Understanding the Components of Garage Door Systems

The functionality of an entryway system relies on a variety of elements that work together seamlessly. Understanding the intricacies of each component enhances our appreciation for this essential structure. By examining the various elements involved, we can gain insight into how they contribute to the overall operation.

Each component plays a specific role, ensuring smooth movement and security. From the essential tracks guiding motion to the springs providing the necessary tension, each piece is crucial. By exploring these features, we can better understand their significance and the importance of maintenance for longevity.

Familiarity with these mechanisms allows for informed decisions regarding repairs and upgrades. Whether enhancing security or improving functionality, knowing the roles of each element empowers homeowners and technicians alike. This knowledge transforms a seemingly simple system into a complex interplay of engineering and design.

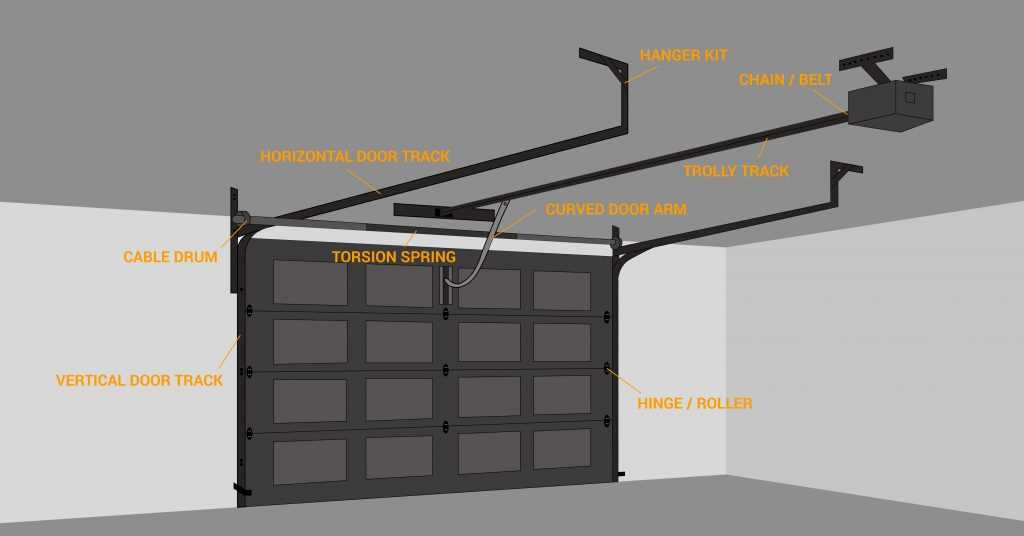

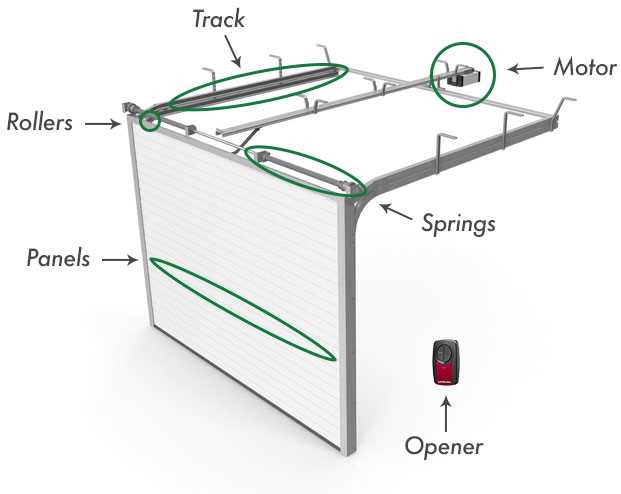

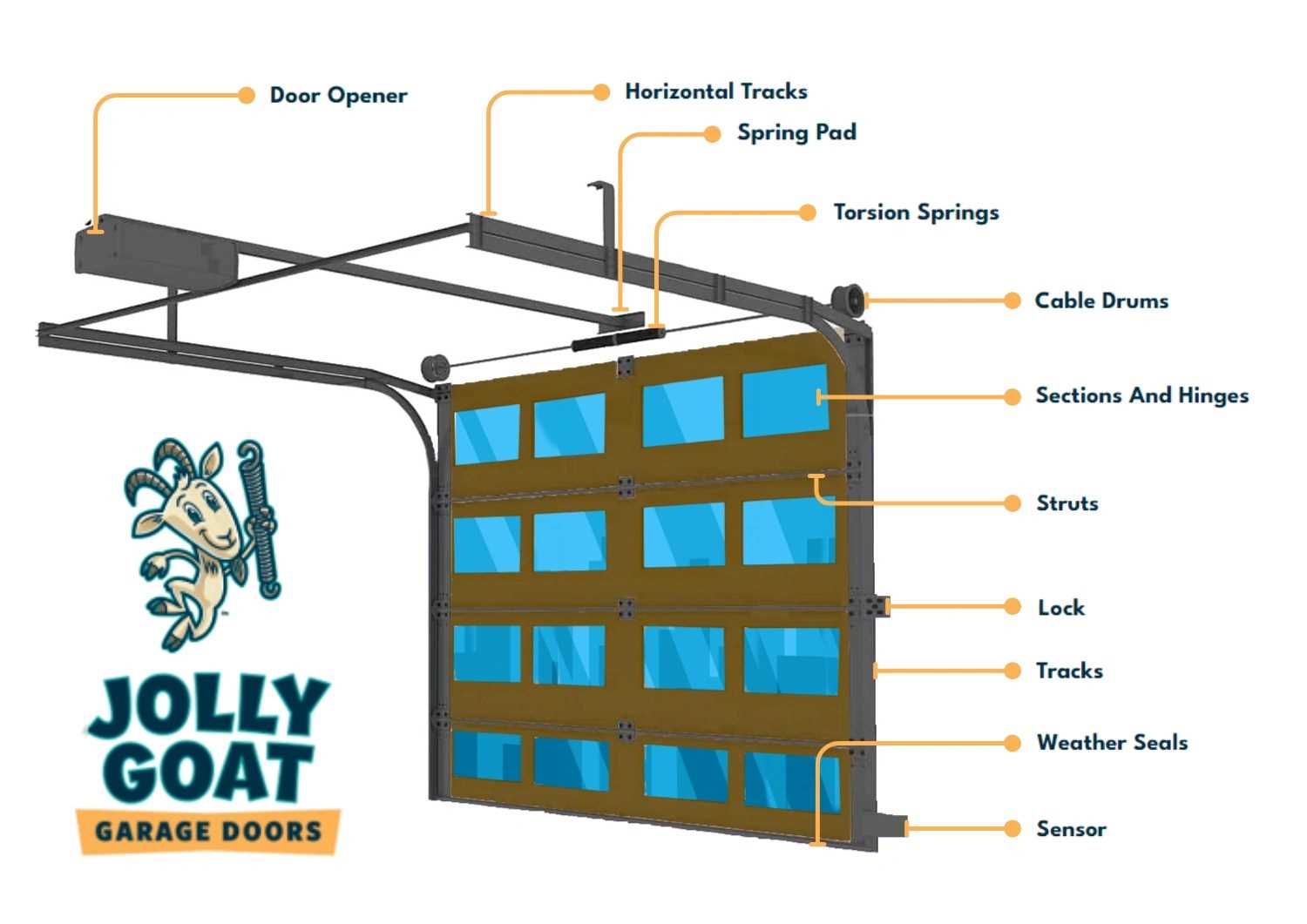

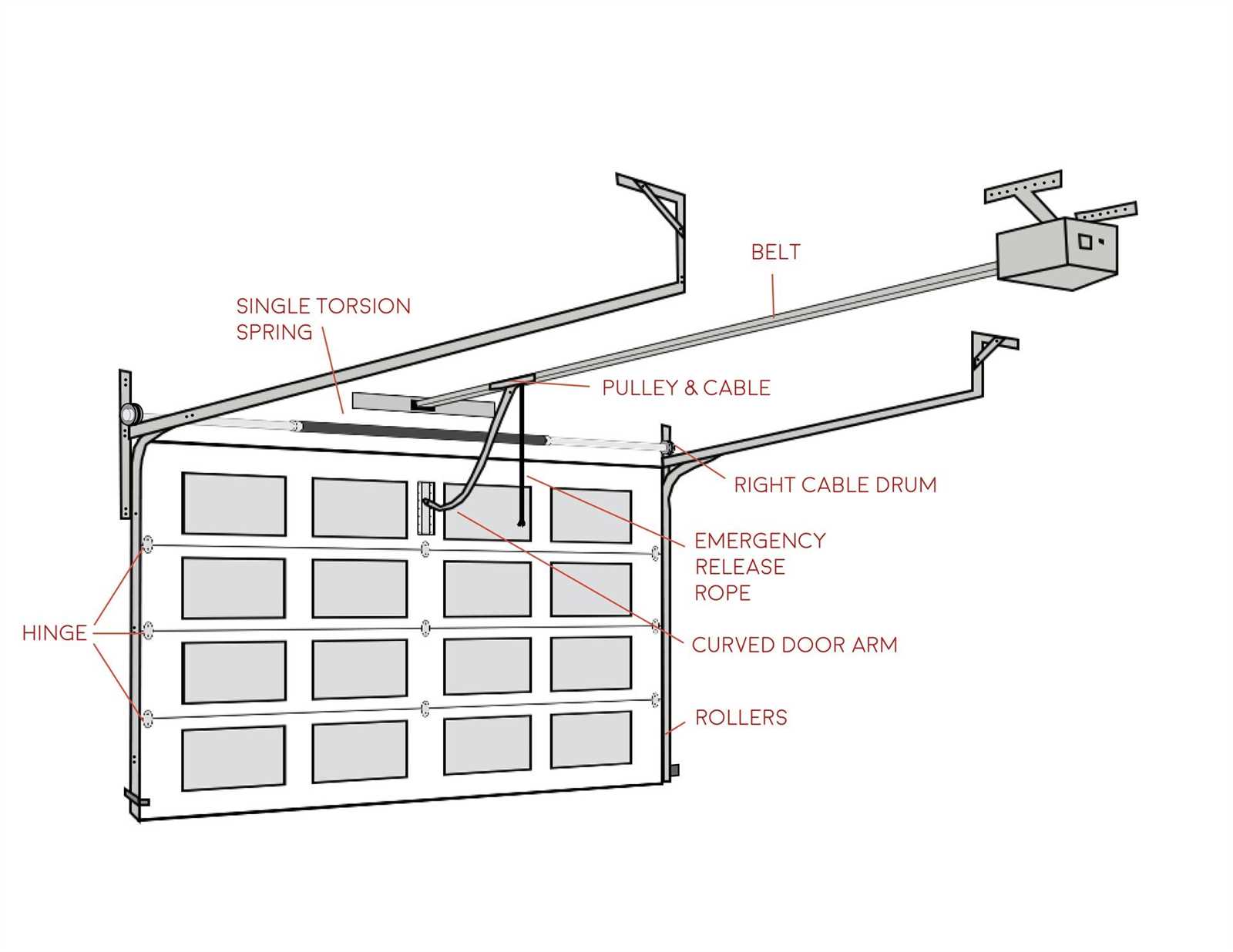

Overview of Garage Door Components

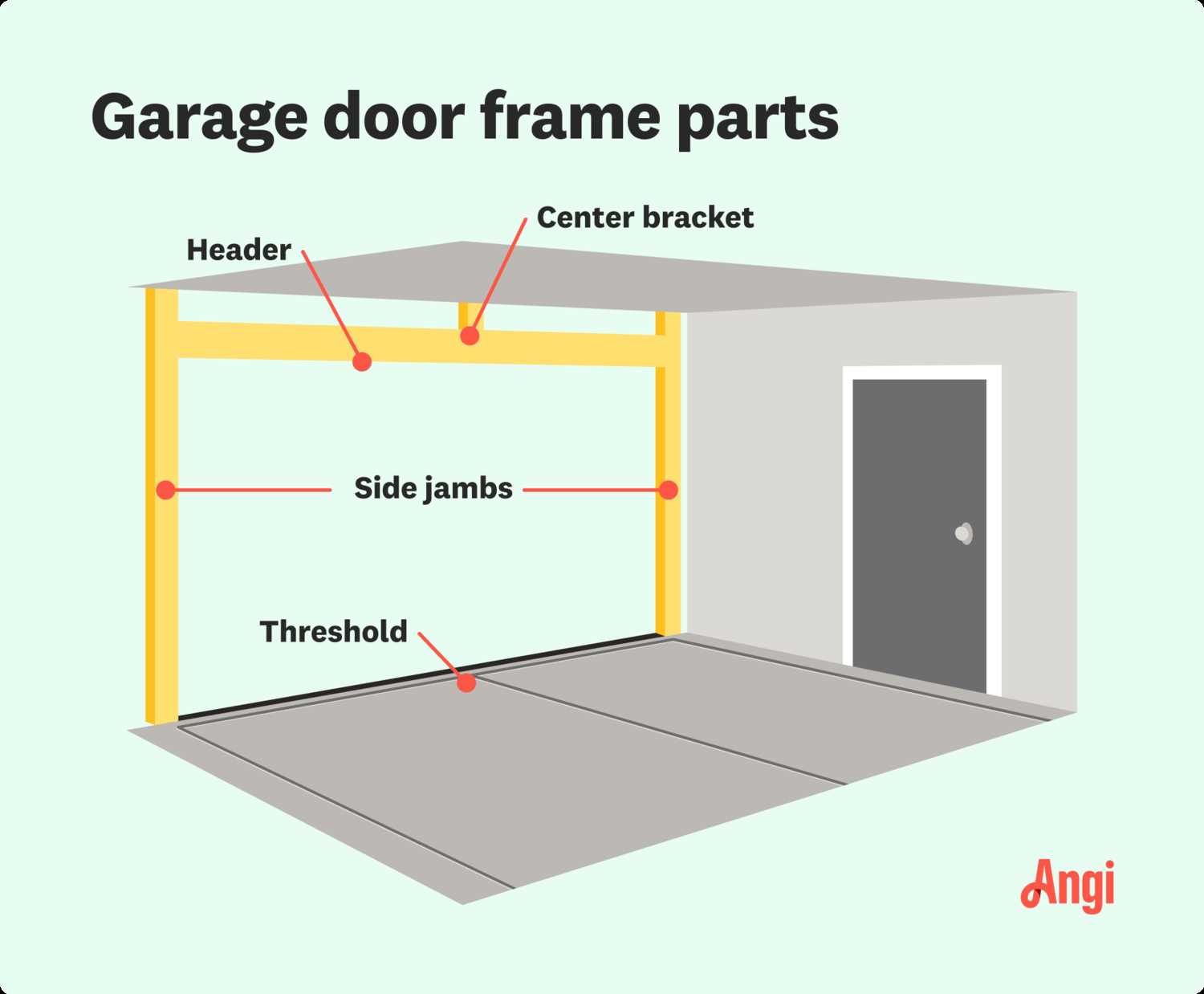

The various elements that contribute to the functionality and operation of an entry system are essential for ensuring its efficiency and safety. Understanding these components helps in appreciating how they work together to facilitate smooth movement and secure closure.

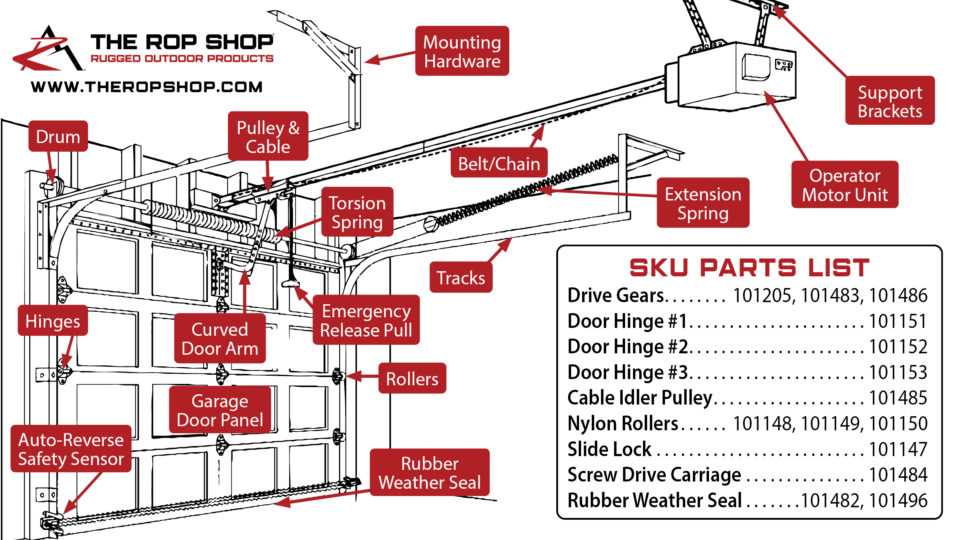

Frames provide the structural integrity, supporting the entire mechanism while maintaining alignment during operation. Tracks guide the movement, allowing smooth transitions as the system opens and closes. Rollers, often overlooked, play a crucial role by enabling seamless movement along the tracks.

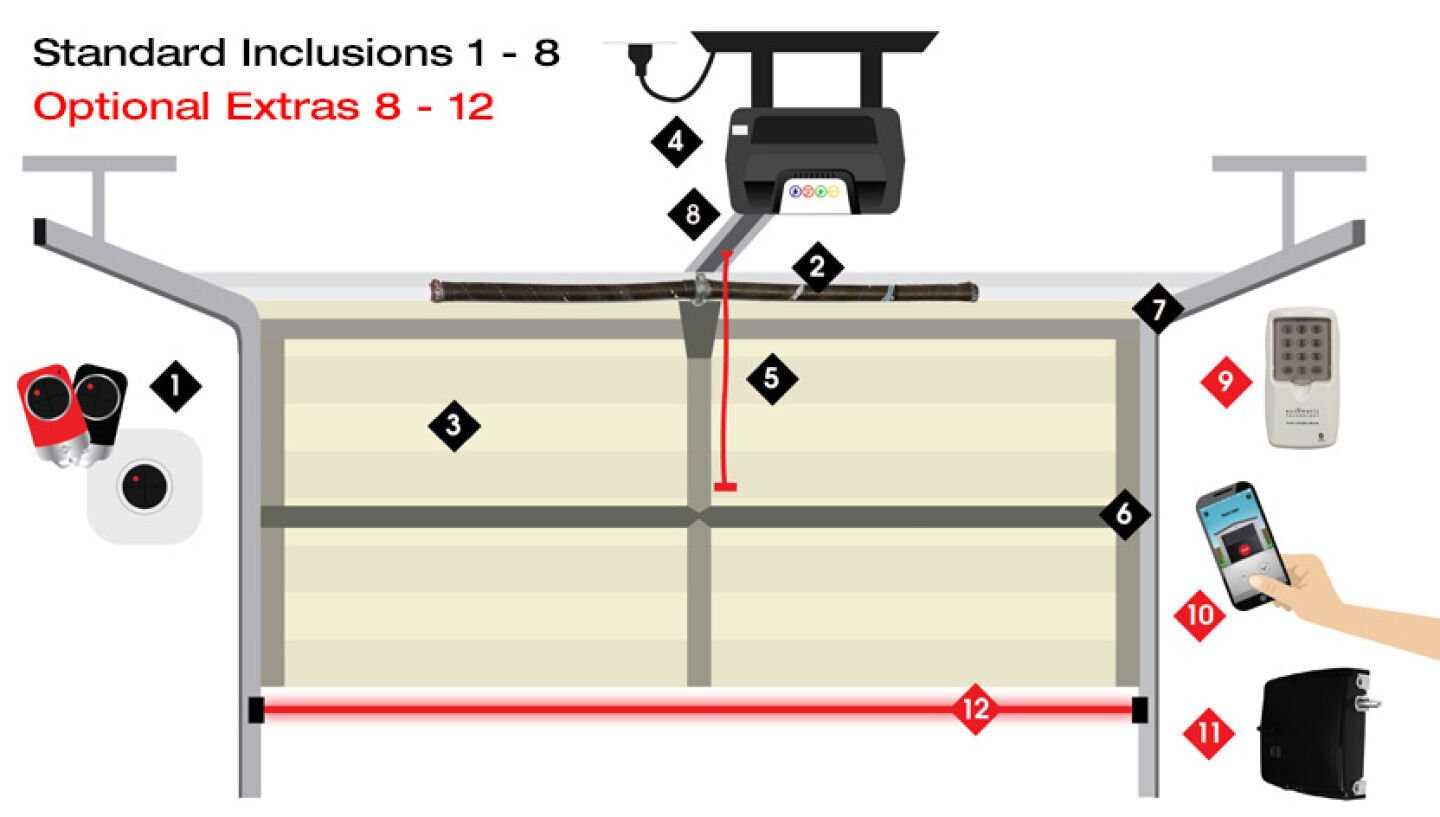

In addition to the structural elements, spring systems are vital for counterbalancing the weight, ensuring ease of use. Openers serve as the motorized heart of the operation, allowing for remote control and automated functions, enhancing convenience and user experience.

Furthermore, sensors contribute to safety, detecting obstacles and preventing accidents during operation. Overall, each component works in harmony to create a reliable and effective entry system, emphasizing the importance of regular maintenance and awareness of their functions.

Functionality of Garage Door Systems

The operation of modern entryway systems involves a complex interplay of components that work together to ensure smooth and reliable access. Understanding the functionality of these systems is essential for proper maintenance and efficient usage.

Typically, these systems comprise various elements that facilitate opening and closing mechanisms. Key functions include:

- Providing security and protection against unauthorized access

- Enhancing convenience for users through automated controls

- Allowing for customized operation based on user preferences

- Offering safety features to prevent accidents during operation

Additionally, the effectiveness of these mechanisms relies on regular maintenance and timely repairs. Components such as motors, tracks, and sensors must be kept in optimal condition to ensure longevity and functionality.

Overall, understanding how these systems operate can help users appreciate their significance and promote proactive care, ensuring seamless performance for years to come.

Types of Garage Door Mechanisms

The functionality of a closing system largely depends on the type of mechanism employed. Various designs offer distinct advantages and operational methods, ensuring the efficient and secure opening and closing of access points. Understanding these different mechanisms can assist in making informed decisions regarding installation and maintenance.

Common Mechanisms

Several common designs are prevalent in modern systems, each with unique characteristics. The choice between these options can affect usability, durability, and overall convenience.

Detailed Comparison

| Mechanism Type | Operation Style | Advantages |

|---|---|---|

| Roller | Vertical lift with horizontal tracks | Space-saving and smooth operation |

| Sectional | Panel-based design folding vertically | Insulation options and customizable designs |

| Slide | Horizontal sliding along a track | Ideal for limited vertical space and unique openings |

| Swing | Hinged panels that open outward | Classic look and minimal mechanical parts |

Common Materials Used in Doors

The choice of materials in the construction of entryways significantly impacts their functionality, durability, and aesthetic appeal. Various substances are employed in creating these structures, each offering unique properties that cater to specific needs and preferences.

Wood

Wood is a traditional option known for its natural beauty and versatility. It provides excellent insulation and can be crafted into various styles. However, it requires regular maintenance to prevent warping and damage from moisture.

Metal

Metal, particularly steel and aluminum, is favored for its strength and security. These materials are often used in modern designs and are resistant to wear and tear. Although metal structures may lack the warmth of wood, they compensate with durability and low maintenance requirements. Additionally, they can be finished in various colors and textures to enhance their visual appeal.

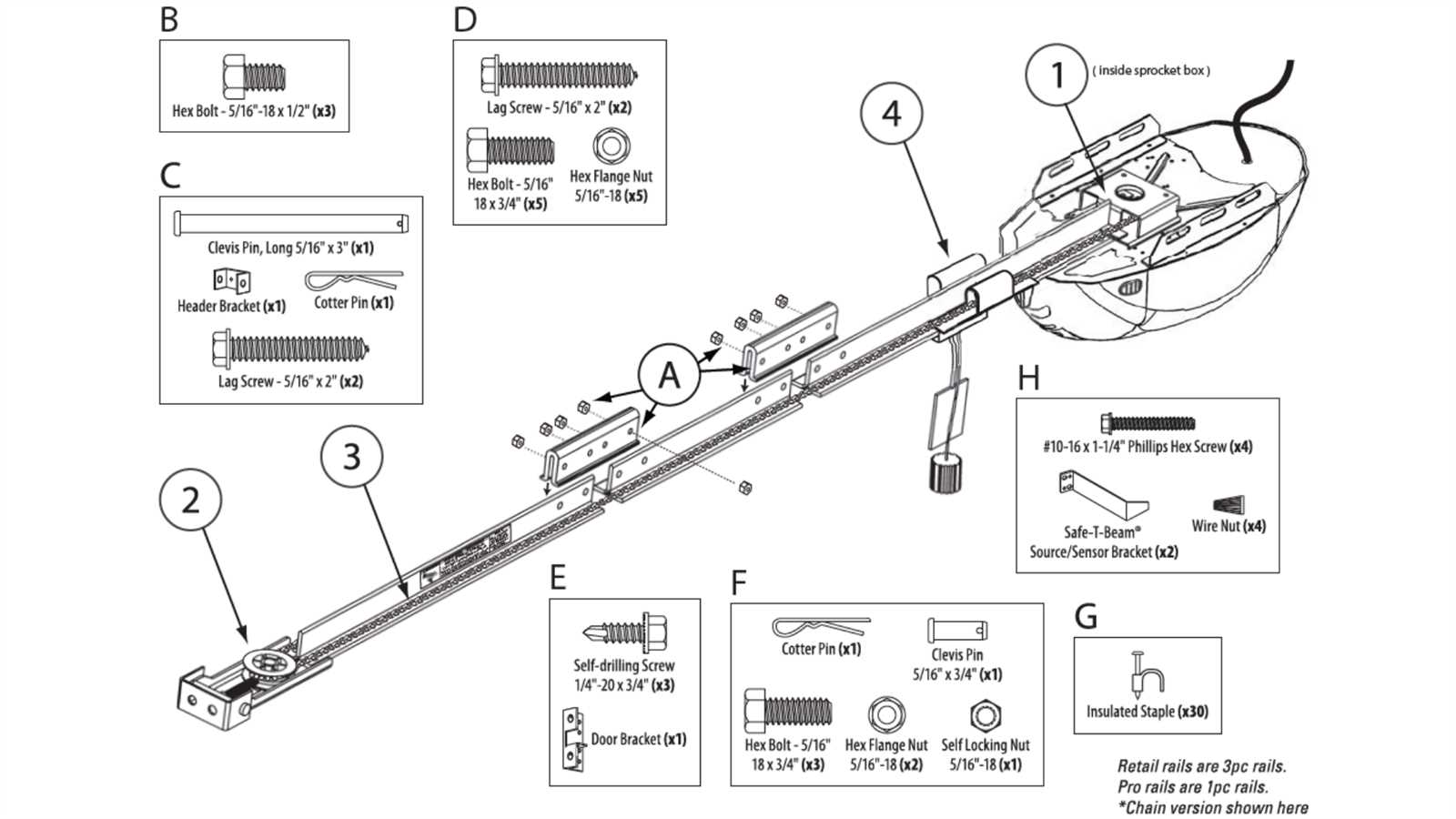

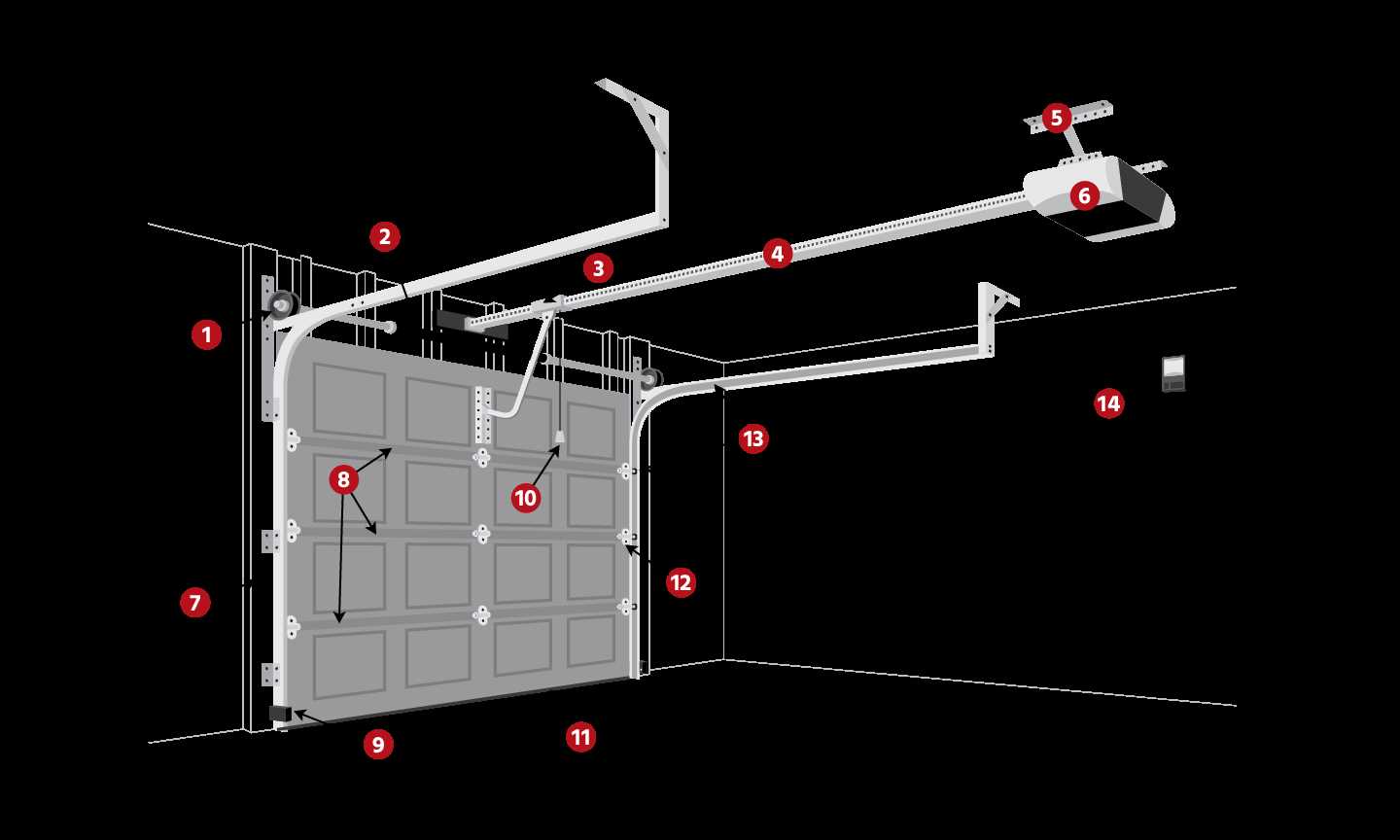

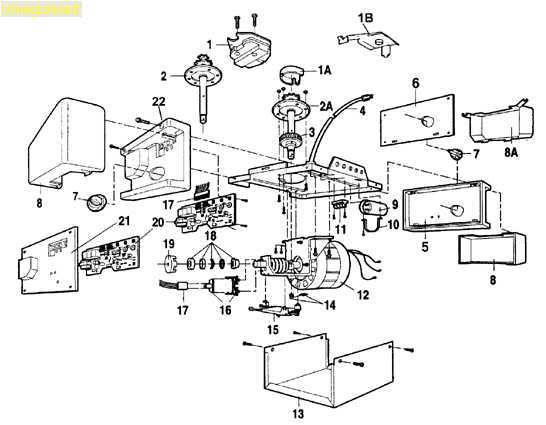

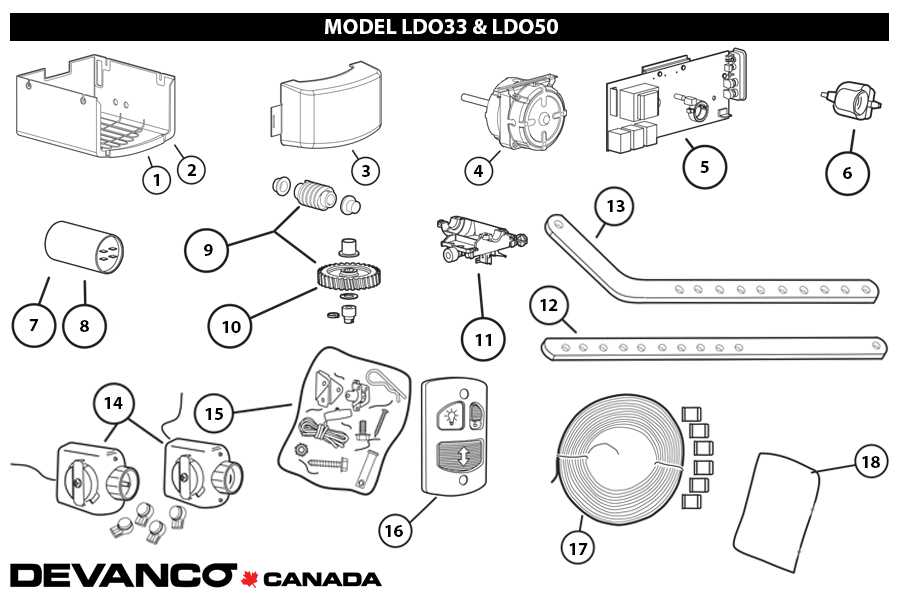

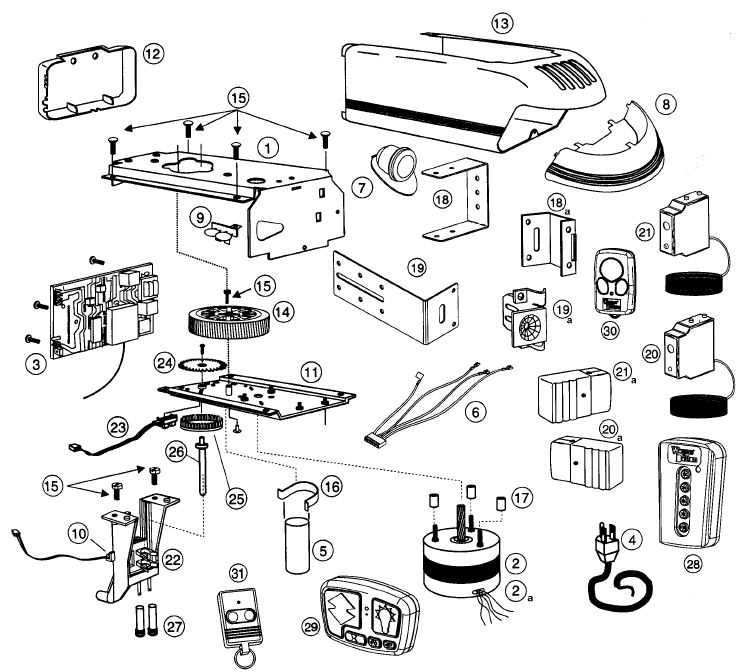

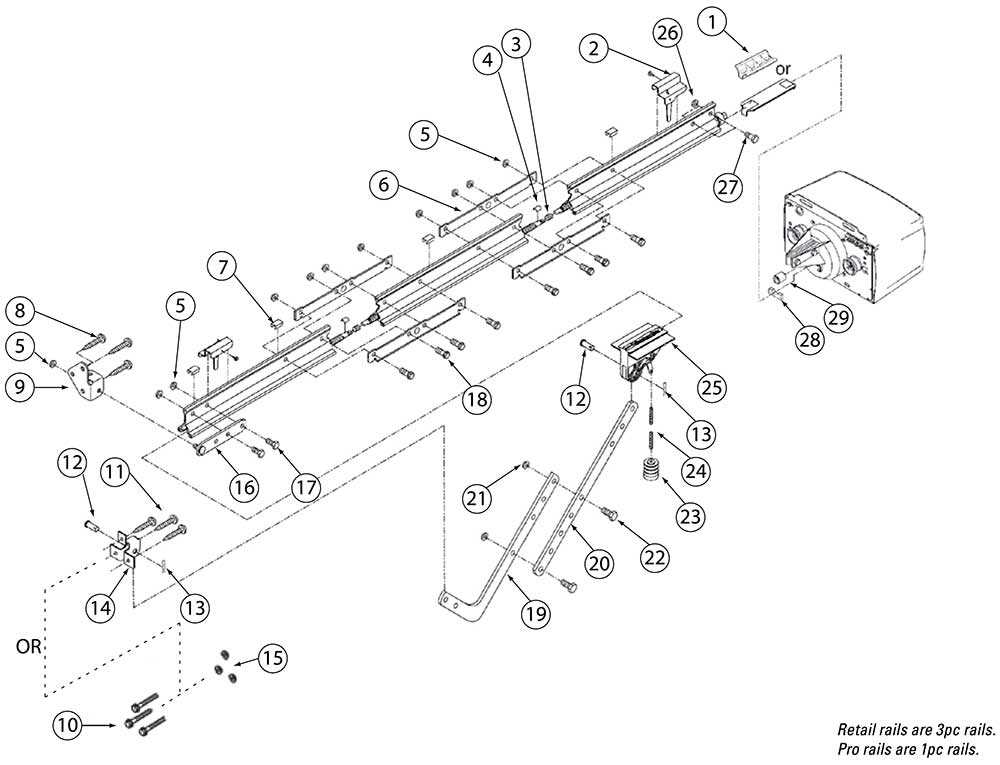

Key Parts of Garage Door Opener

The mechanism responsible for the opening and closing of an entryway involves several essential components that work together to ensure smooth functionality. Understanding these elements is crucial for effective maintenance and troubleshooting.

Main Components

- Motor: The powerhouse of the system, responsible for driving the entire mechanism.

- Track: Guides the movement of the lifting mechanism along a predetermined path.

- Chain or Belt: Connects the motor to the lifting mechanism, transferring power to move it.

- Remote Control: A wireless device that allows users to operate the system from a distance.

- Safety Sensors: Detect obstacles in the path, preventing accidental closures.

Additional Elements

- Power Supply: Provides energy to the entire system, typically connected to the electrical grid.

- Control Panel: A wall-mounted interface that allows for manual operation and setting adjustments.

- Mounting Bracket: Secures the motor and other components to the ceiling or wall, ensuring stability.

Role of Springs in Operation

In the mechanism of various entry systems, springs play a crucial role in facilitating smooth movement and ensuring stability. Their function goes beyond mere support, as they contribute significantly to the overall efficiency and safety of the system.

These elastic components are engineered to store and release energy, allowing for controlled lifting and lowering actions. When engaged, they counterbalance the weight, enabling effortless operation with minimal effort required from the user. The design and tension of the springs are vital, as they must match the specific requirements of the system to function optimally.

Moreover, properly calibrated springs help prevent potential malfunctions by reducing strain on other elements, promoting longevity. Regular maintenance and inspections are essential to ensure these components remain in excellent condition, as any wear or damage can lead to operational issues.

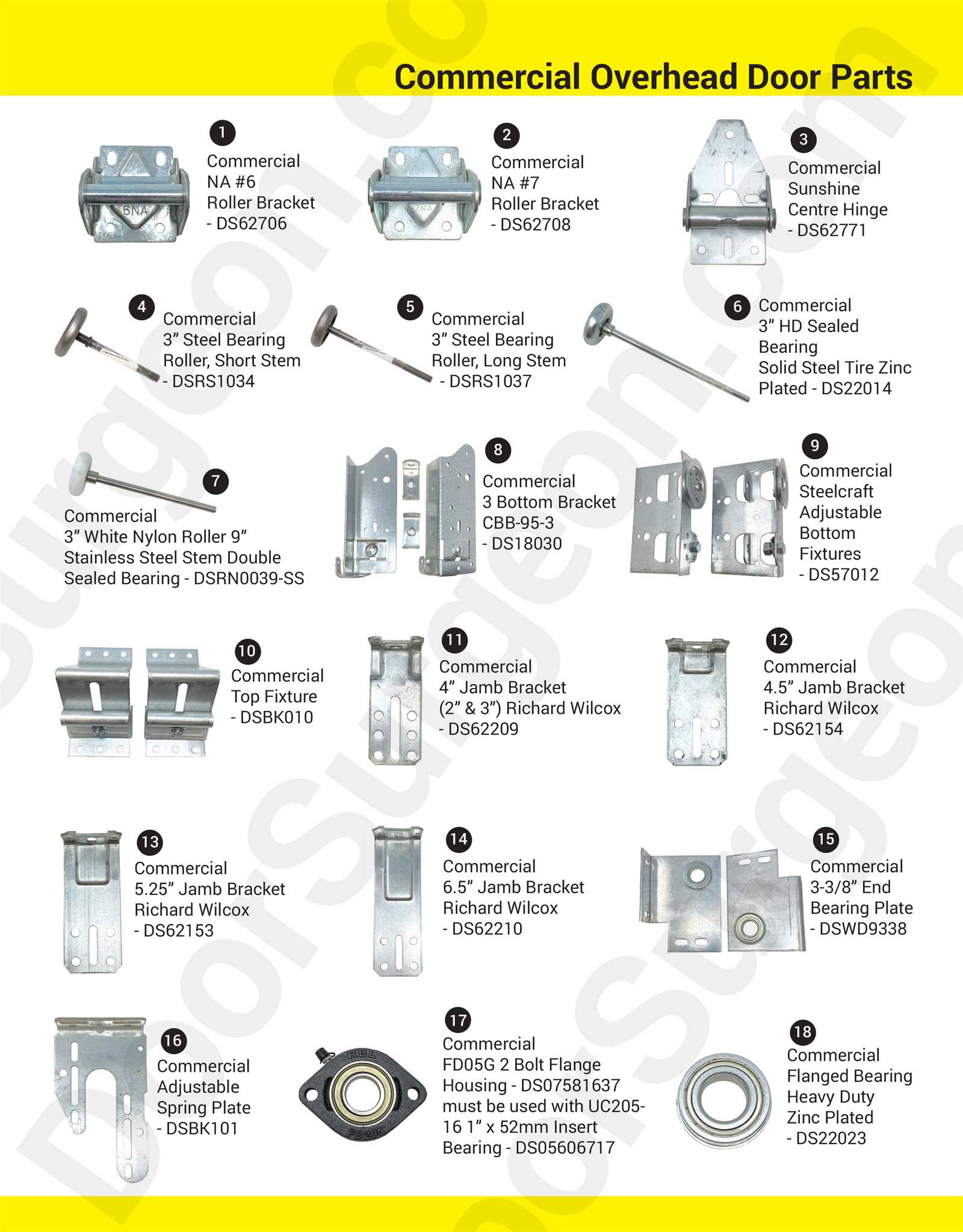

Track System and Its Importance

The mechanism responsible for the seamless movement of an entryway plays a crucial role in ensuring its functionality and safety. A well-designed system facilitates smooth operations, while also contributing to the longevity of the entire assembly. Understanding its components and significance is essential for optimal performance.

Components of the Track System

Several key elements come together to create an efficient movement mechanism:

- Tracks: The guiding pathways that enable smooth travel.

- Rollers: The circular elements that navigate along the tracks, allowing for effortless movement.

- Brackets: The supports that hold the tracks in place, ensuring stability during operation.

- End Stops: The fixtures that prevent the mechanism from moving beyond its intended limits, enhancing safety.

Benefits of a Well-Functioning System

Investing in a high-quality mechanism can yield numerous advantages:

- Smooth Operation: A properly aligned system minimizes friction, resulting in quieter and easier functionality.

- Enhanced Safety: Effective components reduce the risk of malfunction, protecting users and property.

- Durability: A robust assembly can withstand wear and tear, extending the lifespan of the entire setup.

- Convenience: Efficient operations lead to easier access and daily use, improving overall user experience.

Understanding Safety Features

Safety mechanisms are crucial components that ensure the secure operation of any opening system. These features are designed to prevent accidents and protect users, enhancing the overall reliability of the installation. Understanding these systems can provide peace of mind and encourage proper usage.

Modern installations often incorporate various safety elements, such as automatic reversal systems that detect obstacles in the path. Additionally, sensors can play a vital role in monitoring the surroundings, ensuring that the mechanism operates smoothly without endangering individuals or objects nearby.

Another essential aspect is the manual release feature, which allows users to operate the system manually during power outages or emergencies. This ensures that access remains available when needed. Furthermore, regular maintenance and checks of these safety features are important to guarantee their functionality and effectiveness over time.

Importance of Regular Maintenance

Routine care is essential for ensuring the longevity and optimal performance of any mechanical system. By implementing a consistent maintenance schedule, users can identify potential issues early and prevent more significant problems down the line. This proactive approach not only enhances functionality but also increases safety for users.

Regular upkeep offers several key advantages, which can be summarized as follows:

| Benefit | Description |

|---|---|

| Increased Lifespan | Consistent attention can significantly extend the life of mechanical components. |

| Improved Safety | Regular checks help identify wear and tear, minimizing the risk of accidents. |

| Cost Efficiency | Timely maintenance reduces the likelihood of costly repairs and replacements. |

| Optimal Performance | Regular servicing ensures that the system operates smoothly and efficiently. |

Installation Process Explained

Setting up the components of an entryway mechanism requires careful attention to detail and a methodical approach. Understanding the key steps involved can significantly streamline the overall procedure, ensuring everything functions seamlessly once completed.

Preparation and Safety Measures

Before commencing the setup, it is crucial to gather all necessary tools and equipment. Ensure the workspace is clear and safe, minimizing potential hazards. Safety gear such as gloves and goggles should be worn to protect against any accidents during the installation.

Step-by-Step Assembly

The assembly begins by positioning the main structure according to the manufacturer’s guidelines. Each component should be securely attached, following the prescribed order to maintain stability. Regularly check for proper alignment and functionality throughout the process to avoid complications later on. After installation, a thorough inspection is recommended to ensure everything operates smoothly.

Troubleshooting Common Issues

Understanding how to address frequent problems can significantly enhance the longevity and functionality of your equipment. Recognizing symptoms early on allows for prompt action, reducing the risk of more extensive repairs or replacements.

One typical concern involves unusual noises during operation. These sounds can indicate misalignment or insufficient lubrication. Regular maintenance, including oiling moving components, can help prevent these issues from arising.

Another frequent problem is inconsistent performance, where the mechanism may operate slowly or not respond at all. This could be due to worn-out springs or faulty sensors. Inspecting these elements for damage or misalignment is essential for ensuring optimal function.

If you notice unexpected reversals during operation, this might be a result of obstructed pathways or misaligned sensors. Clearing any obstructions and realigning the sensors can often resolve this issue effectively.

In summary, proactive maintenance and prompt attention to these common issues can lead to smoother operation and a longer lifespan for your equipment.

Upgrading Components for Better Performance

Enhancing the functionality of your entry system can lead to significant improvements in efficiency and longevity. By focusing on specific elements, users can achieve smoother operation and greater reliability. An investment in modern materials and technologies often results in noticeable benefits in overall performance.

First and foremost, consider replacing outdated mechanisms with advanced alternatives. For example, newer tracks and rollers can reduce friction, promoting a quieter and more efficient operation. Additionally, high-quality springs can provide improved tension, minimizing wear and tear over time.

Another aspect to explore is the automation of functionality. Upgrading to smart systems allows for remote access and monitoring, enhancing convenience and security. Such enhancements not only improve user experience but also contribute to energy efficiency by minimizing unnecessary usage.

In conclusion, focusing on key components can yield substantial gains in both functionality and durability. Whether through material upgrades or the integration of smart technology, these changes represent a proactive approach to maintaining and enhancing your entry system.