Comprehensive Guide to Elevator Door Parts Diagram

The intricate workings of vertical transport mechanisms play a crucial role in modern architecture, facilitating seamless movement between different levels of buildings. A comprehensive grasp of these systems not only enhances operational efficiency but also ensures safety and reliability. Each component contributes to the overall functionality, reflecting a blend of engineering precision and innovative design.

Within this context, an exploration of the various elements involved reveals the complexity and importance of their arrangement. Recognizing how each segment interacts with others can illuminate potential maintenance needs and operational challenges. This understanding is essential for both users and technicians alike, offering insights into the mechanics behind these essential transportation solutions.

Moreover, a detailed representation of these components can serve as an invaluable resource for training and troubleshooting. By visualizing the relationship between the various elements, stakeholders can better appreciate the necessity of regular inspections and timely repairs. As we delve into this subject, the significance of these integral pieces will become increasingly clear, highlighting their role in the safe and efficient functioning of vertical mobility systems.

Understanding Elevator Door Mechanisms

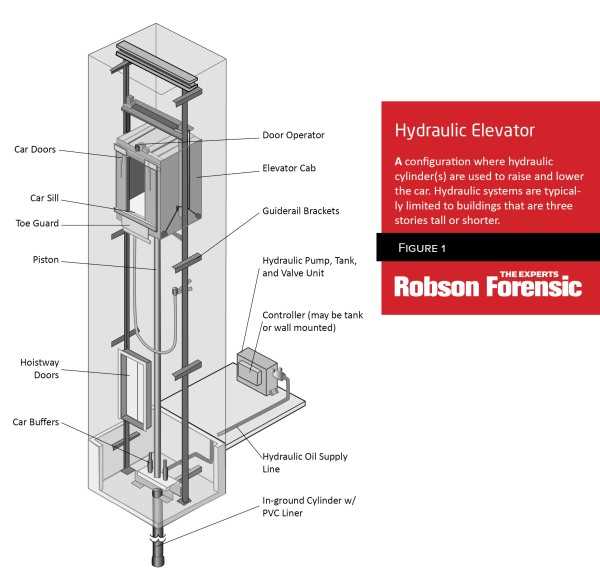

The operation of vertical transport systems involves complex interactions between various components that ensure safe and efficient access for passengers. These mechanisms are designed to provide seamless transitions between levels, emphasizing both functionality and safety. Understanding how these elements work together is crucial for maintenance and troubleshooting.

Key Components of the System

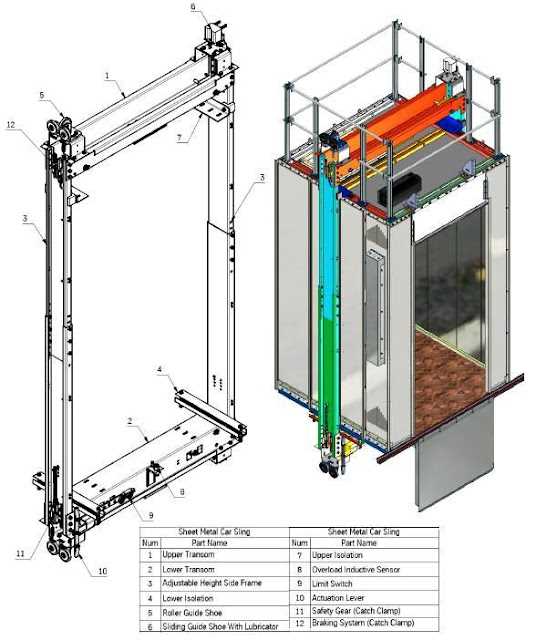

Each mechanism comprises several essential elements, each playing a vital role in the overall functionality. These components work in harmony to facilitate the opening and closing process, ensuring passengers can enter and exit without issues. Below is a summary of the main elements involved:

| Component | Description |

|---|---|

| Actuator | Drives the movement, converting electrical signals into mechanical action. |

| Guide Tracks | Ensure smooth and precise alignment during movement. |

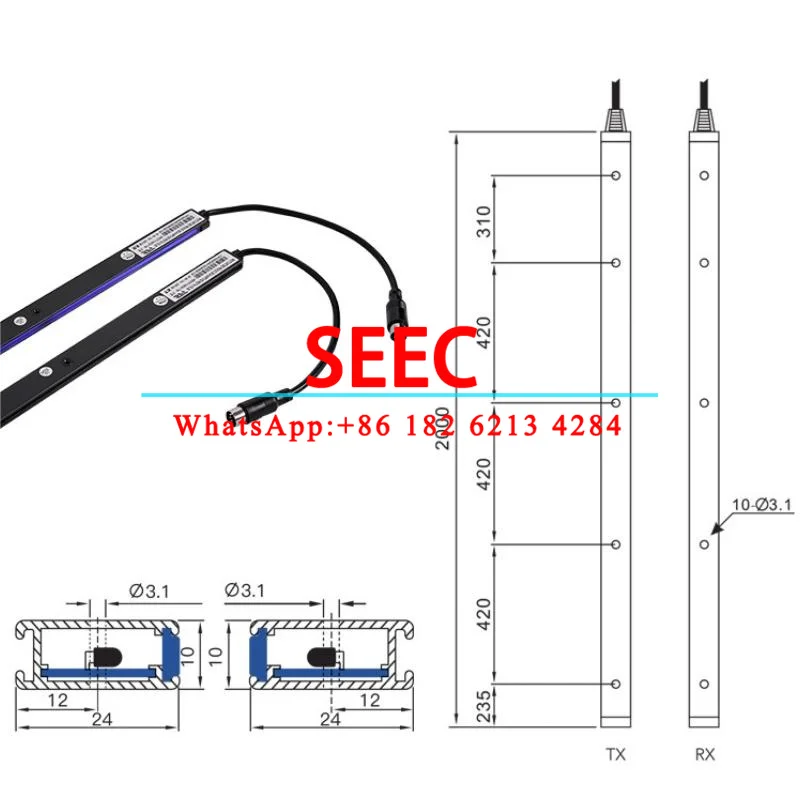

| Safety Sensors | Detect obstacles, preventing accidents during operation. |

| Control System | Coordinates the operation and timing of movements, responding to user inputs. |

Operation Principles

The functioning of these systems relies on both mechanical and electronic principles. When a user requests access, the control unit activates the actuator, initiating the movement. Safety sensors continuously monitor the area to ensure a secure environment. This coordination ensures that the entire process is both efficient and safe, highlighting the intricate engineering behind everyday functionality.

Key Components of Elevator Doors

The functionality and safety of vertical transport systems heavily depend on several essential elements. These components work together to ensure smooth operation, security, and user comfort. Understanding these integral pieces is crucial for both maintenance professionals and users alike.

Main Functional Elements

Among the primary functional elements are mechanisms that facilitate opening and closing, as well as sensors that detect obstructions. Each element plays a pivotal role in preventing accidents and ensuring user safety during transit.

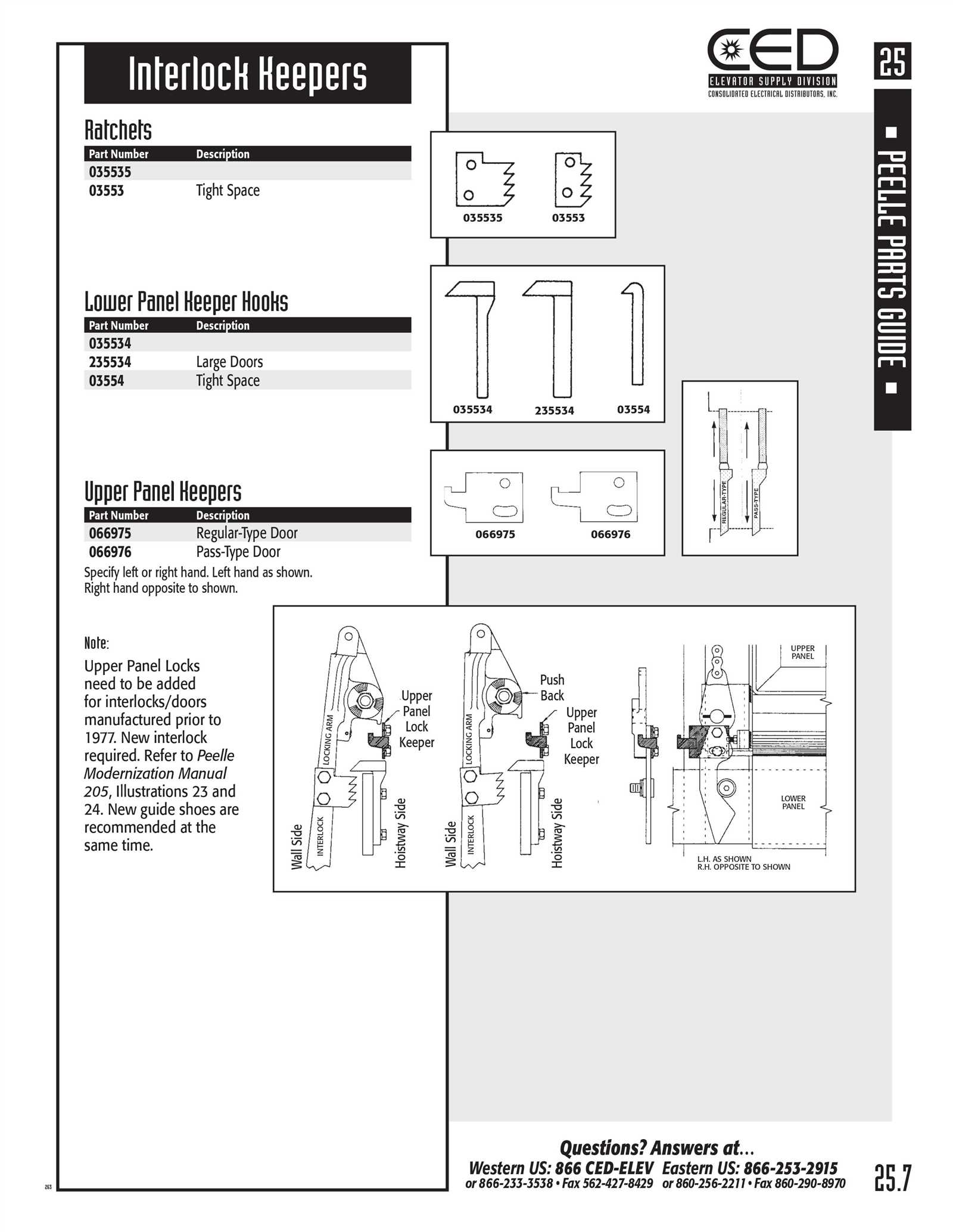

In addition to operational mechanisms, various security features enhance safety. These include locking systems that prevent unintended access and emergency releases designed to function during power outages.

| Component | Function |

|---|---|

| Sliding Mechanism | Allows for smooth and efficient movement. |

| Safety Sensors | Detect obstructions to prevent accidents. |

| Locking System | Prevents unauthorized access. |

| Emergency Release | Enables operation during power failures. |

Types of Elevator Door Systems

The various mechanisms for entry and exit in vertical transport systems play a crucial role in their functionality and user experience. Understanding the distinctions between these mechanisms can aid in selecting the most suitable option for different environments.

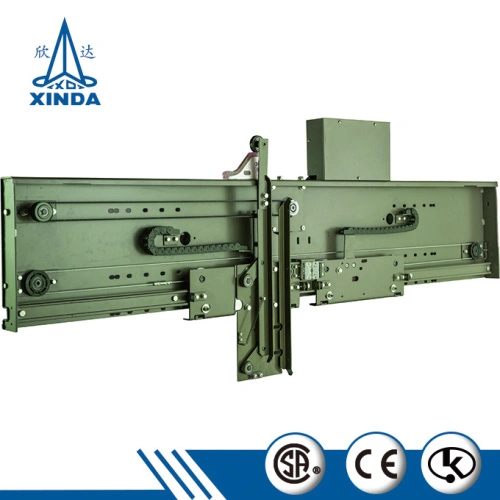

Sliding Systems are among the most common types, featuring panels that glide horizontally along tracks. This design is favored for its space-saving qualities, making it ideal for high-traffic areas.

Swinging Mechanisms, often seen in smaller installations, operate by pivoting on hinges. While they may require more space, their simplicity can be advantageous in certain contexts, particularly in residential settings.

Folding Systems utilize multiple panels that fold together, allowing for a compact solution when space is at a premium. These are particularly useful in environments where access needs to be maximized without sacrificing functionality.

Revolving Solutions offer a unique approach, permitting continuous flow of individuals in and out of the transport compartment. This type is commonly found in commercial buildings, providing a seamless experience while managing crowd control.

Each mechanism has its own advantages and challenges, making it essential to evaluate specific requirements and conditions before making a choice. The right selection can enhance safety, efficiency, and convenience for users.

Functionality of Door Panels

The components responsible for access management play a crucial role in ensuring safety and convenience. Their design and operation contribute significantly to user experience and overall system efficiency.

Key Roles

- Secure access to enclosed spaces.

- Facilitate smooth entry and exit processes.

- Provide safety features to prevent accidental closure.

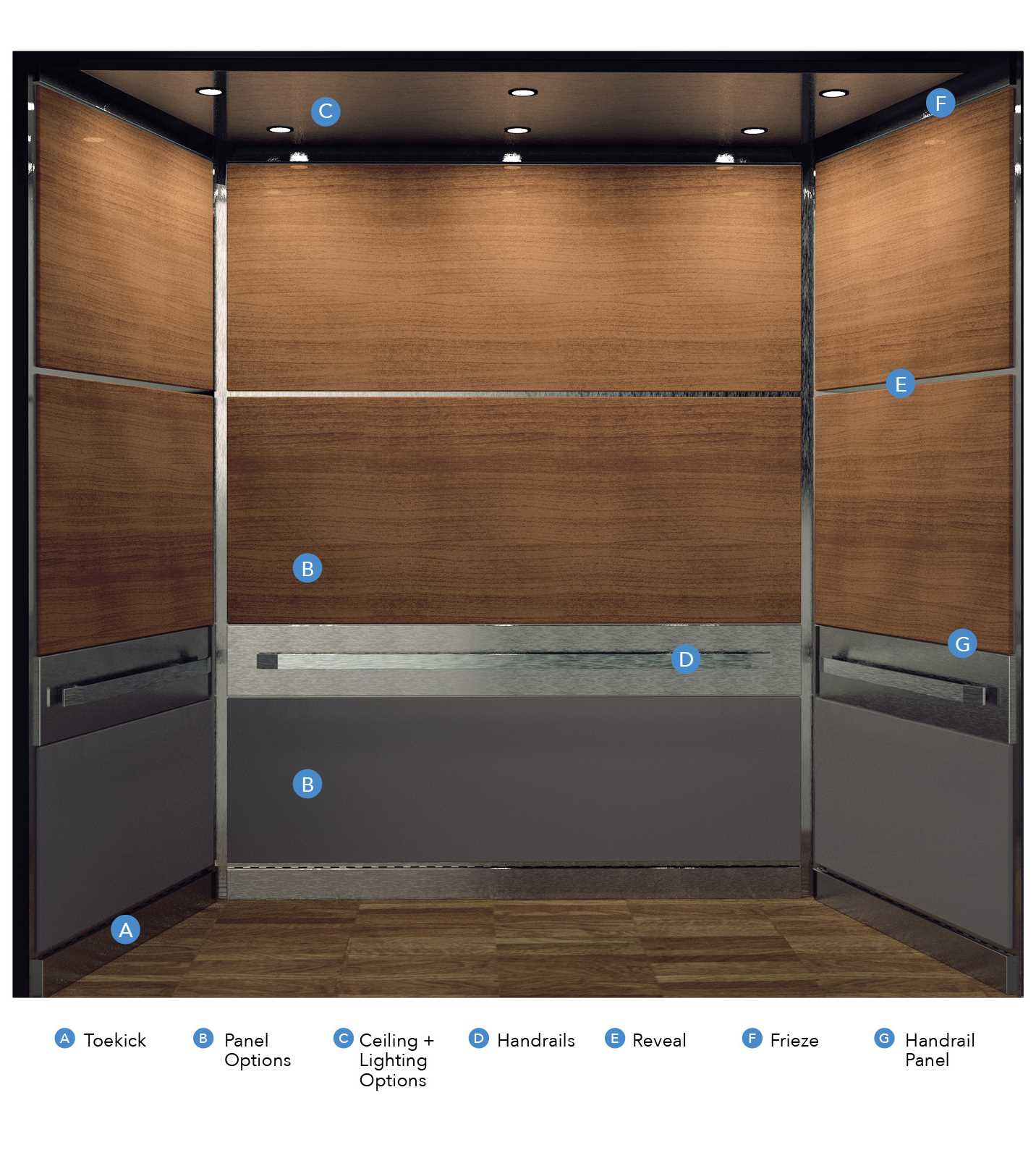

- Enhance the aesthetic appeal of the structure.

Operational Mechanisms

- Opening and Closing: Mechanisms enable panels to slide or swing, allowing easy passage.

- Safety Sensors: Equipped with sensors to detect obstructions, preventing harm during operation.

- Control Systems: Operated through buttons or remote controls, providing user-friendly interaction.

- Material Durability: Crafted from robust materials to withstand frequent use and wear.

Importance of Safety Features

Safety mechanisms play a crucial role in ensuring secure and reliable operation within vertical transport systems. These essential elements are designed to protect users and enhance overall functionality, thereby instilling confidence among passengers and maintenance personnel alike.

Key Reasons for Implementing Safety Mechanisms

- Risk Mitigation: By incorporating advanced protective features, potential hazards can be minimized, reducing the likelihood of accidents.

- User Confidence: When individuals feel safe, they are more likely to utilize these systems without hesitation.

- Compliance with Regulations: Adhering to safety standards is not just a best practice; it is often mandated by law, ensuring accountability.

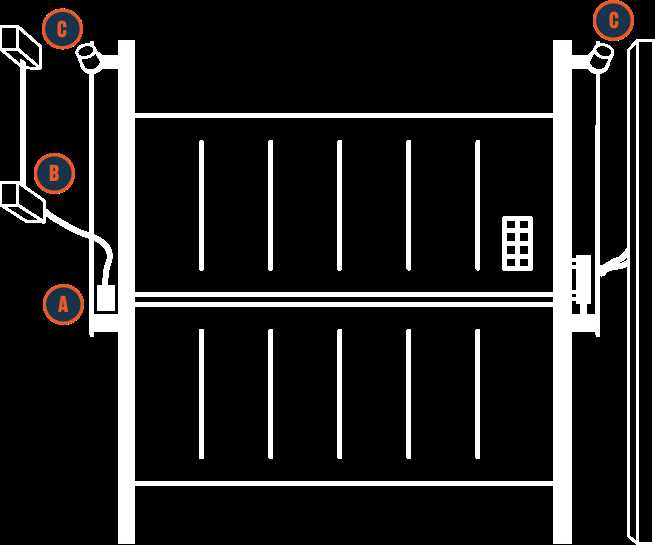

Essential Safety Features

- Emergency Communication Systems: These enable users to contact assistance quickly during unexpected situations.

- Automatic Locking Mechanisms: Such systems prevent access when the platform is not secure, reducing the risk of falls.

- Regular Maintenance Checks: Routine inspections ensure all safety features function optimally, safeguarding users effectively.

Incorporating these safety elements is vital for the reliable operation of any vertical transport mechanism, fostering a secure environment for all users.

Common Materials Used in Construction

In the realm of building and structure development, the selection of materials is pivotal for ensuring durability, safety, and functionality. Various substances are employed to meet the diverse demands of different projects, each offering unique properties that contribute to the overall integrity of the construction.

Among the most widely utilized materials are metals, wood, concrete, and composites. Each material has its distinct advantages and applications, depending on factors such as environmental conditions, aesthetic preferences, and budget constraints.

| Material | Properties | Applications |

|---|---|---|

| Steel | High strength, durability, and resistance to deformation | Frameworks, bridges, and industrial buildings |

| Wood | Lightweight, natural insulation, and aesthetic appeal | Residential homes, furniture, and decorative elements |

| Concrete | High compressive strength, fire-resistant, and low maintenance | Foundations, pavements, and walls |

| Composites | Lightweight, versatile, and corrosion-resistant | Aerospace, automotive, and specialized structures |

Understanding these materials and their properties allows for informed decisions that enhance the quality and sustainability of construction projects, ultimately leading to structures that are not only functional but also resilient over time.

How to Maintain Elevator Doors

Regular upkeep of moving barriers is essential to ensure smooth operation and longevity. Proper maintenance not only enhances functionality but also promotes safety for all users. A proactive approach can prevent unexpected failures and costly repairs.

Routine Inspections

Conducting frequent checks is crucial. Look for wear and tear, unusual noises, or misalignment. Ensure that all components are functioning properly and lubricate moving elements to reduce friction.

Cleaning and Care

Keeping surfaces clean is vital for aesthetics and functionality. Use appropriate cleaning agents to avoid damaging mechanisms. Remove debris and dust regularly to maintain optimal performance.

Installation Process Overview

This section provides a comprehensive look at the steps involved in setting up the components that facilitate vertical movement within a structure. Understanding the sequence of tasks is essential for ensuring efficiency and safety during assembly.

Preparation and Planning

Before initiating the installation, it is crucial to assess the site and gather all necessary tools and materials. A detailed plan should outline each stage, identifying potential challenges and solutions to ensure a smooth process.

Assembly Steps

The assembly involves connecting various elements systematically. Begin with the framework, ensuring stability, followed by the integration of mechanical systems. Each step should be executed with precision to achieve optimal functionality and safety.

Diagnosing Door Malfunctions

Identifying issues related to access openings requires a systematic approach. Proper diagnostics can prevent further complications and ensure safety. This section outlines common signs of malfunction and methods for troubleshooting these problems effectively.

Common Symptoms

- Unusual noises during operation

- Inconsistent or sluggish movement

- Failure to close or open completely

- Visible misalignment

- Unexpected stopping or stalling

Troubleshooting Steps

- Inspect the mechanism for any obstructions or debris.

- Check for signs of wear on moving components.

- Examine alignment and ensure components are properly secured.

- Test the control systems for electrical issues.

- Consult the manufacturer’s guidelines for specific diagnostic procedures.

Addressing these symptoms promptly can enhance functionality and extend the lifespan of the system. Regular maintenance is key to preventing future malfunctions.

Upgrades for Enhanced Performance

In the quest for optimal functionality and reliability, numerous enhancements can be implemented to elevate operational efficiency. These modifications not only improve response times but also contribute to a smoother user experience.

Smart Technology Integration: Incorporating advanced automation systems allows for real-time monitoring and control, ensuring timely maintenance and reduced downtime.

Material Improvements: Utilizing high-quality, durable materials can significantly increase the lifespan of components, minimizing wear and tear while enhancing overall stability.

Energy Efficiency Solutions: Implementing eco-friendly technologies, such as regenerative drives, helps to reduce energy consumption, making the system more sustainable and cost-effective.

By exploring these innovative upgrades, operators can ensure peak performance and longevity, ultimately leading to greater satisfaction for all users.

Impact of Technology on Doors

The evolution of innovation has transformed access solutions in various ways, enhancing security, convenience, and efficiency. Modern advancements are reshaping how entryways operate and interact with users, making them smarter and more responsive to needs.

Enhanced Security Features

- Integration of biometric systems for personalized access.

- Remote monitoring capabilities for real-time surveillance.

- Smart locking mechanisms that offer keyless entry options.

Improved User Experience

- Automated opening systems that enhance accessibility.

- Mobile app controls for remote management.

- Sensors that detect user presence for seamless operation.

Regulatory Standards for Safety

Ensuring the highest level of safety in vertical transportation systems is paramount. Various guidelines and regulations are established to protect users and maintenance personnel, promoting reliable operation and minimizing risks associated with mechanical failures.

Key Standards and Guidelines

- International Organization for Standardization (ISO)

- American National Standards Institute (ANSI)

- National Fire Protection Association (NFPA)

- Occupational Safety and Health Administration (OSHA)

Compliance and Inspection

Regular inspections and adherence to safety standards are crucial. Compliance not only enhances operational efficiency but also fosters public trust. Key aspects include:

- Routine maintenance checks

- Periodic safety audits

- Staff training and certification

Future Trends in Elevator Design

As urban landscapes evolve and technology advances, the future of vertical transportation is set to undergo significant transformations. Innovations in design and engineering will shape how we move within buildings, enhancing efficiency, safety, and user experience. This section explores key trends that are likely to redefine mobility solutions in the coming years.

Smart Technologies

The integration of intelligent systems is becoming increasingly prominent. These technologies not only streamline operations but also enhance user interaction.

- AI Integration: Algorithms will optimize travel routes and waiting times, improving overall efficiency.

- IoT Connectivity: Devices will communicate with one another, allowing for real-time monitoring and maintenance.

- Mobile Integration: Users will be able to summon transportation using their smartphones, reducing wait times.

Sustainability and Energy Efficiency

Environmental concerns are driving the push for greener solutions in mobility systems. Future designs will focus on minimizing ecological footprints.

- Regenerative Drives: These systems will capture and reuse energy, significantly lowering consumption.

- Eco-friendly Materials: Use of sustainable materials in construction will become standard practice.

- Smart Power Management: Advanced systems will optimize energy use based on demand, further enhancing efficiency.

In summary, the future of vertical transportation will be characterized by a blend of cutting-edge technology and sustainable practices, creating a seamless and responsible mobility experience for users.