Understanding the Front End Parts Diagram of the 2012 Dodge Ram 2500

When it comes to robust utility vehicles, the arrangement and functionality of various elements are crucial for performance and longevity. The intricate systems that make up the front section play a pivotal role in both handling and safety, ensuring that these vehicles can withstand demanding tasks and challenging terrains.

In this discussion, we delve into the essential components that constitute the leading part of these sturdy trucks. By examining their configuration and interrelation, we aim to provide a comprehensive overview that assists both enthusiasts and professionals in understanding how these components contribute to overall efficiency and reliability.

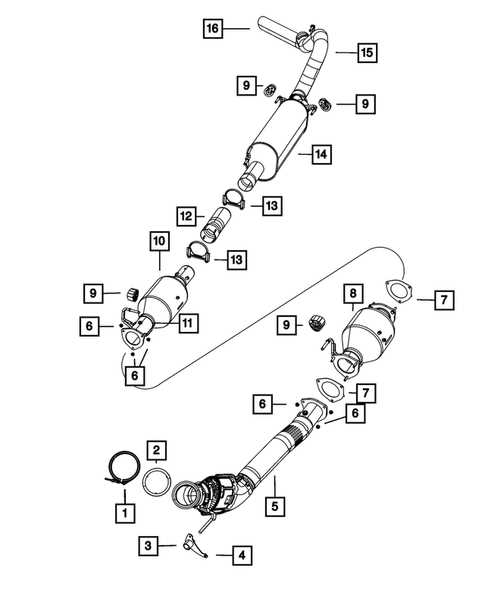

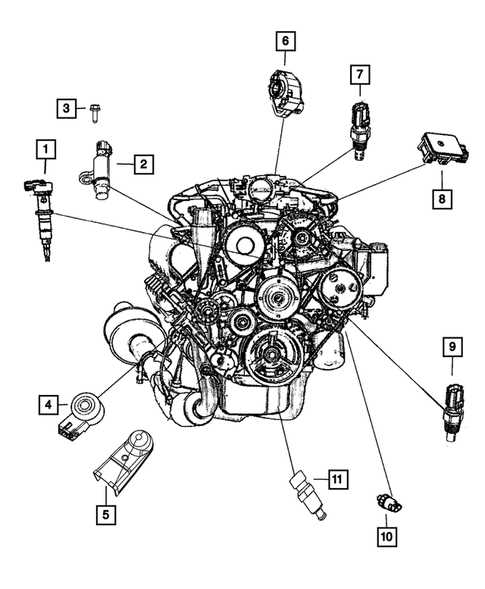

Moreover, visual aids can greatly enhance comprehension of these systems. Illustrations serve as invaluable references for those looking to diagnose issues or undertake modifications, making it easier to identify specific sections and their respective functions. This exploration will facilitate a deeper appreciation of the engineering behind these powerful machines.

Understanding the 2012 Dodge Ram 2500

This section aims to provide insights into a specific heavy-duty vehicle, emphasizing its structural components and their significance for optimal performance. Understanding the various assemblies and mechanisms will aid in maintenance and repair, ensuring longevity and reliability.

Key Components and Their Functions

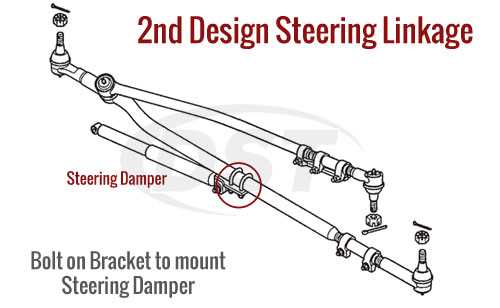

Every vehicle consists of numerous essential elements that work together harmoniously. The suspension system, for example, plays a critical role in ensuring a smooth ride, while the steering mechanism allows for precise handling. Additionally, understanding the role of the braking system is vital for safety, highlighting the importance of maintaining these components.

Maintenance and Upgrades

Regular upkeep is crucial for any automotive system. Routine inspections and timely replacements can prevent more significant issues down the line. Furthermore, exploring potential enhancements can improve performance and efficiency. Upgrading specific assemblies can provide not only better functionality but also contribute to a more enjoyable driving experience.

In conclusion, a thorough grasp of the various assemblies within a specific heavy-duty vehicle can greatly enhance ownership experience. Emphasizing maintenance and understanding functionality will ensure that the vehicle remains reliable for years to come.

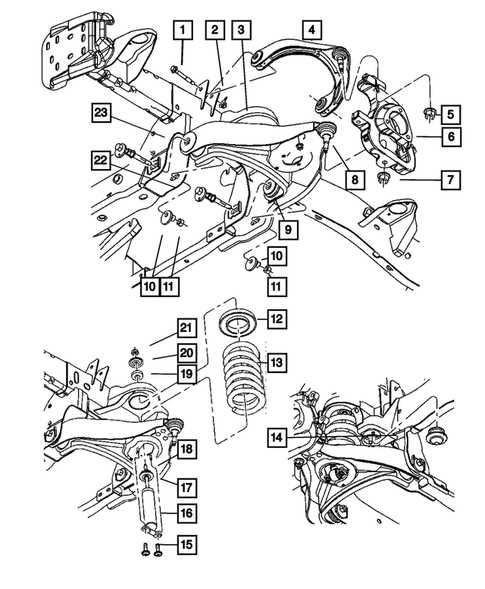

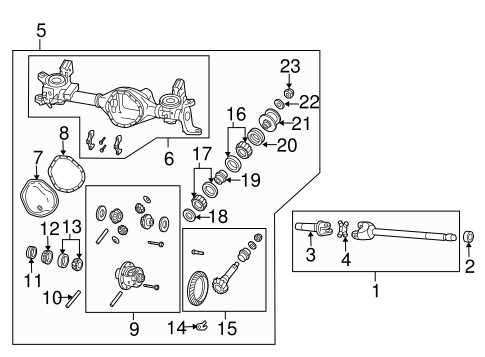

Overview of Front End Components

The components located at the front section of a vehicle play a crucial role in its overall functionality and safety. These elements work in harmony to ensure optimal performance, providing support, stability, and protection. Understanding these components is essential for maintenance and repair, contributing to a smooth driving experience.

Key Components

Among the significant elements are the axles, suspension systems, and steering mechanisms. Each of these parts is designed to enhance maneuverability and absorb road imperfections, ensuring comfort and control. Regular inspection and timely replacement of these components can prevent extensive damage and enhance vehicle longevity.

Importance of Maintenance

Routine checks on these crucial components are vital for safety. Neglecting their condition may lead to unexpected failures and costly repairs. By prioritizing care, drivers can ensure their vehicle remains in peak condition, ultimately leading to a more reliable and enjoyable journey.

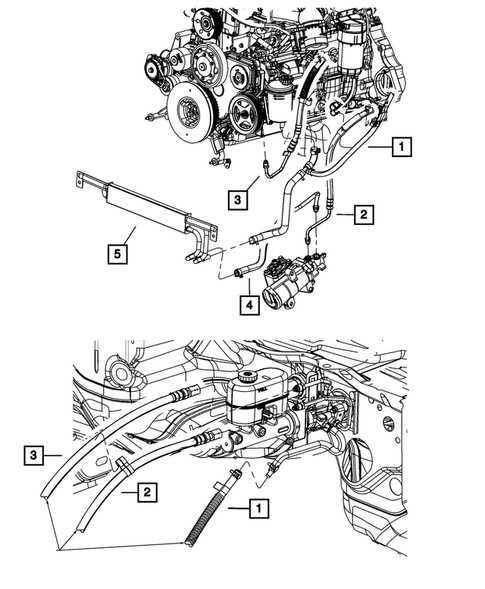

Importance of Proper Diagrams

Clear and accurate illustrations play a vital role in understanding the assembly and functionality of complex systems. These visual representations serve as essential tools for both professionals and enthusiasts, ensuring that components are correctly identified and assembled. When details are laid out effectively, it minimizes the risk of errors and enhances the overall efficiency of any project.

Enhanced Understanding

Well-structured visuals enable users to grasp intricate details quickly. By breaking down complex structures into understandable segments, they facilitate better comprehension of how each element interacts within the whole. This clarity is especially crucial in maintenance and repair tasks, where precision is paramount.

Efficiency and Accuracy

Utilizing accurate illustrations can significantly improve workflow. When individuals have access to reliable references, they can avoid costly mistakes and save time during installation or repair processes. Proper diagrams not only streamline operations but also promote confidence in handling various components. In the long run, this leads to better performance and longevity of the system.

Common Issues with Front End Parts

The components located at the front of a vehicle are essential for ensuring stability, steering, and overall performance. Over time, these elements may experience wear and tear due to various factors, leading to noticeable problems. Understanding these common issues can help in timely maintenance and repairs, ultimately extending the lifespan of your vehicle.

Signs of Wear

One of the primary indicators of deterioration is unusual noise when turning the steering wheel or driving over bumps. Additionally, uneven tire wear can signal misalignment or damaged components. Drivers may also notice a decrease in handling and responsiveness, which could indicate that the steering system or suspension is compromised.

Common Components Affected

| Component | Common Issues |

|---|---|

| Ball Joints | Wear leading to loose steering and clunking noises. |

| Control Arms | Corrosion and bending affecting alignment and stability. |

| Shock Absorbers | Fluid leaks resulting in poor ride quality and excessive bouncing. |

| Steering Rack | Leaks or play causing steering sensitivity issues. |

Regular inspections and maintenance of these components are crucial for safe and efficient vehicle operation. Being proactive can prevent minor issues from escalating into significant problems, ensuring a smoother driving experience.

Identifying OEM vs. Aftermarket Parts

Understanding the distinction between original equipment manufacturer (OEM) and aftermarket components is crucial for any vehicle owner. These options can significantly affect performance, reliability, and overall vehicle integrity. It’s essential to evaluate the advantages and disadvantages of each to make an informed choice that aligns with your needs.

OEM Components

OEM components are produced by the vehicle’s original manufacturer. They are designed to meet specific standards, ensuring a perfect fit and function. Quality assurance is a significant advantage, as these components typically undergo rigorous testing and are backed by warranties. However, they may come at a higher price point.

Aftermarket Alternatives

Aftermarket alternatives are produced by third-party companies and often offer a wider range of options. While some may provide excellent quality and competitive pricing, others might compromise on durability. Research is vital when considering these alternatives, as the performance can vary greatly among different brands.

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for efficient repairs and maintenance. These visuals provide a clear layout of each element, helping you identify and locate necessary items quickly. Familiarizing yourself with this format can enhance your troubleshooting skills.

Key Elements to Recognize

- Labels: Each component is usually marked with a specific identifier, aiding in easy reference.

- Connections: Lines or arrows illustrate how parts interact or link together, which is crucial for assembly or disassembly.

- Legends: Some diagrams include a legend that explains symbols and color codes, providing further clarity.

Steps for Effective Interpretation

- Start by locating the main components in the visual.

- Follow the connections to understand how they work together.

- Refer to any legends or notes for additional information.

- Cross-check with manuals or guides for context if needed.

Tools Needed for Front End Repair

When undertaking repairs on the front assembly of a vehicle, having the right tools is crucial for a successful and efficient job. A well-equipped workspace ensures that tasks are completed safely and effectively.

- Wrenches (both standard and metric)

- Socket set with ratchet

- Torque wrench

- Ball joint separator

- Control arm puller

- Hammer and rubber mallet

- Pry bar

- Jack stands and floor jack

- Safety goggles and gloves

Having these essential tools on hand will allow for a comprehensive approach to addressing any issues that arise in the vehicle’s front structure.

Step-by-Step Installation Guide

This guide provides a comprehensive approach to installing essential components of your vehicle’s front assembly. Following these instructions will ensure proper alignment and functionality, enhancing overall performance and safety.

Tools Required

| Tool | Description |

|---|---|

| Socket Wrench | For loosening and tightening bolts. |

| Torque Wrench | To apply the correct torque to fasteners. |

| Pry Bar | Helps in removing stubborn components. |

| Jack Stands | For securely lifting the vehicle. |

Installation Steps

Begin by securely lifting the vehicle and removing the wheel. Next, detach the existing components, taking care to note their arrangement. Install the new parts in the reverse order, ensuring each piece is properly aligned. Finally, torque all fasteners to manufacturer specifications before reattaching the wheel and lowering the vehicle.

Maintenance Tips for Longevity

Regular upkeep is essential to ensure the durability and reliability of your vehicle. By adhering to a consistent maintenance schedule, you can prevent costly repairs and extend the lifespan of your automobile.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Oil Change | Every 5,000 miles | Improves engine performance and fuel efficiency |

| Tire Rotation | Every 6,000 miles | Ensures even wear and enhances traction |

| Brake Inspection | Every 10,000 miles | Ensures safety and prevents further damage |

| Fluid Checks | Monthly | Prevents overheating and maintains system efficiency |

Implementing these practices will not only safeguard your vehicle’s performance but also contribute to a smoother driving experience over time.

Signs of Wear in Front End Parts

Recognizing the indicators of deterioration in vehicle components is essential for maintaining optimal performance and safety. Understanding these signs can prevent costly repairs and enhance driving stability.

Common symptoms of wear include:

- Unusual Noises: Clunking or squeaking sounds while driving can signal issues with joints or bushings.

- Vibration: Excessive shaking of the steering wheel may indicate imbalances or worn components.

- Pulling to One Side: A vehicle that drifts to the left or right could have misaligned wheels or uneven wear.

- Uneven Tire Wear: Bald spots or uneven tread can suggest problems with alignment or suspension elements.

- Loose Steering: A vague or unresponsive steering feel can indicate worn out linkages or bearings.

Regular inspections can help identify these issues early, ensuring safer and smoother rides.

Comparative Analysis of Models

This section aims to explore the distinctions and similarities among various heavy-duty vehicles, focusing on their structural components and engineering designs. By examining the features and functionalities, we can gain insights into the performance and reliability of each model.

One key area of comparison is the suspension system, which plays a crucial role in ride quality and load handling. Different manufacturers implement unique technologies, impacting durability and handling characteristics. Analyzing these variations reveals the ultimate strengths and weaknesses inherent to each design.

Another important aspect is the materials used in construction, which can affect weight distribution and overall efficiency. Some models prioritize lightweight materials to enhance fuel economy, while others emphasize robust construction for maximum durability under heavy loads.

In addition, the integration of modern technology such as enhanced steering mechanisms and braking systems can significantly influence driver experience and safety. Evaluating these innovations provides a deeper understanding of how each vehicle adapts to consumer needs and industry standards.

Upgrades for Enhanced Performance

Improving vehicle dynamics is essential for those seeking a more robust driving experience. By focusing on specific enhancements, drivers can achieve superior handling, increased stability, and overall better performance. Various modifications can transform the way a vehicle operates, providing both functionality and enjoyment.

Suspension Enhancements

Upgrading the suspension system is one of the most effective ways to enhance performance. Consider installing heavy-duty shock absorbers and coil springs for improved ride quality and load management. Adjustable components allow for tailored setups, ensuring optimal handling under various conditions.

Brake System Upgrades

A high-performance braking system is crucial for safety and efficiency. Replacing standard components with premium rotors and calipers can significantly reduce stopping distances. Upgraded brake pads further enhance performance by providing better grip, especially in demanding situations.

Resources for Parts and Diagrams

When it comes to maintaining and repairing your vehicle, having access to reliable resources for components and schematics is essential. These materials not only aid in the identification of necessary elements but also enhance understanding of their arrangement and functionality. Various platforms and tools are available to ensure you have the information needed for effective upkeep.

Online Databases and Forums

Numerous websites offer extensive databases of components, complete with images and detailed descriptions. Engaging in automotive forums can also provide valuable insights, as enthusiasts and professionals share their experiences and knowledge. These communities often have sections dedicated to specific models, making it easier to find tailored information.

Manufacturer Manuals and Guides

Official manuals from manufacturers are invaluable resources, providing comprehensive details about each element’s specifications and installation procedures. These guides often include exploded views that clarify the assembly of complex systems, ensuring a smoother repair or upgrade process. Utilizing these official documents can significantly reduce the risk of errors during maintenance.