, the choice between original components and those produced by third parties often arises. Each option carries its own set of advantages and disadvantages, impacting performance, cost, and longevity. Understanding these differences is crucial for making informed decisions.

Original equipment manufacturers (OEM) provide components that are specifically designed for a particular machine, ensuring compatibility and reliability. In contrast, aftermarket suppliers offer alternatives that may vary in quality and pricing. Below is a comparison of key factors to consider when choosing between these two options:

| Factor | OEM Parts | Aftermarket Parts |

|---|---|---|

| Quality | Typically higher, designed to meet original specifications | Varies widely, can be lower or comparable |

| Cost | Usually more expensive | Often more affordable |

| Availability | May be limited to authorized dealers | Generally more accessible through various retailers |

| Warranty | Often comes with a manufacturer’s warranty | Warranties can vary, may not be as comprehensive |

| Performance | Engineered for optimal function | Performance can be inconsistent, depending on the brand |

Ultimately, the decision between these two types of components depends on individual priorities, whether it be cost-effectiveness, performance assurance, or long-term reliability.

Assembly Instructions for X740

This section provides essential guidelines for the proper assembly of the equipment, ensuring optimal functionality and safety. Following these steps will lead to a smooth setup process, allowing you to utilize the machine effectively.

Preparation Steps

Before beginning the assembly, gather all necessary tools and components. Verify that each item is present and in good condition to avoid interruptions during the process.

Assembly Process

Carefully follow these sequential steps for successful assembly:

| Step | Description |

|---|---|

| 1 | Attach the main frame securely to the base. |

| 2 | Install the wheel assemblies, ensuring they are aligned correctly. |

| 3 | Connect the power system, checking all wiring for proper placement. |

| 4 | Final checks: inspect all connections and ensure stability. |

Frequently Asked Questions on Parts

This section addresses common inquiries regarding components and their replacements. Understanding these elements can enhance the efficiency and longevity of your equipment, ensuring optimal performance throughout its lifespan.

Common Queries

| Question | Answer |

|---|---|

| What should I consider when replacing a component? | Evaluate compatibility, quality, and warranty options to ensure a seamless fit. |

| How do I find the correct size for a replacement? | Refer to the manufacturer’s specifications or consult an expert for precise measurements. |

Maintenance Tips

Regular inspections and timely replacements can prevent larger issues. Keeping a close eye on wear and tear will help maintain the overall functionality.

Where to Find Reliable Resources

Accessing trustworthy information is crucial for anyone seeking to maintain or repair machinery effectively. Various sources can provide detailed insights and specifications to ensure optimal performance.

- Manufacturer Websites: Official sites often offer comprehensive manuals and guides.

- Online Forums: Communities of enthusiasts can share personal experiences and solutions.

- Repair Shops: Local mechanics may have valuable knowledge and resources.

- Retailers: Authorized dealers often provide catalogs and support for specific models.

- Technical Libraries: Many libraries house detailed manuals and reference materials.

Utilizing these resources can significantly enhance your understanding and assist in finding the necessary components.