Kwikset Door Handle Components Overview

In the world of security fixtures, comprehending the various elements that contribute to functionality is essential. These components work together to ensure ease of use and durability, making them crucial for effective operation. A thorough understanding of these elements can aid in maintenance, repairs, or upgrades.

Exploring these components provides insight into how each part interacts with others, influencing overall performance. Identifying individual components helps users troubleshoot common issues, ensuring smooth operation over time. Whether for residential or commercial applications, recognizing the role of each element enhances user experience and security.

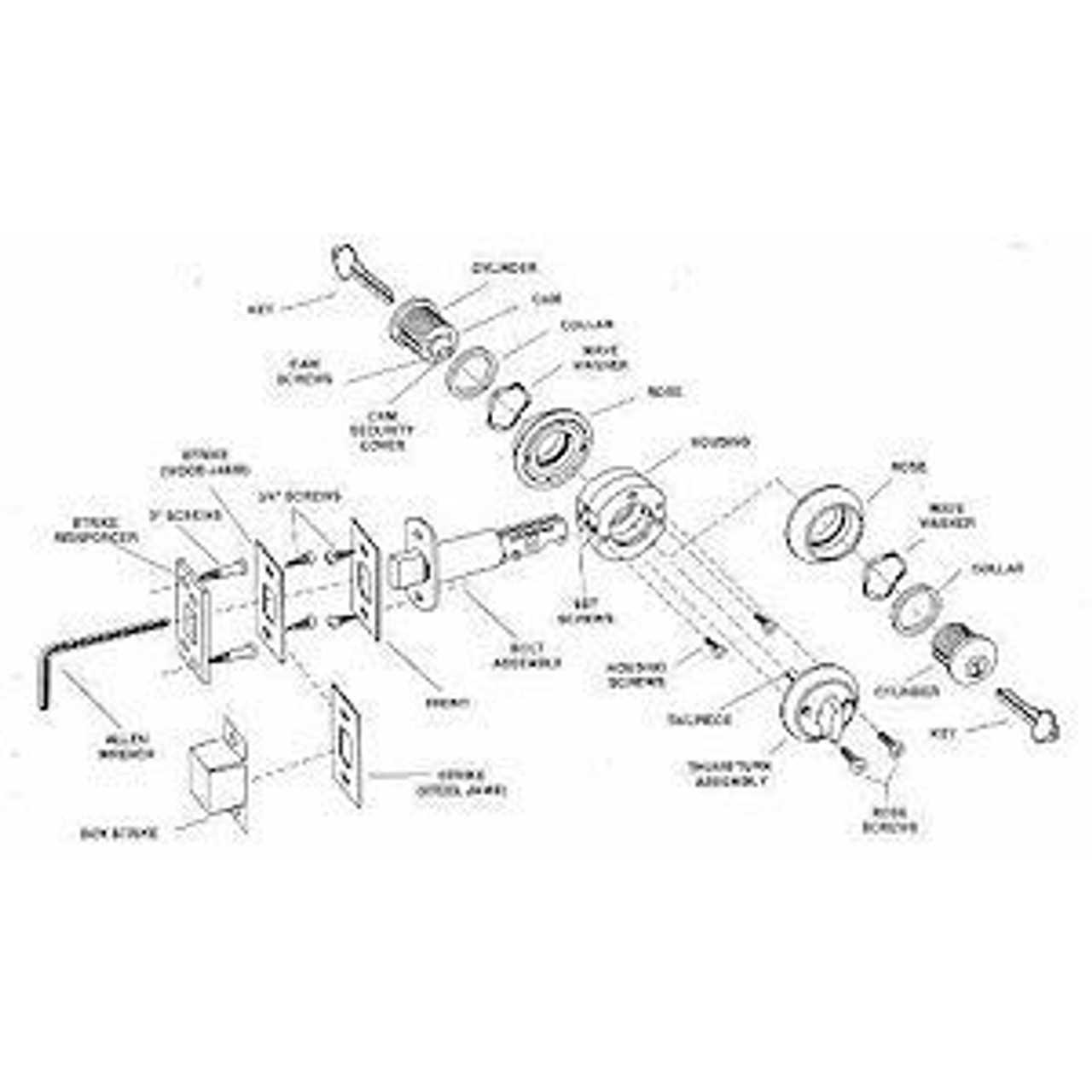

As we delve deeper, visual representations can simplify the learning process. A schematic overview can clarify how each component integrates into the larger mechanism, enabling users to navigate potential challenges confidently. This knowledge empowers individuals to take informed actions regarding their locking mechanisms.

This section aims to provide a comprehensive overview of the essential elements involved in the functioning of a locking mechanism. By breaking down the various components, readers can gain insight into how each piece contributes to the overall operation and security of the entry system.

Understanding these components is crucial for both installation and maintenance, ensuring that users can effectively manage any issues that may arise. The following table outlines the key elements, their functions, and additional notes for better comprehension.

| Component | Function | Notes |

|---|---|---|

| Exterior Plate | Holds the locking mechanism in place | Made of durable materials for longevity |

| Interior Plate | Provides access to the locking system | Often includes a release mechanism |

| Lock Cylinder | Enables the use of a key for unlocking | Can be rekeyed for security upgrades |

| Spindle | Connects the interior and exterior components | Allows for rotation to engage/disengage the lock |

| Strike Plate | Secures the mechanism to the frame | Helps to align the locking system |

Common Issues with Door Handles

Various issues can arise with entry mechanisms, impacting their functionality and security. Understanding these problems is essential for maintaining the integrity of access points in your premises.

Frequent Problems

- Difficulty in Turning: The mechanism may become stiff or unresponsive over time.

- Loose Components: Parts may become detached or less secure, leading to instability.

- Alignment Issues: Misalignment can prevent the mechanism from functioning smoothly.

Maintenance Tips

- Regular Lubrication: Use appropriate lubricants to ensure smooth operation.

- Check for Wear: Inspect components for signs of damage or excessive wear.

- Secure Fastenings: Tighten any loose screws or fixtures to enhance stability.

Identifying Key Parts and Functions

Understanding the essential components of locking mechanisms is crucial for effective maintenance and troubleshooting. Each element plays a specific role in ensuring security and functionality, contributing to the overall performance of the system.

Main Components

- Exterior Plate: This visible element provides aesthetic appeal while also offering protection to the internal mechanisms.

- Interior Plate: Located on the inside, this component often houses the operational parts that allow for locking and unlocking.

- Spindle: This rod connects the exterior and interior sections, facilitating the turning motion that engages the locking mechanism.

- Spring Mechanism: Responsible for returning the lever to its original position after use, ensuring the lock functions smoothly.

- Cylinder: This vital part is where the key is inserted, interacting with pins to enable or disable the lock.

Functions of Each Element

- The exterior plate provides an initial barrier against tampering.

- The interior plate serves as a control hub for operating the lock.

- The spindle translates the motion from the lever into action within the lock.

- The spring mechanism maintains the operational integrity of the lever system.

- The cylinder is the heart of the locking process, determining access based on the inserted key.

Tools Needed for Replacement

When it comes to swapping out your locking mechanism, having the right instruments at your disposal is essential for a smooth and efficient process. Proper tools can help ensure that the replacement is done correctly and safely, minimizing the risk of damage to the surrounding structure.

First and foremost, you will require a reliable screwdriver, typically a flathead or Phillips, to remove any fasteners securing the mechanism. Additionally, a pair of pliers can be invaluable for gripping and twisting any stubborn components. A utility knife may also be necessary for cutting through any adhesive materials that might be present.

Lastly, having a tape measure on hand is advisable to ensure that any new components fit perfectly within the existing framework. By preparing these essential tools ahead of time, you can streamline the replacement process and achieve optimal results.

Step-by-Step Installation Guide

This section provides a detailed methodology for the assembly of your locking mechanism. Follow these instructions carefully to ensure a seamless installation process, enhancing the security and functionality of your entryway.

Preparation and Tools

Before starting, gather the necessary tools: a screwdriver, a drill, and any additional components specified in the installation kit. Ensure that you have a clean workspace to facilitate a smooth installation.

Installation Process

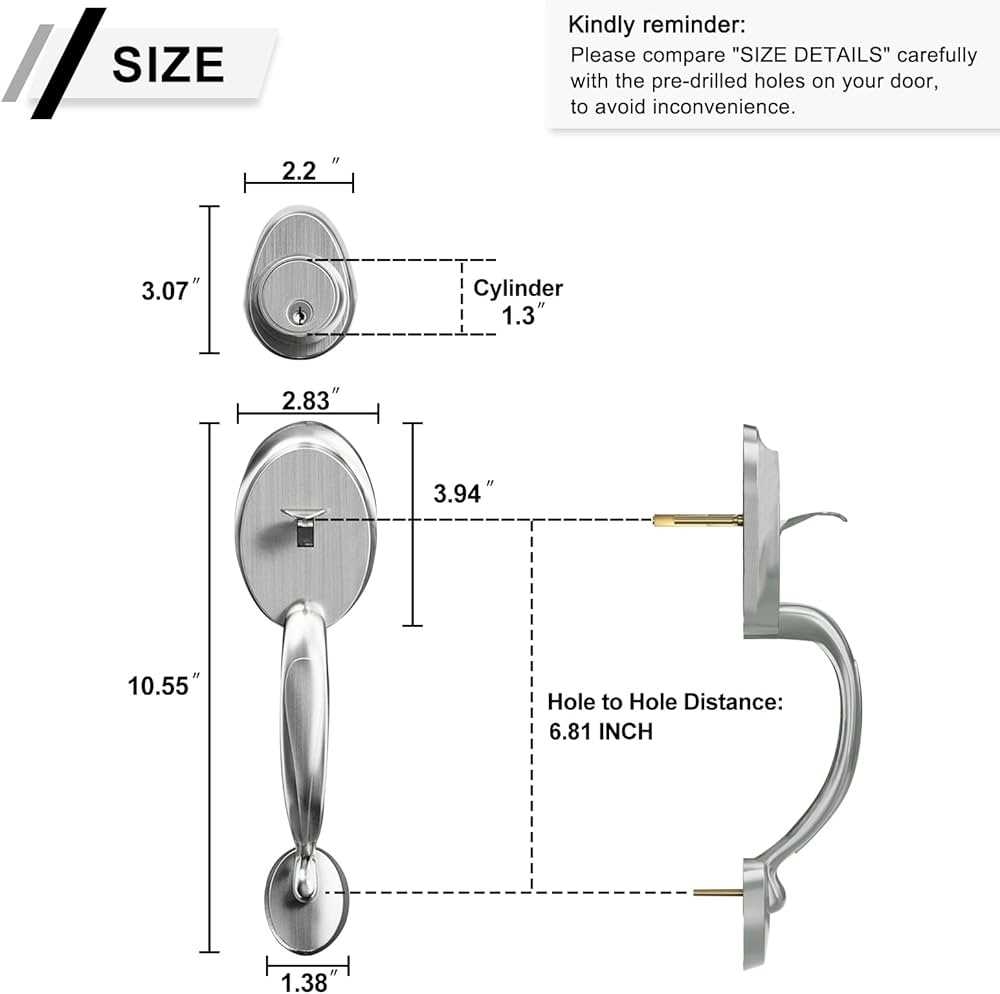

Begin by aligning the main unit with the pre-drilled holes in the frame. Insert the provided screws and secure the assembly tightly, ensuring it is level. Next, attach the inner mechanism, ensuring all components fit snugly together. Finally, test the functionality to confirm proper operation.

Maintenance Tips for Longevity

To ensure the extended functionality and durability of your locking mechanisms, regular upkeep is essential. Implementing a few straightforward practices can significantly enhance their lifespan and efficiency.

Firstly, it is crucial to keep the mechanisms clean and free from debris. Dust and dirt accumulation can interfere with smooth operation, leading to wear and tear. A soft cloth or a gentle brush can help maintain cleanliness.

Additionally, lubrication is vital. Applying a silicone-based lubricant periodically will prevent rust and ensure seamless operation. Avoid using grease, as it can attract more dirt and grime.

Regular inspections should also be part of your maintenance routine. Check for any signs of damage or wear, and address issues promptly to avoid more significant problems in the future.

Lastly, ensure that all screws and fittings are tightened. Loose components can lead to misalignment and hinder the performance of the system. A simple check every few months can help maintain optimal functioning.

Compatibility with Different Models

The interchangeability of components across various mechanisms is crucial for seamless functionality and user satisfaction. Understanding which models are compatible with each other can simplify repairs and enhance overall performance. This section delves into the compatibility of different units, ensuring you can make informed decisions when selecting replacements or upgrades.

Overview of Compatibility

Several designs share similar specifications, allowing for easy substitutions. When assessing compatibility, it is essential to consider the dimensions and functional characteristics of each unit. Many manufacturers strive to maintain consistency in design, which facilitates the use of one mechanism across multiple styles.

Factors Influencing Compatibility

Key factors such as the installation process, locking mechanisms, and aesthetic choices can affect compatibility. It is advisable to consult the manufacturer’s guidelines or seek professional advice to ensure proper alignment and functionality. Paying attention to these details can prevent issues and prolong the lifespan of your components.

Common Misalignments and Fixes

Proper alignment is crucial for the smooth operation of locking mechanisms. Misalignment can lead to difficulties in engaging or disengaging the locking system, causing frustration and potential security issues. Understanding typical alignment problems and their solutions can help maintain functionality and longevity.

Here are some common misalignments and their corresponding fixes:

- Locking Mechanism Misalignment: If the locking mechanism does not fit into the strike plate correctly, it may be due to improper installation or warping over time. To fix this, adjust the position of the strike plate or the locking mechanism itself.

- Frame Alignment Issues: A misaligned frame can prevent smooth operation. Check for level and plumb conditions; if necessary, use shims to adjust the frame for better alignment.

- Weatherstripping Interference: Worn or improperly placed weatherstripping can hinder operation. Ensure that weatherstripping is not overly thick and is correctly installed to allow free movement.

- Hinge Problems: Hinges that are not properly aligned can cause doors to sag, leading to alignment issues. Inspect the hinges and tighten or replace them if needed to ensure proper function.

- Hardware Wear and Tear: Over time, internal components may wear out, affecting alignment. Regularly inspect and replace worn hardware to maintain optimal performance.

By addressing these common issues, users can ensure their locking systems operate smoothly and efficiently, enhancing security and convenience.

Safety Precautions During Installation

Ensuring safety while setting up any locking mechanism is essential to prevent accidents and ensure proper functionality. By following recommended guidelines, users can minimize risks associated with the installation process.

Preparation Before Installation

- Wear protective gloves to avoid injuries from sharp edges.

- Use safety goggles to protect your eyes from debris.

- Ensure the workspace is well-lit to clearly see all components.

- Keep children and pets away from the installation area.

Installation Steps

- Read all instructions thoroughly before starting.

- Gather all necessary tools to avoid interruptions.

- Check the condition of components to ensure they are not damaged.

- Use the correct hardware to secure all fixtures properly.

Frequently Asked Questions

This section aims to address common inquiries related to the components and functionality of locking mechanisms. Whether you’re seeking guidance on installation, troubleshooting, or maintenance, you’ll find valuable insights here.

| Question | Answer |

|---|---|

| What should I do if the locking mechanism is not functioning? | Check for any obstructions or misalignments in the assembly. Lubricating the moving parts may also help resolve the issue. |

| How can I replace a faulty component? | Identify the specific part that needs replacement, purchase a compatible component, and follow the provided instructions for installation. |

| Is regular maintenance necessary? | Yes, periodic maintenance ensures smooth operation and prolongs the lifespan of the mechanism. Regular cleaning and lubrication are recommended. |

| What tools are required for installation? | Typically, a screwdriver, a wrench, and an adjustable plier are sufficient for most installations. Always refer to the specific installation guide for details. |

Resources for Further Assistance

When dealing with installations and maintenance of locking mechanisms, it’s essential to have access to reliable resources. These can provide guidance, troubleshooting tips, and expert insights to enhance your understanding and resolve any issues effectively.

Online Guides and Tutorials

- Manufacturer websites often host comprehensive manuals and how-to articles.

- YouTube channels dedicated to home improvement frequently offer visual step-by-step instructions.

- Online forums allow users to share their experiences and solutions.

Customer Support Services

- Contact customer service for direct assistance with specific inquiries.

- Utilize chat options available on official sites for immediate help.

- Consult local locksmiths who can provide hands-on support and advice.