Dewalt DWS715 Parts Diagram Overview

Maintaining and repairing power tools can significantly extend their lifespan and improve performance. Having a clear understanding of the individual elements that make up your equipment is essential for efficient troubleshooting and servicing. This section aims to provide a comprehensive overview of the various components involved in a popular cutting device, allowing users to familiarize themselves with its structure.

Each part plays a crucial role in the overall functionality of the tool, and recognizing how these elements interact can empower users to make informed decisions during maintenance. Whether you’re replacing a worn-out piece or upgrading specific features, knowing the layout of your tool’s internal mechanisms is invaluable. By gaining insights into the assembly and functions of these components, users can enhance their DIY skills and ensure their equipment operates smoothly.

This model is designed for precision and versatility, making it a valuable addition to any toolkit. Its robust construction and advanced functionality cater to both professional and DIY enthusiasts, ensuring reliable performance across various cutting tasks. Understanding its main attributes can help users make the most out of their experience.

Precision Cutting Capabilities

One of the standout characteristics of this equipment is its ability to deliver clean and accurate cuts. The integrated mechanism allows for precise adjustments, ensuring that users achieve their desired angles and lengths with ease.

Durability and Design

The build quality of this tool is noteworthy. It features high-grade materials that not only enhance its longevity but also provide stability during operation. This design ensures that users can tackle heavy-duty tasks without compromising safety or efficiency.

| Feature | Description |

|---|---|

| Cutting Capacity | Designed to handle a variety of materials with ease, providing flexibility in usage. |

| Angle Adjustment | Allows for quick and precise angle changes, accommodating different project needs. |

| Safety Features | Equipped with advanced safety mechanisms to protect users during operation. |

| Portability | Lightweight construction facilitates easy transportation between job sites. |

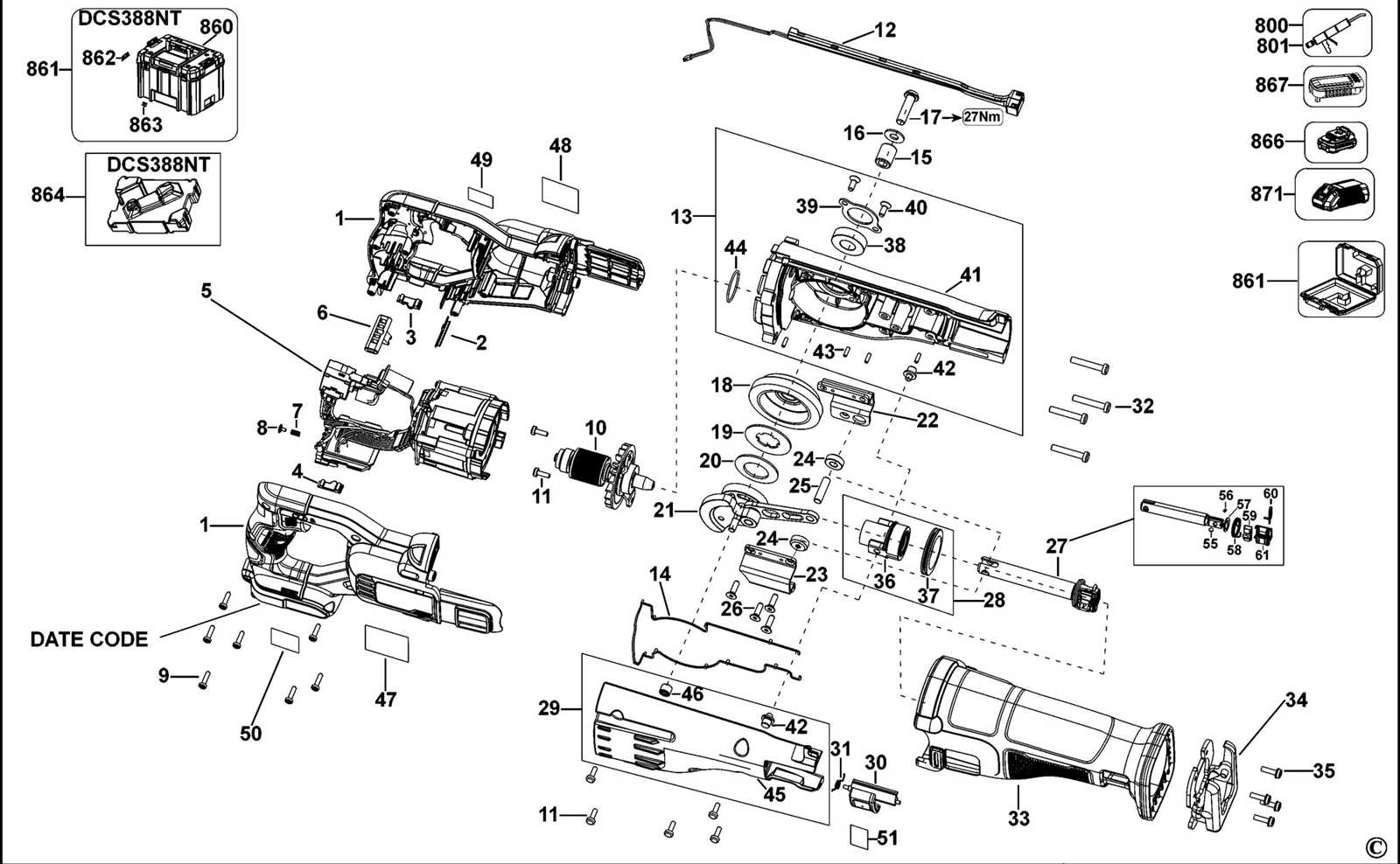

Understanding the Parts Diagram

Grasping the visual representation of components is essential for effective maintenance and repair of machinery. This guide aims to illuminate the layout of the various elements, helping users identify each part’s role and functionality. By familiarizing yourself with this illustration, you can enhance your ability to troubleshoot issues and carry out repairs with confidence.

Key Components and Their Functions

Each section of the illustration highlights specific pieces that work together to ensure optimal performance. Understanding how these elements interact can significantly impact the efficiency of your tool. For instance, the primary motor, which drives the entire mechanism, relies on several smaller components to operate smoothly.

Navigation Tips

When analyzing the visual guide, pay attention to the labels and connections between parts. Color coding or numbering can help you quickly locate the necessary elements when ordering replacements. Recognizing how each segment contributes to the overall functionality will empower you to make informed decisions during repairs.

Essential Components Explained

This section delves into the critical elements that comprise a high-performance cutting tool. Understanding these essential components not only enhances user knowledge but also aids in proper maintenance and troubleshooting. Each part plays a significant role in the overall functionality, ensuring precision and efficiency during operation.

Motor: The motor is the powerhouse of the device, responsible for generating the necessary force to drive the blade. A robust motor contributes to consistent performance and durability, enabling the tool to handle various materials with ease.

Blade: The blade is a vital component that determines the quality of the cut. Different blades are designed for specific applications, such as crosscutting or ripping, and choosing the right blade can significantly affect the outcome of your project.

Base Plate: The base plate provides stability and support during cutting operations. A sturdy base helps maintain accuracy and prevents vibrations that could lead to imprecise cuts, enhancing overall safety and performance.

Adjustable Bevel and Miter Angles: These features allow users to customize the cutting angle, facilitating a range of cuts from simple straight cuts to complex bevels. Mastery of these adjustments is essential for achieving the desired results in various woodworking tasks.

Dust Collection System: An efficient dust collection system helps maintain a clean workspace by capturing debris generated during cutting. This not only promotes safety by reducing hazards but also improves visibility, allowing for better precision.

Understanding these fundamental components will empower users to make informed decisions regarding their equipment, ensuring optimal performance and longevity.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the long-term functionality and performance of your equipment. Regular maintenance not only enhances efficiency but also extends the lifespan of the tool, preventing unexpected breakdowns and costly repairs. Adopting a proactive approach to care can save time and resources, allowing for uninterrupted productivity.

Regular Cleaning

Keeping the device clean is fundamental to its operation. Accumulated dust and debris can hinder performance and cause overheating. After each use, wipe down the surfaces with a dry cloth to remove any particles. For a more thorough clean, use a soft brush or compressed air to eliminate dust from hard-to-reach areas. This routine will help maintain optimal functionality.

Periodic Inspections

Conducting regular inspections can identify potential issues before they escalate. Examine the components for any signs of wear, such as fraying wires or loose connections. Ensure that all fasteners are securely tightened. Additionally, refer to the user manual for specific guidance on checking parts for wear and tear. Addressing minor problems promptly can prevent major malfunctions and ensure consistent performance.

Common Issues and Solutions

This section addresses frequently encountered problems and their respective remedies, ensuring optimal performance of your tool. Understanding these common challenges can help users troubleshoot effectively and maintain efficiency during operation.

One prevalent issue is the tool’s failure to start. This may stem from a variety of factors, such as a depleted power source or a faulty switch. To resolve this, first check the power supply, ensuring connections are secure. If the power source is functional, inspect the switch for any signs of damage.

Another common challenge involves irregular cutting or performance inconsistencies. This can often be attributed to dull blades or improper alignment. Regularly replacing blades and ensuring they are correctly installed can significantly improve cutting quality. If misalignment persists, verify the adjustments on the tool’s base and guide system.

Overheating can also pose a significant problem, typically caused by excessive load or prolonged use without adequate breaks. To mitigate this issue, adhere to the manufacturer’s recommendations regarding operation duration and allow the tool to cool down when necessary. If overheating continues, consider examining the motor for potential defects.

Lastly, accumulation of dust and debris can hinder performance. Regular cleaning and maintenance of the tool are crucial to prevent this buildup. Utilize a soft brush or cloth to remove any particles from the internal components and ensure that air vents remain unobstructed.

How to Order Replacement Parts

When it comes to maintaining your equipment, securing the necessary components is essential for optimal performance. This guide outlines the process for obtaining the required items efficiently, ensuring that your tools remain in top condition.

Identifying the Required Components

Before proceeding with your order, it’s crucial to pinpoint exactly what you need. Refer to the user manual or consult an online resource that provides a comprehensive list of available items. Make a note of the specific names, numbers, or any identifying characteristics of the components to streamline the ordering process.

Placing Your Order

Once you’ve gathered the necessary information, you can place your order through various channels. Many manufacturers offer online platforms where you can browse and select the required items. Alternatively, you may contact a local distributor or authorized retailer. Ensure you provide all relevant details to avoid any delays. Payment options typically include credit cards, PayPal, or other secure methods.

Upgrading Your DWS715 Tool

Enhancing your power tool can significantly improve its performance and efficiency. Upgrades may involve replacing certain components or adding accessories that cater to specific needs. These modifications not only extend the lifespan of the tool but also enhance user experience, making tasks easier and more efficient.

Before proceeding with any upgrades, it’s essential to identify the components that can be improved. Below is a table that outlines various parts you might consider upgrading along with their potential benefits:

| Component | Benefits |

|---|---|

| Blade | Improved cutting efficiency and precision. |

| Motor | Increased power and torque for heavy-duty tasks. |

| Base | Enhanced stability and support during operation. |

| Dust Collection System | Better cleanliness and visibility while working. |

| Laser Guide | Improved accuracy in cutting alignment. |

By carefully selecting and implementing these upgrades, you can transform your tool into a more powerful and effective device, tailored to meet your specific requirements.

Safety Precautions While Operating

Ensuring a safe working environment is crucial when using power tools. By following specific safety guidelines, users can minimize the risk of accidents and injuries. Awareness and preparation are key components in promoting a secure operational experience.

Before starting any work, consider the following essential precautions:

- Always wear appropriate personal protective equipment, including safety glasses, gloves, and ear protection.

- Ensure the workspace is well-lit and free from any clutter or obstructions.

- Check that the tool is in proper working condition before use. Inspect for any damage or wear.

- Keep hands and other body parts away from moving parts while the equipment is in operation.

- Maintain a firm grip and proper body stance to enhance control and stability.

Additionally, be mindful of the following safety practices:

- Read and understand the operator’s manual thoroughly before using the tool.

- Do not override safety features or remove guards that are designed to protect the user.

- Keep children and pets away from the working area to prevent distractions and accidents.

- Stay focused and avoid multitasking while operating power tools.

- Always disconnect the power source when changing accessories or making adjustments.

By adhering to these guidelines, users can significantly enhance their safety while working with power equipment and ensure a more productive and secure experience.

Tools Needed for Repairs

When it comes to performing maintenance and fixing equipment, having the right tools is essential for ensuring efficiency and effectiveness. Various instruments facilitate the disassembly and assembly of components, making the repair process smoother and more precise.

Here’s a list of essential tools to have on hand:

- Screwdrivers: A variety of sizes and types, including Phillips and flathead, are crucial for removing screws from different parts.

- Wrenches: Adjustable and socket wrenches are necessary for loosening and tightening nuts and bolts securely.

- Pliers: These are useful for gripping, twisting, and cutting wires or small components.

- Hex Keys: Also known as Allen wrenches, these tools are essential for assembling and disassembling parts with hexagonal sockets.

- Measuring Tools: A tape measure or caliper is important for taking precise measurements to ensure proper fit and alignment.

- Cleaning Supplies: Brushes, cloths, and cleaning solutions help maintain the equipment’s functionality and extend its lifespan.

- Safety Gear: Gloves, goggles, and masks are vital for protecting oneself during repair tasks.

Having these tools readily available not only simplifies the repair process but also helps achieve a professional result. Proper maintenance is key to ensuring the longevity and performance of your equipment.

Where to Find Technical Support

Accessing reliable assistance for your tools is essential for maintaining their optimal performance. Whether you encounter technical difficulties or require specific information, several resources are available to provide the necessary guidance and solutions.

Official Websites: The primary source for support is the manufacturer’s official website. Here, you can find comprehensive documentation, FAQs, and contact details for customer service representatives who can address your inquiries.

User Manuals: Reference the user manual that accompanied your equipment. These manuals often contain troubleshooting sections that cover common issues and their solutions, offering a quick and easy way to resolve problems.

Online Forums and Communities: Engaging with online communities dedicated to tool enthusiasts can be incredibly beneficial. Websites and forums where users share their experiences can provide insights and practical advice on handling various challenges.

Authorized Service Centers: For more complex issues, visiting an authorized service center can ensure that your equipment is serviced by trained professionals. These centers have access to specialized tools and genuine replacement parts, ensuring quality repairs.

Customer Support Hotlines: Many manufacturers offer customer support hotlines that provide direct access to knowledgeable representatives. Calling these numbers can lead to immediate assistance, making it easier to resolve urgent problems.

Social Media Platforms: Following the official social media channels of the manufacturer can keep you updated on the latest news, tips, and support options. Many companies also respond to inquiries made through these platforms, offering another avenue for assistance.

Comparing DWS715 with Other Models

When considering various cutting machines in the market, it’s essential to evaluate their specifications and performance features. Each model offers unique attributes that cater to different user needs, making a side-by-side comparison invaluable for informed decision-making.

In this comparison, we will focus on key factors that distinguish this particular model from its counterparts:

- Power and Performance: One of the most crucial aspects to consider is the motor’s power output. Some machines boast higher wattage, leading to faster and more efficient cuts.

- Blade Size: The diameter of the blade can significantly impact cutting capacity. While some models utilize larger blades for thicker materials, others may favor portability with smaller sizes.

- Weight and Portability: Depending on user preference, some may prioritize lightweight designs for easy transport, while others might not mind a heavier model if it enhances stability.

- Additional Features: Various machines come with features such as laser guides, dust collection systems, or adjustable angles, which can improve precision and usability.

Ultimately, evaluating these factors against personal requirements and intended applications will help users choose the most suitable tool for their projects. Understanding how each option stacks up against the rest empowers buyers to make the best choice tailored to their specific needs.