Understanding Amarr Garage Door Parts with Detailed Diagrams

The intricacies of vehicle access systems often go unnoticed until an issue arises. A well-functioning entry mechanism is crucial for security and convenience, making it essential to grasp its various elements. Knowing how these components interact can simplify maintenance and troubleshooting, ensuring longevity and reliability.

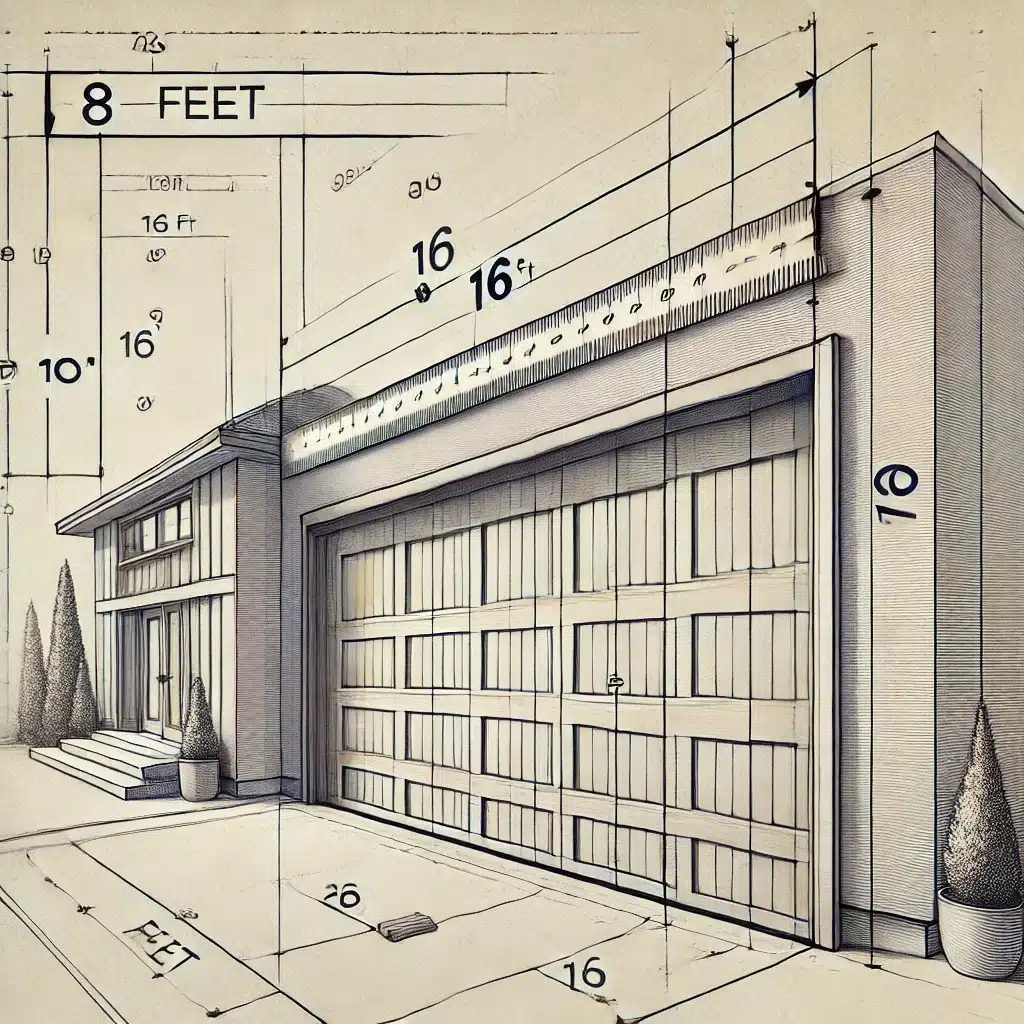

Each element plays a pivotal role in the overall operation, from the mechanism that facilitates movement to the hardware that secures it. Familiarity with these features not only enhances user experience but also empowers individuals to make informed decisions regarding repairs and replacements. A visual representation can be an invaluable tool for understanding the configuration and functionality of these critical components.

By delving into the specifics of these systems, one can appreciate the engineering behind their design and the importance of each individual piece. Whether you’re a homeowner, a technician, or simply curious, comprehending how these elements come together can provide significant insight into their performance and maintenance needs.

Understanding Amarr Garage Door Components

To maintain functionality and ensure smooth operation, it’s essential to grasp the various elements that make up the system. Familiarity with these components allows for effective troubleshooting and maintenance, leading to enhanced longevity.

Main Elements

- Tracks: Guides for movement.

- Springs: Provide tension and support.

- Panels: Create the exterior structure.

- Openers: Mechanisms for automated operation.

- Rollers: Facilitate smooth motion along tracks.

Maintenance Tips

- Regularly inspect springs for wear.

- Lubricate rollers and tracks to prevent friction.

- Ensure all fasteners are tight to maintain stability.

- Test the opener frequently for proper functionality.

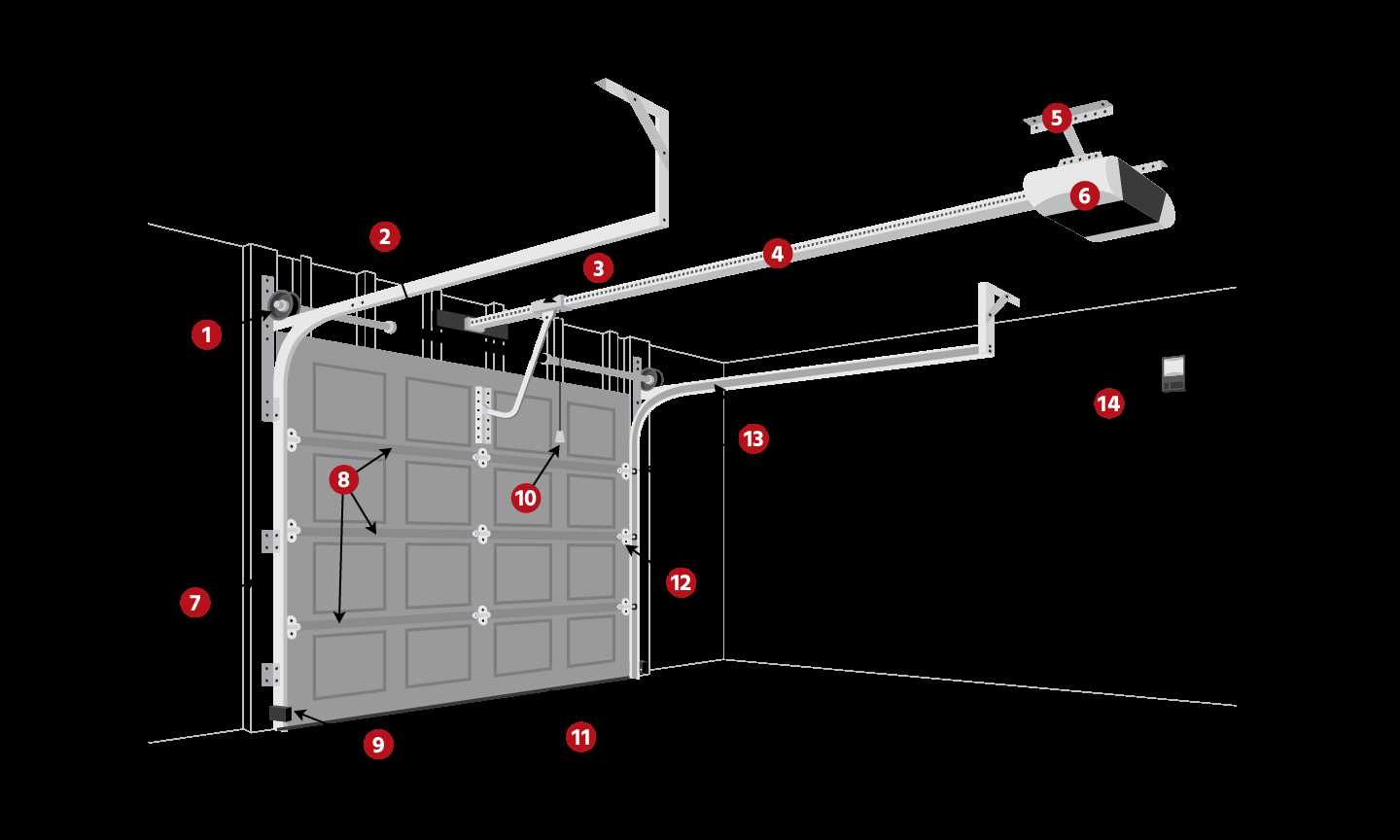

Overview of Garage Door Systems

Understanding the components of an entryway mechanism is crucial for efficient operation and maintenance. These systems incorporate various elements that work in harmony to provide security and convenience. Familiarity with their structure enhances troubleshooting and ensures longevity.

Key Components

The primary elements include the track, rollers, and lifting mechanism. The track serves as the guiding pathway, while the rollers facilitate smooth movement. The lifting mechanism, often powered by an electric opener, enables effortless operation.

Maintenance Tips

Regular inspection is essential for optimal functionality. Lubricating moving parts, checking for wear, and ensuring proper alignment can prevent costly repairs. Understanding these aspects will help in keeping the system in peak condition.

Key Features of Amarr Doors

The products in question stand out for their combination of durability, functionality, and aesthetic appeal. Designed to meet a variety of needs, they offer a range of options that cater to different preferences and requirements. The blend of quality materials and innovative technology ensures that these installations not only enhance the overall look of a property but also provide reliable performance over time.

Durability and Weather Resistance

Constructed with high-quality components, these systems are engineered to withstand harsh environmental conditions. The use of robust materials helps prevent wear and tear, ensuring longevity. Additionally, features such as insulation contribute to energy efficiency, making them suitable for various climates.

Customization Options

Offering a multitude of styles, colors, and finishes, these solutions can be tailored to complement any architectural design. Homeowners have the flexibility to choose features that best suit their aesthetic vision while maintaining the essential functionality needed for daily use.

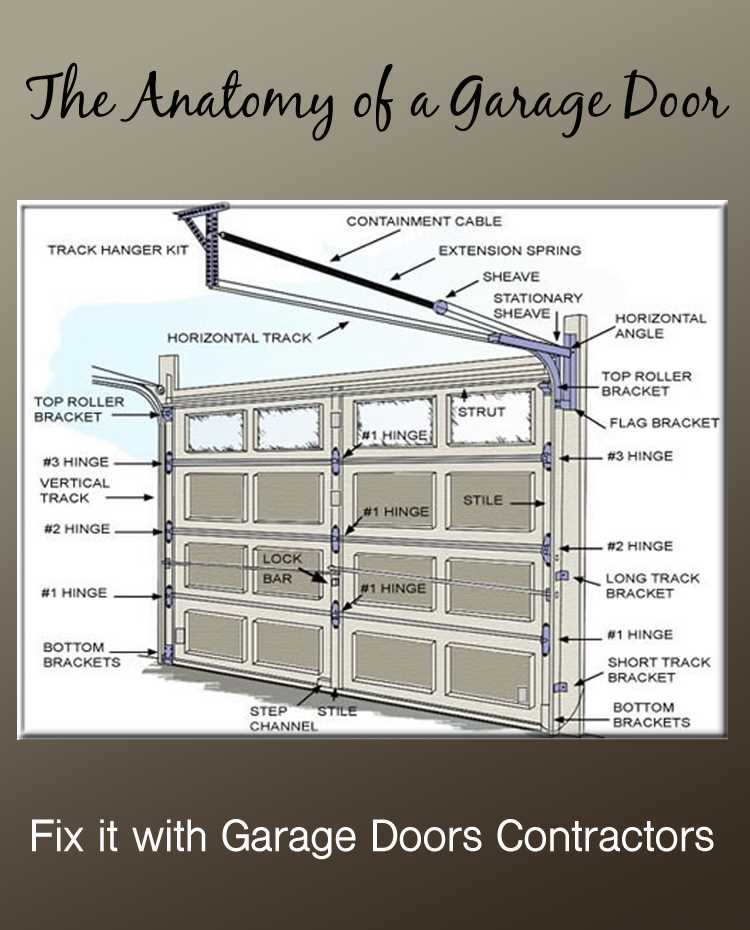

Common Parts and Their Functions

Understanding the components of a typical opening mechanism is essential for maintenance and troubleshooting. Each element plays a vital role in ensuring smooth operation and longevity. Below are some frequently encountered elements and their specific functions.

- Track: Guides the movement of the mechanism, allowing it to open and close seamlessly.

- Rollers: Facilitate smooth motion along the track, reducing friction and wear.

- Spring: Provides the necessary tension for lifting and lowering the unit, balancing the weight effectively.

- Opener: The motorized device that initiates movement, typically controlled by a remote or wall switch.

- Hinges: Connect various sections, allowing for flexible movement and alignment.

- Safety Sensors: Detect obstacles in the pathway, preventing accidents and ensuring user safety.

- Bracket: Secures components in place, providing stability and support to the entire assembly.

Familiarity with these elements not only aids in repairs but also enhances understanding of the overall system functionality.

How to Read a Parts Diagram

Understanding a schematic representation is essential for identifying components and their relationships within a mechanical system. This knowledge allows for effective maintenance and troubleshooting, ensuring longevity and optimal performance.

When examining such a representation, focus on the following aspects:

| Element | Description |

|---|---|

| Symbols | Each symbol represents a specific component; familiarize yourself with their meanings. |

| Labels | Labels provide important information, including part numbers and descriptions, aiding in quick identification. |

| Connections | Lines indicate how elements are interconnected, essential for understanding the overall layout. |

| Scale | Be mindful of the scale, as it can affect the accuracy of measurements and interpretations. |

By focusing on these key features, you can effectively navigate and interpret a schematic representation, making repairs and replacements more manageable.

Safety Mechanisms in Garage Doors

Ensuring the security and reliability of access systems is crucial in modern constructions. Various features are integrated to enhance user protection and prevent accidents. These mechanisms not only safeguard individuals but also prolong the lifespan of the installations.

Obstacle Detection is one of the fundamental components. This feature prevents the closing mechanism from proceeding if an object is detected in its path. It works through sensors that can identify physical obstructions, thereby reducing the risk of injury or damage.

Auto-Reverse Function further enhances safety. When a closing mechanism encounters resistance, it automatically reverses, preventing potential harm. This system is vital in homes with children or pets, ensuring a safe environment during operation.

Manual Release Mechanism is another essential element. In case of power outages or system failures, this feature allows for manual operation, ensuring that individuals can exit or enter safely without relying solely on automated functions.

Finally, Emergency Stop Button provides immediate control in critical situations. Located conveniently, it allows users to halt the movement instantly, offering peace of mind and enhancing overall safety.

Maintenance Tips for Longevity

Ensuring the durability of your entrance barrier involves consistent upkeep and attention to detail. By following a few key practices, you can significantly extend the lifespan of your mechanism and prevent potential issues from arising.

Regular inspection is crucial. Check for any signs of wear or damage, such as frayed cables or rusted components. Addressing minor issues promptly can prevent them from escalating into major problems.

Lubrication is essential for smooth operation. Apply a high-quality lubricant to all moving elements, including hinges and tracks, to reduce friction and minimize wear. This simple step can greatly enhance performance and quiet operation.

Keep the surrounding area clean and free of debris. Ensure that nothing obstructs the path of the mechanism. A clutter-free environment not only promotes efficient functioning but also reduces the risk of accidents.

Finally, consider scheduling professional evaluations. Having an expert assess your system periodically can identify potential issues before they become significant, ensuring long-term reliability and peace of mind.

Replacing Worn Parts Effectively

Maintaining optimal functionality requires addressing components that have deteriorated over time. Recognizing the signs of wear and understanding the process of replacement can significantly enhance performance and prolong the lifespan of the entire mechanism.

Identifying Signs of Wear

Before initiating the replacement process, it’s crucial to pinpoint which components have become ineffective. Look for irregular noises, sluggish movement, or visible damage. Regular inspections can help you catch these issues early, ensuring a smoother operation in the long run.

Steps for Replacement

Once you’ve identified the problematic components, gather the necessary tools and materials. Carefully remove the damaged items, taking note of their installation for accurate reassembly. Replace them with new, compatible components and test the system thoroughly to confirm everything functions as intended. Consistent maintenance checks post-replacement will help in maintaining efficiency and preventing future issues.

Tools Needed for Repairs

When tackling any maintenance or fixing tasks, having the right tools on hand is essential for a successful outcome. The following is a list of equipment that will aid in various repair procedures, ensuring that you can efficiently and safely complete your project.

- Screwdrivers: A set of both flathead and Phillips screwdrivers is crucial for loosening or tightening screws.

- Wrenches: Adjustable and socket wrenches help in managing bolts and nuts effectively.

- Pliers: Useful for gripping, twisting, and cutting wires or small components.

- Hammer: Ideal for tapping or aligning pieces together during assembly or disassembly.

- Drill: A power drill can make creating holes or driving screws much quicker.

- Measuring Tape: Ensures accurate measurements are taken before cutting or installing new elements.

Having these tools readily available will facilitate a smoother repair process, allowing you to address any issues efficiently.

Identifying Parts by Model Number

Understanding the components of your system is crucial for effective maintenance and repairs. By referencing the model number, you can easily pinpoint the necessary elements, ensuring compatibility and functionality. This approach simplifies the process of finding replacements and enhances your overall efficiency.

Why Model Numbers Matter

Model numbers serve as unique identifiers for each assembly. Here are key reasons to consider:

- Streamlined Search: Quickly locate specific components.

- Compatibility Assurance: Verify that replacements fit correctly.

- Access to Resources: Obtain manuals and guides tailored to your model.

How to Locate Model Numbers

Finding the model number can be straightforward if you know where to look:

- Check the manufacturer’s label, often found on the frame.

- Consult your purchase documentation or manuals.

- Visit the manufacturer’s website for online resources.

Where to Purchase Amarr Parts

Finding components for your system can be straightforward if you know where to look. Numerous sources offer a variety of solutions, ensuring you can maintain or upgrade your setup efficiently.

Online Retailers

Many online platforms specialize in providing a wide range of items. Websites like Amazon or specialized home improvement stores often have extensive inventories, making it easy to compare prices and options.

Local Suppliers

Local hardware shops and specialized distributors can be invaluable. They not only offer immediate access to components but also provide expert advice to help you make informed choices.

Frequently Asked Questions About Repairs

This section addresses common inquiries regarding maintenance and troubleshooting for various components involved in the closing mechanism. Understanding these aspects can help in identifying issues and ensuring optimal performance.

What are the signs that something needs fixing?

Look for unusual noises, slow operation, or visible damage, which often indicate underlying problems.

Can I perform repairs myself?

Many minor issues can be addressed independently, but it’s crucial to assess your comfort level and knowledge before attempting more complex fixes.

When should I call a professional?

If the problem persists or involves electrical components, it’s advisable to seek expert assistance to avoid further complications.

How often should I conduct maintenance?

Regular inspections and servicing every six months can significantly extend the lifespan of the components.