Dewalt DWS779 Type 22 Parts Diagram Overview

Maintaining and repairing equipment requires a clear grasp of its inner workings. Each machine comprises various elements, and knowing their layout is crucial for efficient troubleshooting and servicing. This knowledge enhances your ability to address issues promptly, ensuring optimal performance.

Visual aids can significantly simplify the process of identifying individual components. By consulting detailed illustrations, users can delve deeper into the construction of their tools. This not only aids in recognizing parts but also empowers users to undertake repairs with confidence.

Ultimately, familiarizing yourself with the specific elements of your equipment can lead to a more rewarding experience. Armed with this understanding, you’ll be better equipped to extend the life of your tools and maximize their functionality.

Dewalt DWS779 Type 22 Overview

This section provides a comprehensive look at a specific model designed for precision cutting and robust performance in various woodworking projects. Ideal for both professionals and enthusiasts, this tool combines advanced engineering with user-friendly features to enhance productivity and accuracy.

Key Features

- Powerful motor for enhanced cutting capability.

- Compact design for easy transport and storage.

- Adjustable settings for versatility in various applications.

- High-quality materials ensuring durability and longevity.

- User-friendly controls for effortless operation.

Applications

- Framing and trim work.

- Cross-cutting and miter cuts.

- Rip cuts for larger stock.

- Precision bevel cuts for intricate designs.

- Construction and remodeling projects.

With its robust features and ease of use, this model stands out in the woodworking industry, making it a valuable addition to any workshop.

Importance of Parts Diagrams

Understanding the layout and components of complex machinery is essential for maintenance and repair. Visual representations help users identify each element’s role, facilitating efficient troubleshooting and replacements.

Enhanced Maintenance Efficiency

By utilizing visual guides, technicians can quickly locate necessary components, reducing downtime during repairs. This clarity ensures that each part is properly handled, leading to effective maintenance practices.

Streamlined Ordering Process

Clear visuals allow for accurate identification of required components when placing orders. This precision minimizes the risk of errors, ensuring that the correct items are sourced promptly, ultimately saving time and resources.

Key Components of DWS779

Understanding the essential elements of this powerful cutting tool is crucial for optimal performance and maintenance. Each component plays a significant role in ensuring accuracy and durability, making it important for users to familiarize themselves with these parts.

Main Features

- Motor: Provides the necessary power for efficient cutting.

- Blade: Engineered for precision and sharpness, crucial for clean cuts.

- Base: Offers stability and support during operation, enhancing safety.

- Fence: Ensures accurate measurements and alignment while cutting.

Additional Elements

- Bevel Adjustment: Allows for angled cuts with ease.

- Dust Collection: Helps maintain a clean workspace by minimizing debris.

- Handle: Designed for comfort and control, ensuring user safety.

Familiarity with these key features will enhance the overall user experience and contribute to the longevity of the tool.

Common Issues with DWS779 Parts

Every tool can encounter challenges over time, and it’s crucial to be aware of frequent problems to ensure optimal performance. Users often report specific concerns that can hinder functionality and efficiency.

- Wear and Tear: Components can degrade with extensive use, leading to decreased performance.

- Misalignment: Parts may become misaligned, causing inaccuracies during operation.

- Electrical Failures: Wiring and switches can malfunction, impacting power delivery.

- Overheating: Prolonged use can lead to overheating issues, potentially damaging internal elements.

Understanding these common challenges can aid in proactive maintenance and enhance longevity.

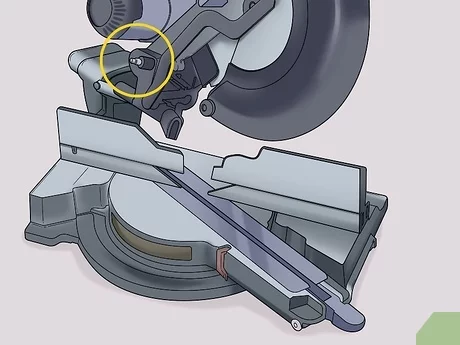

How to Read Parts Diagrams

Understanding visual representations of components can greatly enhance your ability to maintain and repair equipment. These illustrations serve as a guide, detailing the relationship between various elements and their functions. Familiarizing yourself with how to interpret these visuals is essential for effective troubleshooting and replacement.

Identifying Key Components

Each illustration typically includes numbered parts that correspond to a list, allowing you to easily identify specific items. Look for annotations that provide additional information, such as measurements or specifications, which can be crucial during repairs.

Understanding Connections and Assembly

Pay attention to how elements connect with one another. Arrows and lines often indicate relationships, guiding you on how to assemble or disassemble components correctly. Recognizing these connections ensures you understand the overall structure and function.

| Symbol | Meaning |

|---|---|

| Circle | Component |

| Arrow | Connection |

| Number | Part Identifier |

Ordering Replacement Parts Effectively

Ensuring that tools and machinery function optimally often requires sourcing new components when the originals wear out or fail. Effectively acquiring these items can save time and minimize downtime. Understanding the process and knowing where to look are essential for a smooth experience.

Start by identifying the specific item you need, including any model or serial numbers. This information will help in locating the exact replacement. Many suppliers provide catalogs or online databases where you can search for components based on these identifiers.

Consider using authorized distributors or manufacturers to guarantee quality and compatibility. They typically offer reliable options and may provide additional support, such as installation guidance or warranty information.

Compare prices and shipping options across different retailers to ensure you get the best deal. Some platforms may offer bulk purchasing discounts or free shipping on larger orders, which can be beneficial if multiple items are required.

Lastly, read customer reviews and ratings for the components you are considering. Feedback from other users can provide insights into the product’s performance and durability, aiding in making an informed decision.

Maintenance Tips for DWS779

Regular upkeep is essential for ensuring optimal performance and longevity of your cutting tool. Proper maintenance not only enhances efficiency but also ensures safety during operation. Here are some crucial tips to keep your equipment in top shape.

- Clean the Tool: After each use, remove dust and debris from the tool. Use a soft brush or compressed air to clean sensitive areas, ensuring no particles affect performance.

- Inspect Blades: Regularly check the condition of the cutting blades. Look for signs of wear or damage and replace them when necessary to maintain precise cuts.

- Lubricate Moving Parts: Apply lubricant to all moving components as recommended in the user manual. This will prevent wear and tear, ensuring smooth operation.

- Tighten Fasteners: Periodically inspect and tighten any loose screws or bolts. This helps prevent unexpected malfunctions during use.

- Check Electrical Components: Ensure all wiring and electrical parts are in good condition. Look for frays or damages that could pose a safety hazard.

By following these maintenance tips, you can extend the life of your tool and ensure it continues to perform at its best.

Understanding Warranty and Support

When purchasing tools, it’s essential to comprehend the coverage and assistance available to ensure a seamless experience. Warranty terms protect consumers from defects and malfunctions, while support services offer guidance on product usage and troubleshooting.

Types of Coverage

Standard Warranty: This typically covers manufacturing defects for a specified period, allowing users to seek repairs or replacements at no additional cost.

Accessing Support

Customer Assistance: Companies provide various channels, such as phone, email, or live chat, enabling users to delve into issues they may encounter. Furthermore, online resources often include FAQs and instructional videos for self-help.

Accessories Compatible with DWS779

Enhancing your cutting experience often involves integrating various accessories that improve functionality and efficiency. Selecting the right additions can elevate your projects, providing versatility and precision in every cut. This section explores some essential tools and attachments that complement your equipment seamlessly.

Blades

The choice of blade is crucial for achieving optimal results. Look for high-quality options designed for specific materials, such as wood, metal, or composite surfaces. A fine-toothed blade will yield smoother cuts, while a rougher blade may be more suitable for faster, aggressive cutting. Investing in a good selection of blades allows you to tackle various tasks with ease.

Supports and Stands

Sturdy supports and stands are vital for stability during operation. Accessories such as extendable tables or rolling stands can provide additional workspace and improve accuracy. These supports ensure that larger materials are held securely, preventing any unwanted movement that could lead to inaccurate cuts. The right setup enhances both safety and performance, making your work more efficient.

Customer Reviews and Feedback

This section highlights the opinions and experiences of users regarding their tools. Genuine insights from consumers can greatly assist potential buyers in making informed decisions. Here, we summarize various reviews, focusing on functionality, durability, and user satisfaction.

User Experiences

Many individuals have shared their thoughts on performance and ease of use. Common themes include:

- Efficiency in cutting various materials.

- Stability and precision during operation.

- User-friendly features that enhance the overall experience.

Common Praise and Criticism

Feedback often includes both positive aspects and areas for improvement:

- Pros:

- Exceptional power for demanding tasks.

- Robust construction that withstands regular use.

- Highly rated safety features that provide peace of mind.

- Cons:

- Some users report weight as a concern for portability.

- A few mention the initial learning curve for optimal use.

Overall, the insights shared by users serve as valuable resources for anyone considering this tool, providing a well-rounded perspective on its capabilities and limitations.

Comparative Analysis with Other Models

This section delves into a detailed comparison of a specific power tool with its contemporaries in the market. By examining features, performance metrics, and user feedback, we aim to highlight the strengths and weaknesses of each model, providing potential buyers with valuable insights to inform their decisions.

Performance Metrics

When evaluating cutting devices, one must consider aspects such as motor power, cutting capacity, and precision. The model in question boasts a robust motor that delivers consistent performance, making it suitable for both professional and DIY tasks. In contrast, several alternatives may offer similar motor strength but fall short in terms of accuracy or durability. Customer reviews often emphasize the importance of these attributes, further reinforcing the need for a thorough comparison.

Features and Usability

Features such as dust collection systems, ease of blade change, and portability play a significant role in user experience. While the primary model offers an intuitive design and efficient dust management, other competitors might lack in these areas, impacting user satisfaction. Ergonomics also differ among models; some prioritize comfort and reduce fatigue during extended use, while others may feel cumbersome over time. These elements contribute to the overall value of each tool and are crucial for discerning consumers.

Where to Find Additional Resources

Accessing supplementary materials can significantly enhance your understanding and experience with tools and equipment. Numerous platforms offer detailed information, including schematics, user manuals, and repair guides, which are invaluable for both novices and experienced users alike.

Official Manufacturer Websites are a prime source for authentic documentation, often providing downloadable content that includes maintenance tips and instructional videos.

Online Forums and Communities serve as excellent venues for sharing insights, troubleshooting advice, and personal experiences related to various models and their functionalities.

Retailers and Specialty Shops frequently maintain resource sections that list compatible accessories and provide expert recommendations tailored to specific needs.

Lastly, consider video-sharing platforms, where enthusiasts and professionals alike post tutorials and demonstrations that can guide you through complex tasks step-by-step.