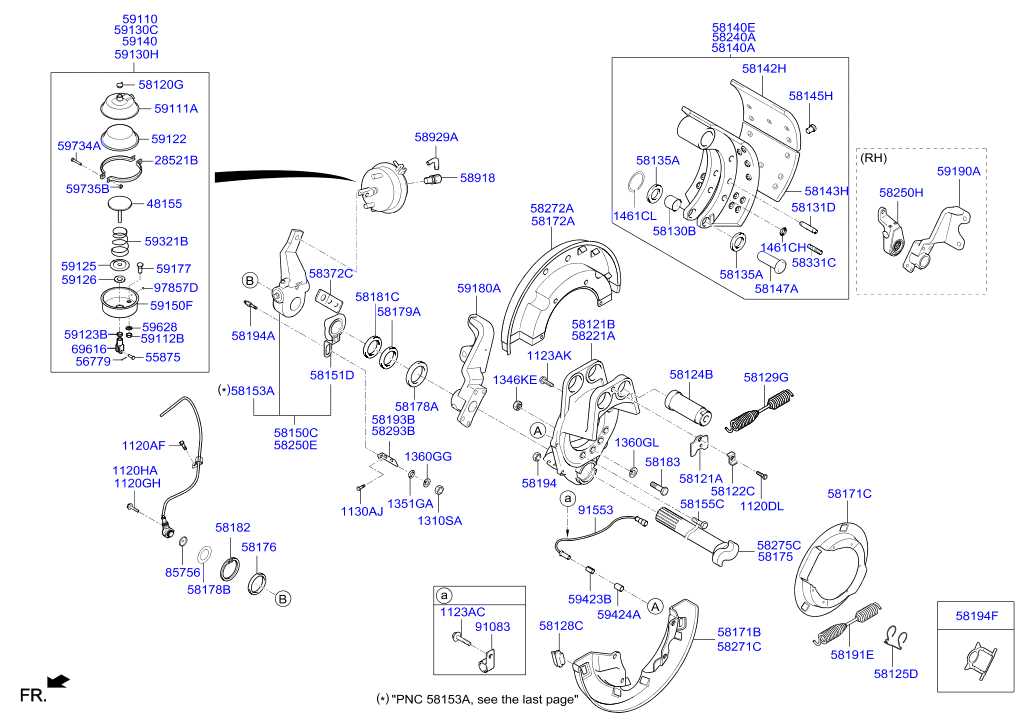

Dewalt DW718 Parts Diagram Overview

When it comes to mastering the intricacies of power equipment, having a clear visual representation of individual elements is essential. Such layouts provide users with the necessary insights to enhance their understanding of assembly, maintenance, and troubleshooting processes. Familiarity with these components not only streamlines repairs but also boosts the overall performance of the machinery.

In any toolkit, knowing the specific functions and relationships between various sections can lead to more efficient usage. These visual guides serve as a valuable resource, allowing enthusiasts and professionals alike to identify parts, ensuring that each component is utilized to its fullest potential. A comprehensive overview can significantly reduce downtime during repairs and maintenance.

Furthermore, recognizing the significance of each element promotes a deeper appreciation for the equipment itself. By delving into the intricate designs and interactions of the machinery, users can develop skills that elevate their proficiency in handling and maintaining their tools. This knowledge fosters confidence, enabling them to tackle challenges head-on.

Dewalt DW718 Parts Overview

This section provides a comprehensive look at the various components that make up a popular power tool model. Understanding the structure and individual elements of this equipment is crucial for both maintenance and repair. Each piece plays a significant role in ensuring optimal performance and longevity.

To begin with, the main assembly includes essential items that contribute to the overall functionality. These elements work in harmony to achieve precise cuts and enhance user safety. Among them, the motor stands out as a critical component, delivering the necessary power for efficient operation.

Additionally, the cutting mechanism is designed to facilitate smooth and accurate cutting actions. The inclusion of various blades and adjustment features allows for versatility in handling different materials. Each blade type is tailored for specific tasks, ensuring that users can achieve their desired results with ease.

Moreover, attention to detail in the support structure contributes to stability and user comfort. Features such as ergonomic handles and adjustable settings enhance usability, making the tool more accessible for extended periods of use. A thorough understanding of these components helps users make informed decisions regarding replacements and upgrades.

In summary, familiarity with the individual elements of this equipment is vital for effective upkeep. This knowledge empowers users to optimize their experience and prolong the lifespan of their tools.

Understanding Key Components

In any power tool, certain essential elements work together to ensure optimal performance and durability. Recognizing these vital parts allows users to make informed decisions regarding maintenance, troubleshooting, and upgrades. This section delves into the critical components that contribute to the functionality and reliability of these machines.

Motor Assembly

The motor assembly serves as the heart of the equipment, converting electrical energy into mechanical energy. Its efficiency directly impacts the tool’s power and speed, making it crucial for a variety of tasks. Regular inspection and maintenance of the motor can significantly extend the lifespan of the tool.

Cutting Mechanism

The cutting mechanism is designed to deliver precision and accuracy in operations. This assembly includes blades and related components that dictate the quality of cuts achieved. Ensuring that these elements are well-maintained and sharp is vital for achieving the desired results and enhancing productivity.

Exploring Assembly Instructions

Proper assembly is crucial for ensuring the functionality and longevity of any tool. This section provides a comprehensive overview of the steps involved in putting together a cutting-edge model. By following the outlined instructions, users can achieve optimal performance and enhance safety during operation.

Essential Components and Their Functions

Understanding each element’s role is vital for successful assembly. Key components typically include the motor, blade holder, and base assembly. Each part interacts with others, contributing to the overall efficiency of the tool. Ensuring that all pieces fit together seamlessly not only improves performance but also minimizes wear and tear over time.

Step-by-Step Assembly Process

Begin by gathering all necessary components and tools to streamline the process. Start with the base, securing it firmly to a stable surface. Next, attach the motor, ensuring that it aligns correctly with the base. Follow by installing the blade holder, paying close attention to the manufacturer’s specifications. Finally, conduct a thorough inspection of the assembled unit to confirm that all parts are securely fastened and functioning as intended.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for ensuring the durability and optimal performance of your tools. Implementing effective maintenance practices can significantly extend their lifespan and improve their efficiency, allowing you to tackle projects with confidence.

To maintain your equipment effectively, consider the following guidelines:

| Maintenance Task | Frequency | Description |

|---|---|---|

| Clean Regularly | After each use | Remove dust, debris, and any residues that could hinder functionality. |

| Inspect Components | Weekly | Check all parts for wear or damage to identify issues before they escalate. |

| Lubricate Moving Parts | Monthly | Apply appropriate lubricants to ensure smooth operation and reduce friction. |

| Sharpen Blades | As needed | Keep blades sharp to ensure precise cutting and minimize strain on the tool. |

| Store Properly | After each use | Keep in a dry, clean environment to prevent rust and damage. |

Following these tips will help you maintain your equipment in top condition, ensuring reliable performance and a longer operational life.

Common Issues and Solutions

Every tool can experience problems over time, impacting its efficiency and functionality. Understanding typical challenges and their corresponding remedies is crucial for maintaining optimal performance. Below are some prevalent issues and practical solutions to enhance your equipment’s longevity.

1. Uneven Cutting: This issue often arises due to dull blades or misalignment. Ensure that the cutting tool is properly aligned and replace the blade if it shows signs of wear.

2. Excessive Vibration: Excessive shaking can indicate loose components or imbalance. Check all screws and bolts for tightness, and inspect the base for stability.

3. Motor Overheating: If the motor gets too hot during use, it could be a sign of overload. Allow the tool to cool down, and consider reducing the workload or checking for any blockages in the motor area.

4. Electrical Issues: Problems with the power supply or damaged cords can hinder operation. Regularly inspect cords for frays and ensure that connections are secure.

5. Dust Accumulation: Dust buildup can affect performance and safety. Regularly clean the equipment, focusing on vents and moving parts, to ensure efficient operation.

Addressing these common issues promptly can help maintain your tool’s functionality and extend its lifespan.

How to Replace Parts Effectively

Replacing components in any power tool requires a systematic approach to ensure smooth operation and longevity. Properly addressing worn or damaged elements can significantly enhance the performance and safety of the equipment. Here are some essential steps to consider when undertaking a replacement task.

- Identify the Issue:

Before initiating any replacement, ascertain the exact problem. This may involve:

- Visual inspections for wear and tear.

- Testing functionality to determine which component is faulty.

- Consulting the manual for troubleshooting guidance.

- Gather Necessary Tools:

Ensure you have all required tools on hand to facilitate a seamless replacement process. Common tools include:

- Screwdrivers (various sizes)

- Wrenches

- Replacement components

- Safety gear (gloves, goggles)

- Follow Manufacturer Instructions:

Refer to the user manual for specific guidance on replacing components. This will provide:

- Step-by-step instructions.

- Safety precautions.

- Any special tools or techniques required.

- Document the Process:

Taking notes or photos during disassembly can help in reassembly. This is particularly useful for:

- Keeping track of screws and small parts.

- Ensuring correct placement of new components.

- Test Functionality:

After completing the replacement, test the tool to ensure proper operation. Check for:

- Unusual noises or vibrations.

- Proper alignment and functionality of new parts.

By following these guidelines, you can effectively manage the replacement of components, ensuring that your equipment operates optimally for years to come.

Tools Required for Repairs

Proper repairs necessitate a selection of essential instruments to ensure efficiency and accuracy. Having the right tools at your disposal not only facilitates the repair process but also enhances safety and effectiveness. Below is a list of necessary tools that can assist in carrying out various repair tasks effectively.

- Screwdrivers: A set of both flathead and Phillips screwdrivers is crucial for loosening and tightening screws.

- Wrenches: Adjustable wrenches and socket sets are ideal for handling nuts and bolts of various sizes.

- Allen Keys: These are needed for hex screws that may be found in the assembly.

- Pliers: A combination of needle-nose and regular pliers will help grip and manipulate parts during repairs.

- Measuring Tools: A tape measure and calipers ensure accurate measurements during disassembly and reassembly.

- Utility Knife: Useful for cutting through various materials or removing damaged parts.

- Cleaning Supplies: Rags and brushes for cleaning components before reassembly.

- Safety Gear: Gloves and goggles are essential to protect against debris and sharp edges during repairs.

Equipped with these tools, you’ll be well-prepared to tackle repairs effectively, ensuring your equipment functions optimally for years to come.

Safety Precautions to Follow

Ensuring safety during the operation of power tools is crucial to prevent accidents and injuries. Following specific guidelines can help create a secure work environment and promote responsible usage of equipment. Here are essential precautions to keep in mind:

- Read the Manual: Familiarize yourself with the equipment by thoroughly reading the user manual before use.

- Wear Protective Gear: Always use appropriate personal protective equipment, such as safety goggles, gloves, and ear protection.

- Check the Work Area: Ensure that the workspace is clean and free from any obstacles or hazards that could lead to accidents.

- Secure Loose Clothing: Avoid wearing loose-fitting clothing or jewelry that could get caught in moving parts.

- Disconnect Power: Always disconnect the power source when changing accessories or making adjustments to the tool.

- Maintain Proper Posture: Stand firmly and maintain a balanced stance while operating the equipment to prevent slips or falls.

- Keep Children Away: Ensure that children and bystanders are kept at a safe distance while you are working.

- Inspect Tools Regularly: Check tools for any signs of damage or wear before use, and perform necessary maintenance as recommended.

By adhering to these safety measures, you can significantly reduce the risk of accidents and ensure a safe and productive working environment.

Comparing DW718 with Similar Models

When evaluating a specific model in the realm of power tools, it is essential to consider how it stacks up against its contemporaries. Various brands offer similar machines, each boasting distinct features and capabilities that cater to different user needs. By comparing specifications, performance, and usability, one can determine which option best suits their requirements.

Key Features to Consider

- Power and Performance: Assess the motor power and cutting capacity. Higher amperage generally translates to better performance in tougher materials.

- Portability: Weight and size play a significant role in user convenience, especially for professionals who transport tools frequently.

- Precision and Accuracy: Look for features that enhance accuracy, such as laser guides or built-in calibration settings.

- Build Quality: Consider the materials used in construction, which can affect durability and longevity.

Similar Models Overview

- Model A: This option features a robust motor and enhanced portability, making it ideal for on-site work.

- Model B: Known for its precision cutting capabilities, it offers advanced features that appeal to professional woodworkers.

- Model C: A budget-friendly alternative that does not compromise on basic functionalities, suitable for DIY enthusiasts.

In conclusion, comparing different models within the same category enables users to make informed decisions based on their specific needs and preferences. Analyzing key features and understanding the strengths of each option can significantly enhance the overall user experience.

Where to Find Replacement Parts

When seeking components for your power tool, knowing where to look can save time and ensure you get the correct items. Various sources provide options for acquiring high-quality replacements, whether you prefer online shopping or visiting local retailers.

Online Retailers

Numerous online platforms specialize in tool accessories, offering a wide selection of components. Consider the following options:

- Manufacturer’s Website: Often the most reliable source, the official website typically features a comprehensive catalog of available replacements.

- Third-Party Retailers: Websites like Amazon, eBay, and specialized tool suppliers often carry a broad range of items, sometimes at competitive prices.

- Parts Suppliers: Websites dedicated solely to replacement items for various brands can be a valuable resource for finding specific components.

Local Stores

For those who prefer to shop in person, local options are available:

- Home Improvement Stores: Major chains frequently stock a selection of common components, making it convenient to find what you need.

- Specialty Tool Shops: These stores may carry hard-to-find items and offer expert advice on compatibility and installation.

- Repair Centers: Some service centers specialize in repairs and may have spare items on hand or be able to order them for you.

Regardless of the source, ensure that you verify the compatibility of any components before making a purchase to avoid any inconveniences during installation.

Customer Reviews and Feedback

This section aims to provide insights from users regarding their experiences with the product, focusing on its performance, reliability, and overall satisfaction. Understanding customer opinions is crucial for potential buyers seeking assurance in their purchase decisions.

Many users have expressed their thoughts about the device’s functionality, highlighting both strengths and areas for improvement. Below is a summary of common feedback themes:

| Aspect | Feedback |

|---|---|

| Performance | Most users appreciate the consistent performance, noting its efficiency in handling various tasks. |

| Durability | Customers often mention the robust construction, indicating it withstands frequent use and challenging conditions. |

| Ease of Use | Many reviews emphasize the intuitive design, making it accessible for both beginners and experienced users. |

| Support | A few users have reported delays in customer service responses, suggesting room for improvement in support systems. |

Frequently Asked Questions

This section addresses common inquiries related to the maintenance and operation of power tools. Here, users can find valuable insights and assistance to enhance their experience and troubleshoot potential issues.

General Inquiries

- What are the essential components of a power tool?

- How can I ensure the longevity of my tool?

- What should I do if I encounter a malfunction?

Maintenance Tips

- Regularly clean the tool after each use.

- Check and replace worn-out components as needed.

- Store the equipment in a dry and secure location.

- Follow the manufacturer’s recommendations for maintenance schedules.