Dewalt Drill Parts Diagram for Easy Identification and Repair

In the realm of power tools, comprehending the intricate components and their interrelations is crucial for effective operation and maintenance. Each element plays a vital role in ensuring that the equipment functions smoothly and efficiently, contributing to overall productivity in various tasks. Gaining insight into how these pieces interact can empower users to troubleshoot issues and optimize performance.

When delving into the specific elements of a particular tool, one can uncover a wealth of information that enhances not only practical usage but also safety awareness. Recognizing the individual functionalities allows operators to approach their projects with confidence, knowing they can address potential malfunctions or wear-and-tear proactively.

Additionally, familiarity with the assembly of these tools can significantly reduce downtime, enabling quick repairs and replacements when necessary. Understanding the layout and connection of each component fosters a deeper appreciation for the engineering behind these machines and highlights the importance of proper maintenance practices.

Dewalt Drill Parts Overview

This section provides a comprehensive look at the various components essential for the functioning of power tools. Understanding these elements is crucial for maintenance and performance optimization.

- Motor: The core element that powers the tool.

- Gearbox: Responsible for torque and speed adjustments.

- Chuck: Holds the accessory in place securely.

- Handle: Provides grip and control during operation.

- Trigger: Initiates the tool’s operation.

Familiarity with these components can enhance your ability to troubleshoot and ensure longevity.

Understanding Drill Components

Exploring the inner workings of power tools reveals a fascinating array of components that work together to achieve precision and efficiency. Each element plays a crucial role, contributing to the overall performance and functionality of the device. Gaining insight into these individual parts enhances the understanding of how they interact and operate seamlessly.

Main Elements

Every power tool is composed of several key elements that influence its effectiveness. Understanding these components allows users to troubleshoot issues, perform maintenance, and appreciate the technology behind the tools they use.

| Component | Function |

|---|---|

| Motor | Converts electrical energy into mechanical energy, driving the tool’s functions. |

| Gearbox | Adjusts speed and torque, allowing for varied applications and material handling. |

| Chuck | Holds the accessory securely in place during operation. |

| Battery | Powers the tool, providing mobility and convenience in various settings. |

Importance of Understanding Components

Knowledge of these individual components not only aids in effective tool operation but also empowers users to perform repairs and select the right tool for their specific tasks. This comprehension fosters a deeper appreciation for the engineering that enables precision in work and creativity in projects.

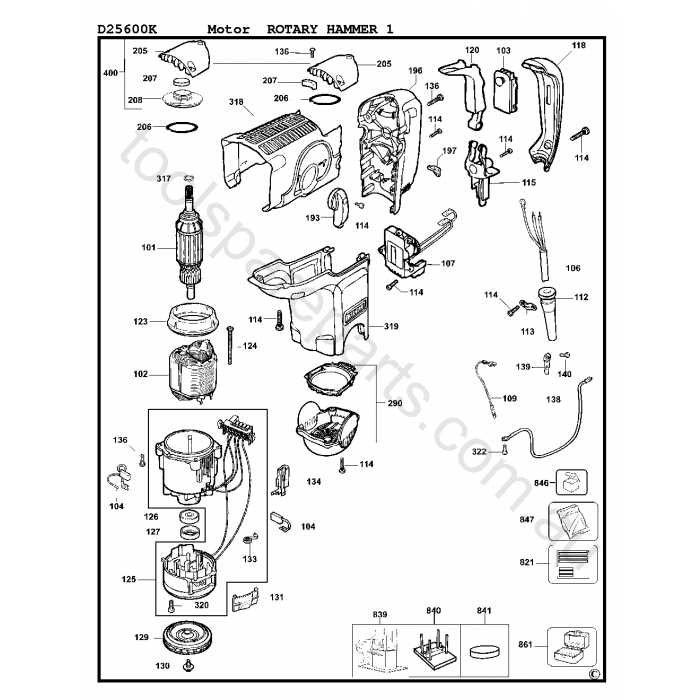

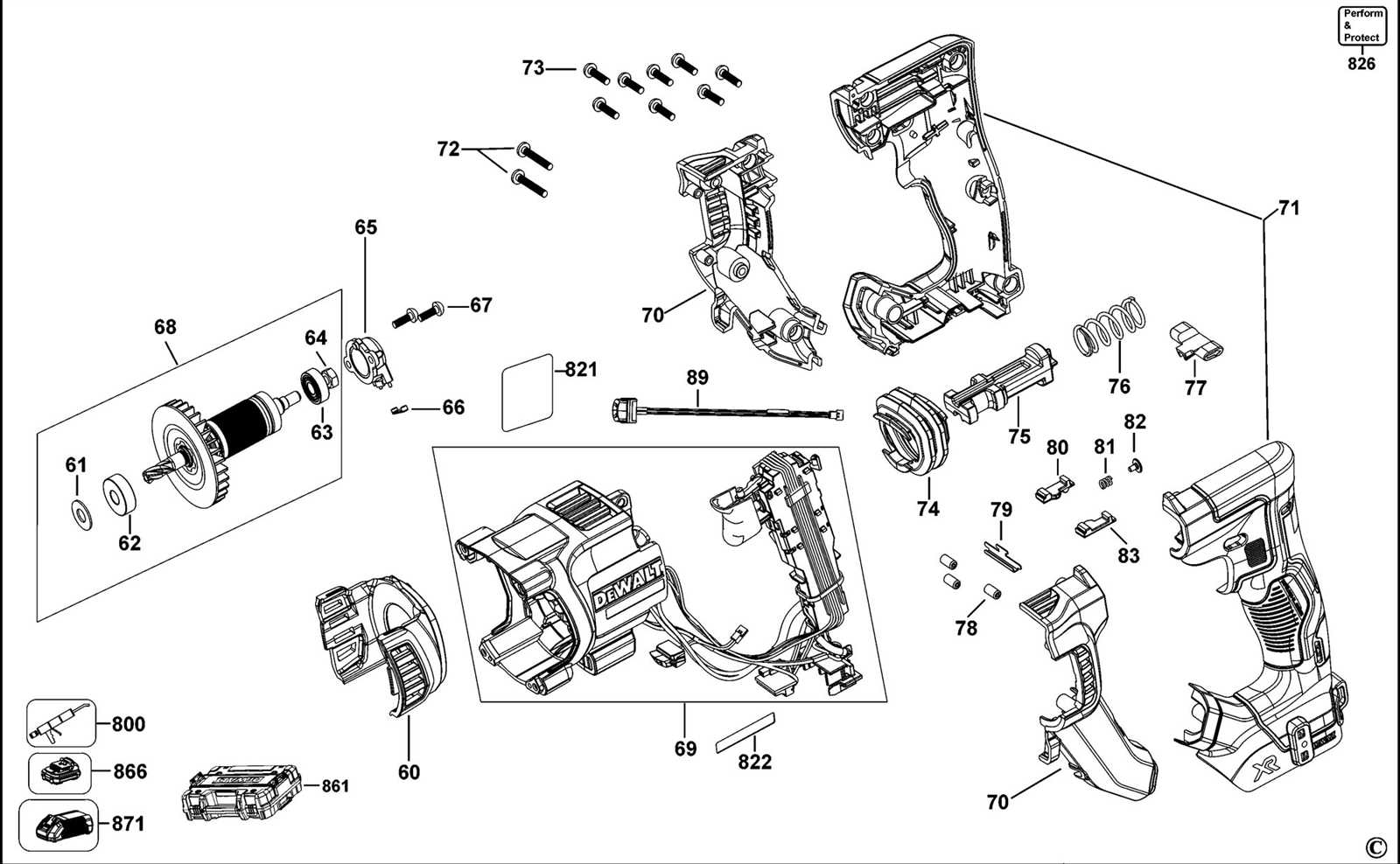

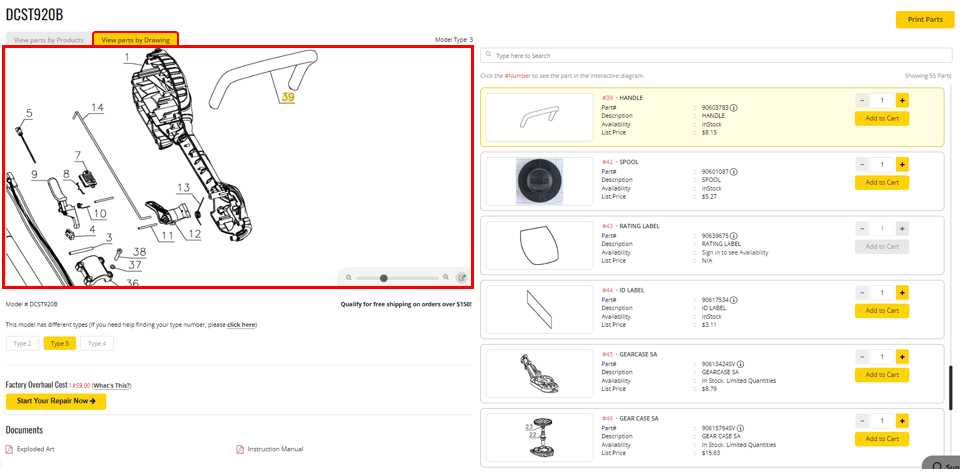

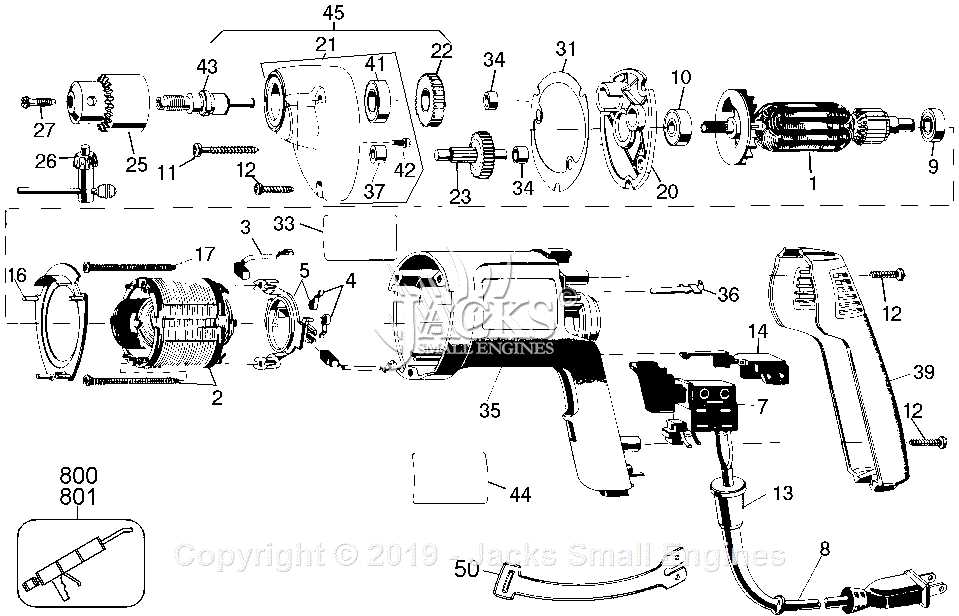

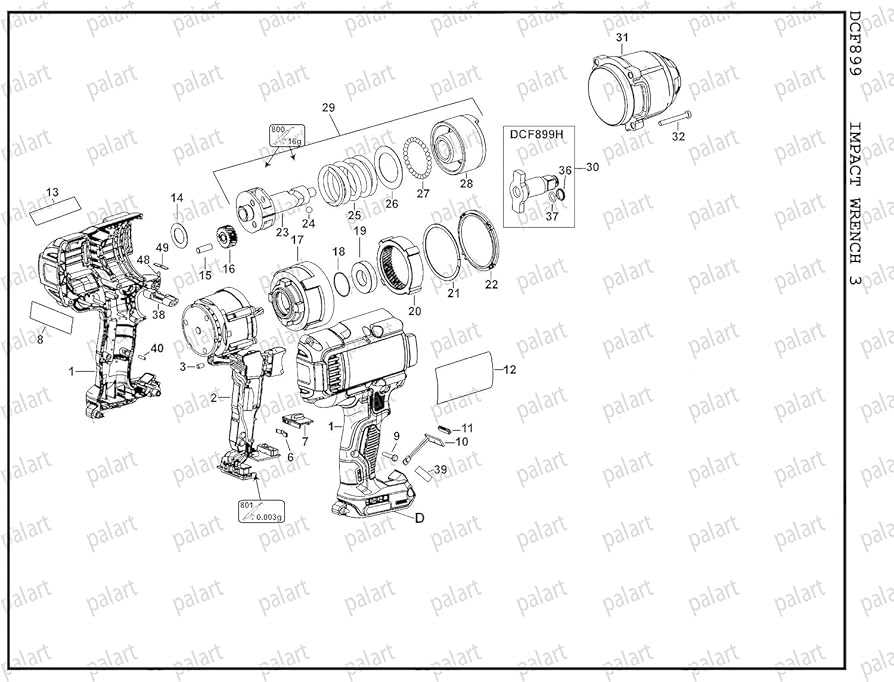

Importance of a Parts Diagram

Understanding the layout and components of a tool is essential for effective maintenance and repair. A visual representation not only simplifies the identification of individual elements but also enhances the overall comprehension of how they function together. This clarity is crucial for both novice and experienced users.

Enhanced Troubleshooting

Having a visual guide allows for quicker diagnosis of issues. Users can easily pinpoint malfunctioning elements, saving time and reducing frustration. A comprehensive overview ensures that no part is overlooked during the assessment process.

Streamlined Repairs

When it comes to fixing or replacing components, a clear illustration serves as a valuable reference. It enables individuals to follow instructions accurately, minimizing errors and ensuring that the assembly is performed correctly.

Common Dewalt Drill Models

This section explores various popular models from a leading brand known for its robust power tools. Each variant offers distinct features tailored for different tasks, making them ideal for both professionals and DIY enthusiasts.

Professional Series

The professional line is designed for heavy-duty applications, providing enhanced torque and durability. These models typically include advanced technology for improved efficiency and longer battery life, catering to demanding environments.

Compact Series

For those seeking portability without sacrificing performance, the compact series delivers excellent results in tight spaces. Lightweight and easy to maneuver, these tools are perfect for everyday tasks and home improvement projects.

Identifying Essential Parts

Understanding the key components of your tool is crucial for effective maintenance and troubleshooting. Each element plays a specific role, contributing to the overall functionality and performance of the equipment. Familiarity with these parts enables users to operate their tools safely and efficiently.

One of the primary components is the motor, which powers the device and dictates its efficiency. Next, the chuck is essential for securing attachments, ensuring that they remain stable during use. Another significant part is the gearbox, responsible for translating motor speed into the desired torque. The trigger provides control over power application, while the housing protects internal mechanisms from external elements.

Lastly, the batteries or power source are critical for providing the necessary energy. Recognizing these fundamental components aids in troubleshooting issues and enhances the longevity of your tool.

Maintenance and Repair Tips

Proper upkeep and timely repairs are essential to prolonging the life of your power tools. Regular maintenance not only enhances performance but also ensures safety during operation. Below are some practical tips to keep your equipment in optimal condition.

Routine Maintenance Steps

- Keep the equipment clean by removing dust and debris after each use.

- Inspect the casing and components for any signs of wear or damage.

- Lubricate moving parts as recommended in the manufacturer’s guidelines.

- Check battery health regularly and clean the terminals to prevent corrosion.

Common Repair Techniques

- Replace worn or damaged accessories promptly to maintain efficiency.

- Test the electrical connections and replace any frayed wires.

- For stubborn jams, carefully disassemble the tool to access the blockage.

- Consult the user manual for specific troubleshooting advice and part replacement procedures.

By following these guidelines, you can ensure your tools operate effectively and safely for years to come.

How to Replace Worn Parts

Maintaining your tools is essential for ensuring optimal performance and longevity. When components become worn or damaged, it’s important to know how to efficiently replace them to restore functionality. This guide outlines the necessary steps to identify and swap out these components with ease.

-

Identify the Worn Components:

- Examine your tool for any signs of wear, such as cracks, discoloration, or reduced efficiency.

- Refer to the user manual for a list of parts and their functions.

-

Gather the Required Tools:

- Ensure you have the appropriate replacement components on hand.

- Prepare necessary tools such as screwdrivers, pliers, and wrenches.

-

Disassemble the Tool:

- Carefully take apart the unit, noting the order of disassembly for reassembly.

- Keep small parts organized to avoid losing them.

-

Replace the Components:

- Remove the damaged items and install the new replacements.

- Ensure all parts fit securely and align correctly.

-

Reassemble and Test:

- Put the tool back together in the reverse order of disassembly.

- Test the functionality to confirm that everything operates smoothly.

By following these steps, you can effectively restore your equipment’s performance and ensure it continues to serve you well.

Tools Needed for Repairs

When tackling maintenance tasks, having the right equipment is essential for effective troubleshooting and repair. The proper tools not only facilitate the process but also ensure safety and efficiency, allowing you to address issues with confidence.

First and foremost, a quality set of screwdrivers is crucial. These come in various sizes and types, enabling you to handle different types of fasteners with ease. Additionally, a reliable wrench set will help you adjust nuts and bolts, providing the leverage needed to make secure connections.

Another vital item is a pair of pliers, which can assist in gripping, twisting, and cutting. They are indispensable for manipulating components that are difficult to access. For more intricate tasks, consider a multimeter, which can help diagnose electrical issues and ensure everything is functioning as intended.

Lastly, a toolbox or organizer is essential for keeping everything in one place, making it easier to find what you need when you need it. With these tools at your disposal, you’ll be well-prepared for any repair job that comes your way.

Benefits of Genuine Parts

Using authentic components in your tools ensures optimal performance and longevity. Genuine items are designed specifically for your equipment, which results in enhanced functionality and reliability. This choice significantly reduces the likelihood of malfunctions and extends the overall lifespan of your machinery.

Quality Assurance

One of the primary advantages of utilizing original components is the assurance of quality. Manufacturers adhere to strict standards, ensuring that each piece meets rigorous performance criteria. As a result, these items undergo extensive testing, providing peace of mind that they will operate effectively under demanding conditions.

Cost-Effectiveness

While the initial investment in authentic items may be higher, the long-term savings are considerable. High-quality components reduce the need for frequent replacements and repairs, ultimately leading to lower maintenance costs. Additionally, using genuine products helps maintain the value of your tools, ensuring they perform at their best over time.

Troubleshooting Common Issues

Understanding frequent challenges with power tools can enhance performance and extend lifespan. By recognizing typical problems, users can effectively address and resolve issues, ensuring optimal functionality.

Common Problems

- Tool not starting

- Reduced power output

- Overheating

- Excessive vibration

Possible Solutions

- Check battery charge or power source.

- Inspect for blockages or worn components.

- Allow cooling time during extended use.

- Ensure all connections are secure and tight.

Upgrading Your Dewalt Drill

Enhancing the performance of your power tool can significantly improve your efficiency and overall results. By integrating new components or features, you can elevate its capabilities, making it more suited to your specific tasks. This guide explores various ways to upgrade your equipment for optimal functionality.

When considering upgrades, it’s essential to identify areas where enhancements can yield the most benefits. Below is a table outlining popular upgrades and their advantages:

| Upgrade Type | Benefits |

|---|---|

| Battery | Increased runtime and faster charging times. |

| Chuck | Improved grip on bits for enhanced precision. |

| Motor | Higher torque for tougher applications. |

| Handle | Better ergonomics and comfort during prolonged use. |

| Speed Settings | Greater versatility for different materials and tasks. |

Choosing the right upgrades depends on your specific needs and the tasks at hand. By carefully selecting and implementing these improvements, you can extend the lifespan and enhance the performance of your essential tools.

Resources for Further Learning

Expanding your knowledge about tools and their components can enhance your skills and confidence in various projects. Understanding the intricacies of these mechanisms can lead to more efficient and effective use. Below are several resources to help you dive deeper into this topic.

Online Tutorials and Videos

- Visit platforms like YouTube for visual guides on assembly and maintenance.

- Check out dedicated websites offering step-by-step tutorials on tool usage.

- Explore forums where enthusiasts share their experiences and solutions.

Books and Manuals

- Look for instructional books that cover tool operation and repair techniques.

- Consult user manuals for detailed information on specific models.

- Find comprehensive guides focusing on general maintenance and safety practices.