Comprehensive Guide to Honda Odyssey Sliding Door Parts Diagram

The intricate systems that facilitate entry and exit in modern vehicles play a crucial role in both functionality and convenience. These mechanisms often involve multiple components that work in harmony to ensure smooth operation. By examining these elements, one can gain insight into their design and functionality.

In this section, we will explore the various components associated with these access systems, highlighting their individual roles and how they contribute to the overall efficiency of the vehicle. Each element is vital, and understanding their interplay can enhance maintenance and repair efforts.

Furthermore, this exploration will enable enthusiasts and technicians alike to identify potential issues and facilitate effective troubleshooting. By delving into the details, we aim to equip readers with the knowledge necessary for optimal vehicle performance.

Understanding Honda Odyssey Sliding Doors

This section explores the mechanisms and components that enable the effortless operation of rear access panels in family vehicles. These features enhance convenience, allowing for easy entry and exit in tight spaces, which is crucial for busy parents and passengers alike.

The engineering behind these access panels involves various elements, including tracks, rollers, and sensors that work together to provide a seamless experience. A proper understanding of these components can lead to better maintenance and troubleshooting, ensuring longevity and reliability.

Common issues may arise from wear and tear or misalignment, affecting the smoothness of operation. Recognizing these problems early can help in identifying the necessary adjustments or replacements to keep everything functioning optimally.

Key Components of Sliding Doors

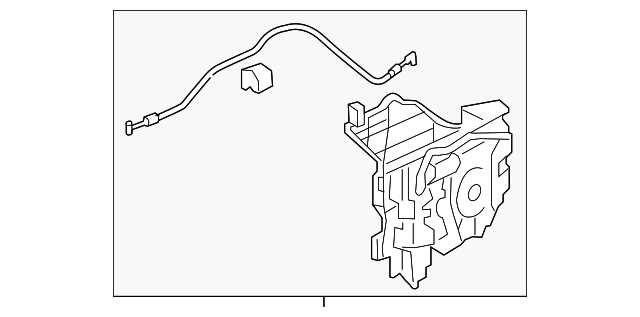

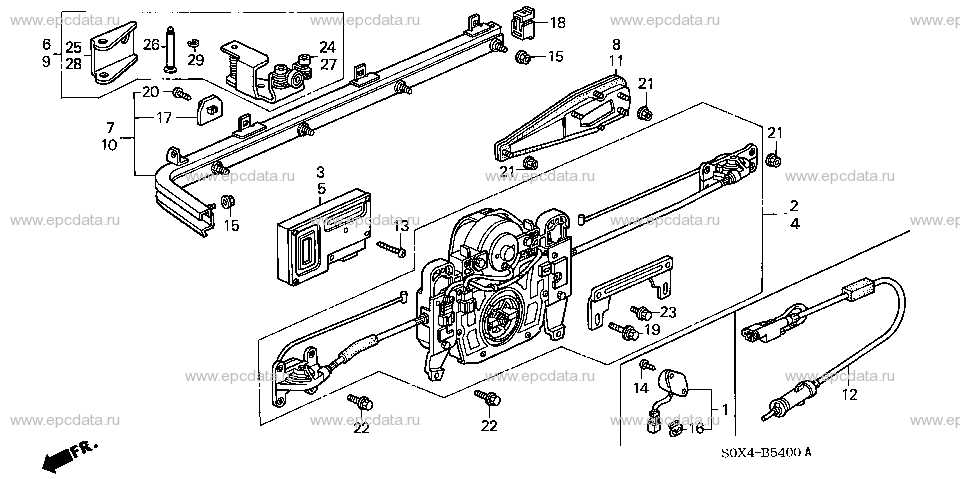

The functionality of an automated entry system relies on various essential elements that work together seamlessly. Understanding these critical components can enhance both maintenance and troubleshooting processes, ensuring smooth operation over time.

Track System: The foundation of any automated entry system is the track system, which guides the movement. This component is designed to provide stability and support, allowing for effortless operation.

Rollers: Attached to the moving panel, rollers are responsible for facilitating movement along the track. Their design and condition greatly influence the ease of opening and closing, making them a vital part of the overall mechanism.

Latch Mechanism: This element secures the entry point when closed. A reliable latch mechanism not only enhances security but also ensures that the system remains tightly shut when not in use.

Weather Stripping: Essential for energy efficiency and protection against the elements, weather stripping creates a seal around the edges. This component plays a crucial role in maintaining indoor climate and preventing water infiltration.

Control System: The heart of automation, the control system regulates the operation. It often includes sensors and buttons that allow users to operate the entry effortlessly, enhancing convenience and accessibility.

Each of these components plays a significant role in the overall functionality and reliability of the entry system. Regular maintenance and awareness of their condition can ensure longevity and performance, providing peace of mind to users.

Common Issues with Sliding Doors

These mechanisms often face a variety of challenges that can affect their functionality. Users may encounter several prevalent concerns that hinder smooth operation and convenience.

| Issue | Description |

|---|---|

| Misalignment | The track may become uneven, causing the mechanism to not function correctly. |

| Obstruction | Foreign objects can block movement, preventing proper closure or opening. |

| Wear and Tear | Over time, components may degrade, leading to increased friction and noise. |

| Electrical Failures | In electric systems, wiring issues can disrupt functionality, causing inoperability. |

| Lubrication Issues | Inadequate lubrication can result in stiffness and jerky movement during operation. |

Benefits of Automatic Sliding Mechanisms

Automatic mechanisms that facilitate the movement of panels offer numerous advantages for users seeking convenience and efficiency in their daily routines. These systems streamline access, enhancing the overall functionality of vehicles and structures alike.

Convenience is a primary benefit, allowing for effortless entry and exit without the need for manual handling. This feature is particularly useful in crowded situations or when carrying items, as it minimizes the physical effort required.

Safety is another critical aspect. Many automated systems are designed with sensors that prevent collisions, ensuring a secure environment for all users. This reduces the risk of accidents, especially for families with children or elderly individuals.

Durability and reliability also stand out. Advanced engineering and quality materials contribute to the longevity of these systems, providing consistent performance over time. Regular maintenance ensures that the mechanisms function optimally, reducing the likelihood of malfunctions.

Ultimately, incorporating automatic mechanisms into designs not only enhances user experience but also contributes to the overall value and appeal of the product.

How to Identify Broken Parts

Identifying malfunctioning components in a vehicle can significantly enhance its performance and longevity. Regular inspection and understanding of potential issues are essential for maintaining optimal functionality.

Start by observing any unusual noises or irregular movements when operating the mechanism. Listen for clicking, grinding, or popping sounds, which may indicate wear or damage. Additionally, examine the mechanism for visible signs of wear, such as cracks or frayed edges.

Next, check the alignment and fit of each element. If parts do not close or open smoothly, this may suggest a deeper issue. Inspect for misalignment, as this can lead to further complications if not addressed promptly.

Lastly, consider the age and usage of the components. Frequent use may lead to quicker degradation, necessitating timely replacements. Keeping a maintenance log can also help in tracking any recurring issues.

Step-by-Step Repair Guide

This section offers a comprehensive approach to restoring the functionality of your vehicle’s access mechanisms. By following the outlined steps, you can effectively address common issues that may arise, ensuring smooth operation and reliability.

Tools and Materials Needed

- Screwdrivers (flat and Phillips)

- Socket set

- Pliers

- Lubricant

- Replacement components (if necessary)

- Cleaning cloth

Repair Steps

- Start by ensuring the vehicle is parked safely and the ignition is off.

- Remove any covers or panels that obstruct access to the mechanism.

- Inspect all components for wear or damage, noting any that require replacement.

- If any parts are stuck, apply lubricant to free them without causing harm.

- Replace any faulty components, ensuring they are correctly aligned and secured.

- Reattach any covers or panels, making sure they fit snugly.

- Test the mechanism multiple times to confirm that everything operates smoothly.

Following these steps will help restore your vehicle’s access features, enhancing both convenience and safety.

Tools Required for Repairs

When embarking on maintenance or repair tasks, having the right tools at your disposal is essential for achieving optimal results. This section outlines the necessary equipment that will facilitate a smooth and effective repair process, ensuring that you can tackle any issues with confidence.

Essential Equipment

Here is a list of the primary tools you will need:

| Tool | Description |

|---|---|

| Screwdriver Set | Various sizes and types to handle different screws. |

| Socket Wrench | For loosening and tightening bolts effectively. |

| Pry Bar | Useful for separating components without damage. |

| Torque Wrench | Ensures proper tightening to manufacturer specifications. |

Safety Gear

In addition to tools, safety gear is crucial. Always wear protective eyewear and gloves to safeguard against potential hazards during your repair work.

Maintaining Your Sliding Doors

Proper upkeep of your vehicle’s access mechanisms is crucial for ensuring smooth operation and longevity. Regular attention can prevent wear and tear, enhancing functionality and safety. Here, we will explore essential practices for optimal maintenance.

Regular Inspection

Consistent checks for any signs of wear, damage, or misalignment can help identify issues early. Look for debris in tracks and examine seals for integrity.

Lubrication Techniques

Utilizing appropriate lubricants can significantly enhance the movement of the mechanisms. Apply lubricants to tracks and moving parts to reduce friction and prevent sticking.

| Maintenance Task | Frequency |

|---|---|

| Inspect for debris | Monthly |

| Check seals | Every 6 months |

| Apply lubricant | Every 3 months |

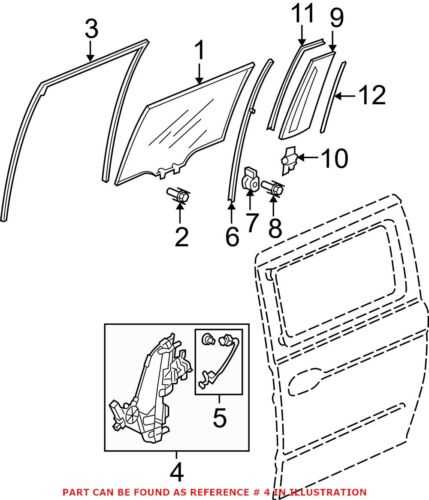

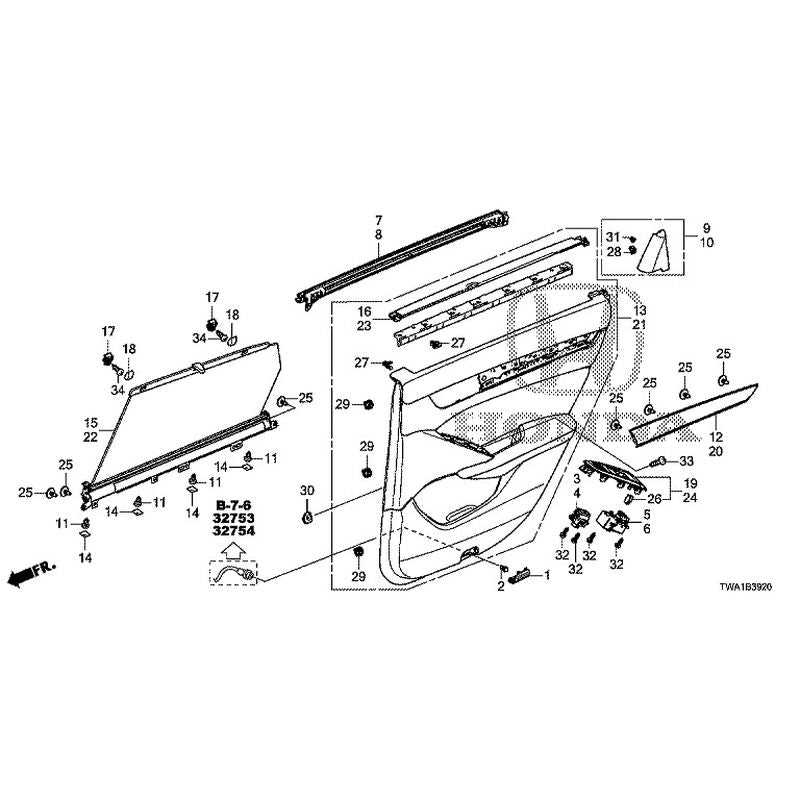

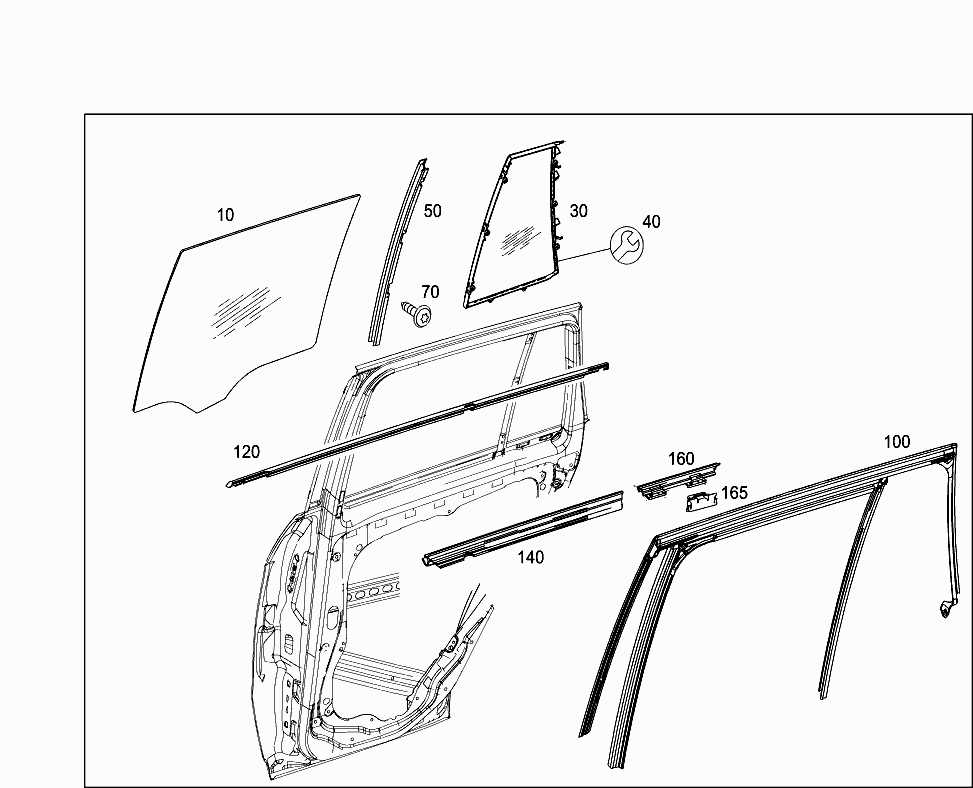

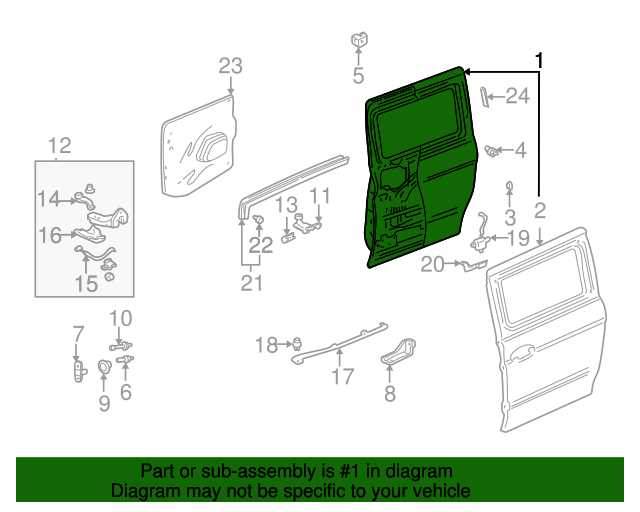

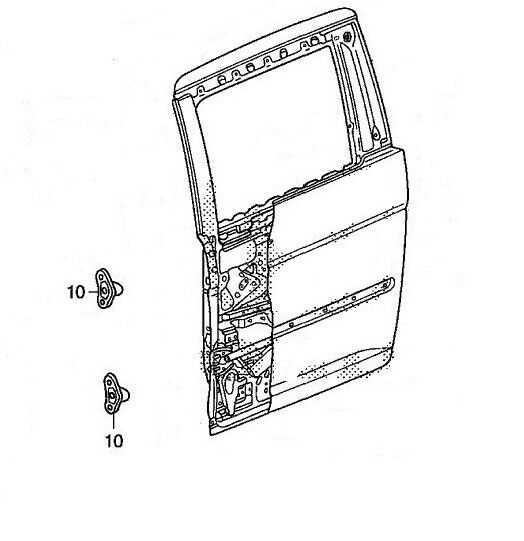

Parts Diagram Overview

This section provides a comprehensive look at the components that make up the unique entry system of a vehicle. Understanding these elements is crucial for maintenance and repair, as each piece plays a vital role in functionality and safety.

Visual representations serve as invaluable tools for both enthusiasts and professionals. They offer clarity and facilitate an easier identification of individual components, ensuring that repairs and replacements are executed efficiently.

In-depth knowledge of the structure allows for informed decisions when troubleshooting issues. Each segment, from the mechanisms to the electronic systems, is designed to work in harmony, enhancing the overall performance of the vehicle.

Where to Find Replacement Parts

Locating suitable components for vehicle maintenance can be a straightforward process with the right resources. Below are some reliable avenues to explore when seeking replacements for essential mechanisms.

- Online Retailers: Websites specializing in automotive supplies often carry a wide range of options.

- Local Dealerships: Authorized vendors can provide genuine components specific to your model.

- Auto Salvage Yards: Salvage facilities may have pre-owned items at reduced prices.

- Specialty Forums: Community forums can connect you with sellers or offer recommendations.

Comparing prices and reviews will help you make the ultimate choice for quality and cost-effectiveness.

Cost Considerations for Repairs

When addressing mechanical issues, understanding the financial implications is crucial. Various factors contribute to the overall expenses associated with restoring functionality, from labor costs to component prices. Evaluating these elements helps in making informed decisions about repairs and potential upgrades.

Labor Expenses

The cost of skilled labor can significantly affect the total repair bill. Technicians with specialized knowledge may charge higher rates, reflecting their expertise. Assessing the complexity of the work required can guide owners in budgeting appropriately for professional assistance.

Component Pricing

The cost of replacement components can vary widely based on quality and source. Genuine parts often come at a premium but may ensure better longevity and performance. On the other hand, aftermarket alternatives might offer savings but can impact overall reliability. It’s essential to weigh these options carefully.

DIY vs. Professional Repairs

When it comes to vehicle maintenance and restoration, enthusiasts often face the choice between tackling repairs independently or seeking assistance from experienced technicians. Each option has its advantages and challenges that can significantly impact the outcome of the repair process.

Choosing to handle repairs yourself can be a rewarding experience. Here are some benefits:

- Cost Savings: Performing repairs on your own can often reduce labor costs associated with hiring a professional.

- Skill Development: Engaging in hands-on work can enhance your mechanical knowledge and capabilities.

- Flexibility: You can work on your schedule, allowing for more convenience.

However, DIY repairs come with certain risks. Consider the following:

- Time-Consuming: Repairs may take longer than anticipated, especially if you encounter unforeseen issues.

- Potential for Errors: Lack of experience can lead to mistakes, potentially resulting in further damage.

- Limited Access to Tools: Some repairs require specialized equipment that may not be readily available.

On the other hand, opting for professional assistance offers distinct advantages:

- Expertise: Professionals bring years of experience and specialized knowledge to the table.

- Warranty on Work: Many services provide guarantees, giving you peace of mind.

- Efficiency: Technicians can often complete repairs more quickly due to their familiarity with common issues.

Despite these benefits, there are drawbacks to consider:

- Higher Costs: Labor fees can add significantly to the overall expense of repairs.

- Less Control: You may have limited input in the repair process and materials used.

- Scheduling Conflicts: Appointments may require you to wait, which can be inconvenient.

Ultimately, the decision between self-repair and professional help depends on your skill level, available resources, and comfort with the complexities involved. Evaluating the situation thoroughly will help you make an informed choice that best suits your needs.

Customer Experiences and Feedback

This section aims to provide insights from users regarding their encounters with the vehicle’s access mechanisms. Real-life testimonials often highlight both satisfaction and areas for improvement, showcasing how these features meet daily needs.

Positive Experiences

- Many users appreciate the ease of use, especially when loading children or groceries.

- Several customers report that the mechanisms operate smoothly even after extended use.

- Convenience during tight parking situations is frequently praised.

Areas for Improvement

- Some users have experienced occasional malfunctions that require timely repairs.

- A few feedback points suggest enhancements in the durability of components.

- Users express a desire for more intuitive control options in newer models.