Kubota SVL75 Door Parts Diagram Guide

In the realm of machinery and equipment, the intricacies of entry mechanisms play a crucial role in functionality and safety. A comprehensive understanding of these elements is essential for maintaining optimal performance. This section delves into the various components that make up these access systems, ensuring users can effectively navigate and manage their upkeep.

When dealing with complex machinery, it is important to recognize how each element interconnects to facilitate seamless operation. By examining the assembly of these components, one can gain insights into the overall design and engineering behind the structure. This knowledge not only aids in troubleshooting but also enhances the ability to execute repairs and replacements when necessary.

Furthermore, grasping the layout of these components empowers operators and technicians alike. With a clear visualization of how each piece fits into the larger system, individuals are better equipped to handle maintenance tasks efficiently. This section aims to provide a detailed overview, fostering a deeper appreciation for the craftsmanship involved in the design of these access solutions.

Kubota SVL75 Overview

This section provides a comprehensive introduction to a highly regarded compact track loader known for its versatility and performance in various applications. This machine is designed to meet the demands of both professional contractors and agricultural users, offering reliability and ease of operation.

Key Features

The compact loader boasts several features that enhance its functionality and user experience. From its powerful engine to its advanced hydraulic system, every component is crafted to deliver optimal performance.

| Feature | Description |

|---|---|

| Engine Power | Equipped with a robust engine that ensures high productivity and efficiency. |

| Hydraulic System | Advanced hydraulics provide precise control and increased lifting capacity. |

| Cab Comfort | Ergonomically designed operator station for enhanced comfort during long hours of work. |

| Attachments | Compatible with various attachments, making it suitable for multiple tasks. |

Applications

This versatile machine is ideal for a wide range of applications, including landscaping, construction, and agricultural tasks. Its ability to maneuver in tight spaces while delivering powerful performance makes it a favorite among operators in diverse industries.

Importance of Door Components

Understanding the significance of individual elements within an entryway system is crucial for optimal functionality and safety. Each component plays a vital role in ensuring a secure and efficient operation, contributing to the overall integrity of the structure.

Durability is a primary factor; high-quality materials ensure that each element withstands wear and tear, prolonging the lifespan of the entire assembly. Furthermore, proper alignment of components facilitates smooth movement, reducing the risk of malfunctions or accidents.

Additionally, insulation properties are enhanced by well-designed elements, promoting energy efficiency and comfort. Overall, a thorough understanding of these components allows for better maintenance and improvements, ultimately leading to enhanced user experience.

Parts Identification Guide

This section serves as a comprehensive resource for recognizing various components associated with a specific machinery model. Accurate identification is crucial for maintenance and repairs, ensuring optimal performance and longevity.

Understanding Component Types

Familiarity with the different categories of elements can simplify troubleshooting and replacement tasks. Each category plays a vital role in the overall functionality of the equipment.

Identification Table

| Component Type | Description | Common Issues |

|---|---|---|

| Frame | The main structure providing support. | Corrosion, misalignment. |

| Seals | Ensure protection against dust and moisture. | Wear and tear, leaks. |

| Hinges | Facilitate movement and accessibility. | Rust, breakage. |

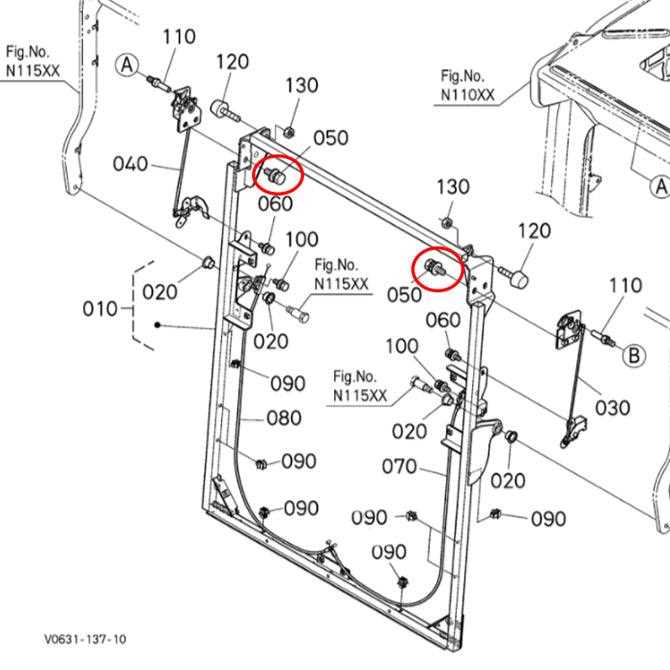

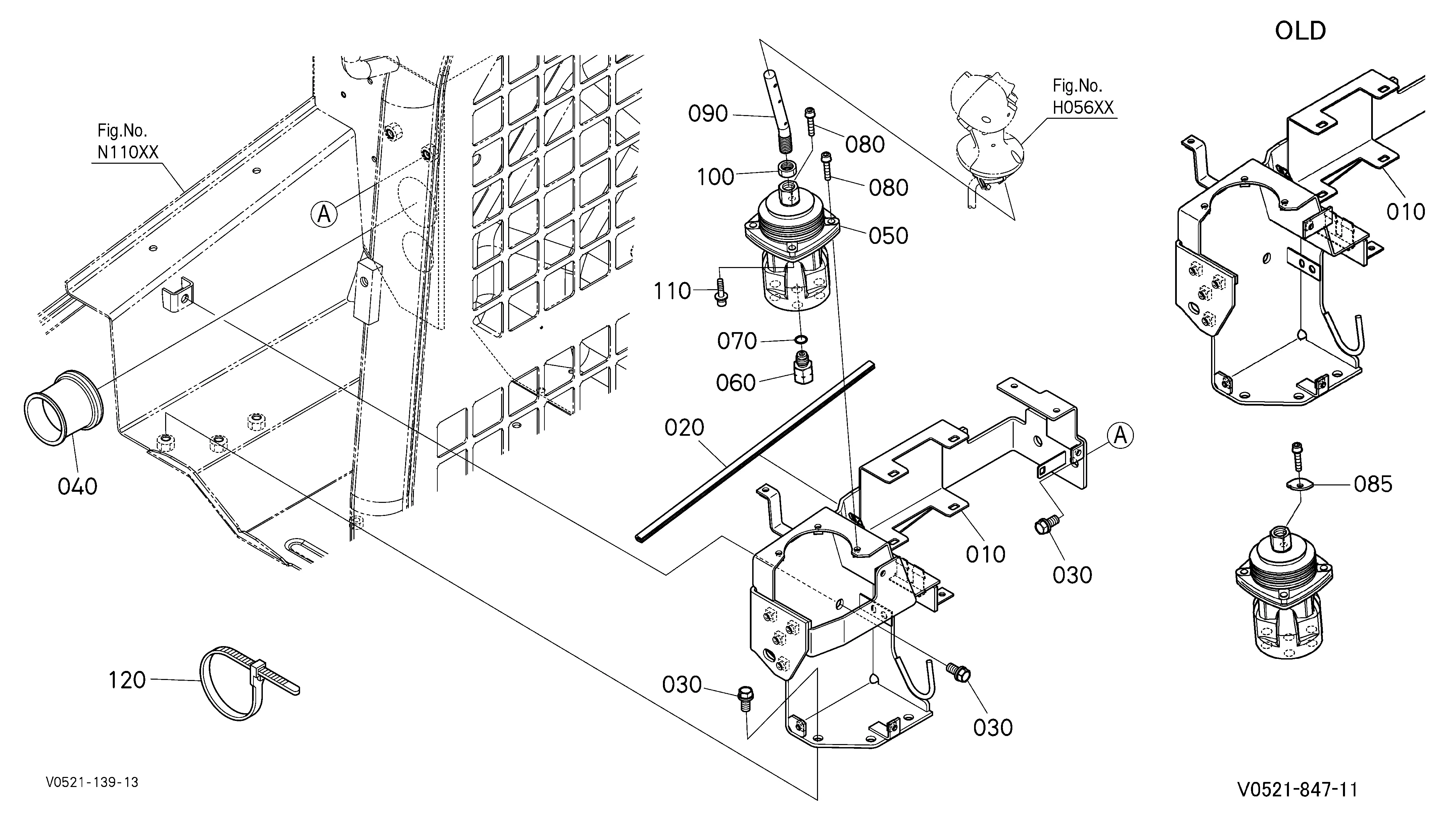

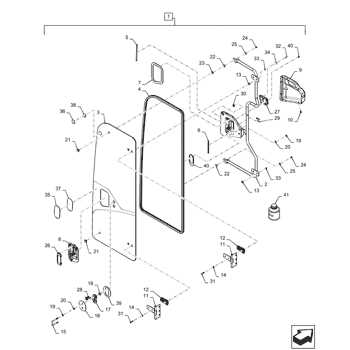

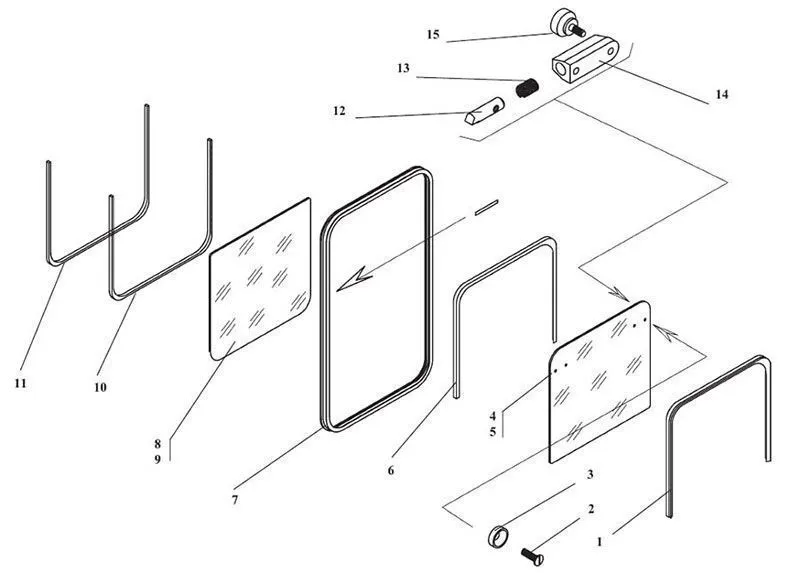

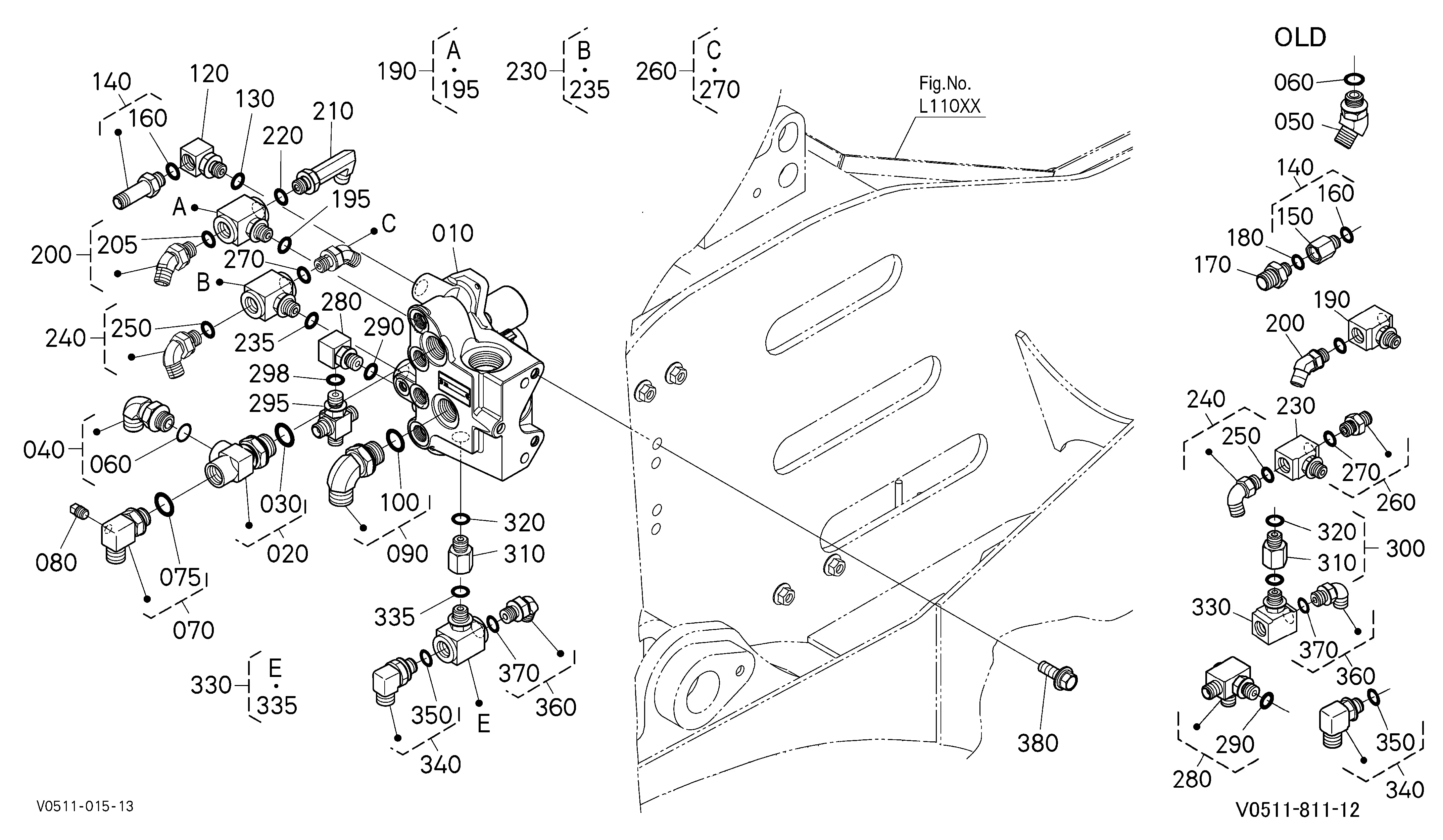

Detailed Door Parts Diagram

This section presents an intricate visual representation that illustrates the various components involved in the entryway mechanism. Understanding these elements is essential for efficient maintenance and repair.

Key Components: Each section showcases distinct elements, ranging from the structural framework to the functional accessories. This comprehensive overview aids in recognizing how each component contributes to the overall functionality.

Maintenance Tips: Regular inspections of these elements can prevent issues and ensure smooth operation. Familiarity with the layout can significantly enhance troubleshooting efforts.

By exploring this detailed representation, users can gain valuable insights into the assembly and care of the entry mechanism, ultimately improving longevity and performance.

Common Issues with Door Parts

When it comes to access points on machinery, several challenges can arise that affect functionality and safety. These concerns often stem from wear and tear, environmental factors, or improper maintenance, leading to various operational difficulties. Understanding these issues is crucial for ensuring longevity and efficiency.

Wear and Tear

Over time, components can become worn due to constant use, which may result in misalignment or malfunction. This deterioration can compromise the integrity of the structure, making it essential to monitor and replace aging elements to maintain optimal performance.

Environmental Impact

Exposure to harsh conditions such as moisture, dirt, and extreme temperatures can lead to corrosion and other forms of damage. Regular inspection and proper sealing are vital in mitigating these effects, ensuring that the access points remain functional and secure.

How to Replace Door Parts

Replacing components related to entryways can enhance functionality and security. This guide will walk you through the necessary steps to successfully complete the task with ease and efficiency.

Tools and Materials Needed

- Screwdriver set

- Replacement components

- Pliers

- Lubricant

- Cleaning cloth

Steps to Follow

- Begin by removing any screws or fasteners securing the existing components.

- Carefully detach the old items from the frame.

- Clean the area to ensure a proper fit for the new components.

- Install the replacement items, ensuring they are aligned correctly.

- Secure everything tightly and apply lubricant to moving parts.

- Test the functionality to confirm everything operates smoothly.

Maintenance Tips for Door Components

Proper upkeep of access barriers is essential for ensuring smooth operation and longevity. Regular attention to these elements can prevent wear and tear, ultimately enhancing performance and safety. Understanding key maintenance practices can help maintain the integrity of these structures.

Regular Inspection

Conduct periodic examinations to identify any signs of damage or deterioration. Look for cracks, rust, or misalignment that could hinder functionality. Addressing these issues promptly can save time and resources in the long run.

Lubrication and Cleaning

Routine lubrication of moving mechanisms is crucial to ensure they operate smoothly. Use appropriate lubricants to reduce friction and prevent corrosion. Additionally, keep surfaces clean from dirt and debris, as buildup can lead to operational failures. Regular cleaning not only extends the lifespan but also enhances the overall appearance.

Incorporating these practices into your maintenance routine will help keep access mechanisms in optimal condition, allowing for reliable use and minimizing the risk of unexpected malfunctions.

Tools Required for Repair

When undertaking any maintenance or restoration task, having the right instruments at hand is crucial for efficiency and effectiveness. Various tools facilitate the process, ensuring that repairs are executed smoothly and with precision.

Essential items typically include wrenches, screwdrivers, pliers, and specialized equipment designed for specific components. Additionally, safety gear such as gloves and goggles is vital to protect against potential hazards during the repair process.

For more intricate tasks, consider using a torque wrench to ensure proper fastening and alignment. Having a well-organized toolkit can significantly enhance the workflow, reducing downtime and improving the overall quality of the work.

Safety Precautions During Repairs

When undertaking maintenance tasks, prioritizing safety is essential. Proper precautions can prevent accidents and ensure a smooth repair process. Familiarizing oneself with safety protocols not only protects the individual but also safeguards the equipment involved.

Essential Safety Gear

Utilizing appropriate safety equipment is crucial in any repair environment. Essential items can include gloves, goggles, and hard hats, which collectively reduce the risk of injuries. It is important to ensure that all gear is well-maintained and suitable for the specific tasks at hand.

Work Environment Considerations

A well-organized workspace contributes significantly to safety. Keeping tools and materials neatly arranged minimizes hazards and promotes efficiency. Additionally, ensuring that the area is well-lit and free of clutter can prevent accidents and facilitate better focus during repairs.

| Safety Gear | Purpose |

|---|---|

| Gloves | Protect hands from cuts and abrasions |

| Goggles | Shield eyes from debris and harmful substances |

| Hard Hats | Prevent head injuries from falling objects |

| Steel-Toed Boots | Protect feet from heavy equipment |

Finding Genuine Kubota Parts

When maintaining heavy machinery, sourcing authentic components is crucial for ensuring optimal performance and longevity. Using original parts not only guarantees compatibility but also enhances the overall reliability of the equipment.

Why Choose Authentic Components?

Opting for genuine replacements offers several advantages:

- Enhanced durability and lifespan

- Perfect fit and compatibility

- Maintained warranty and resale value

- Assured quality and performance

Where to Locate Original Items

Finding legitimate replacements can be straightforward if you know where to look:

- Authorized dealerships and retailers

- Reputable online marketplaces specializing in equipment

- Manufacturer’s official website

- Local repair shops with good reputations

Aftermarket vs. OEM Parts

When it comes to maintaining machinery, choosing the right components can significantly impact performance and longevity. Two primary categories of replacements exist: original equipment and alternative options. Understanding the differences between these choices is crucial for making informed decisions.

Original equipment components are manufactured by the same company that produced the original machinery. These items are designed to meet strict quality and performance standards, ensuring compatibility and reliability. In contrast, alternative options are produced by third-party manufacturers, often at a lower cost, but their quality and fit can vary.

- Quality Assurance: OEM products typically undergo rigorous testing to meet specific standards, while aftermarket items may not always adhere to the same level of scrutiny.

- Cost Considerations: Alternative components are generally more affordable, appealing to budget-conscious consumers, but potential hidden costs can arise from reduced durability.

- Availability: Aftermarket suppliers often provide a wider range of options, making it easier to find specific replacements, whereas OEM options may have limited availability.

- Warranty and Support: OEM components usually come with manufacturer warranties, ensuring peace of mind, whereas aftermarket products may offer varying levels of support.

Ultimately, the choice between original equipment and alternative options will depend on individual priorities, including budget, quality, and specific needs for maintenance and repairs.

Customer Reviews and Experiences

This section highlights the feedback and insights from users regarding their experiences with the machinery and its components. Understanding real-world usage can provide valuable perspectives for potential buyers and current owners alike. Here, we compile a variety of testimonials that reflect satisfaction, concerns, and suggestions from the community.

| Reviewer | Experience | Rating |

|---|---|---|

| John D. | Exceptional durability and ease of operation. Made my work much more efficient. | 5/5 |

| Lisa M. | Had some issues with the installation, but customer support was very helpful. | 4/5 |

| Tom S. | Performance is great, but I expected better longevity from the components. | 3/5 |

| Emily R. | Impressed with the functionality; it exceeded my expectations in various tasks. | 5/5 |

| Mark T. | Parts availability can be a challenge, but the machinery itself works well. | 4/5 |

Where to Buy Kubota Parts

Finding reliable sources for replacement components is essential for maintaining machinery efficiency. Whether you need to fix a malfunction or upgrade your equipment, knowing where to look can save you time and money.

Online Retailers

Numerous online platforms specialize in offering a wide range of components. These retailers often provide competitive pricing and convenient shipping options.

Local Dealers

Your nearest dealership can be a valuable resource for high-quality replacements. They typically have knowledgeable staff who can assist with specific inquiries and provide expert advice.

| Source Type | Advantages |

|---|---|

| Online Retailers | Competitive prices, vast selection, home delivery |

| Local Dealers | Expert advice, immediate availability, quality assurance |