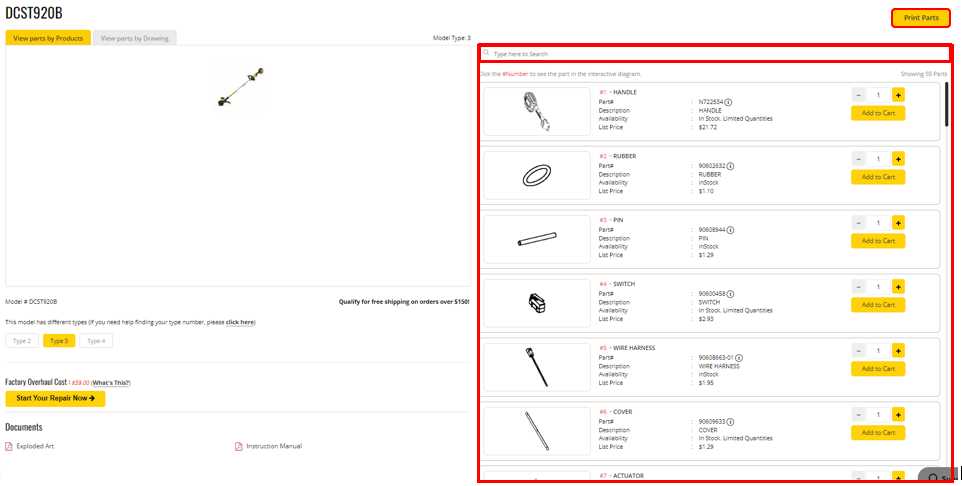

Dewalt DCPR320 Parts Breakdown Guide

The structure of technical devices often includes numerous integral elements, each designed to ensure optimal performance and longevity. Understanding the layout of these elements is crucial for proper maintenance and repair work, which can enhance the overall functionality of the equipment.

In many cases, having a clear visualization of these components can make the process of replacement or adjustment significantly easier. By familiarizing yourself with the internal structure, you can efficiently diagnose any issues and apply the appropriate solutions.

In the following guide, we will explore the key aspects and organization of crucial components, providing a detailed look at their placement and role within the system. This knowledge can aid both professionals and enthusiasts in managing and maintaining their tools effectively.

Overview and Key Features

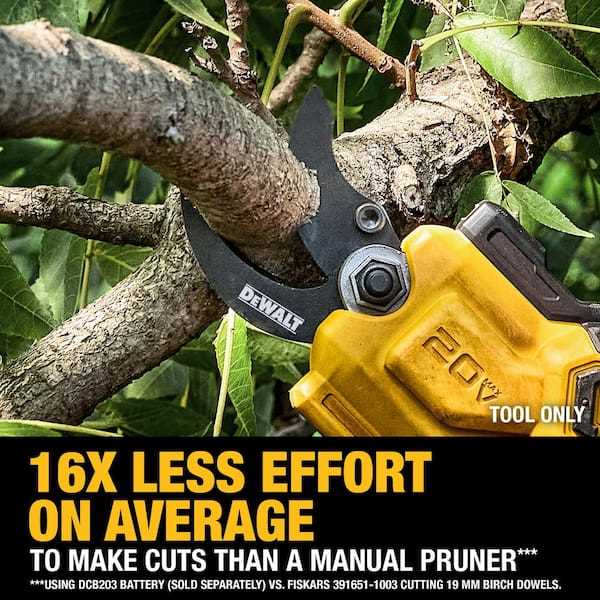

This versatile tool offers an excellent combination of power and precision, designed to handle various tasks efficiently. Its compact size and ergonomic design ensure comfortable handling, even during extended periods of use, making it an ideal choice for both professional and personal projects.

Below is a breakdown of its main characteristics:

| Feature | Description |

|---|---|

| Motor Performance | Delivers high-speed output, providing optimal performance in challenging environments. |

| Battery Efficiency | Equipped with advanced battery technology for prolonged operation and quick recharge capabilities. |

| Build Quality | Crafted with durable materials, ensuring long-lasting use and resistance to wear and tear. |

| Precision Control | Offers enhanced control for more accurate and detailed work, reducing mistakes during operation. |

Exploring the Essential Components

Understanding the key elements that make up a high-performance tool is crucial for ensuring its optimal functionality. Each piece plays a significant role in maintaining efficiency, durability, and ease of use. By focusing on these primary components, one can gain a clearer view of how the equipment operates as a whole.

From the driving mechanism to the handling structure, each element contributes to the overall reliability of the tool. These parts are intricately designed to work together, providing a smooth and effective performance that meets the demands of various tasks. Knowing these vital components allows users to identify areas for maintenance or replacement when necessary.

Guide to Blade Assembly

The process of attaching and securing the cutting component requires attention to detail for proper functionality. Ensuring that the blade is positioned and fastened correctly is key to maintaining optimal performance and safety during use.

Preparing the Assembly

Before beginning, make sure that all necessary tools are readily available and that the working area is clean and well-lit. It’s essential to inspect the cutting piece for any signs of wear or damage to avoid issues during assembly.

Step-by-Step Instructions

First, align the blade carefully with the central mounting point. Ensure that it fits securely and sits flush with the surface. Next, use the designated fasteners to tighten it in place, avoiding overtightening, which can cause strain or damage. Once everything is in position, double-check the alignment to guarantee smooth operation.

Battery Pack Configuration and Maintenance

Proper configuration and upkeep of the power cell system are critical for ensuring consistent performance and extending its lifespan. Regular inspection and adherence to maintenance guidelines can prevent potential issues and improve operational efficiency.

- Cell Arrangement: Ensure the correct alignment of the cells within the pack to maintain optimal energy flow and prevent overheating.

- Charging Practices: Always follow recommended charging cycles. Avoid overcharging, which can degrade the battery’s capacity over time.

- Storage Conditions: Store the unit in a dry, cool environment. Excessive heat or moisture can damage the cells and reduce overall efficiency.

- Regular Checks: Periodically inspect for any signs of wear, such as swelling or leaks, and replace components as necessary.

Following these guidelines will help preserve the functionality of the power system, ensuring reliable performance across multiple uses.

Understanding the Motor System

The motor system is the core component responsible for powering various devices and ensuring their smooth operation. It transforms electrical energy into mechanical movement, allowing for efficient functionality. Understanding how this system works is essential for troubleshooting and maintaining equipment.

Key Components of the Motor

The motor system consists of several vital elements, including the rotor, stator, and windings. These parts work together to generate the necessary motion. The rotor rotates within the stator, while the windings help convert electrical energy into mechanical power.

Maintenance and Efficiency

Proper care of the motor system ensures longevity and efficiency. Regular inspection of key components, such as the bearings and windings, can prevent wear and tear. Maintaining optimal conditions not only enhances performance but also extends the lifespan of the device.

Handle and Control Panel Breakdown

The handle and control panel of this tool are essential for ensuring smooth and precise operation. Understanding the structure and functionality of these components helps improve usability and extends the overall lifespan of the equipment. This section provides a detailed look into how these elements are constructed and how they contribute to efficient handling and control.

Handle Structure

The handle is designed to provide a comfortable grip, allowing for better maneuverability during operation. Its ergonomic shape helps reduce strain on the user’s hands, ensuring a secure hold even during prolonged use. Additionally, the material used in its construction enhances durability and provides a non-slip surface.

Control Panel Features

The control panel is equipped with essential switches and indicators that allow for easy adjustments and monitoring during operation. Each component of the panel is strategically placed to offer intuitive access, ensuring smooth transitions between different settings. The layout is designed to simplify the overall control process, enabling a more seamless user experience.

Wiring Diagram and Electrical Parts

The electrical layout of a device is crucial for understanding its functionality and maintenance. A comprehensive overview of the connections and components ensures proper assembly and troubleshooting. This section delves into the essential elements of the electrical system, providing insight into their roles and interconnections.

Components Overview: The electrical system typically includes various elements such as switches, connectors, and circuit boards. Each part serves a specific purpose, contributing to the overall performance of the equipment. Understanding how these components interact is vital for efficient repairs and modifications.

Connection Insights: Proper wiring is essential for optimal performance. Clear identification of each connection point helps in maintaining the integrity of the electrical flow. Users should familiarize themselves with the layout to ensure safe and effective handling of the device during repairs or upgrades.

Tips for Replacing Key Parts

When it comes to maintaining your equipment, knowing how to effectively replace essential components can greatly enhance its performance and longevity. This guide provides practical advice to ensure a smooth and efficient replacement process.

Before beginning, gather all necessary tools and have the replacement components ready. Proper preparation can save time and reduce frustration during the repair process. Always consult the user manual for guidance specific to your model, as this can provide valuable insights on the best practices for replacement.

Here are some useful tips to keep in mind:

| Tip | Description |

|---|---|

| 1. Turn Off Power | Ensure the device is completely powered down to prevent any accidents. |

| 2. Use the Right Tools | Select the appropriate tools to avoid damaging the equipment during replacement. |

| 3. Take Notes | Document the disassembly process to make reassembly easier. |

| 4. Clean the Area | Keep your workspace tidy to avoid losing small components. |

| 5. Double-Check Compatibility | Verify that the new components match the specifications required for your equipment. |

By following these steps, you can ensure a successful replacement of vital components, allowing your equipment to function optimally.

Deck and Frame Structure Analysis

The analysis of the deck and frame structure is crucial for ensuring stability and durability in various applications. This section aims to explore the fundamental components, their interrelationships, and how they contribute to the overall integrity of the assembly. Understanding the roles of different elements can enhance performance and longevity, leading to effective design and construction practices.

Key aspects to consider include the materials used, the load-bearing capabilities, and the construction techniques employed. By examining these factors, one can identify potential weaknesses and areas for improvement in the structural framework.

| Component | Function | Material |

|---|---|---|

| Joists | Support the deck surface and distribute loads | Wood, Steel, or Composite |

| Beams | Carry the load from the joists and transfer it to the supports | Steel or Engineered Wood |

| Decking | Provides the walking surface and protects underlying components | Composite, Wood, or PVC |

| Support Posts | Uphold the beams and help maintain structural stability | Wood or Metal |

A comprehensive understanding of these elements allows for better planning and execution of construction projects, ensuring that the final product meets safety standards and user expectations.

Troubleshooting Common Component Issues

Understanding and resolving common issues with equipment components can significantly enhance performance and extend the lifespan of your tools. This section provides guidance on identifying typical problems and their potential solutions, enabling users to maintain their devices effectively.

When faced with malfunctions, consider the following common issues:

- Power Failures: Ensure that the power source is functioning correctly and all connections are secure.

- Overheating: Check for obstructions that may restrict airflow and inspect for worn or damaged parts.

- Noisy Operation: Investigate any loose components or damaged bearings that could contribute to excessive noise.

- Inconsistent Performance: Evaluate the settings and ensure that components are properly calibrated and free from debris.

For each of these issues, here are some recommended steps:

- Begin with a thorough inspection of the device to identify any visible signs of wear or damage.

- Refer to the user manual for specific troubleshooting steps tailored to your equipment.

- If necessary, replace any faulty components with high-quality substitutes to restore optimal functionality.

- Test the equipment after any adjustments to ensure that the problem has been resolved.

By systematically addressing these issues, users can ensure their equipment remains in excellent working condition, ultimately leading to enhanced efficiency and reliability.

Sharpening and Replacing Blades

Maintaining optimal cutting performance requires regular attention to the condition of your tools. Ensuring that blades are sharp and properly aligned not only enhances efficiency but also extends the lifespan of the equipment. This section covers essential practices for sharpening and replacing cutting edges to achieve consistent results.

Sharpening Techniques

To maintain cutting precision, blades should be sharpened frequently. A dull edge can lead to increased friction, which in turn can cause overheating and damage. Employing a sharpening stone or file, you can restore the blade’s edge by following the original bevel angle. Always ensure that the tool is securely held during the sharpening process to prevent accidents.

Replacement Process

When blades become excessively worn or damaged, replacing them is crucial for safe and effective operation. Begin by disconnecting the tool from its power source to ensure safety. Follow the manufacturer’s instructions for removing the old blade, taking care to note the orientation and placement of all components. Once the new blade is secured, perform a brief test run to confirm that it operates smoothly and efficiently. Regularly replacing worn blades will not only improve performance but also reduce the risk of injury.

Identifying Small Parts and Fasteners

Understanding the various components and connectors used in power tools is essential for effective maintenance and repair. These small elements often play a crucial role in ensuring the functionality and longevity of equipment. Familiarizing yourself with their characteristics can simplify the assembly and disassembly processes.

Types of Small Components

Small elements such as screws, nuts, and washers are integral to the operation of many tools. Each type has specific properties that make it suitable for particular applications. Knowing the differences can help in selecting the right component for repairs or replacements.

Fasteners and Their Functions

Fasteners are designed to hold various parts together securely. They come in various shapes and sizes, each serving a unique purpose. Identifying the correct fasteners is crucial for maintaining structural integrity.

| Component Type | Description | Common Use |

|---|---|---|

| Screws | Threaded fasteners for joining materials | Attaching panels, securing components |

| Nuts | Hexagonal pieces that fit onto bolts | Creating strong joints with bolts |

| Washers | Flat discs placed under nuts or screws | Distributing load and preventing loosening |

| Rivets | Permanent mechanical fasteners | Joining metal parts together |

Maintenance Tips for Longevity

Ensuring the durability of your tools requires regular upkeep and attention to detail. By implementing effective care practices, you can significantly extend their lifespan and enhance performance. Regular maintenance not only prevents wear and tear but also keeps your equipment functioning at its best.

Regular Cleaning: Keep your tools clean from dust and debris. Use a soft brush or cloth to remove particles, and avoid using harsh chemicals that may damage surfaces. Regular cleaning helps prevent corrosion and keeps components in optimal condition.

Lubrication: Apply suitable lubricants to moving parts to reduce friction. Regularly check for any signs of wear and replace lubricants as needed to ensure smooth operation.

Inspect for Damage: Frequently examine your equipment for any signs of damage or wear. Early detection of issues can prevent further deterioration and costly repairs. Address any problems immediately to maintain efficiency.

Proper Storage: Store your tools in a dry and secure location. Use protective cases or racks to prevent accidental damage. Proper storage minimizes exposure to environmental factors that can lead to rust or degradation.

By following these maintenance practices, you can ensure that your tools remain reliable and effective for years to come.