Comprehensive Guide to Manual Garage Door Parts Diagram

Every home features essential elements that ensure convenience and security, particularly regarding the access points. Comprehending how these systems function can greatly enhance your ability to maintain and troubleshoot them effectively. Knowledge of individual components empowers homeowners to address issues proactively and efficiently.

Within this section, we delve into the intricate assembly of your entryway mechanism, highlighting the various elements that contribute to its operation. Each component plays a crucial role, and understanding their interactions can provide insights into improving performance and longevity.

By familiarizing yourself with the specific features and functions of these crucial items, you will be better equipped to undertake repairs or adjustments. This guide aims to clarify each element’s purpose and position within the overall framework, fostering a deeper appreciation for this essential household fixture.

Understanding Garage Door Components

Every mechanical system is composed of various elements that work together to achieve seamless functionality. In the realm of home access systems, recognizing these elements is essential for effective maintenance and troubleshooting. Each component plays a critical role in ensuring that the overall mechanism operates smoothly and reliably.

The frame serves as the foundational structure, providing support and stability. Complementing this are the cables, which facilitate movement by connecting different parts and transferring force. Additionally, rollers are pivotal, allowing for effortless sliding along the tracks.

Another key component is the opener, which automates the process, enabling convenience and efficiency. This is often accompanied by springs that assist in balancing the weight, reducing strain during operation. Finally, the track system guides movement, ensuring alignment and precision during the opening and closing phases.

Understanding these crucial elements not only enhances awareness but also empowers homeowners to make informed decisions regarding maintenance and repairs.

Essential Parts of Manual Doors

Understanding the key components of a typical entryway system is crucial for proper maintenance and functionality. Each element plays a vital role in ensuring smooth operation and security. Below are the fundamental elements that make up these systems.

- Frame: The sturdy structure that supports the entire assembly and provides stability.

- Panels: These are the individual sections that create the visible surface and can vary in design and material.

- Hinges: Critical for movement, these allow the sections to swing or slide open and closed with ease.

- Handles: Essential for operation, providing a secure grip for users when opening or closing.

- Locks: Vital for security, these mechanisms ensure that the entryway can be securely fastened when not in use.

By familiarizing yourself with these key elements, you can better appreciate how each contributes to the overall functionality and security of your entryway system.

How Garage Doors Operate Mechanically

The functioning of these structures relies on a combination of various components working in unison. Understanding the mechanical principles behind their operation provides insight into the intricacies of how they open and close effectively while ensuring safety and efficiency.

Basic Mechanisms Involved

The primary mechanism involves a system of springs, tracks, and rollers. Springs store energy, allowing the structure to be lifted with minimal effort. The tracks guide the movement, while rollers facilitate smooth transitions between positions.

Energy and Movement

When activated, the springs release energy, enabling the structure to ascend or descend along the tracks. This coordinated movement is crucial for the overall functionality and longevity of the system. Regular maintenance of these components is essential to prevent wear and ensure smooth operation.

| Component | Function |

|---|---|

| Springs | Store and release energy |

| Tracks | Guide movement |

| Rollers | Facilitate smooth transitions |

| Opener | Controls operation |

Common Types of Manual Garage Doors

When it comes to residential access systems, various styles cater to different preferences and functional needs. Each variant offers unique features that enhance usability and aesthetic appeal, making the selection process an important consideration for homeowners.

Sectional Systems

Sectional designs consist of multiple horizontal panels that articulate as they move. These options are particularly favored for their space efficiency and ability to fit into a variety of architectural styles. Durability and insulation properties also contribute to their popularity, making them a wise choice for many households.

Roll-Up Models

Roll-up configurations operate by winding around a drum, allowing them to retract neatly into a compact space. This functionality is ideal for areas with limited clearance, providing a practical solution without compromising on security. Their robust construction often includes heavy-duty materials, ensuring long-lasting performance and reliability.

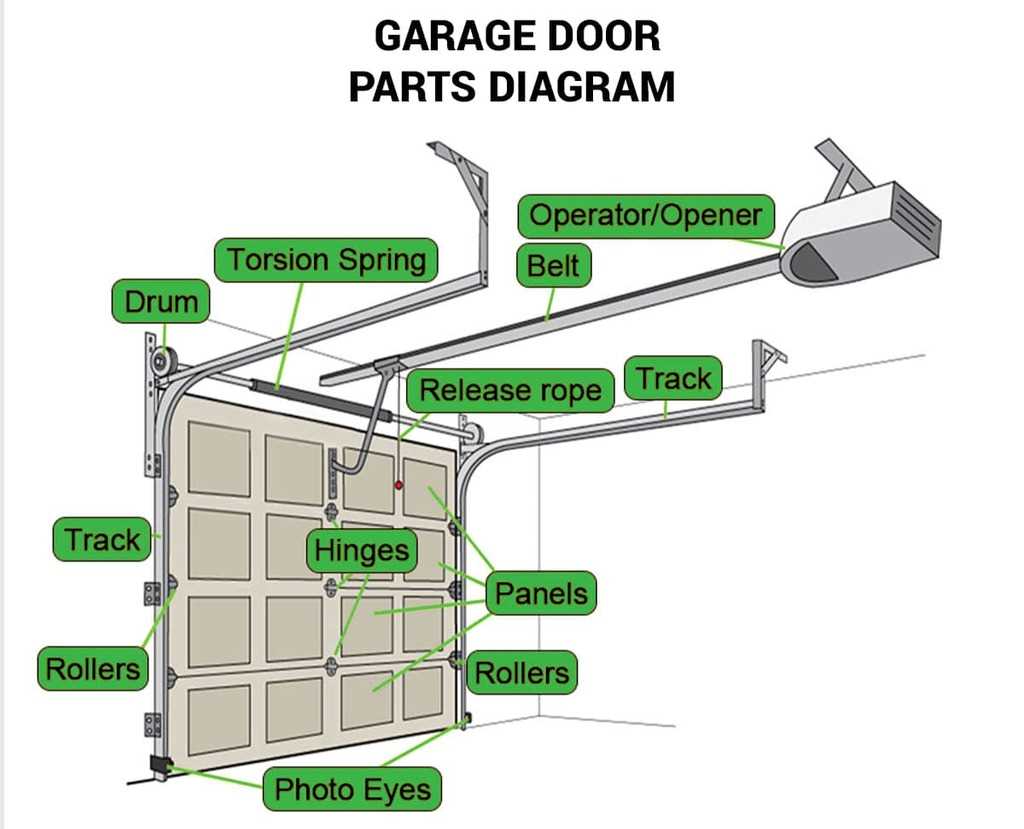

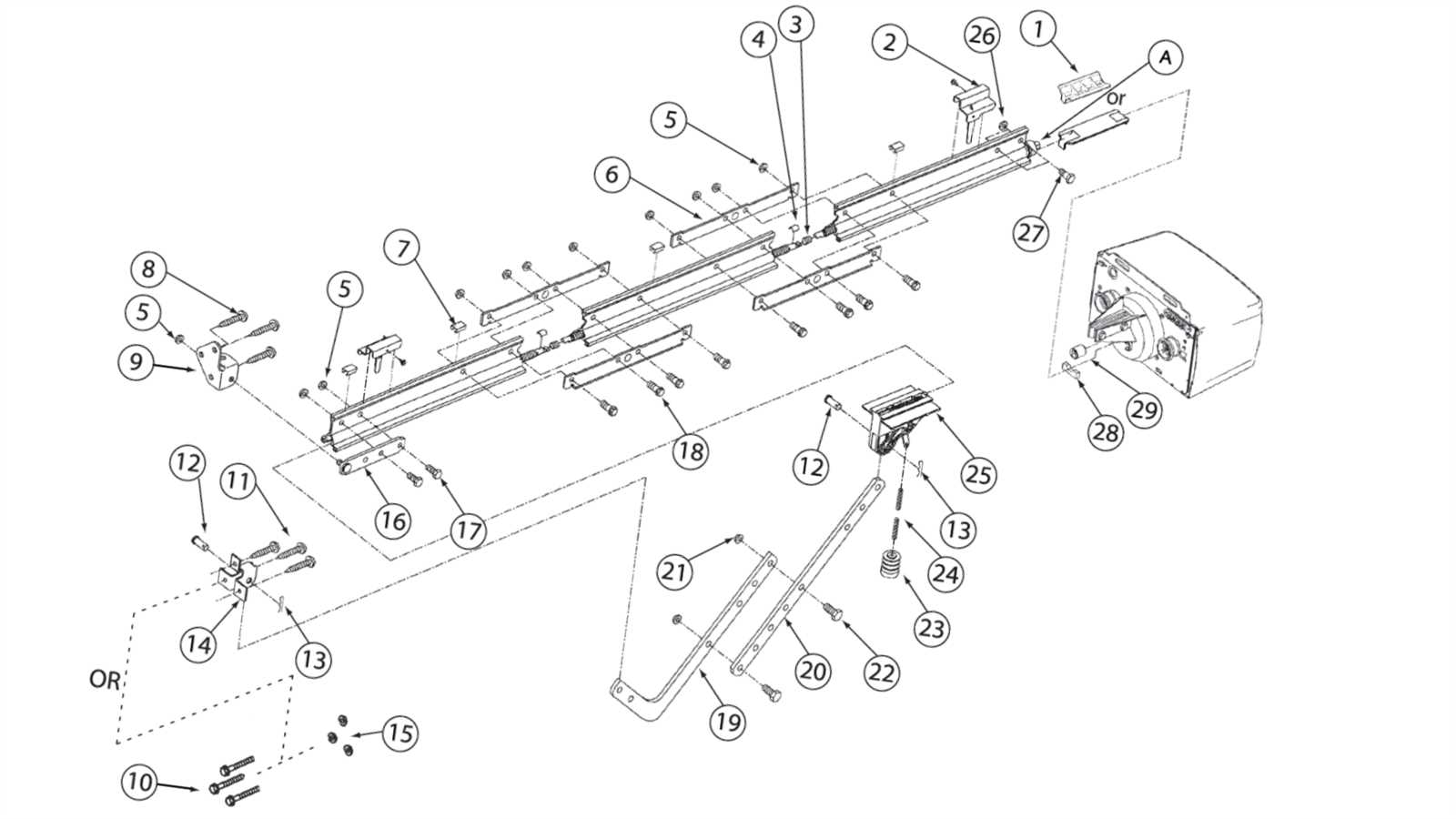

Detailed Diagram of Garage Door Parts

Understanding the intricate components that facilitate the operation of a closure system is essential for maintenance and repair. Each element plays a crucial role in ensuring functionality, safety, and efficiency. This section provides a comprehensive overview of these essential components, illustrating their interconnections and significance in the overall mechanism.

Track: The metal pathway that guides the movement of the panel as it opens and closes, ensuring smooth operation.

Spring: A vital element responsible for counterbalancing the weight, making it easier to lift or lower the structure.

Hinge: Connecting the segments of the panel, these fittings allow for flexibility and smooth transitions during movement.

Roller: Positioned within the track, these wheels facilitate the smooth gliding of the structure, reducing friction and wear.

Operator: The mechanism that provides the power needed to open and close the closure system, often controlled remotely for convenience.

Safety Sensor: An essential feature designed to prevent accidents by detecting obstacles in the path of the moving section.

Brackets: These support elements anchor the mechanism securely, ensuring stability and alignment during operation.

By familiarizing yourself with these components, you can better appreciate the complexity and design that contribute to the effective functioning of this vital access feature.

Identifying Parts for Maintenance

Understanding the various components of your system is crucial for effective upkeep. Recognizing these elements enables you to diagnose issues, perform regular checks, and ensure optimal functionality. Familiarity with the individual pieces can save time and prevent costly repairs in the long run.

Key Components to Examine

Start by familiarizing yourself with the essential elements that make up your setup. Look for springs, which provide the necessary tension and balance, and rollers, crucial for smooth movement. Additionally, check tracks for alignment and wear, as these play a significant role in overall performance.

Regular Inspection Practices

Schedule periodic assessments to catch potential problems early. Inspect cables for fraying, as well as hinges and locks for proper operation. Addressing small issues promptly can enhance longevity and reliability, ensuring that your system remains in peak condition.

Tools Required for Repairs

Understanding the essential instruments needed for fixing and maintaining your system is crucial for achieving effective results. Having the right tools on hand not only simplifies the repair process but also enhances safety and efficiency. Below, we outline the key equipment that can assist in various types of repairs.

Essential Tools

The following table lists the fundamental tools typically required for repair tasks, along with their primary functions:

| Tool | Purpose |

|---|---|

| Screwdriver Set | For loosening and tightening screws in components. |

| Wrench | Used for gripping and turning nuts and bolts. |

| Pliers | Ideal for gripping, twisting, and cutting wires. |

| Level | Ensures components are aligned properly. |

| Measuring Tape | For accurate measurement of parts and clearances. |

Additional Equipment

In addition to the basic tools, certain specialized equipment may be beneficial for more complex tasks:

| Tool | Purpose |

|---|---|

| Drill | Used for creating holes in various materials. |

| Safety Goggles | Protects eyes from debris during repairs. |

| Lubricant | Reduces friction in moving parts, enhancing functionality. |

| Gloves | Provides hand protection while working. |

Common Issues with Manual Doors

When dealing with traditional access points, several challenges can arise that may hinder their functionality and ease of use. Understanding these common problems can help in maintaining optimal performance and ensuring smooth operation.

Wear and Tear

Over time, components may experience degradation due to frequent usage and exposure to various environmental factors. This can lead to difficulties in opening or closing, requiring timely maintenance or replacement of affected elements.

Alignment Problems

Improper alignment is a frequent issue that can cause jamming or uneven movement. Factors such as settling of structures or wear on support mechanisms can contribute to misalignment, necessitating adjustments for proper operation.

Step-by-Step Repair Guide

This section provides a comprehensive approach to addressing common issues encountered with various mechanisms. By following the outlined steps, you can effectively troubleshoot and resolve malfunctions, ensuring optimal functionality and longevity of your system.

Begin by identifying the specific problem you are experiencing. Common symptoms may include unusual noises, difficulty in operation, or signs of wear. Take note of these issues, as they will guide your repair process.

Next, gather the necessary tools and replacement components. Standard tools may include wrenches, screwdrivers, and pliers. Having everything ready will streamline the repair and minimize downtime.

After preparing your workspace, carefully disassemble the affected mechanism. Follow a logical order, taking photos if needed, to ensure you can reassemble everything correctly later. Pay close attention to how components fit together.

Once disassembled, inspect each part for damage or wear. Replace any defective components as required. Ensure that new pieces match the specifications of the originals to maintain compatibility.

Reassemble the mechanism meticulously, reversing the disassembly steps. Make sure all connections are secure and components are aligned properly. This is crucial for ensuring smooth operation once everything is back in place.

Finally, test the functionality of the system. Operate it several times to ensure it works seamlessly and check for any lingering issues. If everything functions as expected, you have successfully completed the repair!

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is crucial to prevent accidents and injuries. When engaging in repair activities, it is essential to adopt certain practices that protect both the individual and the surrounding environment. Awareness of potential hazards and proper preparation can significantly reduce risks associated with the process.

First and foremost, always wear appropriate personal protective equipment (PPE). This includes gloves, safety glasses, and sturdy footwear. These items act as a barrier against sharp edges, heavy components, and other potential dangers that may arise during repairs.

Moreover, before starting any work, ensure that the area is clear of obstacles and hazards. A tidy workspace minimizes the chance of tripping or falling, allowing for a more focused and efficient repair process.

Additionally, it is vital to disconnect any power sources to prevent accidental activation of machinery. Always verify that tools are in good working condition and suitable for the task at hand. Using faulty or inappropriate equipment can lead to unexpected failures and injuries.

Finally, consider enlisting the help of a second person whenever possible. Having an extra set of hands can be invaluable in maintaining safety and providing assistance in case of an emergency. Always keep a phone nearby to call for help if needed.

Upgrading Your Garage Door System

Enhancing your entryway system can significantly improve both functionality and aesthetics. Whether you’re aiming for increased efficiency, added security, or simply a modern look, various upgrades are available to elevate your setup. A thoughtful approach can lead to substantial benefits in convenience and performance.

Choosing the Right Components

Selecting high-quality elements is crucial for a successful enhancement. Consider options like smart technology for remote access, robust materials for longevity, and advanced safety features. Investing in reliable accessories ensures not only a seamless operation but also peace of mind.

Installation and Maintenance Tips

Proper installation and regular upkeep are key to maximizing your investment. Engage a professional if needed, and ensure to follow maintenance guidelines for the best results. Routine checks can prevent issues and prolong the lifespan of your upgraded system, keeping everything running smoothly.

Choosing Quality Replacement Parts

When it comes to maintaining your property’s access system, selecting high-quality components is essential for ensuring longevity and reliability. The right items not only enhance performance but also provide peace of mind, knowing that your investment is protected.

Researching manufacturers is a crucial first step. Look for brands with a solid reputation and positive customer reviews. Reliable manufacturers often offer warranties, which can be a good indicator of their commitment to quality.

It’s also important to consider material durability. Opt for components made from robust materials that can withstand wear and tear. For example, galvanized steel or high-grade polymers often provide superior resistance to corrosion and environmental damage.

Compatibility with your existing system is another factor to keep in mind. Even the best components won’t perform well if they aren’t suited to your setup. Always double-check specifications and measurements to avoid future issues.

Finally, don’t overlook price versus value. While it may be tempting to choose the cheapest option, remember that investing in quality can save you money in the long run through reduced maintenance and replacement costs.

Benefits of Regular Maintenance Checks

Conducting routine inspections and upkeep of mechanical systems is crucial for ensuring their longevity and optimal performance. Regular maintenance not only enhances functionality but also helps in identifying potential issues before they escalate into significant problems.

Enhanced Safety

Regular examinations contribute significantly to safety. By detecting wear and tear early, users can prevent accidents that may arise from equipment failure. Ensuring that all components function properly creates a secure environment for everyone involved.

Cost Efficiency

Investing time in consistent upkeep can lead to substantial savings over time. Addressing minor repairs during inspections is often less costly than dealing with extensive damage caused by neglect. Moreover, maintaining efficiency can reduce energy consumption, further lowering expenses.

| Benefit | Description |

|---|---|

| Increased Lifespan | Regular checks help extend the life of the system by preventing premature wear. |

| Improved Performance | Routine maintenance ensures that everything operates at peak efficiency. |

| Reduced Repair Costs | Identifying issues early can save money on major repairs down the line. |

| Enhanced Reliability | Regular upkeep builds trust in the system’s performance and reliability. |