Dewalt Impact Driver Parts Diagram Explained

In the realm of power tools, a thorough comprehension of their structure is essential for both enthusiasts and professionals. Knowing how each element interacts not only enhances functionality but also aids in troubleshooting and maintenance.

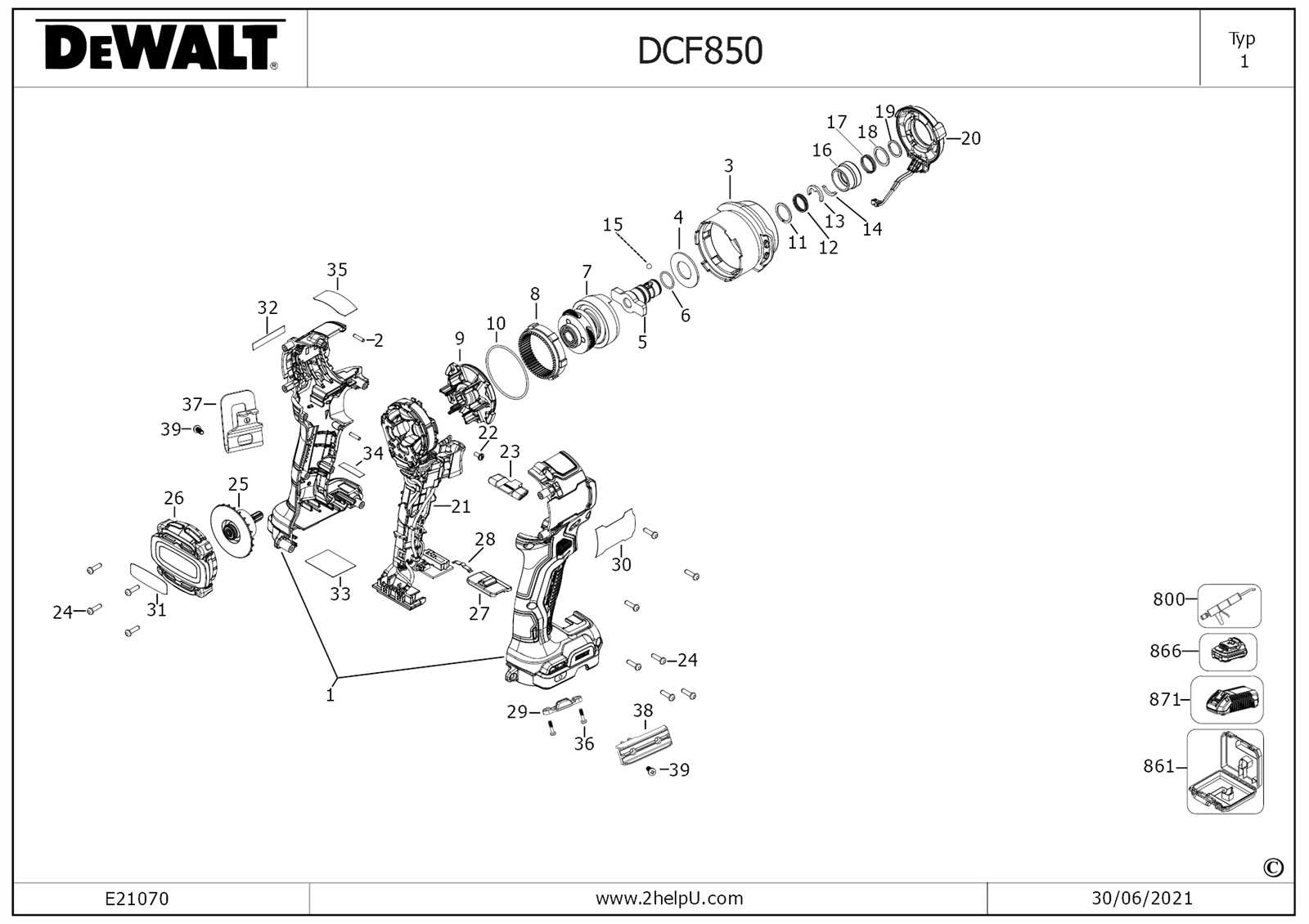

Visual representations of these tools serve as invaluable resources, allowing users to easily identify individual components and their roles. By examining these schematics, one can delve into the intricacies of tool assembly, ensuring optimal performance and longevity.

The ultimate goal is to empower users with the knowledge needed to effectively manage their equipment. Whether for repairs, upgrades, or general understanding, mastering the layout of tool elements is a critical skill for anyone invested in the trade.

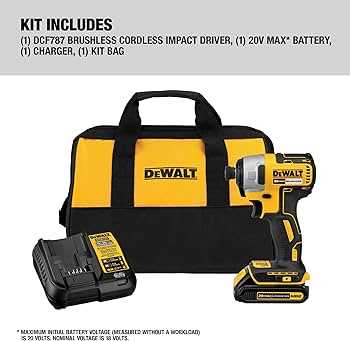

Dewalt Impact Driver Overview

This section provides an in-depth look at a powerful tool designed for heavy-duty fastening and loosening tasks. Its robust design and advanced technology make it an essential addition to both professional workshops and DIY enthusiasts’ toolkits.

Featuring a high torque output, this device excels in driving screws and bolts with efficiency and precision. The lightweight construction ensures ease of handling, while ergonomic features enhance user comfort during prolonged use.

Additionally, the tool incorporates various speed settings and torque adjustments, allowing for versatility across different materials and applications. Its durable build is engineered to withstand the rigors of demanding environments, ensuring longevity and reliability.

Understanding the key components and functionalities of this equipment is crucial for maximizing its performance and maintaining its optimal condition over time.

Understanding Impact Driver Functionality

Grasping how a powerful tool operates is essential for maximizing its efficiency and effectiveness in various tasks. The mechanisms behind these devices involve intricate engineering designed to deliver substantial torque while minimizing user fatigue. This section explores the fundamental principles that govern their performance, providing insight into their unique capabilities.

Key Mechanisms at Play

At the core of these instruments is a robust motor that generates high rotational force. Coupled with a hammering action, this allows for rapid delivery of energy, enabling users to drive fasteners into tough materials with ease. The combination of rotational and linear movements creates a dynamic that distinguishes them from traditional counterparts, making them invaluable for heavy-duty applications.

Applications and Benefits

These tools are particularly beneficial for tasks requiring repetitive fastening, such as construction and assembly projects. Their ability to work efficiently in tight spaces further enhances their versatility. Moreover, advancements in technology have introduced features such as variable speed settings and built-in lighting, improving user experience and overall functionality.

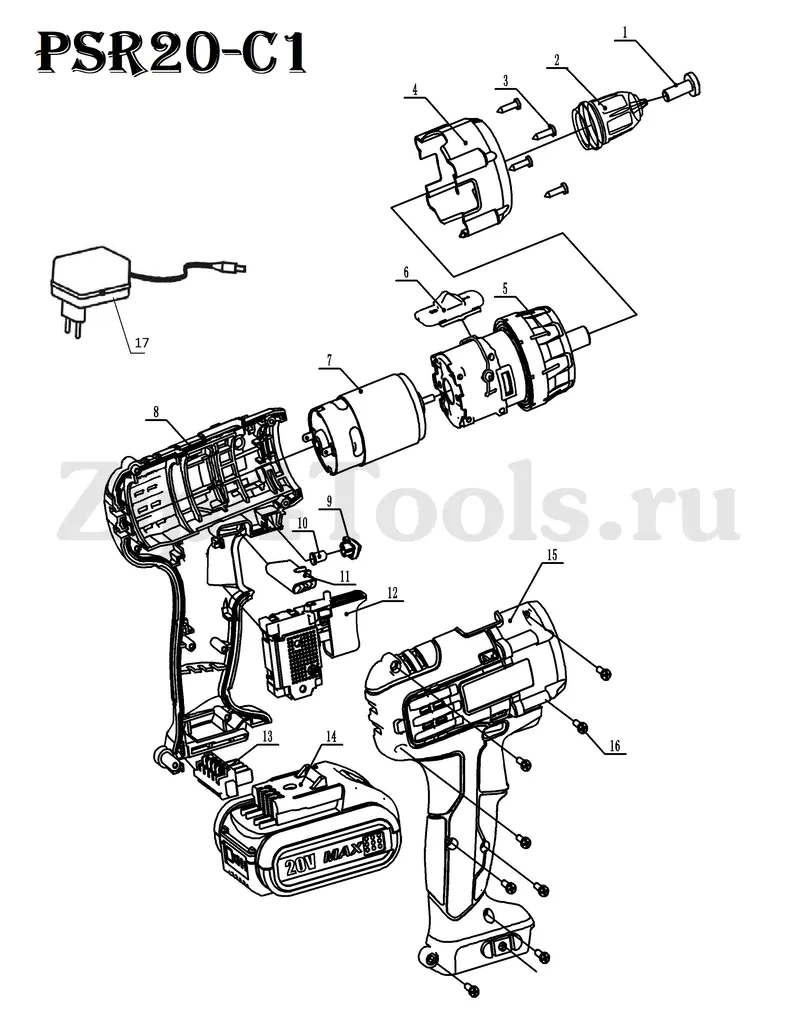

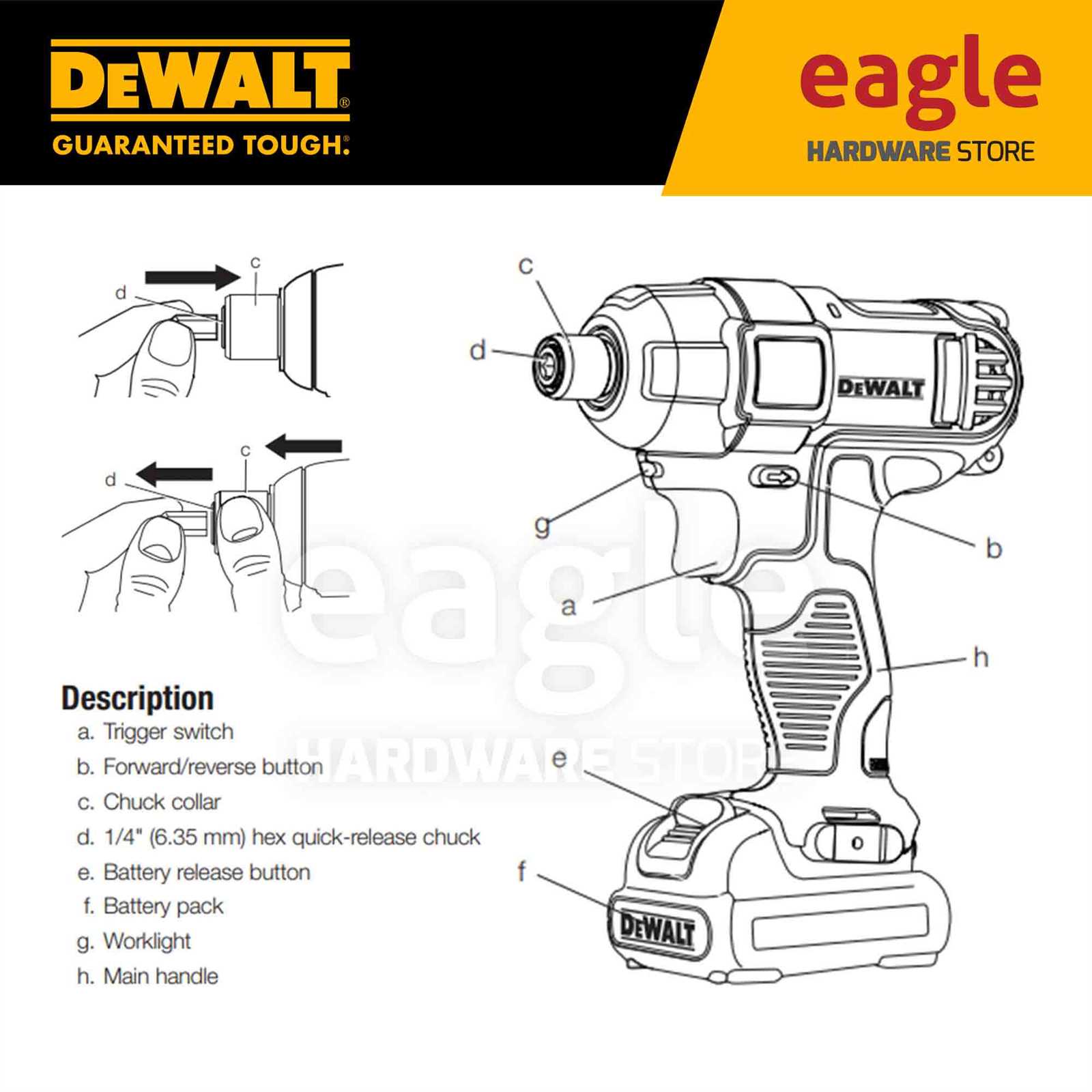

Key Components of Dewalt Tools

This section explores the essential elements that contribute to the efficiency and performance of power tools, highlighting their significance in various applications. Understanding these components can enhance the user experience and ensure optimal functionality.

Core Elements

- Motor: The driving force behind tool performance.

- Battery: Provides the necessary energy for cordless operation.

- Gearbox: Transmits power and adjusts torque settings.

- Chuck: Holds the accessory securely during operation.

Additional Features

- Handle: Ergonomically designed for comfort and control.

- LED Light: Illuminates work areas for improved visibility.

- Speed Control: Allows for adjustable power according to task requirements.

- Cooling System: Prevents overheating during extended use.

Benefits of Using Impact Drivers

Power tools designed for high torque applications have revolutionized the way we approach fastening tasks. Their unique mechanics allow for greater efficiency and effectiveness, making them indispensable for both professionals and DIY enthusiasts. The enhanced performance and ease of use contribute to faster completion of projects, minimizing fatigue and maximizing productivity.

Enhanced Efficiency

The ability of these tools to deliver rapid bursts of power translates to quicker fastening, reducing the time spent on each task. This efficiency is especially beneficial in construction and assembly work, where deadlines are often tight. Users can experience a noticeable decrease in the effort required, allowing for a more enjoyable and less strenuous workflow.

Versatility Across Applications

These tools are designed to handle a wide range of tasks, from driving screws into wood to working with tougher materials like metal and masonry. Their adaptability makes them suitable for various projects, including home improvement, automotive repairs, and woodworking. This multifunctionality means fewer tools are needed in your toolkit, saving both space and investment.

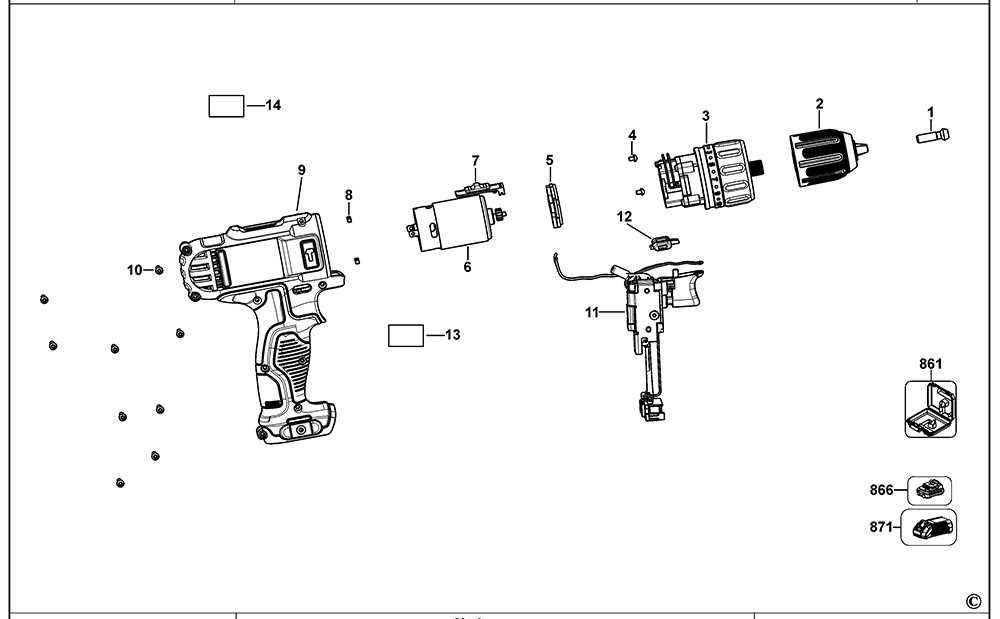

Common Parts in Dewalt Models

This section explores the essential components found in various models, highlighting their significance and functionality. Understanding these elements can aid in effective maintenance and troubleshooting, ensuring optimal performance of the tools.

Motor: The heart of any power tool, the motor drives the device’s performance. Different models may feature varying power ratings, affecting torque and speed.

Chuck: This component holds the bit securely in place, allowing for quick changes and ensuring stability during operation. Some versions come with a keyless design for added convenience.

Battery: A critical element for cordless tools, the battery type and capacity directly influence runtime and efficiency. Lithium-ion batteries are commonly favored for their lightweight and long-lasting properties.

Switch: The on/off mechanism controls the operation of the tool. A durable switch design contributes to user safety and ease of use.

Housing: The outer casing not only provides protection for internal components but also contributes to the overall ergonomics and grip, enhancing user comfort during extended tasks.

Brushes: In certain models, these components maintain the motor’s performance by conducting electricity. Regular inspection can prevent performance issues and prolong the tool’s lifespan.

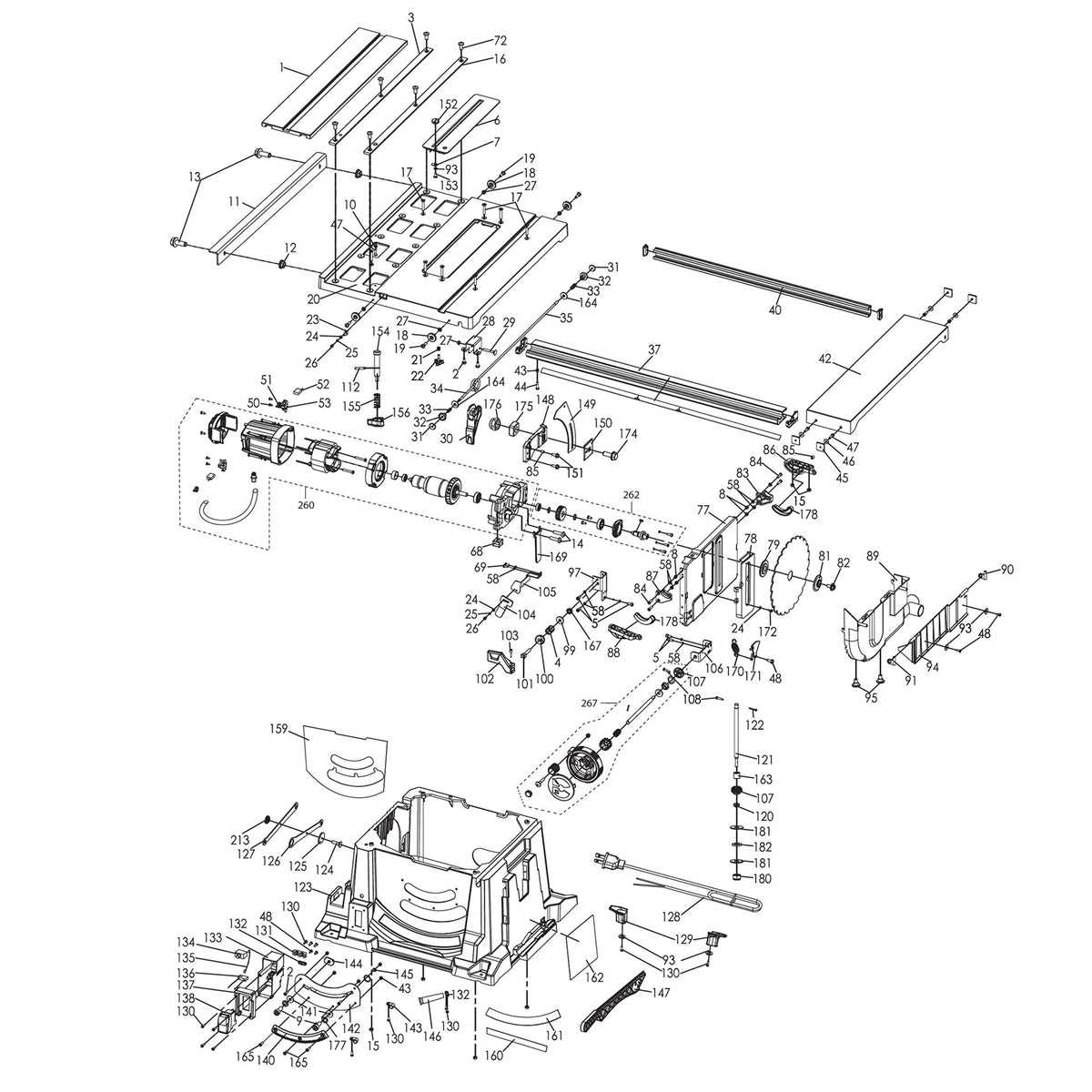

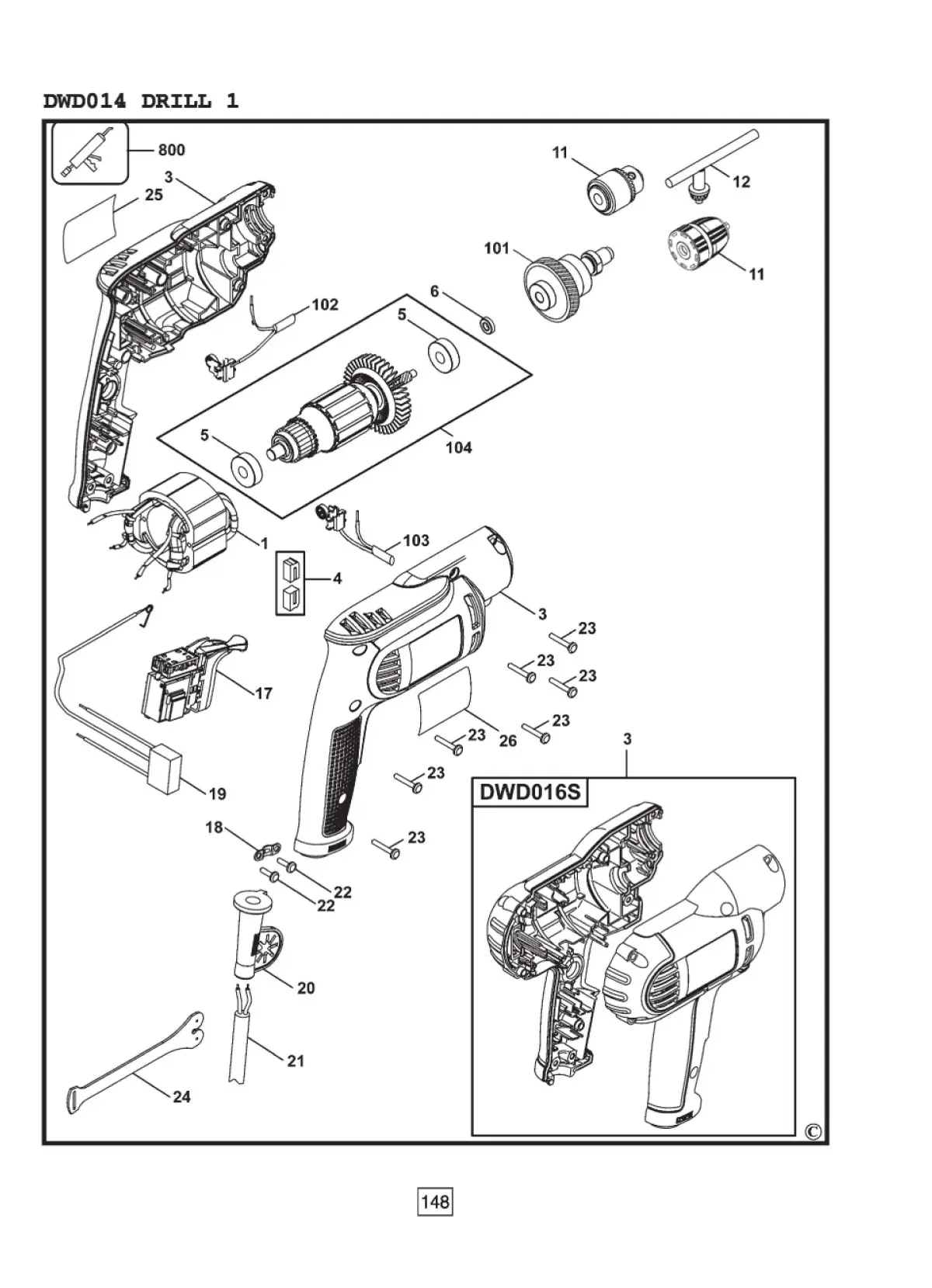

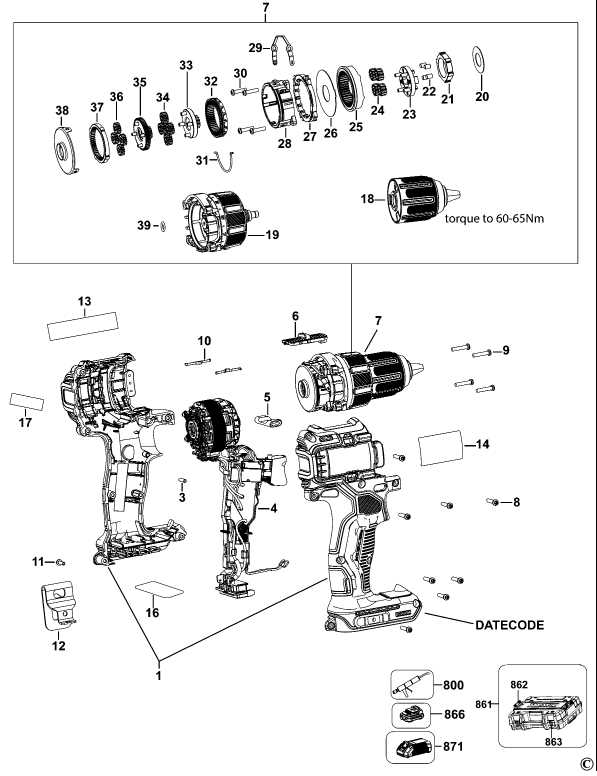

How to Read Parts Diagrams

Understanding a visual representation of components is essential for effective maintenance and repair. These illustrations serve as a roadmap, helping users identify each piece and its function within the overall assembly. Mastering this skill can significantly enhance your troubleshooting abilities and streamline the repair process.

To begin, familiarize yourself with the layout. Typically, components are labeled with numbers or letters, which correspond to a list provided separately. Pay attention to the arrangement, as it often reflects the sequence in which parts are assembled or disassembled.

Next, consider the materials and colors used in the illustration. Different hues may signify various materials or functionalities, guiding you in selecting the appropriate replacements. Additionally, note any accompanying annotations that provide further context or instructions.

Finally, practice makes perfect. The more you delve into these visuals, the more intuitive they become. This skill is not only beneficial for repairs but also enhances your overall understanding of how the machinery operates.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the lifespan of your tools and ensuring optimal performance. Regular attention to specific areas can significantly enhance efficiency and reliability over time.

1. Regular Cleaning: Keep your equipment free from dust and debris. Use a soft brush or compressed air to clean sensitive areas, preventing buildup that can hinder functionality.

2. Lubrication: Apply appropriate lubricants to moving parts periodically. This reduces friction and wear, promoting smooth operation and prolonging tool life.

3. Battery Care: Store batteries in a cool, dry place and avoid complete discharge. This practice helps maintain battery health and maximizes charge cycles.

4. Check for Wear: Inspect components regularly for signs of wear or damage. Addressing issues early can prevent more significant problems down the line.

5. Follow Manufacturer Guidelines: Adhere to recommended maintenance schedules and procedures to ensure your tools remain in peak condition.

By implementing these strategies, you can delve into the ultimate care for your equipment, ensuring they serve you well for years to come.

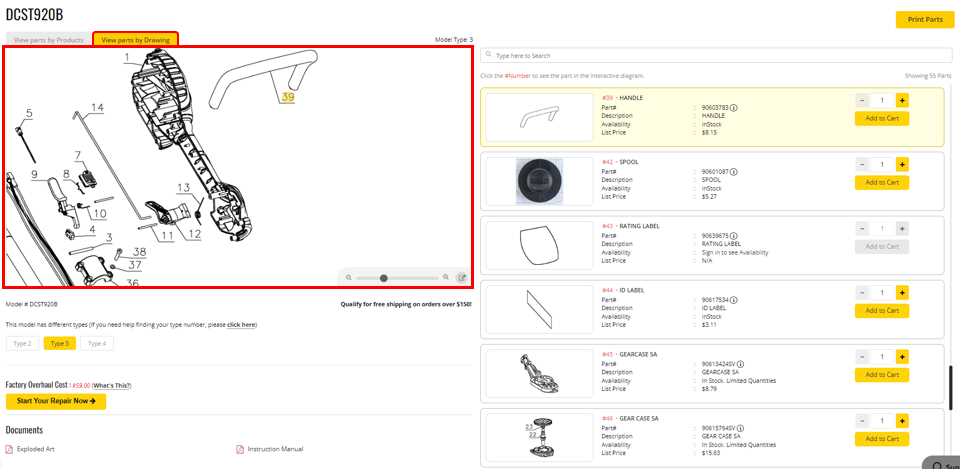

Identifying Replacement Parts Easily

Understanding how to recognize and locate components for your tools can significantly enhance their longevity and performance. By familiarizing yourself with various elements and their functions, you can efficiently address any issues that arise.

Common Components to Know

Focusing on essential elements can streamline your replacement process. Here are some frequently encountered parts:

| Component | Description |

|---|---|

| Motor | Drives the tool’s functionality and power. |

| Chuck | Secures the tool accessories in place. |

| Battery | Provides the necessary power supply. |

Finding the Right Fit

When searching for replacements, consult manuals or online resources that offer visual aids. These tools can help you delve deeper into identifying the ultimate fit for your needs.

Comparing Different Dewalt Models

This section explores the various options available within a popular brand’s toolkit, highlighting key differences and similarities across their range of high-performance devices. Understanding these distinctions can help users select the most suitable model for their specific needs.

| Model | Power (Volts) | Torque (In-Lbs) | Weight (lbs) | Battery Type |

|---|---|---|---|---|

| Model A | 20 | 1500 | 3.5 | Li-ion |

| Model B | 18 | 1300 | 3.0 | NiCad |

| Model C | 20 | 1600 | 4.0 | Li-ion |

Each model is designed for specific tasks, ensuring users can achieve optimal performance depending on the requirements of their projects.

Tools for Impact Driver Repair

When it comes to maintaining and fixing your powerful tools, having the right equipment is essential. A well-equipped toolkit not only simplifies the process but also ensures that your devices function optimally for a longer period. Understanding the necessary instruments can make repairs more efficient and effective.

1. Screwdriver Set: A comprehensive set of screwdrivers, including various sizes and types, is crucial for loosening and tightening screws. Ensure you have both flathead and Phillips options to accommodate different fasteners.

2. Pliers: A quality pair of pliers can assist in gripping, twisting, and cutting wires or other materials. Needle-nose pliers are particularly useful for reaching tight spots.

3. Wrench Set: Adjustable wrenches and socket sets are invaluable for tightening or loosening nuts and bolts. Make sure to have multiple sizes to cover all possibilities.

4. Torque Wrench: To ensure fasteners are secured to the correct specifications, a torque wrench is necessary. This tool allows for precise control over the amount of force applied.

5. Cleaning Supplies: Keeping your equipment clean is vital for longevity. Use brushes, cloths, and cleaning solutions to remove dust and debris that can hinder performance.

6. Lubricants: Regular lubrication of moving parts can prevent wear and tear. Choose appropriate lubricants to ensure smooth operation.

7. Safety Gear: Always prioritize safety by wearing protective eyewear and gloves during any repair work. This minimizes the risk of injury while handling tools and components.

By equipping yourself with these essential instruments, you can tackle repairs confidently and maintain the functionality of your equipment over time.

Where to Buy Dewalt Parts

Finding replacement components for your power tools can be a crucial task to maintain their performance and longevity. Various sources provide access to high-quality alternatives, ensuring that your equipment remains in top condition. Here are some reliable options to consider when seeking these essential items.

Authorized Retailers

One of the most straightforward methods is to visit authorized retailers. These stores often stock a wide range of components directly from the manufacturer, guaranteeing compatibility and quality. Check both local hardware shops and large home improvement chains for availability. You can also inquire about specific items to ensure they can meet your needs.

Online Marketplaces

Online platforms have become increasingly popular for purchasing tool components. Websites specializing in tools and accessories often have extensive inventories, allowing for easy comparisons and price checks. Look for reputable sites that offer customer reviews, as this can help you make informed decisions. Additionally, consider checking manufacturer websites for direct purchases, which can sometimes offer exclusive deals.

Frequently Asked Questions About Parts

This section aims to address common inquiries related to components and their functionalities, providing clarity and insight for users seeking information. Understanding these elements is crucial for optimal performance and maintenance.

What are the most common issues with components? Common problems include wear and tear, misalignment, and insufficient power transfer, which can affect overall efficiency.

How can I identify the right replacement? Always refer to the model number and specifications to ensure compatibility with your tool, ensuring seamless operation.

What maintenance tips should I follow? Regular cleaning, lubrication, and inspection can significantly extend the lifespan of each element, preventing unnecessary replacements.

Are there warranties on these components? Many manufacturers offer warranties, so it’s essential to check the terms for any specific coverage related to your purchase.

Where can I find quality components? Reputable retailers and official service centers are ideal sources, ensuring you receive authentic and reliable items.