Front End Parts Diagram for 2006 Dodge Ram 2500

In the realm of heavy-duty trucks, the effectiveness of the suspension system is crucial for both performance and safety. This section delves into the various elements that constitute the assembly at the front, emphasizing their roles and interactions. By gaining insight into these components, enthusiasts and technicians alike can enhance their understanding of vehicle mechanics and maintenance.

The suspension system is designed to absorb shocks and ensure a smooth ride, contributing significantly to the vehicle’s handling and stability. Each element within this assembly serves a specific function, whether it be in supporting the weight of the vehicle, maintaining alignment, or facilitating steering. A thorough exploration of these components allows for better diagnostics and informed decision-making when it comes to repairs and upgrades.

By examining the intricate layout of this assembly, individuals can better appreciate the engineering that goes into heavy-duty vehicles. Whether for personal projects or professional work, knowledge of these components is essential for anyone looking to optimize performance and prolong the lifespan of their vehicle.

Various components located at the front section of a vehicle often experience specific challenges that can affect overall performance and safety. Understanding these common problems is essential for maintaining optimal function and ensuring a smooth driving experience.

One frequent issue encountered is the wear and tear of suspension components, which can lead to decreased handling capabilities and increased road noise. Additionally, misalignment of various elements can result in uneven tire wear, further compromising vehicle stability.

Another concern involves the degradation of rubber bushings, which can cause vibrations and noises during operation. Failure to address these issues promptly can lead to more extensive repairs and potentially hazardous driving conditions.

| Component | Common Issue | Symptoms |

|---|---|---|

| Suspension Arms | Worn Bushings | Vibration, Noise |

| Steering Rack | Fluid Leaks | Difficulty Steering |

| Shock Absorbers | Loss of Dampening | Rough Ride, Body Roll |

| Ball Joints | Excess Play | Steering Wander |

Regular inspection and timely maintenance of these components are crucial in preventing serious complications. Addressing minor issues early on can save time and resources in the long run, ensuring a safer and more reliable vehicle operation.

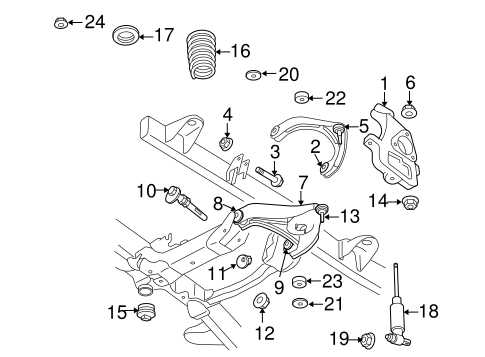

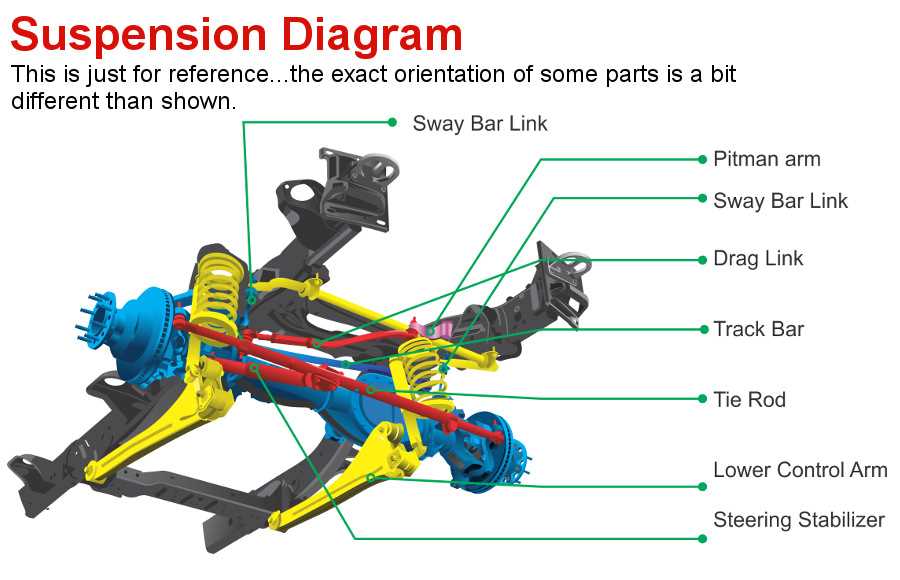

Understanding the Front Suspension System

The front suspension assembly plays a crucial role in a vehicle’s handling and ride quality. This system is designed to absorb shocks from the road, ensuring that the vehicle remains stable and comfortable for passengers. By understanding its components and their functions, one can appreciate the intricate engineering that contributes to a smooth driving experience.

Key Components of the Suspension Assembly

At the heart of the suspension layout are several essential elements. The control arms serve to connect the chassis to the wheels, allowing for controlled movement while maintaining alignment. Shocks and struts are responsible for dampening the impact of road irregularities, providing stability during motion. Additionally, the sway bar enhances the vehicle’s cornering capability by minimizing body roll.

Importance of Regular Maintenance

Regular inspection and upkeep of the suspension system are vital for safe and effective vehicle operation. Worn components can lead to reduced handling performance and increased tire wear. Timely replacement of deteriorated parts not only prolongs the lifespan of the system but also ensures a safer driving experience.

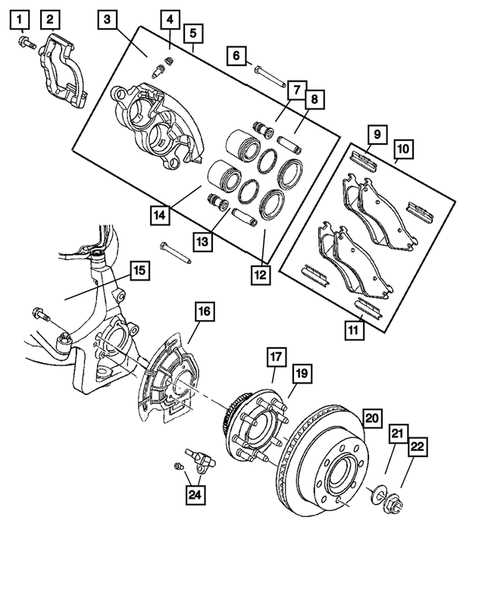

Identifying Front End Parts by Function

Understanding the components located at the front section of a vehicle is crucial for effective maintenance and repair. Each element plays a specific role, contributing to overall performance and safety. By recognizing these functions, owners can make informed decisions regarding upgrades or replacements.

Suspension components are essential for providing stability and support while driving. They absorb shocks and enhance ride comfort, ensuring that the vehicle handles well on various terrains.

Steering elements facilitate directional control, allowing the driver to maneuver the vehicle with precision. A well-maintained steering system is vital for safe driving, as it directly influences responsiveness.

Brake assemblies play a significant role in safety. These components ensure the vehicle can decelerate effectively and stop when necessary. Regular inspection of the braking system is crucial for avoiding potential hazards.

Additionally, cooling systems are integrated into the structure to prevent overheating. These components maintain optimal engine temperature, which is essential for long-term functionality.

Lastly, body structures contribute to both aesthetics and aerodynamics, affecting fuel efficiency and overall vehicle dynamics. Recognizing these various functions allows for better comprehension of maintenance needs and performance enhancements.

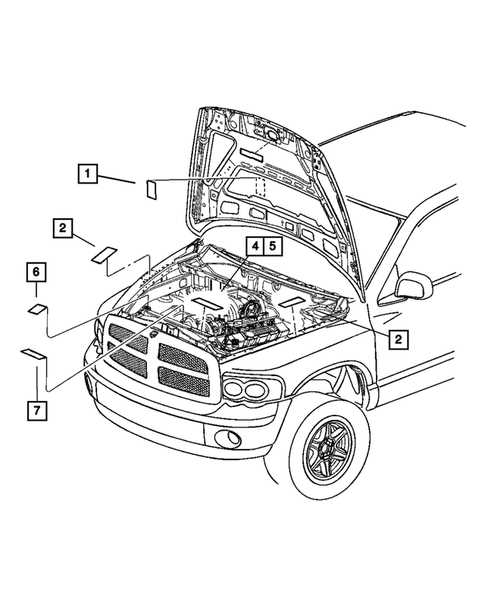

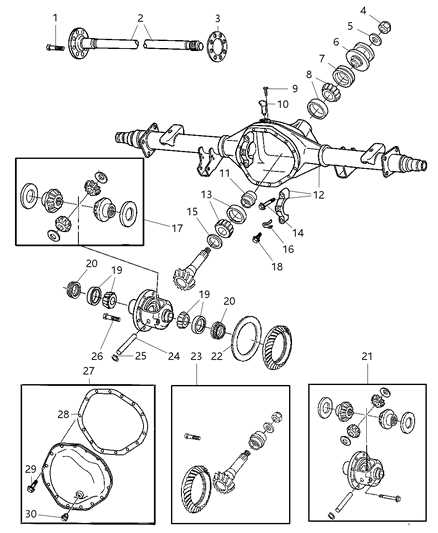

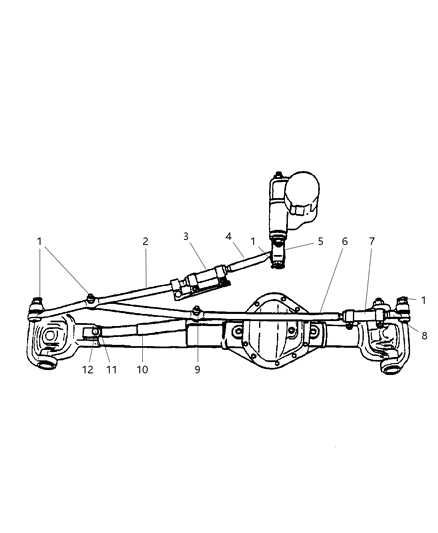

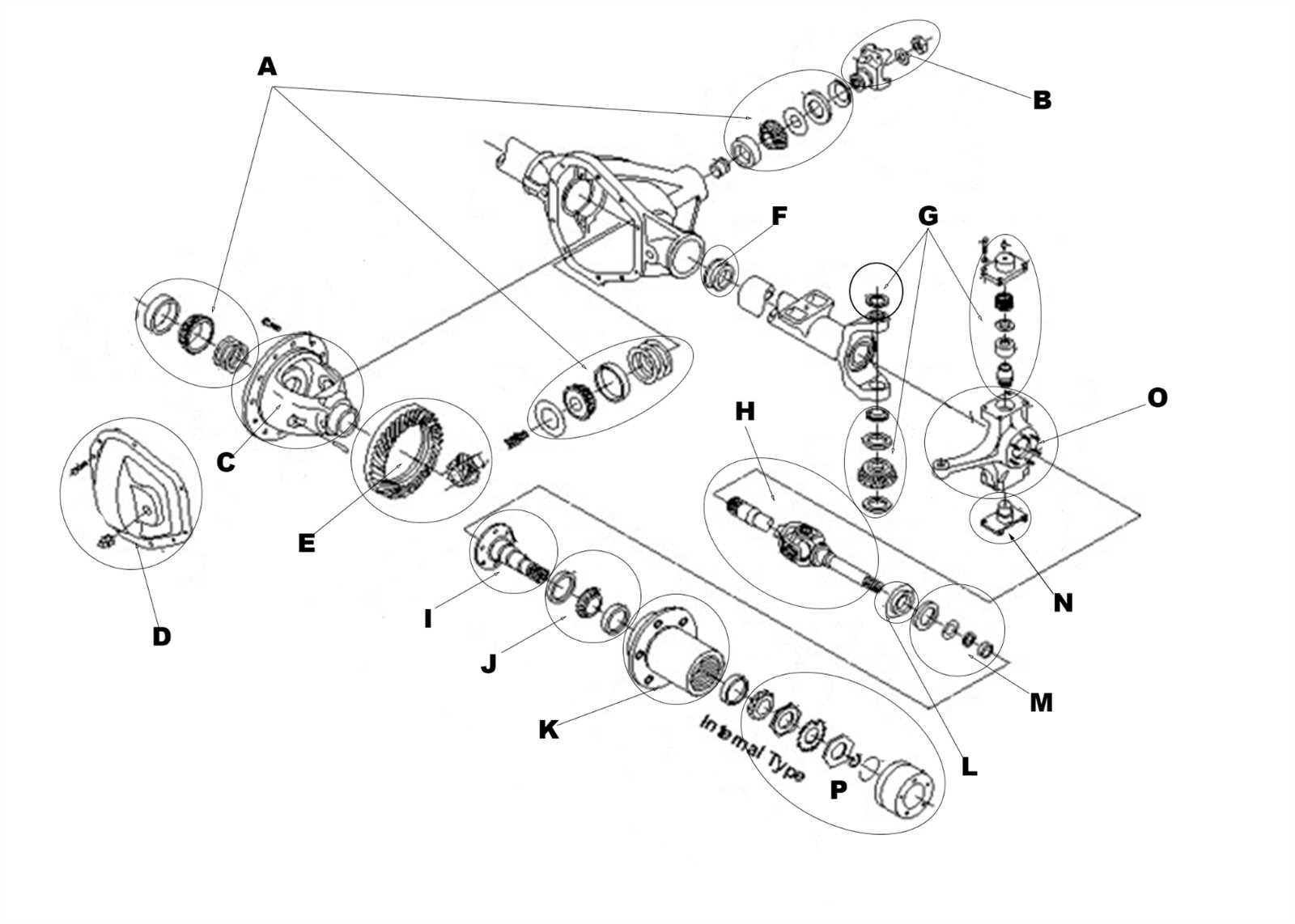

Visual Reference for Part Locations

This section provides a comprehensive guide to identifying the various components within the vehicle’s architecture. By utilizing a visual reference, users can easily locate and understand the arrangement of each element, facilitating maintenance and repair tasks.

Understanding the Layout: A clear illustration can significantly enhance one’s ability to navigate through the complex structure. By familiarizing oneself with the configuration, individuals can swiftly pinpoint specific items that may require attention or replacement.

Importance of Clarity: Accurate depictions not only aid in locating components but also ensure that all necessary tools and resources are at hand before commencing work. This preparation can lead to a more efficient process and prevent potential errors during the repair or installation procedures.

Replacement Options for Worn Components

Maintaining optimal vehicle performance often necessitates the replacement of aged or damaged elements in the suspension and steering system. Addressing these issues promptly not only enhances safety but also contributes to improved driving experience. Various alternatives are available to ensure that your vehicle remains in excellent condition, each with its own benefits and considerations.

Aftermarket Alternatives

Aftermarket options can provide a cost-effective solution when seeking replacements. These components, produced by third-party manufacturers, often come with a competitive price point while still meeting necessary standards for quality and performance. It is essential to choose reputable brands to avoid compromising the vehicle’s integrity.

OEM Components

Original Equipment Manufacturer (OEM) components are another choice for those who prefer parts that match the specifications of the original vehicle. While often more expensive, these pieces are designed for a precise fit and optimal functionality, ensuring that the replacement maintains the vehicle’s original performance characteristics.

| Component Type | Aftermarket Options | OEM Options |

|---|---|---|

| Shock Absorbers | Varied brands with adjustable features | Manufacturer-specific designs for exact fit |

| Control Arms | Durable materials at lower costs | High-quality, original specifications |

| Steering Rack | Compatible models available from multiple suppliers | Guaranteed to fit with factory performance |

Tools Needed for Front End Repairs

When tackling repairs in the front assembly of a vehicle, having the right tools is essential for achieving successful outcomes. Proper equipment ensures that tasks can be performed efficiently and safely, minimizing the risk of damage to components. Below is a selection of tools that are commonly required for these types of maintenance and repairs.

Essential Tools

The following tools are fundamental for addressing various repair tasks in the front assembly:

| Tool | Purpose |

|---|---|

| Socket Set | Used for loosening and tightening bolts and nuts. |

| Torque Wrench | Ensures that fasteners are tightened to the manufacturer’s specifications. |

| Pry Bar | Helps in removing stubborn components by providing leverage. |

| Jack Stands | Stabilizes the vehicle while working underneath it for safety. |

| Ball Joint Separator | Facilitates the removal of ball joints without damaging surrounding parts. |

Additional Equipment

In addition to the essential tools, other equipment can enhance the repair process:

| Tool | Purpose |

|---|---|

| Impact Wrench | Speeds up the removal of bolts and nuts by providing high torque. |

| Mechanic’s Creeper | Allows easy movement under the vehicle while working. |

| Wire Brush | Removes rust and debris from components for better contact. |

| Multimeter | Used for diagnosing electrical issues within the assembly. |

| Service Manual | Provides detailed information and specifications for repairs. |

Step-by-Step Assembly Process

The process of reassembling the vehicle’s frontal components requires careful attention to detail and methodical execution. Each component plays a crucial role in ensuring structural integrity and functionality, making it essential to follow the assembly procedure accurately.

1. Prepare the Workspace: Ensure the workspace is clean and organized. Gather all necessary tools and components to streamline the assembly process.

2. Install the Chassis Components: Begin by securing the main chassis components in place. Ensure that each piece fits snugly and aligns properly to maintain the vehicle’s stability.

3. Attach Supporting Brackets: Next, attach the supporting brackets. These pieces provide additional stability and support for other components, so it’s vital to ensure they are fastened correctly.

4. Mount the Primary Structure: Carefully mount the primary structure onto the chassis. Check for proper alignment and secure all fasteners tightly to prevent any movement.

5. Connect Auxiliary Components: Once the primary structure is in place, connect any auxiliary components. This may include systems for cooling or electrical connections, depending on the specific setup.

6. Verify Fit and Function: After assembly, take time to verify that all components fit correctly and function as intended. Conduct thorough checks to ensure that nothing is misaligned or improperly installed.

7. Final Inspection: Finally, perform a comprehensive inspection of the entire assembly. Look for any loose fasteners, misalignments, or potential issues that could affect performance.

By following these steps diligently, you can achieve a successful assembly that enhances the overall performance and durability of the vehicle.

Upgrades for Enhanced Performance

When aiming to elevate the capabilities of a heavy-duty vehicle, focusing on specific enhancements can make a significant difference. Whether you’re looking to boost handling, increase towing capacity, or improve overall stability, various modifications can be implemented to achieve these goals.

Suspension improvements are among the most effective modifications. Upgrading to high-performance shocks and struts can greatly enhance ride quality and handling, particularly under heavy loads. This adjustment not only increases comfort but also provides better control on rough terrains.

Another vital aspect is the braking system. Installing upgraded rotors and pads can improve stopping power and reduce brake fade, ensuring safety and reliability. Enhanced braking components contribute to a more confident driving experience, especially when towing or carrying heavy loads.

Additionally, consider engine tuning options that can optimize fuel efficiency and increase horsepower. Aftermarket performance chips or tuners can adjust the engine’s settings for better power delivery and responsiveness, resulting in a more engaging driving experience.

Lastly, tire upgrades should not be overlooked. Choosing high-quality, all-terrain tires can improve traction and handling, making it easier to navigate various surfaces while ensuring better durability. Investing in the right tires can lead to enhanced performance and safety on the road.

Safety Tips During Repair Work

Engaging in maintenance tasks can be rewarding, yet it is essential to prioritize safety throughout the process. Taking precautionary measures can prevent accidents and injuries, ensuring a smooth and successful repair experience. Whether you’re a seasoned professional or a novice enthusiast, adhering to safety guidelines will help you work more efficiently and confidently.

Essential Precautions

Before starting any repair work, it is vital to familiarize yourself with the tools and equipment needed. Proper understanding can significantly reduce the risk of mishaps. Additionally, ensuring that your workspace is well-organized can create a safer environment.

| Tip | Description |

|---|---|

| Wear Protective Gear | Always use safety glasses, gloves, and appropriate footwear to safeguard against injuries. |

| Disconnect Power Sources | Before working on electrical components, ensure all power sources are disconnected to avoid shocks. |

| Use Tools Correctly | Utilize tools as intended, and ensure they are in good condition to prevent accidents. |

| Maintain Ventilation | Ensure adequate airflow in the workspace, especially when using chemicals or solvents. |

Post-Repair Procedures

Once the maintenance task is completed, take time to clean up the workspace. Proper disposal of materials and organizing tools will help prevent accidents in the future. Regularly reviewing safety practices will reinforce a culture of caution and preparedness for all repair activities.