Comprehensive Guide to 2004 Dodge Ram 1500 Front End Parts Diagram

Exploring the intricate structure of a pickup vehicle’s leading segment reveals essential insights for both enthusiasts and professionals. This segment not only impacts the vehicle’s aesthetics but also plays a critical role in its functionality and safety.

Comprehending the layout of these crucial elements allows for better maintenance and repairs. By familiarizing oneself with the various components involved, individuals can enhance their knowledge and skills when it comes to vehicle upkeep.

Whether you’re a seasoned mechanic or a curious owner, gaining familiarity with these assemblies can ultimately lead to improved performance and longevity of your vehicle. This guide aims to provide clarity on the relationships between different sections and their significance within the overall framework.

Understanding the 2004 Dodge Ram 1500

This section delves into the intricacies of a specific pickup model, highlighting its design elements, mechanical components, and overall performance. Recognizing these aspects is essential for owners and enthusiasts alike, as they contribute to the vehicle’s durability and reliability.

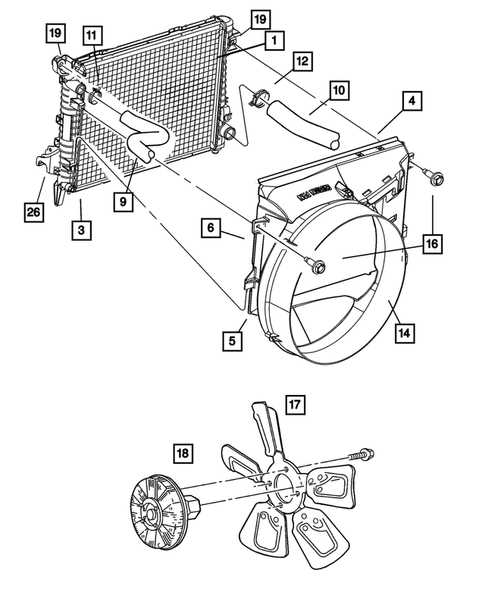

The construction of this vehicle incorporates a blend of robust features and innovative engineering, making it a popular choice among drivers seeking versatility and power. Key areas of focus include the suspension system, steering mechanisms, and other critical assemblies that enhance driving dynamics.

| Component | Description |

|---|---|

| Suspension System | Designed for stability and comfort, it allows for effective handling over various terrains. |

| Steering Mechanism | Provides precise control and responsiveness, ensuring a smooth driving experience. |

| Braking System | Equipped with reliable components that ensure safety and efficient stopping power. |

| Drivetrain | Robust configuration that delivers power to the wheels, enhancing performance and towing capacity. |

Understanding these features not only aids in maintenance but also enhances the driving experience, ensuring that owners can fully appreciate the capabilities of their vehicle.

Importance of Front End Components

The significance of various structural elements at the forefront of a vehicle cannot be overstated. These components play a crucial role in ensuring stability, steering precision, and overall safety during operation. Their design and functionality directly influence the driving experience and vehicle performance.

Durability is one of the primary reasons why these elements are vital. They are engineered to withstand stress and impact, contributing to the longevity of the vehicle. Additionally, alignment among these components is essential for optimal handling and tire wear, enhancing efficiency and comfort.

Moreover, the integration of advanced materials and technologies in these systems fosters improved responsiveness and control, which is critical for maneuvering in various conditions. Investing in quality components can ultimately lead to a more reliable and enjoyable driving experience.

Common Issues with Front End Components

Maintenance and performance can be significantly impacted by wear and tear in various components of a vehicle’s suspension and steering system. Identifying and addressing these common challenges early can enhance safety and prolong the lifespan of the vehicle.

Typical Problems

- Worn Bushings: These rubber or polyurethane pieces can degrade over time, leading to poor handling and increased vibrations.

- Ball Joint Failure: A crucial joint that allows for movement, failure can result in a clunking noise and uneven tire wear.

- Steering Rack Issues: Problems here can lead to difficulty steering, abnormal noises, or fluid leaks.

- Misaligned Components: Misalignment can cause uneven tire wear, poor handling, and increased fuel consumption.

Signs of Trouble

- Increased play in the steering wheel.

- Unusual noises when turning or driving over bumps.

- Uneven tire wear patterns.

- Vibrations or shaking at higher speeds.

Addressing these issues promptly can improve overall driving experience and vehicle safety.

Overview of the Parts Diagram

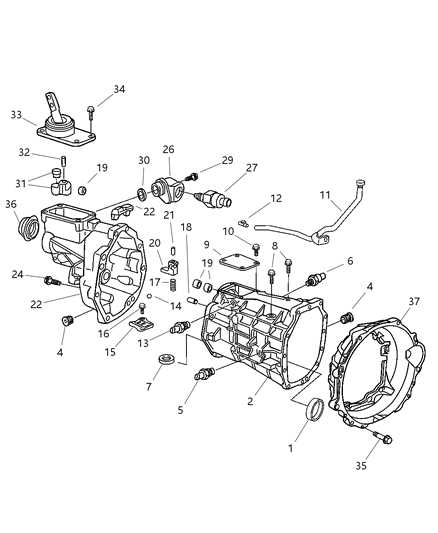

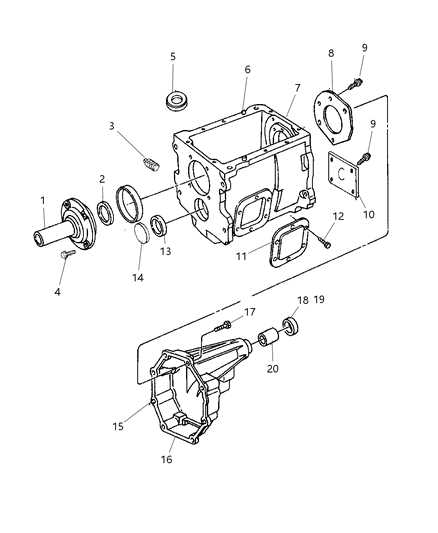

This section provides a comprehensive examination of the components involved in the vehicle’s front assembly. Understanding these elements is essential for effective maintenance and repair.

- Structure: Highlights the foundational elements supporting overall integrity.

- Suspension: Details the system crucial for handling and ride comfort.

- Steering: Describes mechanisms that facilitate directional control.

- Braking: Outlines components that ensure safety during operation.

By familiarizing yourself with these parts, you can delve deeper into specific functionalities and their interactions within the assembly.

Key Components in the Diagram

This section explores the essential elements represented in the visual layout, highlighting their significance and functions within the assembly. Understanding these components can enhance maintenance and repair efforts.

Essential Elements

- Suspension System

- Steering Mechanism

- Braking Components

- Crossmembers

- Control Arms

Functionality Overview

- Suspension System: Provides stability and comfort during operation.

- Steering Mechanism: Facilitates directional control.

- Braking Components: Ensures effective stopping power.

- Crossmembers: Offers structural support.

- Control Arms: Connects the suspension to the vehicle’s frame.

How to Read the Diagram

Understanding a schematic representation can greatly enhance your ability to identify and work with various components of a vehicle’s structure. This section will provide you with essential insights on interpreting such illustrations effectively.

- Familiarize Yourself with Symbols: Different symbols represent various components. Make sure to know what each symbol signifies.

- Follow the Lines: Lines indicate connections between elements. Pay attention to how they guide you through the layout.

- Check the Legend: Most diagrams include a legend or key. This will clarify any symbols or markings used in the illustration.

- Note the Labels: Labels provide valuable information regarding each component. Read them carefully to avoid confusion.

By keeping these points in mind, you will be better equipped to navigate the schematic and grasp the ultimate relationships between components.

Maintenance Tips for Front End Parts

Ensuring the longevity and optimal performance of your vehicle’s steering and suspension components is crucial. Regular attention can prevent costly repairs and enhance safety. Here are some essential maintenance strategies.

Routine Inspections

- Check for wear on bushings and joints.

- Inspect steering components for signs of damage.

- Look for leaks in hydraulic systems.

Regular Lubrication

- Apply grease to fittings as recommended by the manufacturer.

- Use appropriate lubricants to reduce friction.

- Ensure all moving parts are adequately maintained.

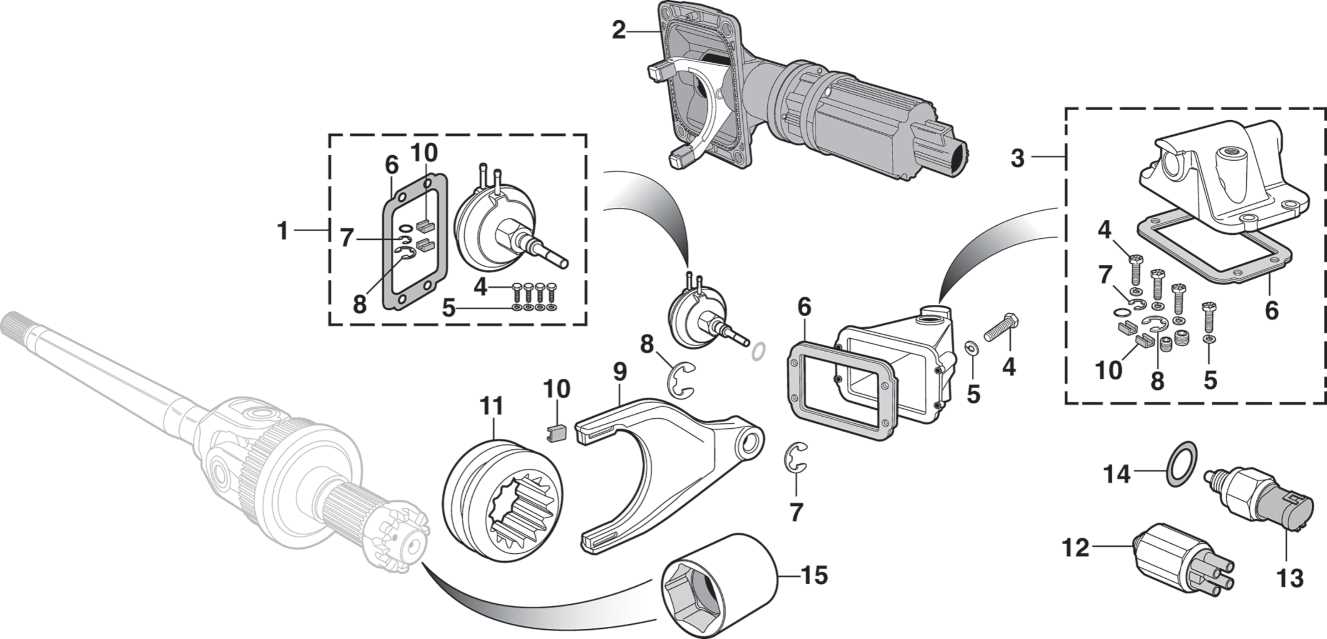

Replacing Front End Components

Maintaining and updating the essential components at the vehicle’s front can enhance performance and safety. This process involves understanding the various elements that require attention, ensuring a smoother ride and better handling.

Common Components to Replace

- Bumpers

- Grilles

- Fenders

- Headlights

- Suspension Parts

Steps for Replacement

- Gather necessary tools and replacement items.

- Carefully remove the old component.

- Inspect surrounding areas for any damage.

- Install the new part securely.

- Test functionality and alignment.

Following these guidelines will help ensure that the vehicle operates optimally and maintains its appearance. Always consult a professional if unsure about any steps.

Tools Needed for Replacement

When undertaking the task of replacing components in your vehicle’s front assembly, having the right equipment is essential for a successful and efficient process. Proper tools not only ensure safety but also help achieve precise results, minimizing the risk of damage to the new and existing components.

Essential Tools

| Tool | Purpose |

|---|---|

| Socket Set | For loosening and tightening bolts and nuts. |

| Wrench | To access tight spaces and secure fittings. |

| Jack Stands | To safely support the vehicle during work. |

| Torque Wrench | For applying precise torque to fasteners. |

| Screwdrivers | For removing and installing screws. |

Additional Items

Consider having items like a rubber mallet for gentle adjustments, pliers for gripping, and a shop vacuum for cleaning up debris. Gathering all necessary tools beforehand can streamline the replacement process and enhance overall efficiency.

Cost Estimates for Repairs

When addressing repairs for a vehicle’s exterior components, it’s essential to consider various factors that influence the overall expenses. These factors include the type of damage, the quality of replacement items, and labor costs associated with the repairs. Understanding these elements can help in planning a budget for necessary maintenance.

| Component | Estimated Cost (Parts) | Estimated Labor Cost |

|---|---|---|

| Bumper | $150 – $500 | $100 – $200 |

| Grille | $50 – $200 | $50 – $150 |

| Fender | $100 – $300 | $75 – $175 |

| Headlight Assembly | $75 – $300 | $50 – $100 |

| Suspension Components | $200 – $700 | $150 – $300 |

Finding Quality Replacement Parts

When it comes to maintaining your vehicle’s performance, sourcing high-quality components is essential. Properly chosen replacements can enhance reliability and extend the lifespan of your automobile. This section will guide you through the process of finding trustworthy alternatives, ensuring your ride remains in top condition.

Here are some key factors to consider while searching for suitable components:

| Factor | Description |

|---|---|

| Material Quality | Look for components made from durable materials to withstand wear and tear. |

| Brand Reputation | Choose well-known brands that are recognized for their reliability and performance. |

| Warranty | A solid warranty indicates confidence in the product and protects your investment. |

| Customer Reviews | Check feedback from other buyers to gauge the effectiveness and durability of the items. |

| Compatibility | Ensure that the replacements are compatible with your vehicle model for optimal performance. |

By focusing on these aspects, you can confidently make informed decisions and ensure your vehicle operates smoothly for years to come.

Aftermarket vs. OEM Parts

When it comes to vehicle maintenance and repairs, choosing the right components is crucial for ensuring performance and longevity. Two primary categories of components are often considered: those produced by original manufacturers and those made by third-party vendors. Each option presents unique advantages and potential drawbacks that can significantly impact vehicle reliability and owner satisfaction.

Quality and Reliability

Original equipment manufacturer (OEM) components are designed specifically for a particular make and model, ensuring a precise fit and function. They often come with warranties that reflect their quality and reliability. In contrast, aftermarket alternatives can vary widely in terms of construction and performance. Some may exceed OEM standards, while others might fall short, making it essential for consumers to research and select reputable brands.

Cost Considerations

Pricing is another key factor influencing the decision between OEM and alternative components. Typically, OEM items tend to be more expensive due to their guaranteed quality and brand recognition. Conversely, aftermarket options can be more budget-friendly, offering a range of prices and choices. However, the lower upfront cost of aftermarket components may not always translate to long-term savings if they require more frequent replacements.

Ultimately, the choice between original and alternative components will depend on individual priorities, including budget, desired quality, and long-term vehicle performance goals.

Expert Advice on Installation

When undertaking the task of replacing components in a vehicle’s suspension and steering system, it’s crucial to approach the installation process methodically. Proper techniques can ensure optimal performance and longevity of the new components.

Preparation Steps

- Gather all necessary tools and replacement components.

- Consult the service manual for specific guidelines related to your vehicle model.

- Work in a well-lit and organized environment to avoid misplacing parts.

Installation Tips

- Always use high-quality replacement components to enhance reliability.

- Follow a systematic approach; start with the easier components before progressing to more complex ones.

- Torque all fasteners to manufacturer specifications to prevent loosening over time.