Front End Parts Diagram for 2003 Dodge Ram 2500

When it comes to robust vehicles designed for tough tasks, comprehending their structural components is essential. A detailed overview of specific elements can greatly enhance maintenance and repair processes, ensuring longevity and performance. By exploring the intricate arrangement of these features, enthusiasts and professionals alike can optimize their understanding and care for their machines.

In this section, we will explore the essential components that contribute to the overall functionality of a heavy-duty truck’s architecture. From crucial mechanical elements to auxiliary supports, each piece plays a pivotal role in ensuring the vehicle operates efficiently under various conditions. This knowledge not only aids in repairs but also empowers owners to make informed decisions regarding upgrades and replacements.

Furthermore, visual representations of these components can significantly aid in grasping their interrelations and specific functions. Utilizing diagrams allows for a clearer understanding of how each element contributes to the vehicle’s performance and reliability. Ultimately, this exploration will provide valuable insights into maintaining the durability and effectiveness of your heavy-duty truck.

Understanding the 2003 Dodge Ram 2500

This section focuses on comprehending the key components and systems that make up this heavy-duty vehicle. By exploring its architecture, enthusiasts and mechanics can better appreciate the intricacies involved in its performance and maintenance.

Key Components Overview

The construction of this model includes various crucial elements that contribute to its robustness and functionality. Understanding each part’s role is essential for effective upkeep and troubleshooting.

| Component | Description |

|---|---|

| Chassis | The main framework providing structural support. |

| Suspension | System designed to absorb shocks and improve handling. |

| Steering Mechanism | Enables precise direction control for the vehicle. |

Maintenance Tips

Common Front End Issues

Vehicle stability and handling often depend on the integrity of its leading components. Numerous challenges can arise in this area, affecting performance and safety. Understanding these common concerns is essential for maintaining optimal functionality and ensuring a smooth driving experience.

One prevalent issue is wear in the steering linkage, which can lead to decreased responsiveness and increased play in the steering wheel. This often results in difficulty maintaining a straight trajectory and can compromise control during maneuvers.

Another common concern is the degradation of suspension components, which can manifest as excessive bouncing or uneven tire wear. These problems can significantly impact ride comfort and handling, necessitating timely inspections and repairs.

Additionally, misalignment is a frequent problem that can cause uneven tire wear and handling difficulties. Regular alignment checks are crucial to prevent these issues and extend the lifespan of the vehicle’s tires and suspension system.

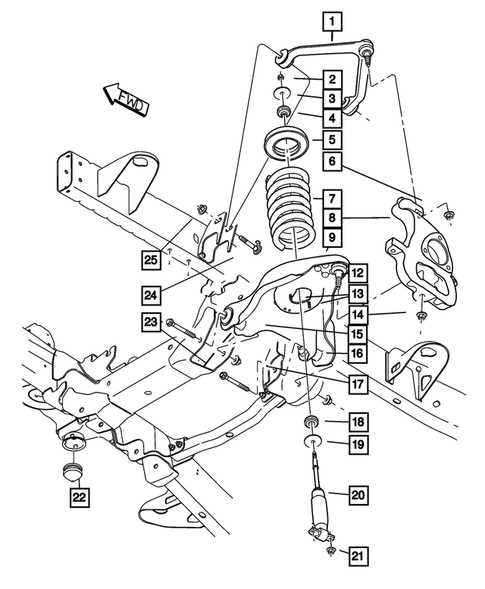

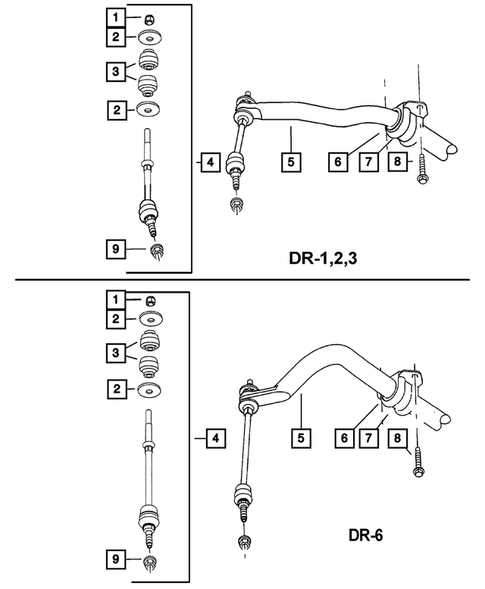

Parts Overview and Functions

This section provides a comprehensive look at the various components located at the front of a heavy-duty vehicle, highlighting their roles and interconnections. Understanding the function of each element is crucial for effective maintenance and performance optimization.

Key Components

The assembly includes crucial elements such as the suspension system, steering mechanism, and braking apparatus. Each component works in harmony to ensure stability and control, contributing to a safe driving experience. For instance, the suspension system absorbs shocks from the road, enhancing comfort and handling, while the steering system allows for precise maneuvering.

Functionality and Maintenance

Regular inspection and upkeep of these elements are essential for longevity and reliability. Attention to wear and tear, particularly in the suspension and braking systems, can prevent significant issues and enhance overall vehicle performance. Keeping these components in optimal condition ensures not only safety but also improved driving dynamics.

Importance of Regular Maintenance

Consistent upkeep of vehicles plays a crucial role in ensuring their longevity and optimal performance. By adhering to a structured maintenance schedule, owners can prevent minor issues from escalating into major problems, ultimately saving time and financial resources.

Regular inspections and timely replacements of worn components not only enhance safety but also improve efficiency. This proactive approach contributes to a smoother driving experience and helps maintain the vehicle’s resale value.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Oil Change | Every 3,000-5,000 miles | Reduces engine wear, improves fuel efficiency |

| Tire Rotation | Every 5,000-7,500 miles | Ensures even wear, extends tire lifespan |

| Brake Inspection | Every 10,000 miles | Enhances safety, prevents costly repairs |

| Fluid Check | Monthly | Prevents overheating, maintains performance |

In conclusion, prioritizing regular maintenance is essential for preserving the functionality and reliability of any vehicle. By investing time and effort into these practices, owners can ensure their vehicles remain in peak condition for years to come.

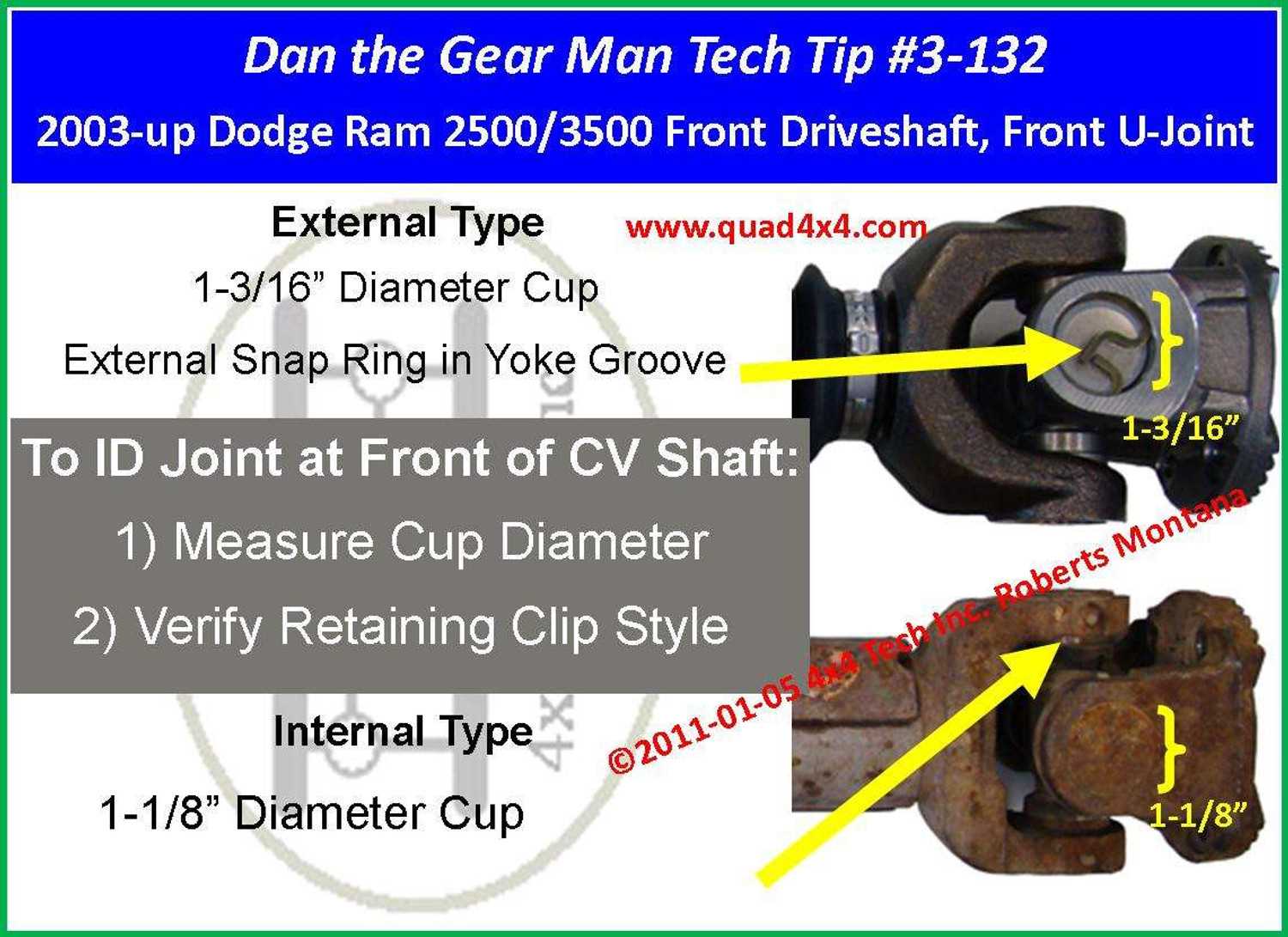

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. These illustrations serve as a visual guide, helping users identify various elements and their relationships within a system. Familiarity with the layout and symbols used in these visuals can significantly enhance one’s ability to troubleshoot and replace items accurately.

Key Elements of a Schematic

When examining a schematic, focus on the following components:

| Element | Description |

|---|---|

| Labels | Each part is usually accompanied by a label indicating its name or function, which aids in identification. |

| Connections | Lines or arrows represent how different elements connect and interact, illustrating their relationships. |

| Legend | A key may be included to explain symbols or abbreviations used throughout the schematic, clarifying their meanings. |

Interpreting the Information

To effectively utilize a schematic, start by familiarizing yourself with the layout. Identify the primary components and their respective labels. Next, trace the connections to understand how they interact. Finally, refer to the legend for clarification on any unfamiliar symbols. This methodical approach will enhance your comprehension and application of the schematic in practical scenarios.

Essential Tools for Repairs

When embarking on a repair project, having the right tools at your disposal is crucial for ensuring efficiency and effectiveness. A well-equipped toolkit not only streamlines the process but also enhances safety and accuracy during various tasks. Below is a selection of indispensable tools that every mechanic should consider for tackling repair jobs.

| Tool | Purpose |

|---|---|

| Wrench Set | Used for tightening and loosening bolts and nuts. |

| Screwdriver Set | Essential for driving screws in and out of components. |

| Pliers | Handy for gripping, twisting, and cutting wires or other materials. |

| Jack and Stands | Necessary for lifting the vehicle safely for access to the underside. |

| Torque Wrench | Ensures bolts are tightened to the manufacturer’s specifications. |

| Multimeter | Used for measuring electrical voltage, current, and resistance. |

| Diagnostic Scanner | Helps in reading error codes from the vehicle’s computer system. |

| Oil Filter Wrench | Designed specifically for removing and installing oil filters. |

Aftermarket vs. OEM Components

When it comes to vehicle maintenance and repair, choosing between original equipment manufacturer (OEM) components and aftermarket alternatives is a significant consideration for many owners. Each option presents its own set of advantages and disadvantages that can impact performance, durability, and cost.

OEM parts are produced by the vehicle’s manufacturer and are designed to meet the exact specifications of the original components. In contrast, aftermarket options are made by third-party companies and can vary in quality and price. Here are some key points to consider:

- Quality: OEM components typically maintain higher quality standards due to strict manufacturing processes.

- Cost: Aftermarket parts often offer a more budget-friendly solution, but the quality may vary widely.

- Availability: Aftermarket options might provide a wider range of choices and quicker access to certain components.

- Warranty: OEM parts generally come with manufacturer warranties, whereas aftermarket warranties can differ significantly.

Ultimately, the choice between these two types of components can influence your vehicle’s performance and longevity, making it essential to delve into your specific needs and preferences before making a decision.

Step-by-Step Replacement Guide

Replacing components in the suspension system of a heavy-duty vehicle can seem daunting, but with the right approach and tools, it can be a manageable task. This guide provides a clear, structured method to assist you in completing the replacement effectively and safely.

Follow these steps to ensure a successful replacement:

| Step | Description |

|---|---|

| 1 | Gather all necessary tools and parts before beginning the replacement process. Common tools include a jack, jack stands, wrenches, and sockets. |

| 2 | Lift the vehicle using the jack and secure it with jack stands to ensure stability while you work. |

| 3 | Remove the wheel to access the suspension components easily. Ensure that lug nuts are loosened before lifting. |

| 4 | Inspect the components for wear or damage, making a note of which parts need replacement. |

| 5 | Carefully detach the damaged components using the appropriate tools, taking care to follow the manufacturer’s guidelines. |

| 6 | Install the new components, ensuring they are secured tightly and positioned correctly. |

| 7 | Reattach the wheel and lower the vehicle back to the ground, ensuring all fasteners are tightened to specification. |

| 8 | Test drive the vehicle at low speeds to ensure everything is functioning correctly, listening for any unusual noises. |

Following these structured steps will help you confidently complete the replacement process, ensuring your vehicle’s suspension operates smoothly and safely.

Safety Tips During Repairs

When undertaking any mechanical maintenance, prioritizing safety is essential to ensure both personal well-being and the integrity of the vehicle. Proper precautions can prevent accidents and promote an efficient working environment.

1. Wear Appropriate Gear: Always equip yourself with gloves, safety glasses, and steel-toed boots. This attire minimizes the risk of injury from sharp tools or heavy components.

2. Secure the Vehicle: Use wheel chocks and jack stands to stabilize the vehicle. Never rely solely on a hydraulic jack, as it can fail unexpectedly.

3. Organize Your Workspace: Keep your tools and materials neatly arranged. A clutter-free area reduces the chances of tripping or losing focus during repairs.

4. Follow Manufacturer Guidelines: Consult manuals and follow recommended procedures to avoid mishaps. Understanding the vehicle’s specific requirements is crucial for safe handling.

5. Keep a Fire Extinguisher Nearby: Having a fire extinguisher on hand is a smart precaution, especially when working with flammable substances.

6. Work in a Well-Ventilated Area: Ensure proper airflow to avoid inhaling harmful fumes or gases released during maintenance activities.

7. Take Breaks: Regular breaks help maintain focus and prevent fatigue, which can lead to careless mistakes.

Implementing these guidelines can greatly enhance safety, allowing for a smoother and more secure repair experience.

Finding Quality Replacement Parts

When it comes to maintaining and enhancing your vehicle’s performance, sourcing high-quality components is essential. The right elements not only ensure optimal functionality but also contribute to the longevity of your automobile. Here, we will explore effective strategies for identifying superior replacements that meet your needs.

To start, it’s important to prioritize reliability and performance. Whether you’re repairing or upgrading, considering the following factors will help you make informed decisions:

| Factor | Description |

|---|---|

| Brand Reputation | Choose well-known manufacturers with a history of producing durable and efficient components. |

| Material Quality | Look for components made from robust materials that can withstand wear and tear. |

| Warranty | A solid warranty indicates the manufacturer’s confidence in their product and provides peace of mind. |

| Customer Reviews | Read feedback from other users to gauge the performance and reliability of the components you’re considering. |

By focusing on these elements, you can significantly increase your chances of finding the best replacements for your vehicle, ensuring that it remains in top condition for years to come.

Frequently Asked Questions

This section addresses common inquiries related to the components and assembly of specific vehicle structures. Here, you’ll find valuable insights to enhance your understanding and assist in any maintenance or repair endeavors.

Common Inquiries

| Question | Answer |

|---|---|

| What are the essential components of this assembly? | Key elements include the suspension system, steering mechanism, and associated hardware. |

| How can I identify worn-out elements? | Look for unusual noises, vibrations, or misalignment during operation as indicators of wear. |

Maintenance Tips

| Tip | Description |

|---|---|

| Regular Inspections | Check components periodically to prevent major issues and ensure safe performance. |

| Use Quality Parts | Always opt for high-quality replacements to maintain reliability and longevity. |