Comprehensive Guide to John Deere Z235 Parts Diagram

In the realm of garden maintenance, familiarity with the various elements of mowing machines is essential for effective upkeep and repair. Knowing how these machines are constructed can greatly enhance your ability to troubleshoot issues and perform necessary maintenance. This knowledge not only saves time but can also prevent costly repairs in the long run.

Every mower model has its unique configuration, featuring distinct components that work together to ensure optimal performance. By examining the layout of these elements, users can gain insights into their functions and interrelationships. Such an understanding empowers individuals to tackle repairs with confidence, whether it’s replacing a blade or addressing engine concerns.

In this section, we will delve into a comprehensive overview of the assembly of a specific mowing machine, detailing its critical components and their placements. This exploration will serve as a valuable resource for both novice and experienced users, enabling informed decisions during maintenance tasks. Embracing this knowledge ultimately leads to more efficient and effective gardening experiences.

Understanding the John Deere Z235

This section explores the essential features and functionality of a popular lawn maintenance machine. It highlights its capabilities, design, and the advantages it offers to users looking for efficiency and reliability in outdoor tasks.

Key Features

The machine is equipped with a powerful engine, allowing for effective cutting and maneuverability. Its innovative design ensures ease of use, making it suitable for both residential and commercial purposes. The user-friendly controls enhance the overall experience, catering to both novices and experienced operators.

Maintenance and Care

Key Components of the Z235

This section explores the essential elements that contribute to the efficient functioning of this lawn maintenance machine. Understanding these components helps users appreciate how each part plays a vital role in overall performance and reliability.

Major Elements

The primary components include the engine, transmission, and cutting deck, each designed to enhance operation and durability. These elements work together seamlessly to ensure effective grass management.

Table of Components

| Component | Description |

|---|---|

| Engine | Provides the power necessary for operation. |

| Transmission | Facilitates speed control and movement. |

| Cutting Deck | Responsible for grass trimming and handling. |

| Wheels | Support mobility and stability on various terrains. |

| Control System | Enables user interaction and operational adjustments. |

Importance of Maintenance for Longevity

Proper upkeep of machinery is crucial for ensuring its extended lifespan and optimal performance. Regular care not only prevents unexpected breakdowns but also enhances efficiency, allowing for smoother operations over time. Ignoring maintenance can lead to costly repairs and reduced functionality.

Benefits of Routine Care

Routine inspections and servicing are essential for identifying potential issues before they escalate. These proactive measures help in maintaining the functionality of critical components, thus reducing the risk of failure during usage. Regular maintenance can significantly extend the life of equipment.

Cost-Effectiveness

Investing in regular maintenance proves to be cost-effective in the long run. By preventing major repairs and optimizing performance, users can save money while enjoying reliable service. Ultimately, a well-maintained machine is a valuable asset that contributes positively to productivity.

Common Issues with Z235 Parts

Understanding frequent challenges associated with specific components can significantly enhance maintenance and performance. Recognizing these common problems allows for timely intervention and effective solutions.

Frequent Challenges

- Wear and tear from regular use can lead to reduced efficiency.

- Misalignment issues may arise, impacting functionality.

- Corrosion from exposure to elements can weaken certain materials.

Maintenance Tips

- Regularly inspect components for signs of damage.

- Keep all connections clean to prevent malfunction.

- Use appropriate lubricants to enhance longevity.

Where to Find Replacement Parts

When your equipment requires new components, knowing where to look can save time and money. Numerous options are available to help you find the necessary replacements, from authorized dealers to online marketplaces. Understanding these sources will enable you to make informed choices for your machinery maintenance and repair needs.

Authorized Dealers

One of the most reliable options is to visit authorized retailers. These locations often carry a wide selection of original components and can provide expert advice. Additionally, they may offer warranty support, ensuring that your new parts meet the required standards of quality and compatibility.

Online Marketplaces

For those who prefer shopping from home, online platforms can be a great resource. Websites specializing in machinery components often feature detailed descriptions and customer reviews, allowing you to compare various options. However, be cautious and verify the credibility of the seller to avoid counterfeit items. Utilizing filters can also streamline your search process, helping you quickly locate what you need.

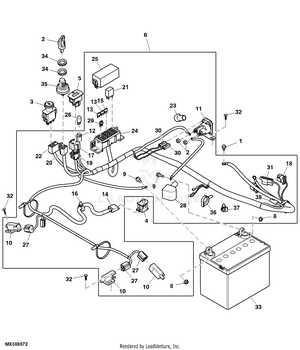

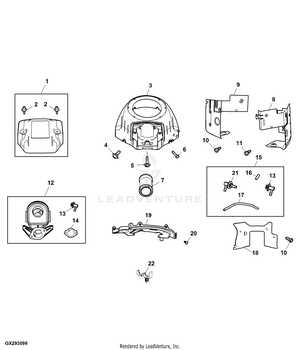

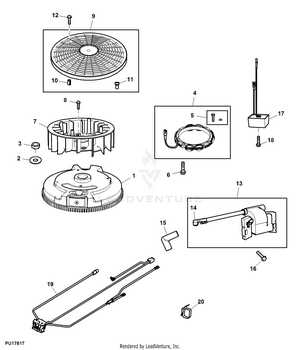

How to Interpret Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and repair. These illustrations provide a detailed view of the assembly, showcasing how individual elements fit together. By familiarizing yourself with the symbols and layout, you can streamline the repair process and ensure that each piece is correctly identified and utilized.

Familiarize with Symbols and Labels

Each visual guide typically employs specific symbols to denote various components. Take time to review the legend or key provided, as this will explain what each symbol represents. Common indicators might include numbers, letters, or color codes, which help differentiate between similar parts. Understanding these will enhance your ability to locate and order the right items.

Study the Layout and Flow

Pay attention to how components are arranged in the visual layout. This often reflects the assembly process, indicating which parts must be installed first and how they interact with one another. Analyzing the connections and flow can prevent mistakes during installation and improve overall efficiency in repairs.

Tools Needed for DIY Repairs

Embarking on do-it-yourself maintenance projects requires a well-equipped toolkit to ensure efficiency and effectiveness. Having the right implements at your disposal can make the difference between a smooth repair process and a frustrating experience.

Basic hand tools such as wrenches, screwdrivers, and pliers are essential for tackling various tasks. Additionally, specialized instruments like torque wrenches and socket sets can provide precision and ease in more intricate jobs.

For safety, don’t overlook protective gear such as gloves and goggles. Finally, a reliable workbench and good lighting will enhance your workspace, allowing for meticulous attention to detail.

Tips for Efficient Lawn Care

Maintaining a vibrant and healthy yard requires a combination of knowledge, strategy, and the right tools. By adopting effective practices, you can ensure your outdoor space flourishes while minimizing time and effort spent on upkeep. Here are some key strategies to enhance your lawn care routine.

Understanding Soil Health

Healthy soil is the foundation of a thriving lawn. Regularly testing your soil can provide insight into its nutrient levels and pH balance. Amending the soil with organic matter, such as compost, can improve its structure and fertility. This creates an optimal environment for grass roots to grow, resulting in a lush green landscape.

Proper Mowing Techniques

Cutting grass at the right height is crucial for promoting healthy growth. Regular mowing helps prevent weeds and encourages thicker turf. Aim to cut no more than one-third of the grass height at each mowing session. Additionally, keeping your mower blades sharp will ensure a clean cut, which helps reduce stress on the grass.

Upgrades and Modifications for Performance

Enhancing the efficiency and capability of outdoor equipment can lead to significant improvements in overall functionality and user experience. By implementing strategic upgrades and modifications, operators can achieve better performance, increased reliability, and enhanced features tailored to specific tasks.

Here are some popular upgrades to consider:

- Engine Enhancements: Boosting power output can be achieved through modifications such as performance air filters, high-flow exhaust systems, or tuning the engine management system.

- Transmission Upgrades: Improving the transmission can result in smoother operation and quicker response times. Options include upgrading to a more efficient gearbox or installing performance clutches.

- Suspension Improvements: Enhancing suspension components can provide better stability and control, especially in uneven terrain. Consider adjustable shock absorbers or heavy-duty springs.

- Cutting Deck Modifications: Upgrading blades or implementing a mulching kit can improve cutting efficiency and finish, making tasks quicker and more effective.

- Wheels and Tires: Choosing the right wheels and tires can enhance traction and maneuverability. Larger or specialized tires can improve performance on various surfaces.

Each of these modifications can contribute to improved operation, making outdoor tasks easier and more efficient. It’s essential to consider compatibility and the intended use when planning enhancements.

Comparing Z235 with Other Models

This section explores the similarities and differences between a specific lawn mower model and its counterparts. By examining features, performance, and design, we aim to provide insight for potential buyers or enthusiasts considering various options in the market.

Performance and Efficiency

When evaluating performance, certain models stand out with enhanced power and fuel efficiency. While one variant may excel in speed and cutting precision, another might offer superior durability, making it essential to consider specific needs before making a decision.

Design and Usability

The design elements of different models can significantly affect user experience. Ergonomics, ease of operation, and maintenance requirements vary widely. Some machines incorporate advanced technology for convenience, while others prioritize straightforward mechanics for simplicity.

Customer Reviews and Feedback

This section highlights the thoughts and experiences shared by users regarding their machinery components. Feedback from customers plays a vital role in understanding product quality and performance.

Here are some common themes from customer reviews:

- Durability: Many users appreciate the robust nature of the equipment, noting its ability to withstand various conditions.

- Ease of Maintenance: Reviewers often mention how straightforward it is to perform upkeep and repairs, enhancing overall satisfaction.

- Performance: Customers frequently comment on the efficiency and effectiveness of the machinery in their tasks.

Overall, the collective feedback serves as an ultimate resource for potential buyers looking to make informed decisions.