Understanding the Components of Dock Door Systems

In the realm of logistics and warehousing, the functionality of entry systems plays a crucial role in ensuring seamless operations. A comprehensive grasp of the intricate elements that comprise these mechanisms can significantly enhance efficiency and safety during the loading and unloading processes. Recognizing how each segment interacts contributes to the overall performance and reliability of the system.

Familiarity with the various components involved not only aids in maintenance but also empowers personnel to troubleshoot potential issues swiftly. Each unit serves a specific purpose, collectively working to facilitate smooth transitions between vehicles and storage areas. Gaining insight into these individual functions can lead to better decision-making and operational practices.

Moreover, understanding the anatomy of these structures fosters a proactive approach to improvements and upgrades. Whether it’s optimizing space or enhancing safety features, knowing the underlying mechanics can inform effective strategies that align with organizational goals. Emphasizing the importance of these elements ensures a well-rounded perspective on enhancing the efficiency of loading bays.

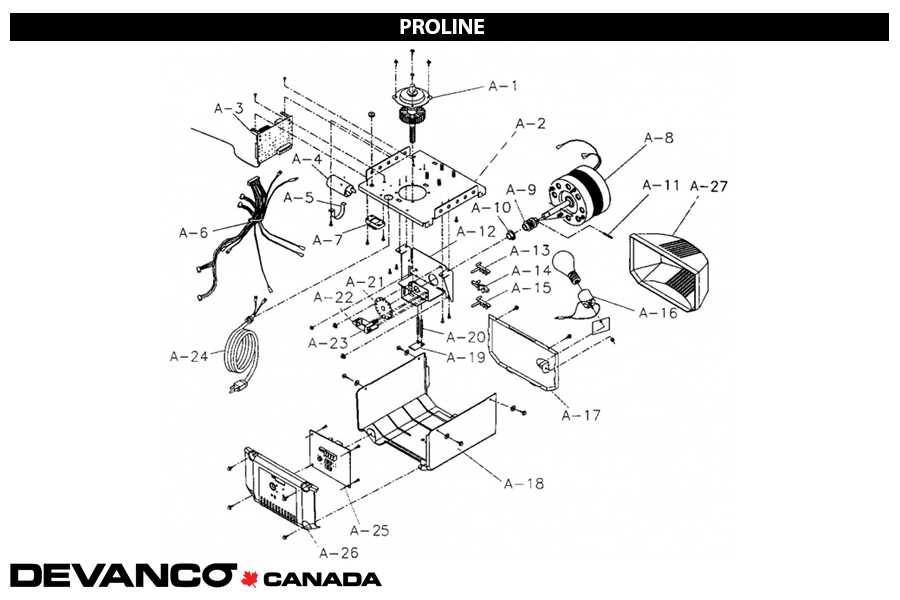

Understanding Dock Door Components

In any loading and unloading environment, familiarity with the essential elements that facilitate seamless operations is crucial. These components play a vital role in ensuring efficiency and safety, contributing significantly to the overall functionality of the system.

Key Elements

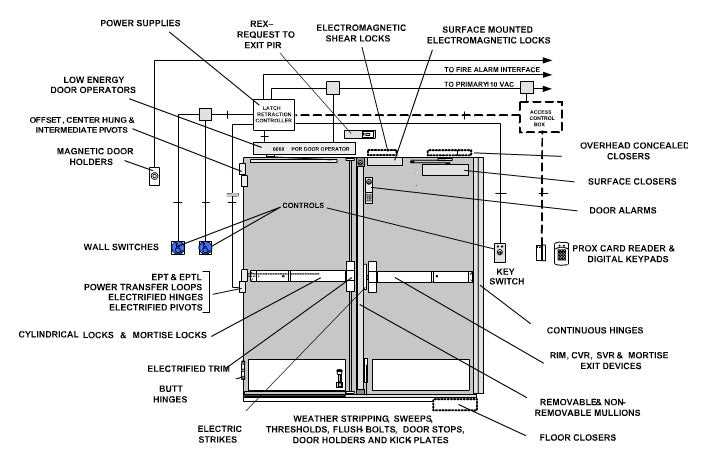

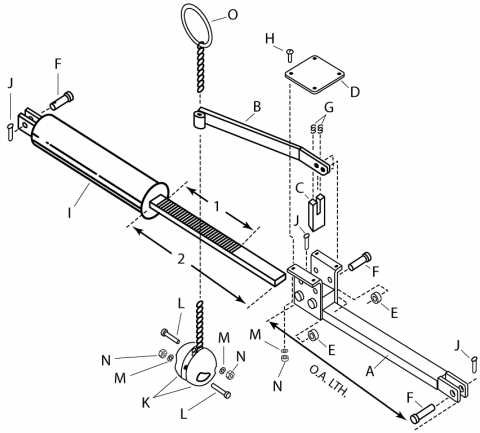

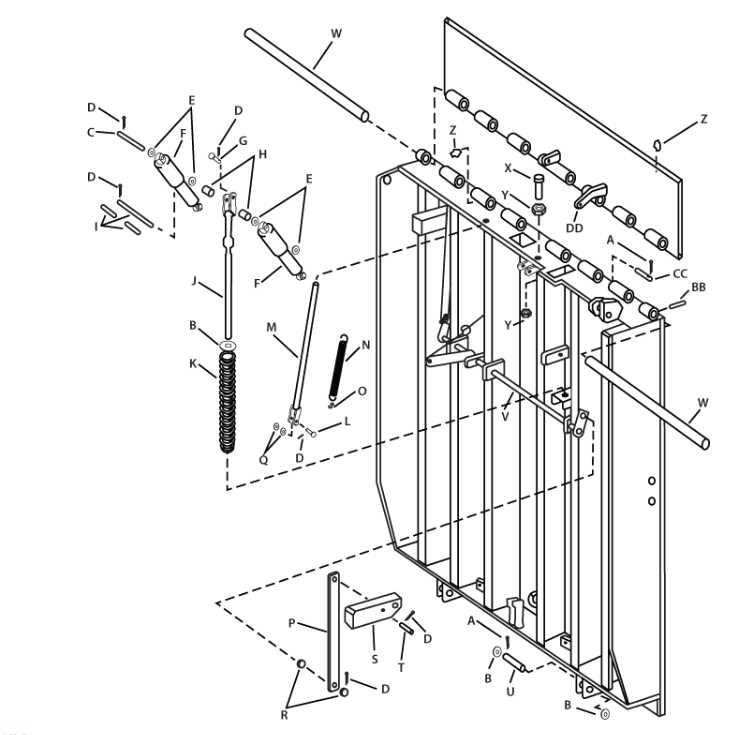

The primary components include frames, seals, and access mechanisms. Each element serves a specific purpose, enhancing durability and security while optimizing workflow. Recognizing their roles helps in maintaining and improving the entire setup.

Maintenance and Care

Regular inspection and maintenance of these crucial elements can prevent unexpected failures. Understanding how each component interacts enables operators to make informed decisions regarding repairs and replacements, ultimately ensuring longevity and performance.

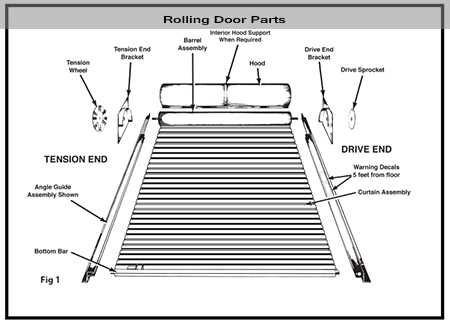

Essential Parts of Dock Doors

Understanding the key components that contribute to the functionality of loading access systems is crucial for efficient operations. Each element plays a specific role in ensuring safe and smooth transitions between vehicles and facilities.

- Frame: The structural backbone that supports the entire assembly.

- Seal: A vital element for maintaining temperature control and preventing moisture ingress.

- Operator: The mechanism that allows for the opening and closing motions, often powered or manual.

- Threshold: The ground-level interface that provides stability and smooth access.

- Weatherstrip: An essential feature for protecting against the elements and enhancing insulation.

Each of these components works in harmony to optimize efficiency, safety, and durability in loading operations.

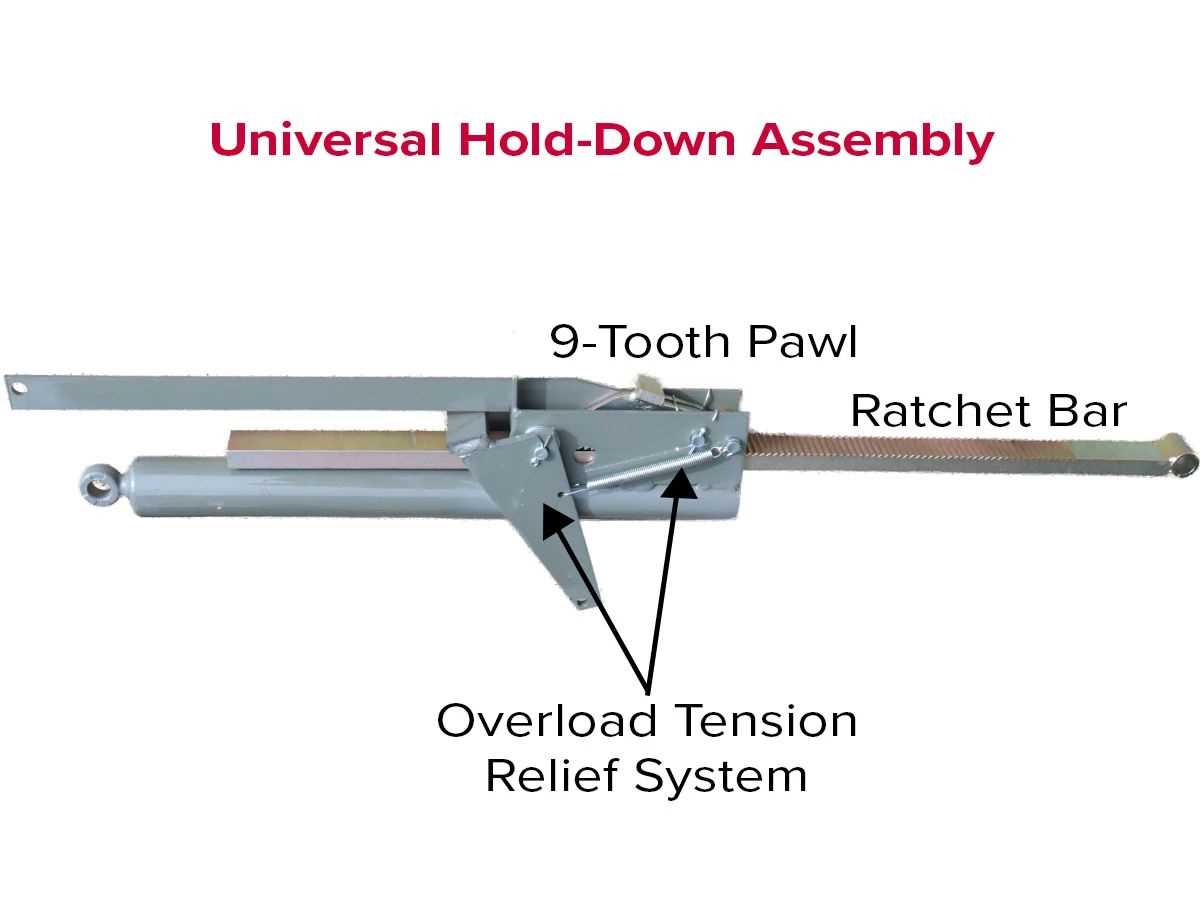

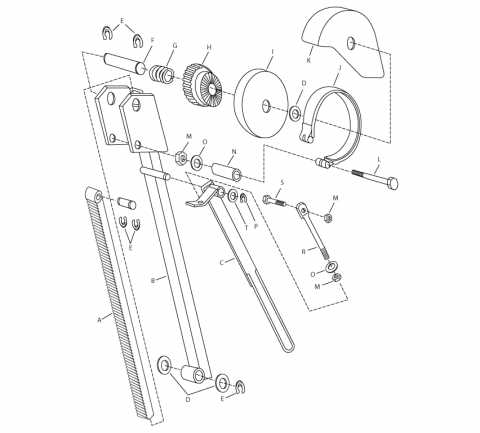

Functionality of Dock Door Hardware

The efficiency and safety of loading and unloading areas rely on various mechanical elements designed to enhance movement and provide stability. These components are critical for maintaining secure access and operational control in high-traffic environments. Each part plays a unique role, contributing to the overall smooth operation of the system.

Components Designed for Secure Operation

Several mechanisms are implemented to ensure secure handling and minimize risks. These systems are built to handle repetitive use while maintaining consistent performance. They provide strength and resilience, which are essential for maintaining the integrity of access points under various conditions.

Improving Operational Efficiency

Other elements focus on optimizing performance, allowing for quicker adjustments and ease of movement. These parts are designed to reduce friction, ensuring seamless operation and minimizing wear. This contributes to a more streamlined process, improving overall efficiency while ensuring long-term durability.

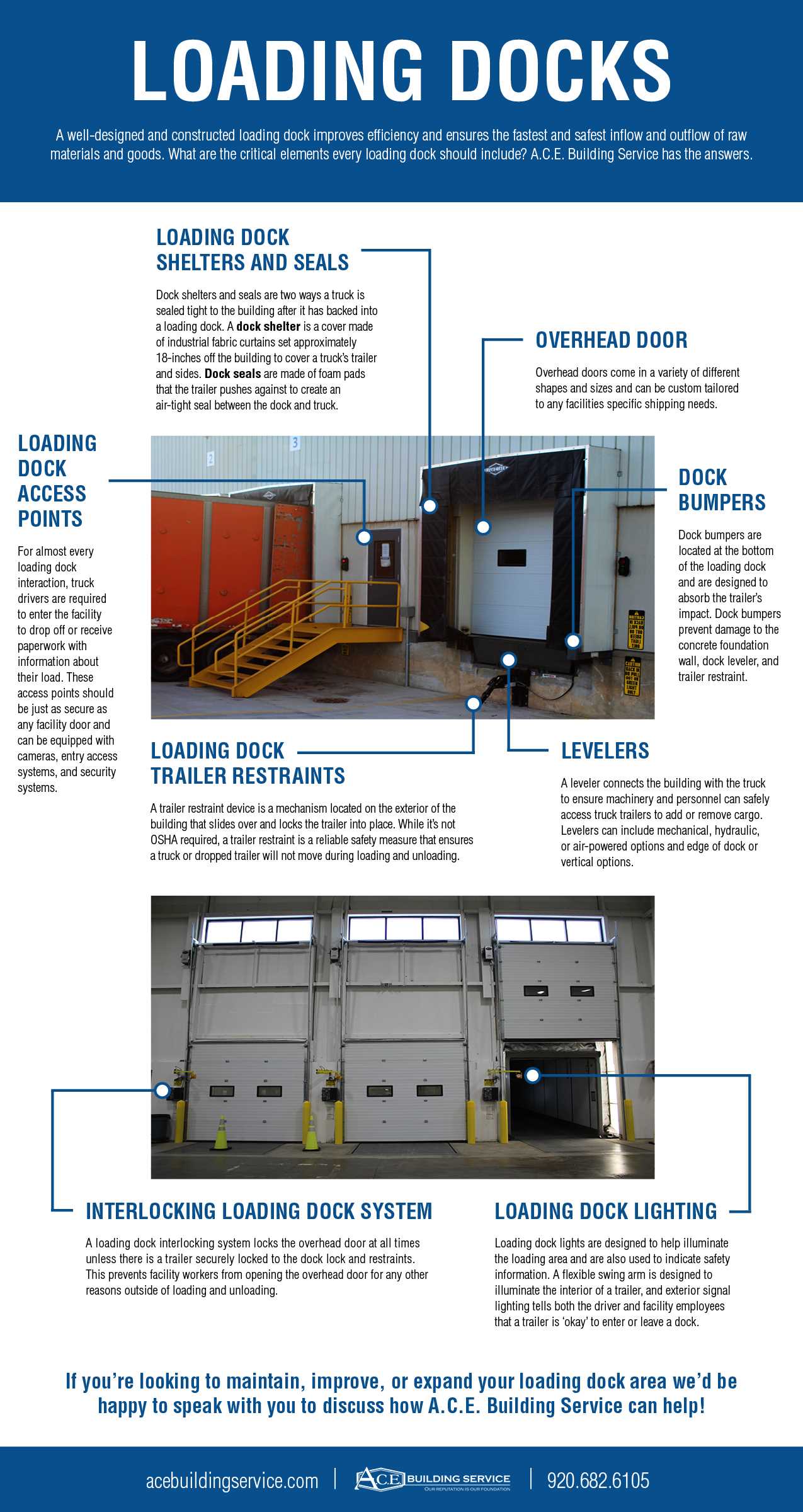

Types of Dock Door Systems

There are several distinct systems designed to manage entry points for different environments. These systems vary depending on factors such as security needs, frequency of use, and environmental considerations. Each type is tailored to provide efficient operation while addressing specific functional demands.

| System Type | Features |

|---|---|

| Sectional Systems | These systems consist of panels that allow flexible movement, making them ideal for spaces with varying height requirements. |

| Roll-Up Mechanisms | Designed for high-frequency access, they are space-efficient and suitable for areas with limited clearance. |

| High-Speed Solutions | Commonly used in fast-paced environments, these systems ensure quick opening and closing, enhancing efficiency and reducing energy loss. |

Common Materials for Dock Doors

Various types of barriers are constructed from materials that enhance both functionality and durability. The choice of substance affects the performance, longevity, and resistance to external factors. It’s essential to select the right composition based on the intended environment and usage requirements.

Steel and Its Advantages

Steel is a popular option due to its strength and ability to withstand heavy use. It is known for being resistant to impact, which makes it suitable for demanding settings. This material also offers a high level of protection against wear and environmental damage, ensuring a longer lifespan.

Aluminum for Lightweight Applications

Aluminum provides a lighter alternative, ideal for less intensive scenarios. Despite its lighter weight, it maintains sufficient toughness, especially in conditions where constant movement is required. Additionally, it is more resistant to corrosion, making it a preferred choice in specific environments.

Maintenance Tips for Dock Doors

Regular upkeep is crucial to ensure that the mechanisms in loading areas remain efficient and safe. By paying attention to small details and performing routine inspections, you can prevent costly repairs and downtime. Proper care extends the life of the equipment and enhances overall functionality.

One key practice is to check for wear on moving elements and ensure that all components are properly lubricated. This will reduce friction and prevent unnecessary strain on the system. Also, make sure all fastenings are tight to avoid any loosening that could lead to malfunction.

It’s essential to inspect the alignment and balance of the structure regularly. Misalignment can cause uneven operation and increase the risk of damage. Additionally, cleaning the surfaces and removing debris will help the system operate smoothly without obstructions.

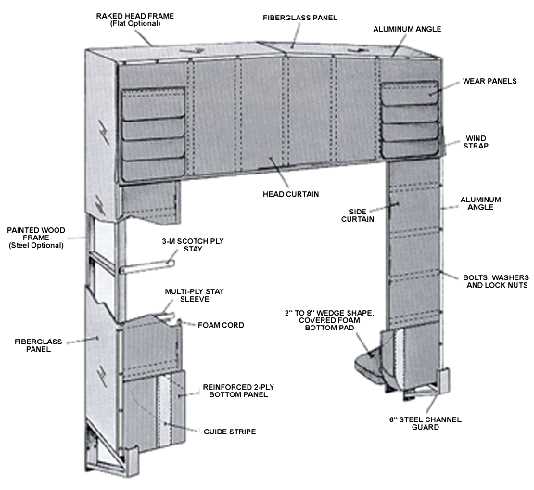

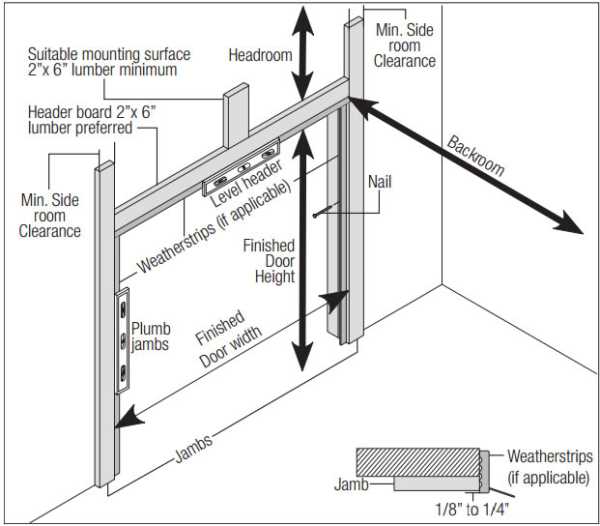

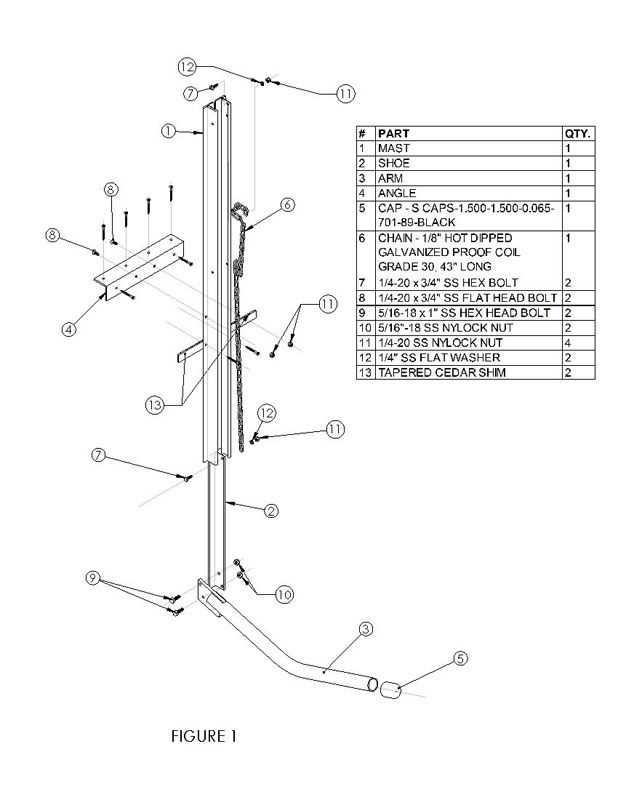

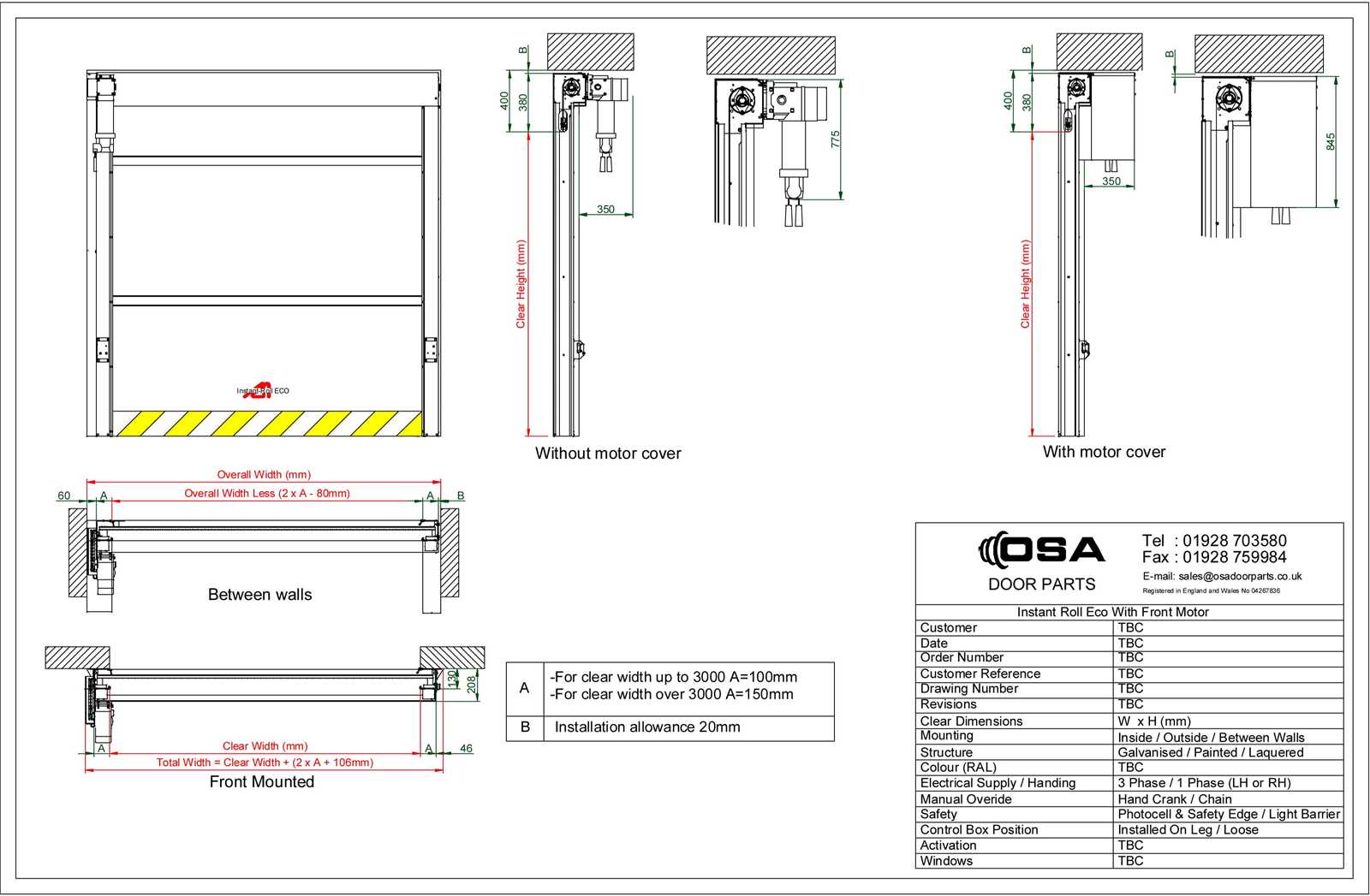

Installation Guidelines for Dock Doors

Setting up access solutions for loading and unloading areas requires careful planning and adherence to certain steps. By following specific instructions, you can ensure smooth and efficient operation of these systems. The process includes not only preparing the installation site but also ensuring all components are properly aligned and secured.

Start by evaluating the entryway dimensions and surrounding space to accommodate the structure. This is essential for proper fitment and avoiding operational issues. The next step is to verify that all the necessary equipment is present and undamaged, ensuring that the setup proceeds without complications.

Carefully follow the mounting instructions for the main structure, ensuring the frame is securely anchored. It’s also important to check that the mechanism for raising and lowering operates smoothly without resistance. Adjustments may be necessary during this phase to ensure precision in the system’s function.

Once the main assembly is complete, verify the alignment and functionality of the entire setup. Test the movement multiple times to ensure it operates consistently under different conditions. Finally, perform a thorough inspection of all fastenings and hardware to confirm everything is securely in place.

Safety Features in Dock Door Design

When it comes to the security and smooth operation of entry systems, proper safety measures are essential. By integrating specific protective mechanisms, these structures ensure both the welfare of users and the prevention of accidents. The thoughtful combination of different elements helps create a reliable environment, safeguarding individuals while minimizing potential risks.

Protective Mechanisms for User Safety

A key aspect of these systems is the installation of mechanisms that respond swiftly to any irregularity. Whether it’s a malfunction or unexpected obstruction, these features are designed to act immediately, preventing harm. Safety sensors, for instance, can detect when an object is in the way and trigger an appropriate response to avoid injury.

Emergency Prevention Systems

Equally important is the integration of prevention systems that address potential emergencies. Built-in safeguards like automatic stoppage and controlled movements during malfunction help reduce the chances of accidents. These precautions ensure the system remains operational without endangering users, even under unforeseen circumstances.

Identifying Dock Door Malfunctions

When mechanisms involved in regular operations begin to show signs of wear or unexpected issues, it can lead to disruptions in daily processes. Recognizing the early signs of these problems is crucial for maintaining efficient functionality and avoiding further damage.

Uneven Movement of the structure can indicate underlying mechanical or alignment problems. This can lead to inconsistent operation, which might escalate into more serious issues if left unattended.

Unexpected noises, such as grinding or screeching sounds, often suggest that certain components are experiencing excessive strain. Identifying these sounds early can prevent costly repairs down the line.

Additionally, slow or hesitant responses during operation often point to issues with the control systems or power supply, which need to be addressed to avoid complete failure.

Upgrading Your Dock Door System

Enhancing the efficiency of your loading system can significantly boost performance, safety, and longevity. Making the right upgrades involves careful consideration of modern technologies, advanced materials, and energy-saving solutions. This section will explore key ways to elevate your current setup for better results.

Benefits of Modern Solutions

- Improved functionality with automated systems

- Enhanced durability through reinforced materials

- Energy savings with insulated components

- Increased safety with advanced sensors and controls

Steps to Implement an Upgrade

- Assess your current system for inefficiencies

- Research new technologies that suit your needs

- Plan for the integration of new components

- Hire professionals for installation and calibration

Benefits of Automated Dock Doors

Implementing automated entry systems in loading areas brings significant advantages to various operations. These systems offer enhanced convenience, allowing for smoother transitions and reducing the need for manual intervention. By incorporating advanced technology, businesses can streamline their workflows and improve overall efficiency.

Another key advantage is the ability to maintain a consistent and secure environment. Automated mechanisms ensure reliable access control, helping to minimize potential risks and improve safety for personnel and goods. This leads to fewer disruptions and optimized productivity.

Lastly, such systems can contribute to energy savings by efficiently regulating access, reducing unnecessary opening and closing. This can lead to lower energy consumption and operational costs, further benefiting long-term sustainability efforts.

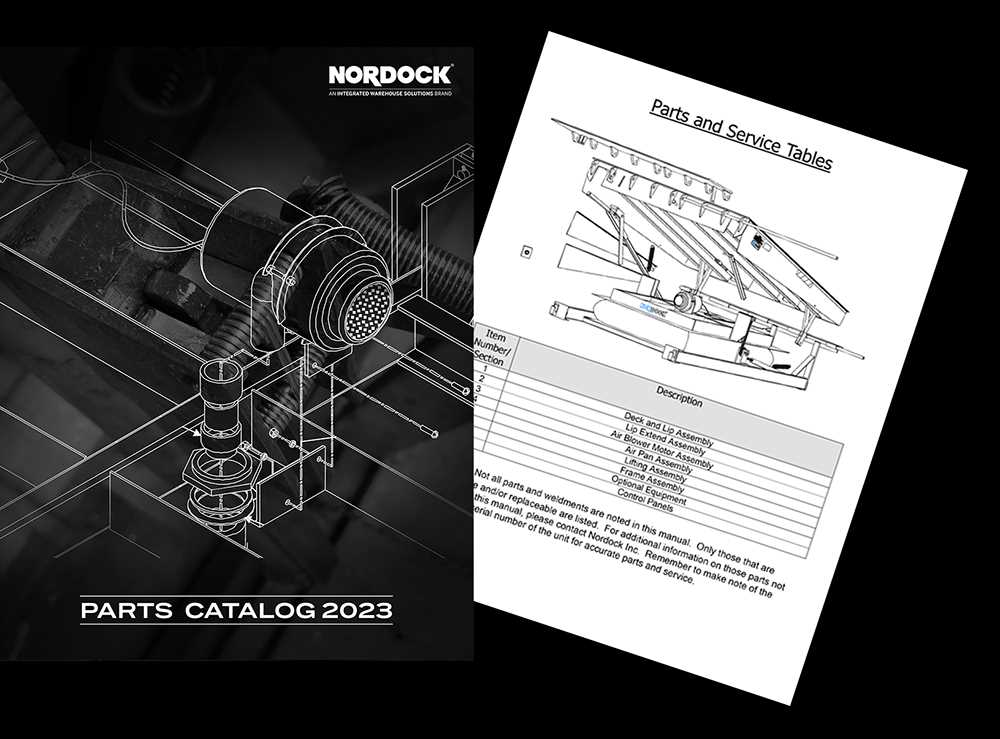

Choosing the Right Dock Door Parts

When selecting components for your loading area, it’s important to consider the environment, the frequency of use, and the overall functionality of the system. Ensuring the right fit not only increases efficiency but also extends the life of the equipment.

Considerations for Material Quality

High-quality materials are essential for long-term reliability and durability. Whether you’re looking for strong metals, corrosion-resistant alloys, or flexible seals, choosing the appropriate material can significantly impact performance.

Compatibility and Size

Understanding the dimensions and compatibility with existing equipment is crucial. Even small discrepancies in size can lead to improper fitting, causing disruptions. Always double-check measurements and ensure that the pieces fit seamlessly with your system.

| Component | Material | Durability |

|---|---|---|

| Frame Support | Steel | High |

| Sealing Mechanism | Rubber | Medium |

| Fasteners | Stainless Steel | High |