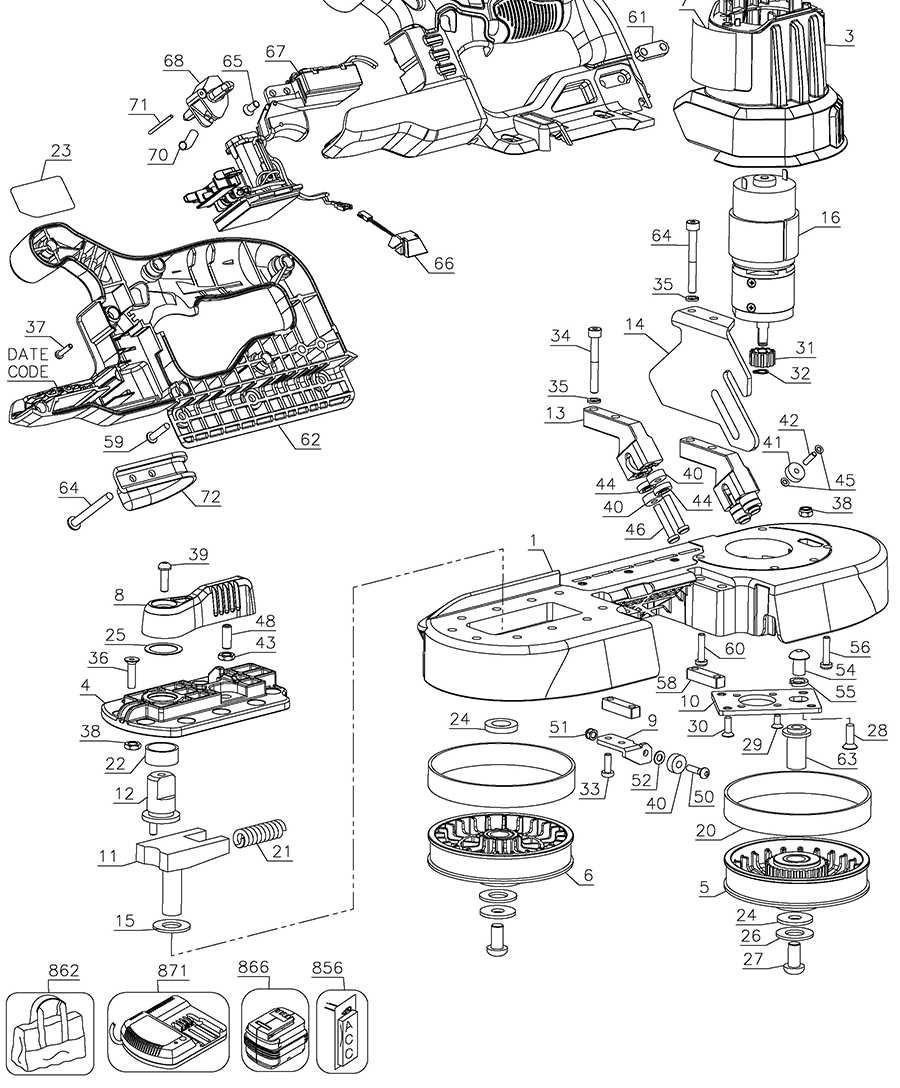

Dewalt Chop Saw Parts Diagram for Easy Identification

The efficient operation of cutting machinery relies on a clear understanding of its various components. Each element plays a crucial role in the overall functionality, contributing to precision and performance. A comprehensive overview of these elements not only aids in effective maintenance but also enhances user proficiency.

For those who work with these tools regularly, familiarizing oneself with the layout and interaction of individual segments can significantly improve operational efficiency. Whether for professional use or DIY projects, recognizing how each piece fits into the larger assembly is essential for troubleshooting and optimization.

In this section, we will delve into the intricate design of cutting instruments, providing insight into the arrangement of key elements. This knowledge empowers users to make informed decisions regarding repairs, upgrades, and safe handling practices, ultimately leading to better outcomes in various applications.

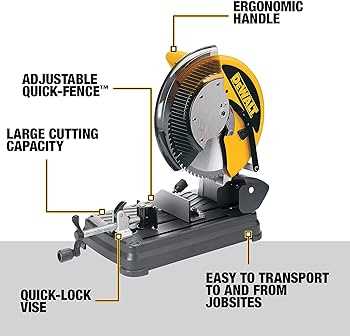

Dewalt Chop Saw Overview

This section provides an insight into a powerful cutting tool designed for precision and efficiency in various applications. Renowned for its robust performance, this equipment is an essential choice for both professionals and DIY enthusiasts, ensuring clean and accurate cuts in diverse materials.

Key Features

Equipped with advanced technology, this instrument offers enhanced safety features and user-friendly controls. Its durable construction ensures longevity, while the ergonomic design promotes comfort during extended use, making it suitable for demanding tasks.

Applications

This versatile tool is ideal for a range of projects, from framing and woodworking to metal fabrication. Its ability to handle different materials allows users to tackle various challenges efficiently, ultimately boosting productivity on any job site.

Importance of Understanding Parts

Comprehending the various components of a tool is essential for effective usage and maintenance. Each element plays a vital role in ensuring optimal performance, safety, and longevity. Familiarity with these components enables users to troubleshoot issues, make informed repairs, and enhance their overall experience.

Benefits of Knowing Each Component

- Improved Performance: Understanding how each part functions allows for better handling and utilization of the equipment.

- Enhanced Safety: Knowledge of components can help prevent accidents and injuries by ensuring proper usage.

- Effective Troubleshooting: Recognizing the signs of wear or malfunction in specific elements can lead to quicker resolutions.

- Cost Efficiency: Being aware of which parts can be easily replaced or serviced reduces the need for costly professional repairs.

Key Areas to Focus On

- Functionality: Understand the role each element plays in the overall operation.

- Maintenance: Learn about regular upkeep to extend the lifespan of the equipment.

- Replacement: Know which components are most likely to need replacement and how to identify them.

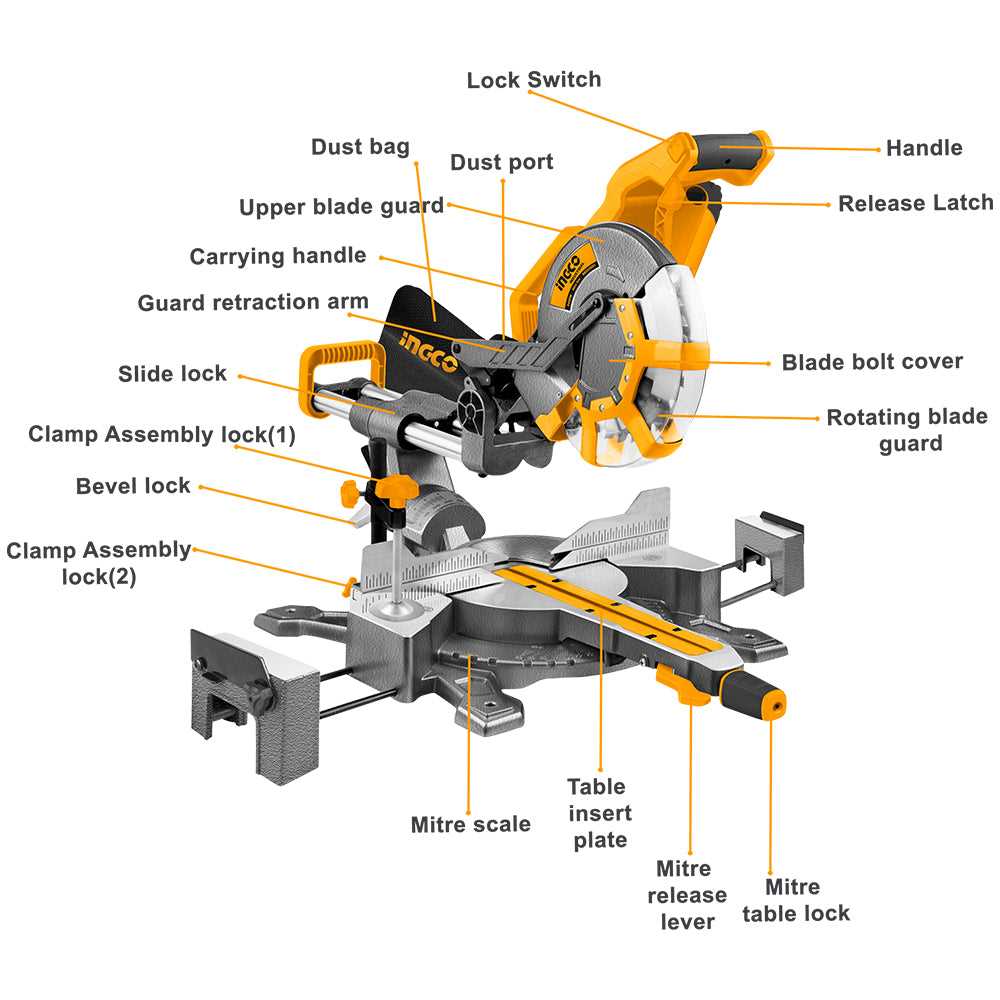

Common Components of Chop Saws

Understanding the essential elements of cutting machines can enhance both their functionality and maintenance. Each part plays a critical role in ensuring efficient performance and precision in various tasks.

| Component | Description |

|---|---|

| Motor | The powerhouse that drives the cutting mechanism, providing the necessary speed and torque. |

| Blade | The primary tool used for cutting through materials, available in various sizes and types for different applications. |

| Base | A sturdy platform that supports the entire assembly and provides stability during operation. |

| Table | The surface where materials are placed for cutting, often adjustable to accommodate different angles and lengths. |

| Fence | A guide that helps align materials accurately for straight cuts, enhancing precision. |

| Handle | The grip used to maneuver the equipment, allowing for better control and safety during operation. |

| Safety Guard | A protective cover that shields the user from debris and potential hazards while cutting. |

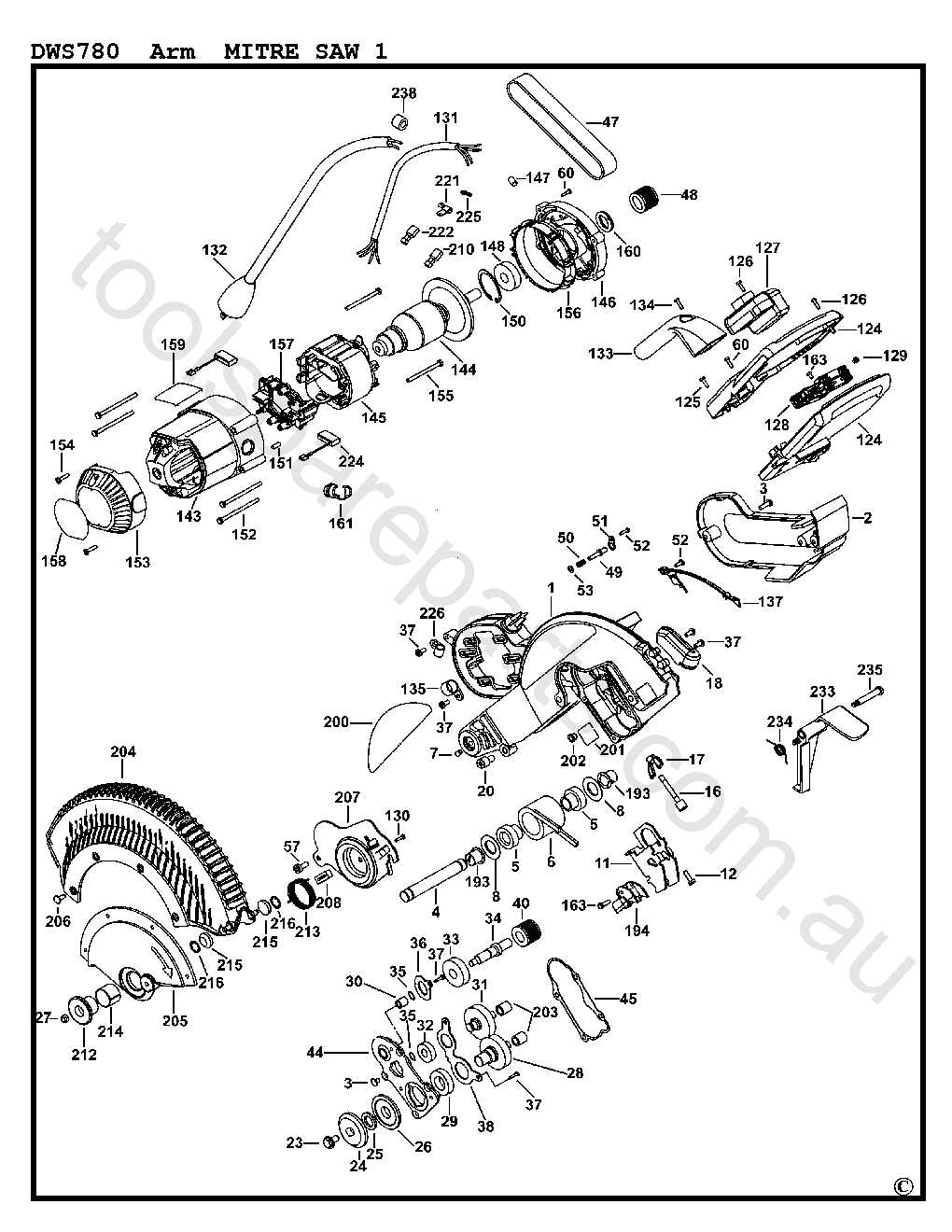

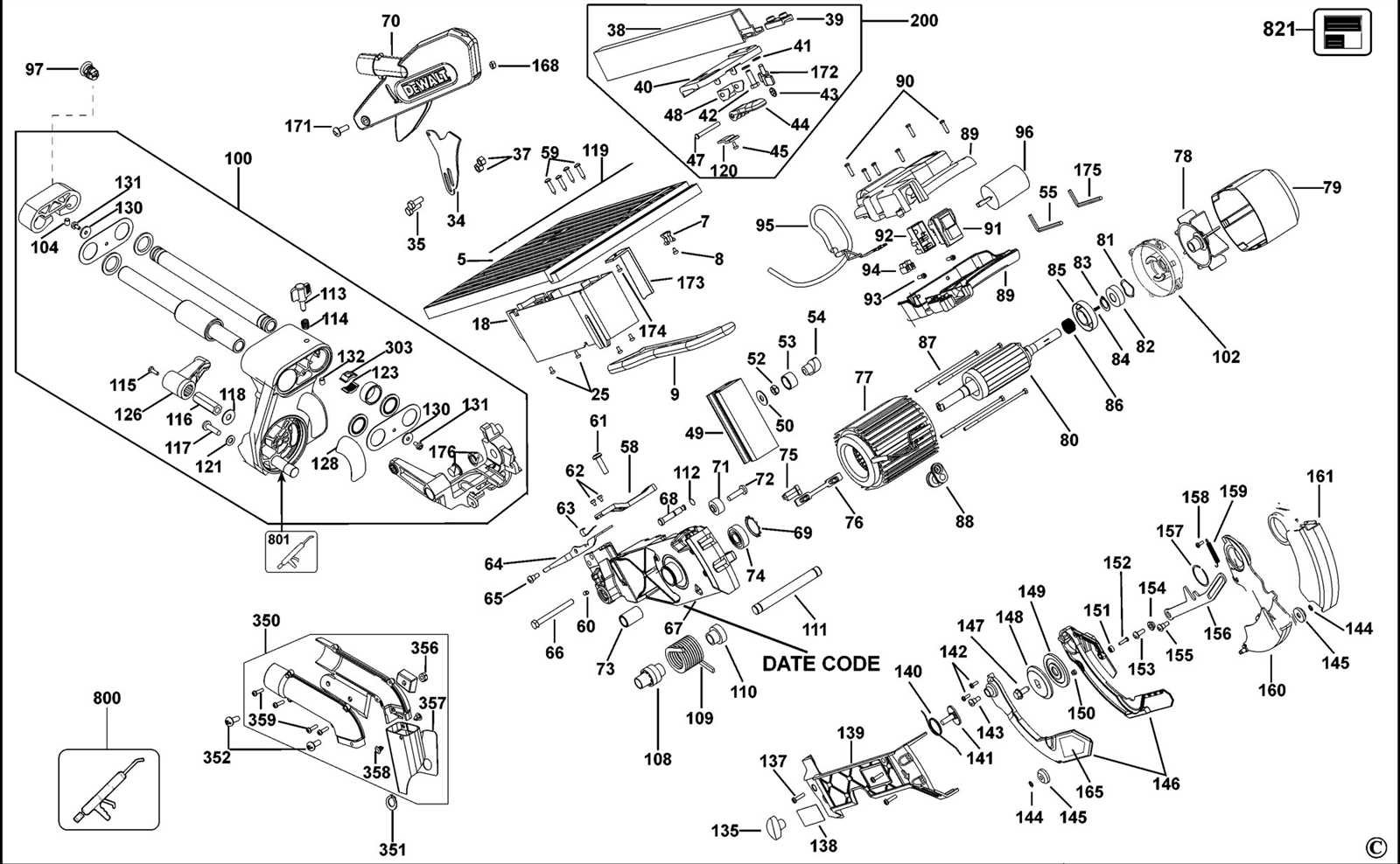

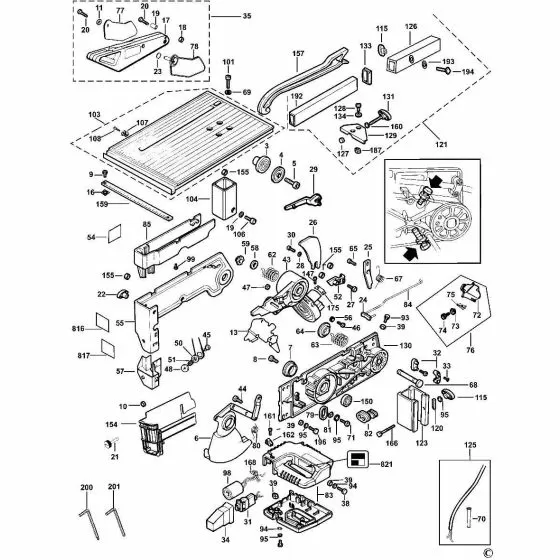

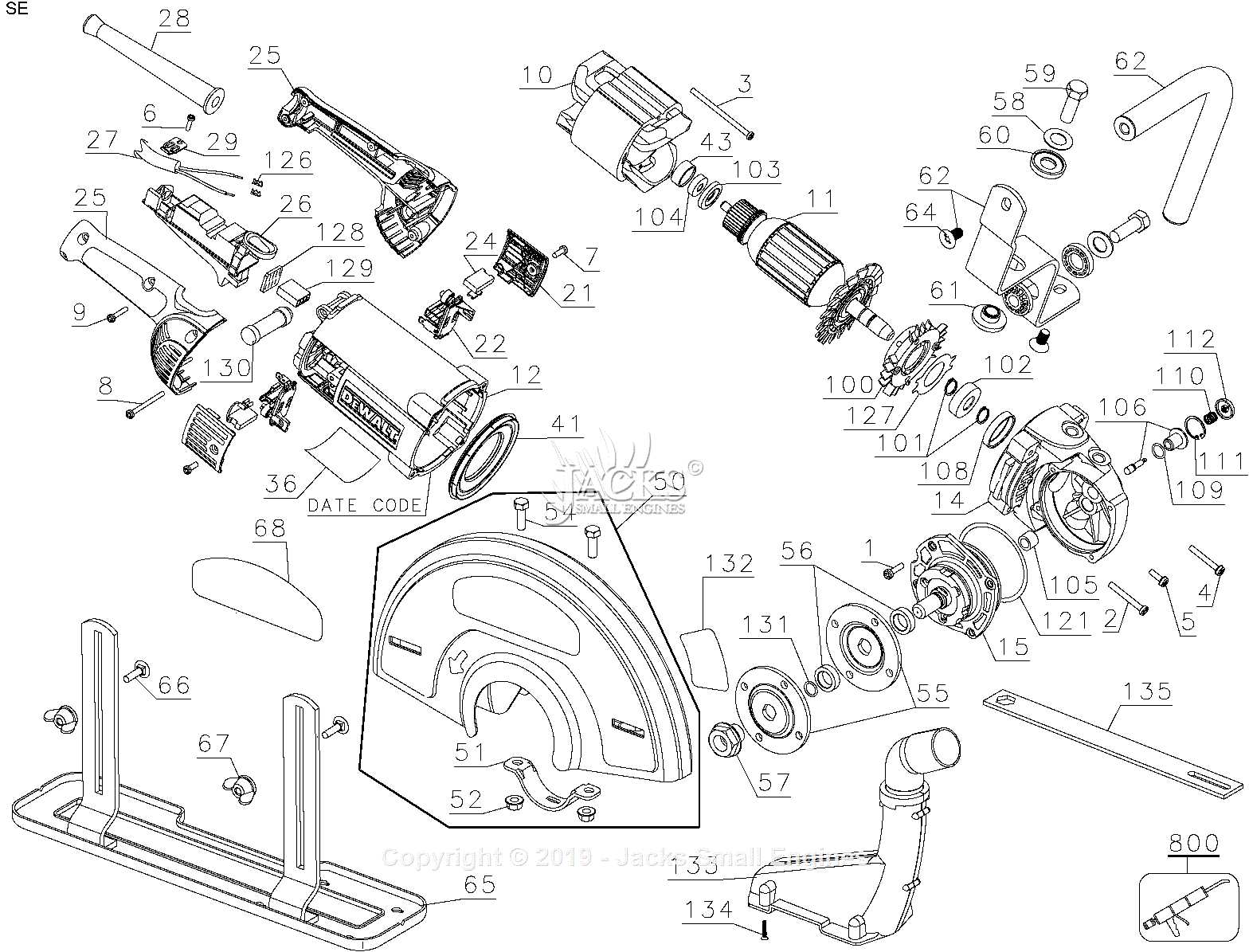

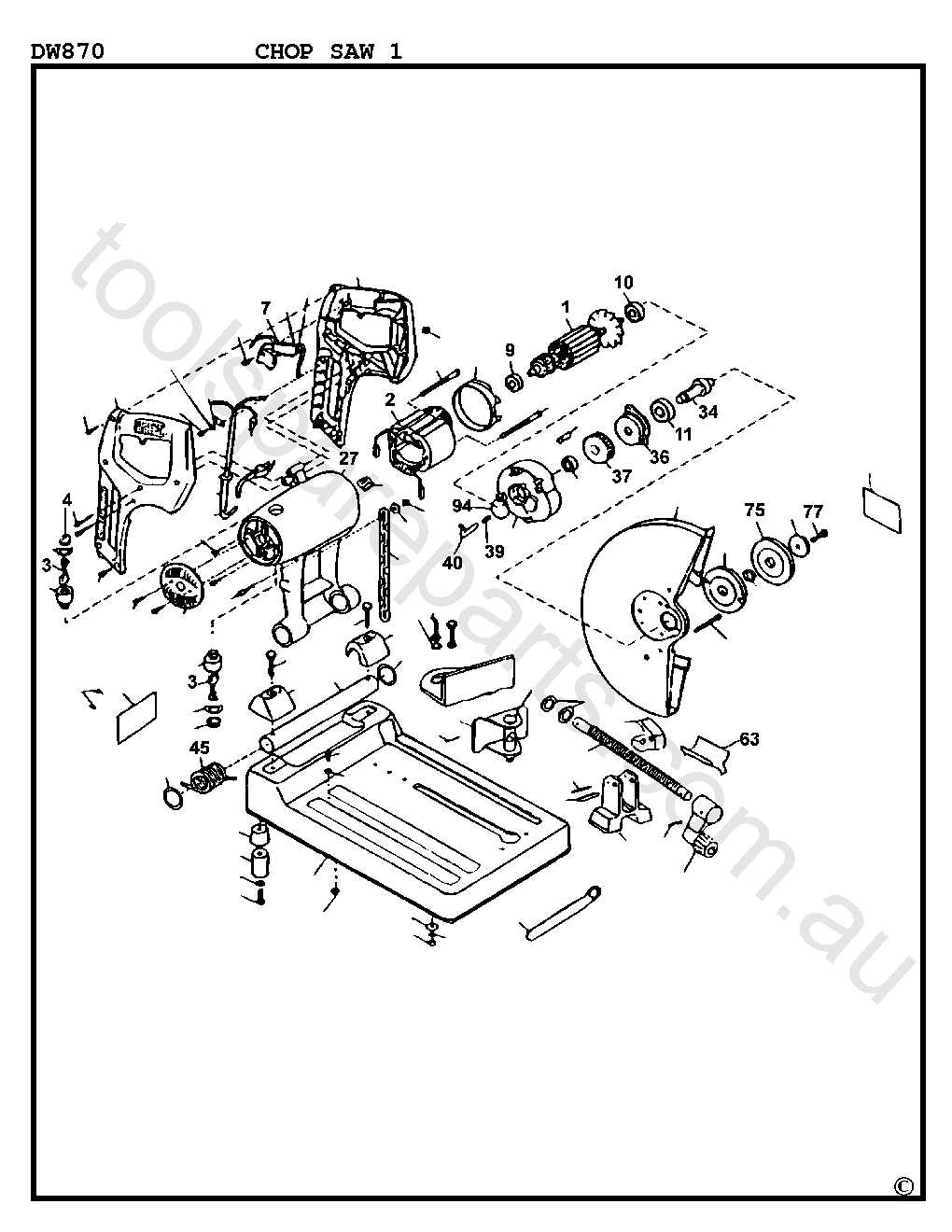

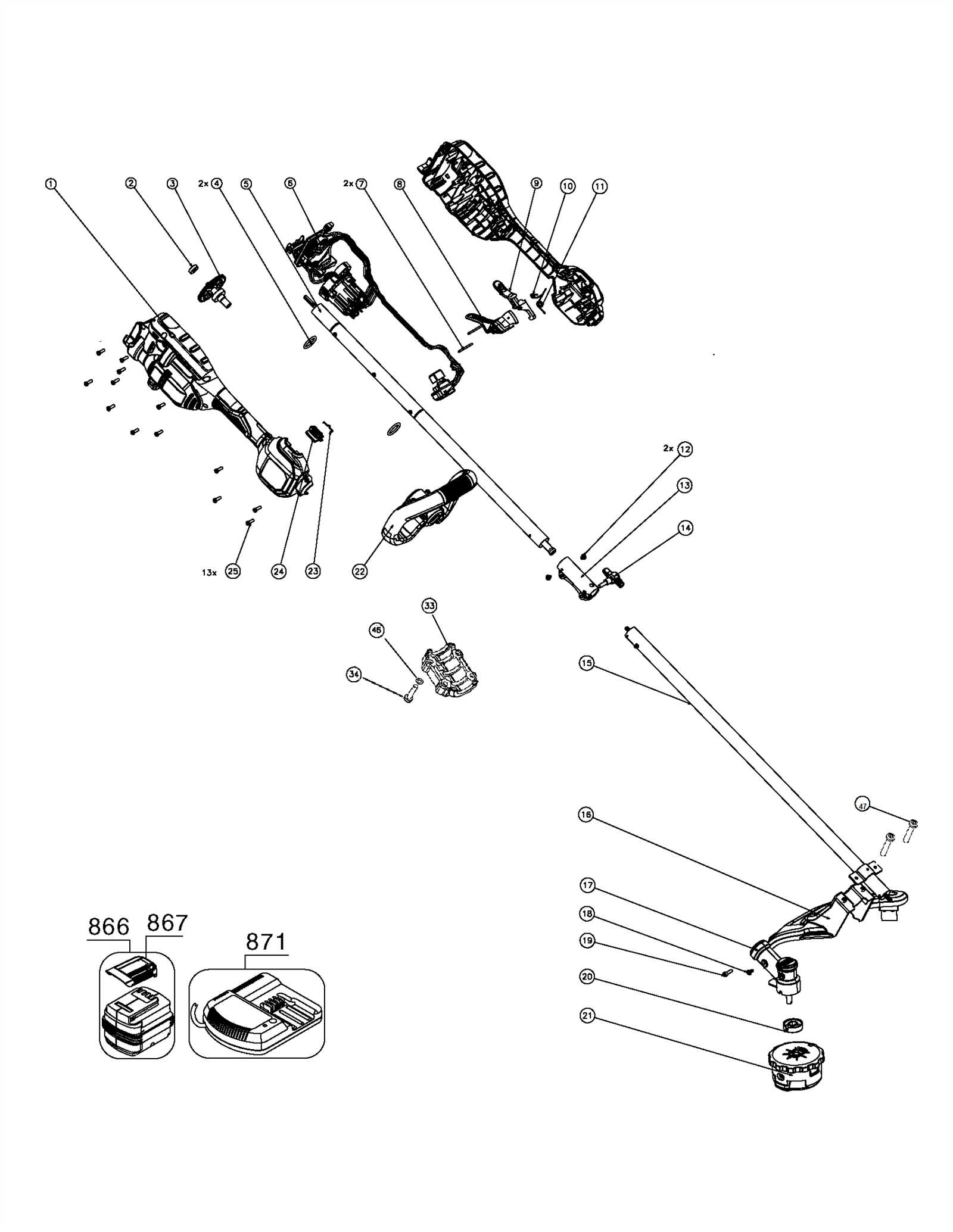

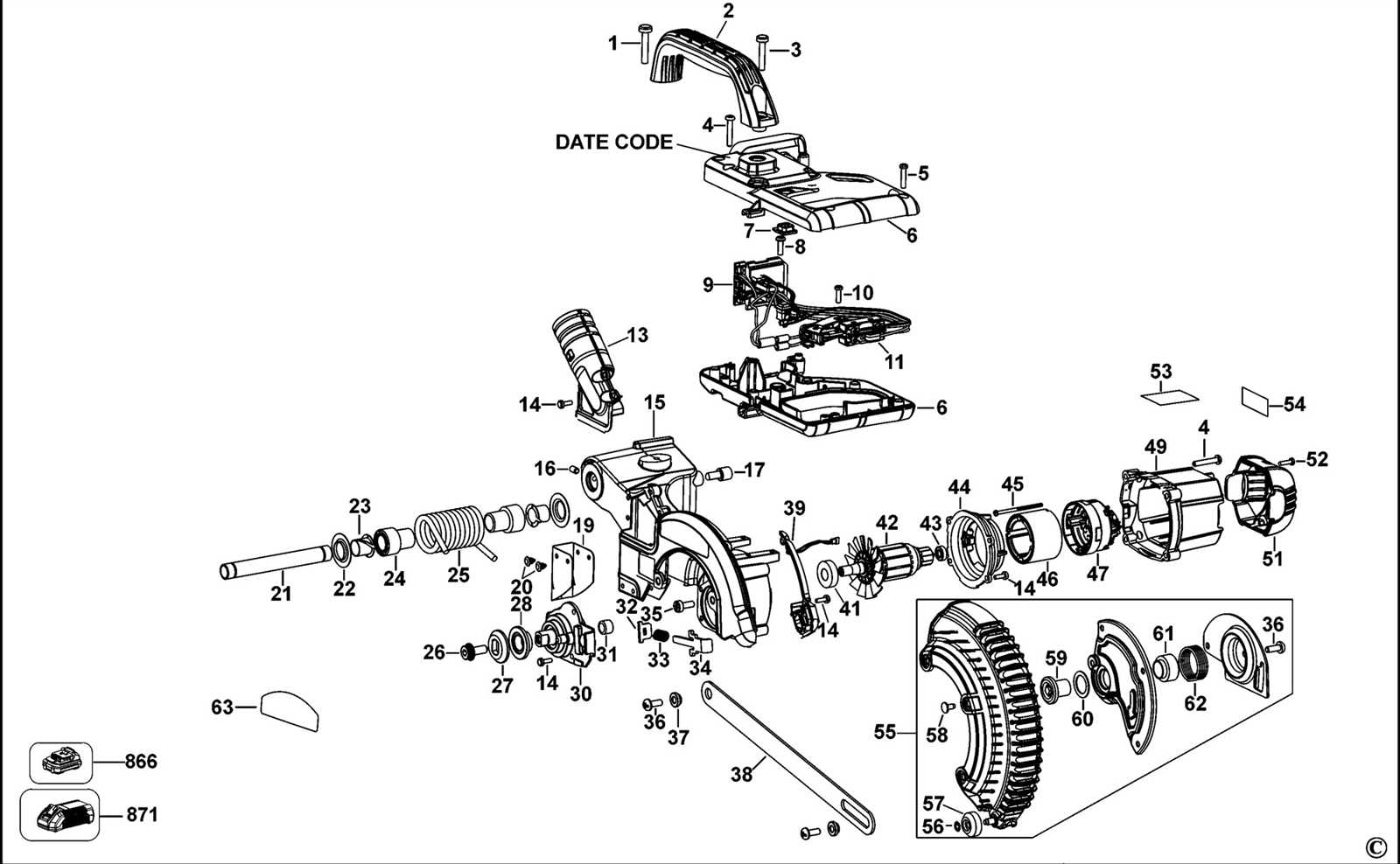

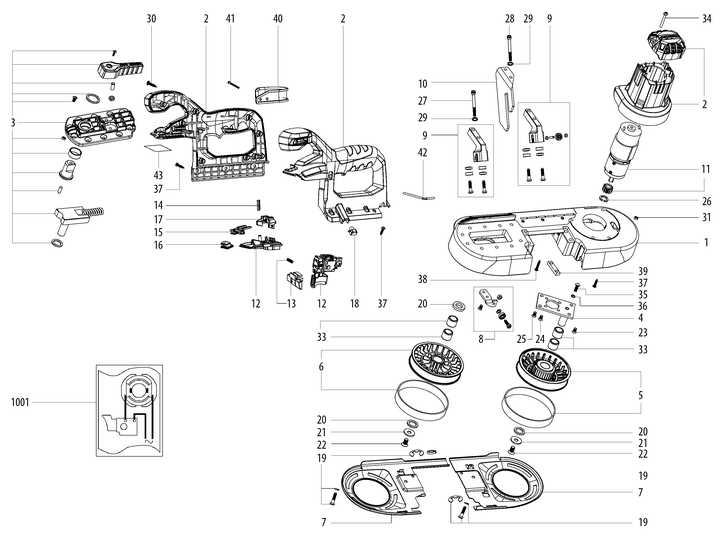

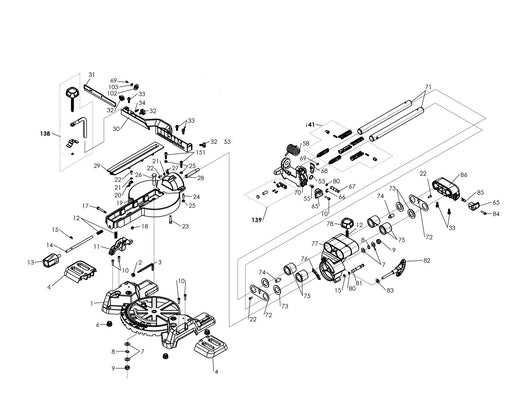

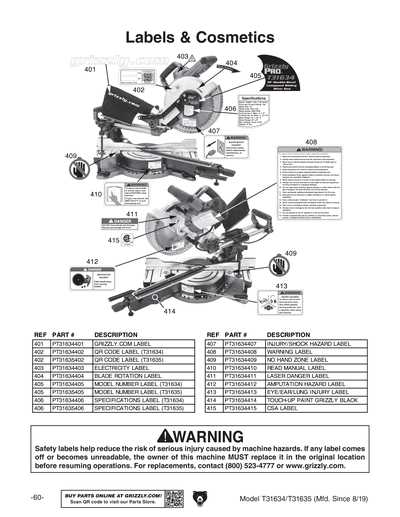

Visual Guide to Dewalt Parts

This section offers an insightful overview of components and their functions within your equipment. Understanding these elements is crucial for effective maintenance and optimal performance. A well-structured visual reference can enhance your familiarity with each item, allowing for smoother operation and repairs.

Key Components Overview

Each tool consists of several essential elements, including the motor assembly, base, and cutting mechanism. Familiarizing yourself with these parts will help you identify potential issues and ensure longevity. Regular inspection and proper handling of these components can significantly reduce wear and tear, ultimately improving efficiency.

Maintenance and Replacement

Regular upkeep is vital for sustaining functionality. Knowing how to replace worn-out items is essential for maintaining peak performance. A visual reference not only simplifies the identification of these elements but also guides you through the replacement process, ensuring you have the right tools and techniques at your disposal.

Identifying Essential Replacement Parts

Understanding the key components of a cutting tool is crucial for maintaining its efficiency and longevity. Recognizing when specific elements require replacement can significantly enhance performance and safety during operation.

Common Components to Monitor

- Blades: Essential for achieving precise cuts; check for wear and damage.

- Motor: The powerhouse of the tool; listen for unusual noises or decreased power.

- Base: Provides stability; ensure it is intact and free from cracks.

- Guards: Safety features that prevent accidents; inspect for any breaks or misalignments.

Signs of Wear and Tear

- Inconsistent cutting performance.

- Excessive vibration during use.

- Visible damage on cutting edges.

- Frequent overheating of the tool.

Maintenance Tips for Longevity

Proper care and regular upkeep of your equipment can significantly enhance its lifespan and performance. By following a few essential guidelines, you can ensure that your tools remain reliable and effective over time.

| Tip | Description |

|---|---|

| Regular Cleaning | Keep the equipment free from dust and debris to prevent overheating and maintain optimal performance. |

| Inspect Components | Frequent checks on vital components help identify wear and tear, allowing for timely replacements. |

| Lubrication | Apply appropriate lubricants to moving parts to reduce friction and enhance efficiency. |

| Correct Storage | Store tools in a dry, safe environment to prevent rust and damage. |

| Follow Manufacturer Guidelines | Adhere to specific maintenance instructions provided by the manufacturer for optimal care. |

How to Troubleshoot Issues

Identifying and resolving problems with power tools can significantly enhance their performance and longevity. By following a systematic approach, users can pinpoint malfunctions and apply effective solutions to restore functionality.

1. Examine the Power Source: Ensure that the electrical supply is functioning correctly. Check for tripped circuit breakers or faulty outlets.

2. Inspect the Blades: Dull or damaged cutting edges can lead to poor performance. Regularly examine and replace blades as necessary.

3. Clean and Maintain: Accumulated debris can hinder operation. Regular cleaning helps maintain optimal performance.

4. Check for Loose Connections: Loose wires or components can cause operational issues. Tighten any visible connections and ensure secure fittings.

5. Consult the Manual: User manuals often provide troubleshooting sections tailored to specific models, offering valuable insights into common issues.

Ordering Parts Online Effectively

In today’s digital age, acquiring components for tools and equipment has become increasingly accessible through online platforms. However, navigating this process can sometimes be challenging. Understanding the key aspects of ordering parts efficiently can save time and ensure that you receive the correct items needed for your projects.

Research and Verification

Before placing an order, it is crucial to conduct thorough research. Identify the specific item required and verify its compatibility with your equipment. Reading reviews and checking specifications can provide insights into the quality and functionality of the component.

Utilizing Reliable Sources

Selecting trustworthy websites is vital to a successful purchase. Look for reputable suppliers that offer detailed descriptions, diagrams, and customer support. Consider using the following table to compare different online retailers:

| Website | Reputation | Customer Support | Shipping Options |

|---|---|---|---|

| Site A | High | Available | Standard, Express |

| Site B | Medium | Limited | Standard |

| Site C | High | Available | Standard, International |

By following these steps and using reliable platforms, you can streamline your ordering process and ensure you receive the correct components promptly.

Compatibility with Other Models

This section explores how specific components can interchange between various tools, highlighting their shared features and potential uses. Understanding these relationships can enhance versatility and efficiency in your projects.

Interchangeable Components: Many elements are designed to be compatible across different brands, allowing for greater flexibility. This compatibility can save both time and money when seeking replacements or upgrades.

Model Variations: It’s essential to note that not all models will have identical specifications, so always check compatibility before purchasing. Doing so ensures optimal performance and safety in operation.

Benefits of Compatibility: Utilizing compatible parts can simplify maintenance and repair processes. Additionally, it can provide opportunities to improve tool functionality by integrating high-quality components from different manufacturers.

DIY Repair vs. Professional Help

When it comes to fixing machinery or tools, individuals often face the choice between tackling the repair themselves or seeking assistance from a skilled technician. Each option has its advantages and drawbacks, depending on factors such as complexity, cost, and personal expertise. Understanding these aspects can help in making an informed decision that aligns with your needs.

Advantages of DIY Repairs

Opting for a do-it-yourself approach can be highly rewarding. It offers the opportunity to learn new skills, save money, and gain a sense of accomplishment. Many enthusiasts find that engaging directly with the equipment enhances their understanding and ability to troubleshoot future issues. Moreover, it can be a quicker option if parts are readily available and the problem is straightforward.

Benefits of Professional Assistance

On the other hand, enlisting the help of a professional can ensure that the job is done correctly and efficiently. Experts bring experience and specialized tools that may not be accessible to the average person. Additionally, relying on a technician can prevent potential mishaps that could arise from inexperience, ultimately saving time and reducing stress.

Cost Considerations for Replacements

When it comes to maintaining power tools, budgeting for replacements is essential. Understanding the various factors that influence costs can help in making informed decisions and ensuring that the investment in equipment remains manageable over time.

Factors Influencing Replacement Costs

Several elements play a crucial role in determining the expenses associated with replacements. These include the quality of the components, brand reputation, and availability of compatible options. Higher-quality components often come at a premium, but they can provide enhanced durability and performance.

Budgeting Tips

To effectively manage replacement costs, consider the following strategies:

| Tip | Description |

|---|---|

| Research Options | Investigate different brands and models to find the best value for money. |

| Buy in Bulk | Purchasing multiple items at once can often lead to discounts. |

| Look for Sales | Take advantage of seasonal promotions or clearance events. |

| Consider Used Items | Refurbished or gently used components may provide significant savings. |

By carefully evaluating these factors and employing strategic budgeting, one can minimize the financial impact of necessary replacements and maintain the efficiency of their equipment.

Where to Find Detailed Diagrams

Locating comprehensive illustrations for tools can significantly aid in understanding their components and functions. Various resources provide in-depth visual guides that can assist users in maintenance and repair tasks.

Online Resources

Several websites offer extensive collections of schematics and manuals. These platforms often feature user-friendly interfaces that make navigation straightforward.

Physical Manuals

In addition to digital options, many manufacturers provide printed guides with their products. These documents are valuable for users who prefer traditional methods of reference.

| Resource Type | Examples |

|---|---|

| Online Platforms | Manufacturer websites, repair forums |

| Physical Manuals | User guides, repair books |