Understanding the various elements that make up an entryway fixture is crucial for ensuring its functionality and longevity. Each component plays a significant role in the overall operation, contributing to both the security and usability of the entryway. A well-structured assembly can enhance convenience and provide protection against the elements.

In this section, we will explore the essential elements involved in the assembly, detailing their individual functions and interconnections. By familiarizing yourself with these components, you can make informed decisions regarding maintenance and repairs. This knowledge is invaluable for both homeowners and professionals looking to optimize the performance of these essential installations.

Focusing on each segment’s unique characteristics allows for a deeper appreciation of how they work together. Whether you’re planning to upgrade your existing setup or troubleshoot a specific issue, having a comprehensive understanding of these elements will empower you to achieve the best results.

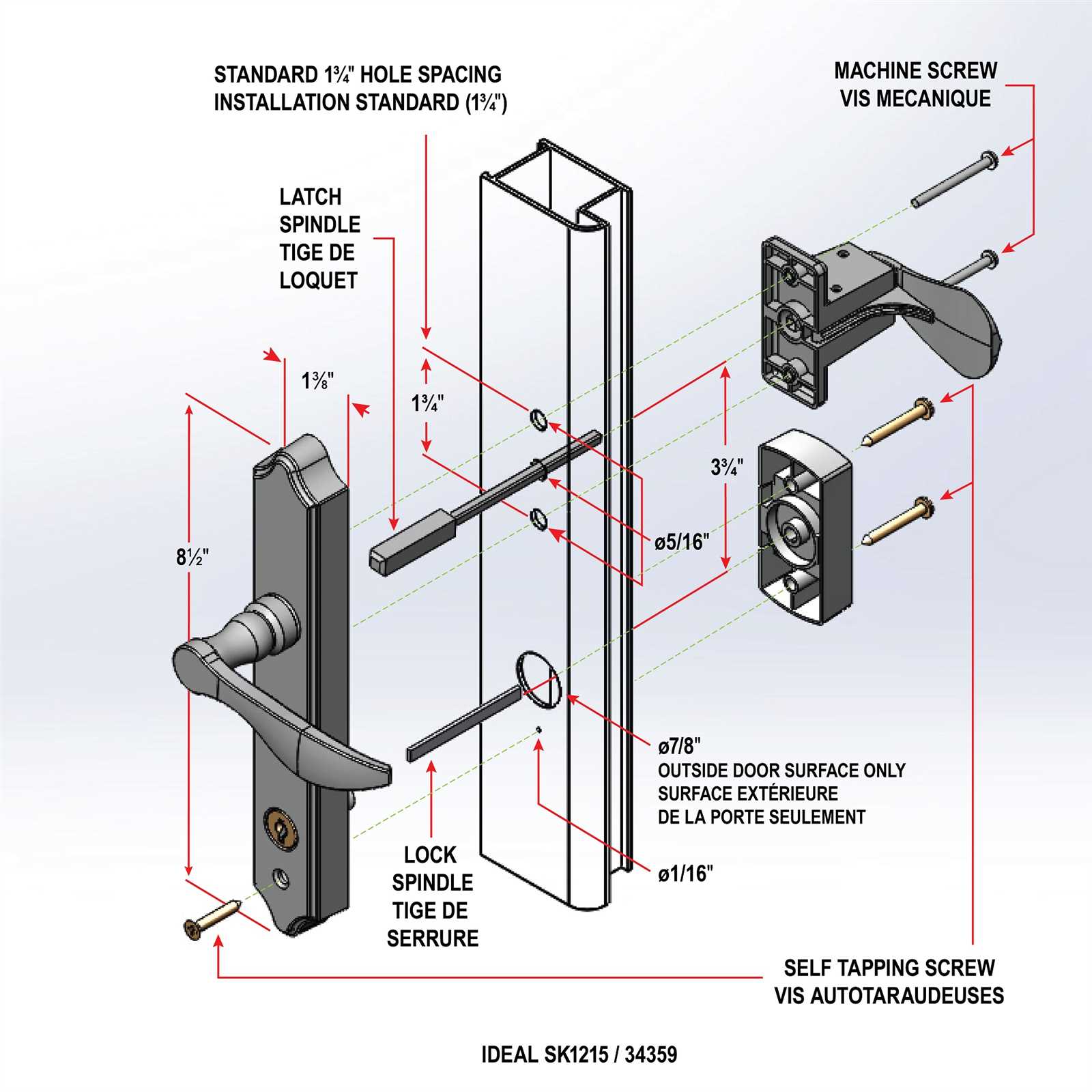

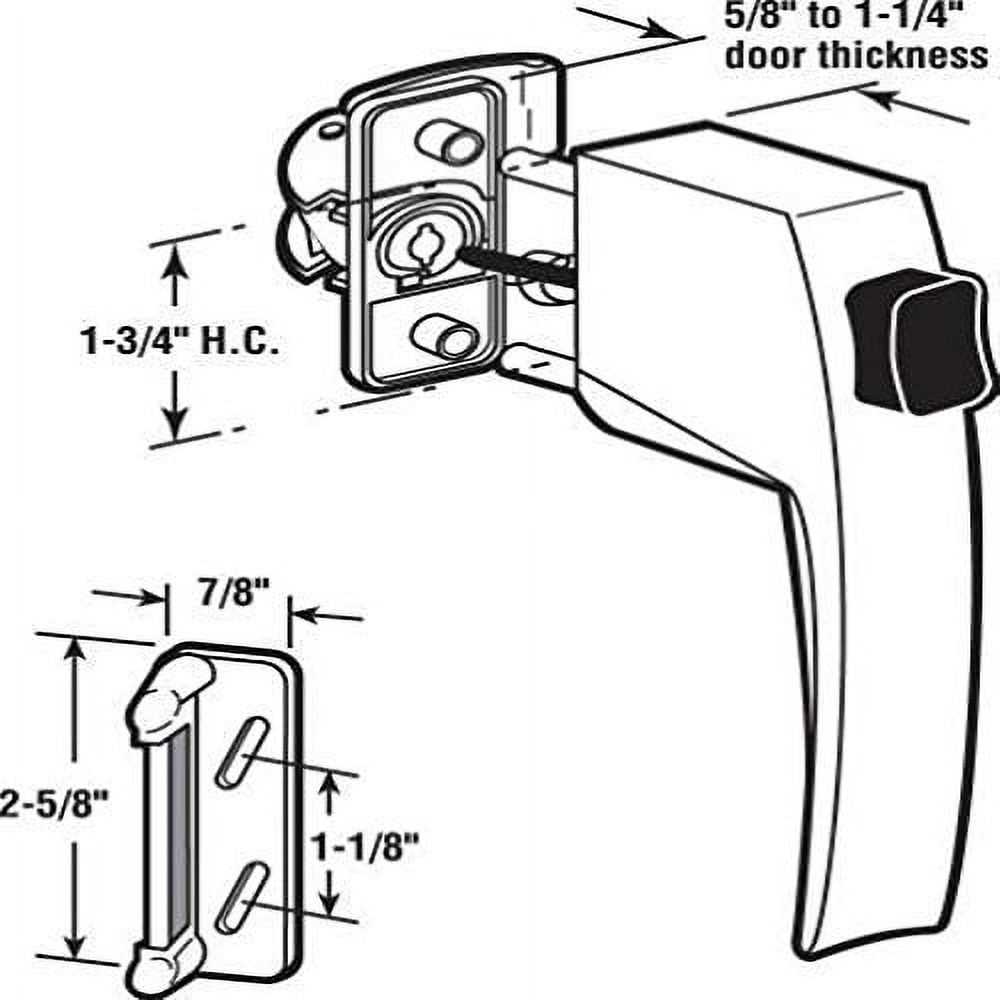

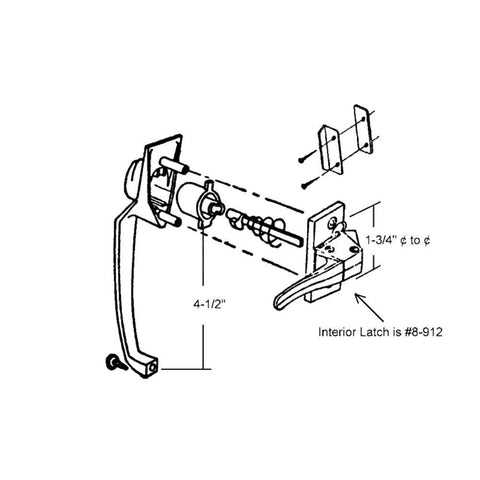

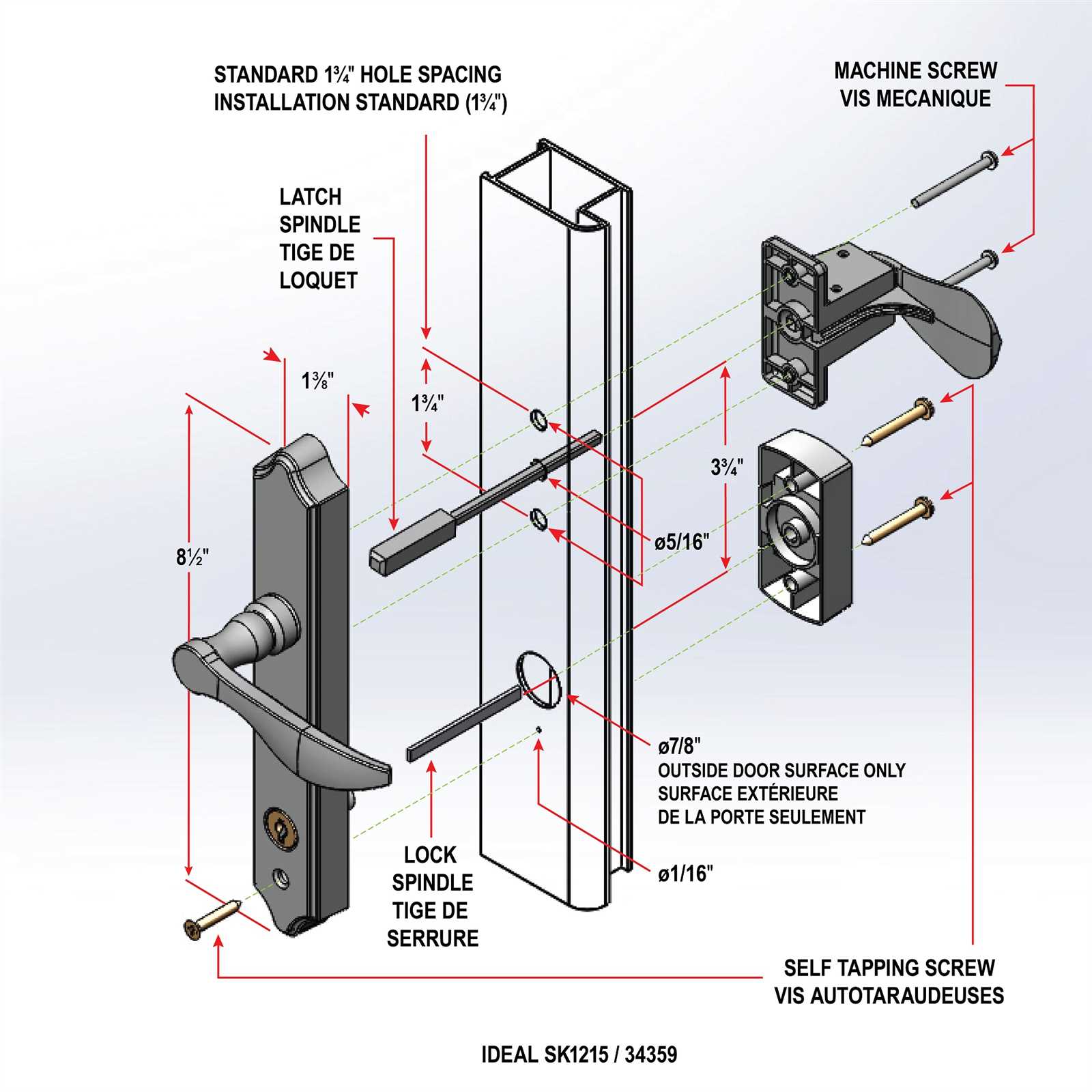

Key Components of a Storm Door Handle

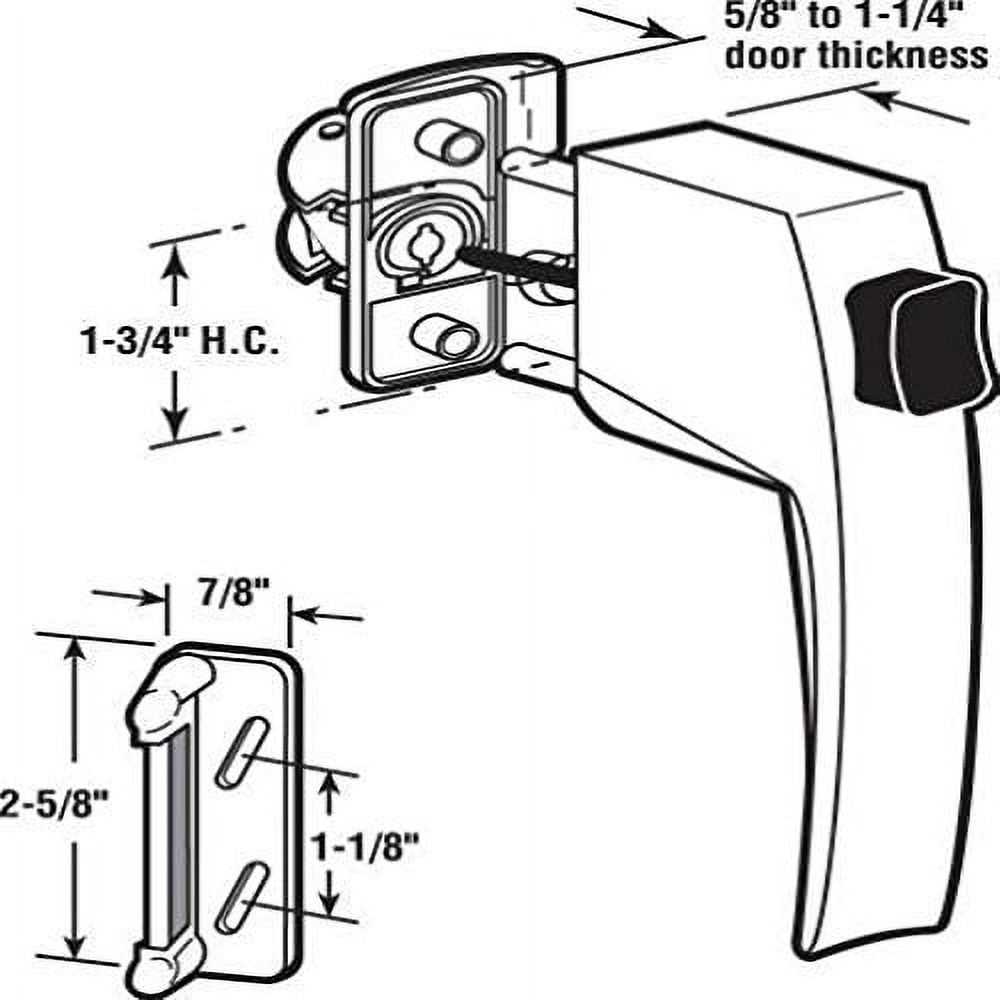

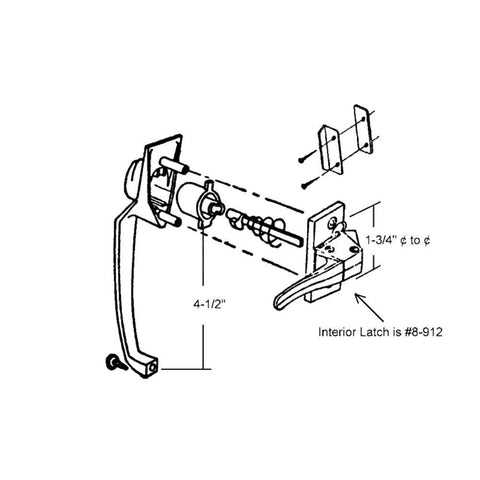

The mechanism of the entrance latch consists of several interconnected elements that ensure smooth operation and security. Each part contributes to the overall functionality, allowing for seamless locking, opening, and closing motions. Understanding these elements is essential for maintaining and replacing them when needed.

Main Assembly

The core section of the entry latch mechanism includes the central unit responsible for controlling the lock and release actions. This area typically contains springs and pins, which allow for smooth transitions between locking and unlocking functions.

Supportive Elements

Additional elements, such as levers and fasteners, play a crucial role in keeping the mechanism aligned and operational. These supportive parts ensure that the latch remains securely attached and functions properly over time.

| Component |

Function |

| Latch Plate |

Secures the mechanism to the frame, allowing it to engage or disengage the lock. |

| Lever Arm |

Transfers motion to engage or release the locking mechanism. |

| Mounting Screws |

How the Handle Mechanism Operates

The operating mechanism is a simple yet effective system that allows for smooth movement and reliable functionality. It relies on a combination of internal components that work together to engage and disengage, ensuring proper control during use. Understanding this system can provide insight into the overall performance and durability of the entire setup.

Internal Components Working in Unison

The mechanism consists of various internal elements, including springs, levers, and connectors, that coordinate to allow for fluid movement. When pressure is applied, these elements shift in a specific sequence, allowing for seamless transitions between locked and unlocked positions. Proper alignment and maintenance of these elements are crucial for optimal performance.

Importance of Regular Maintenance

Over time, the internal parts may experience wear due to continuous use. Regular inspections and adjustments are recommended to ensure the system remains in good working order. Lubricating the moving elements can also extend the longevity of the entire setup, ensuring smooth operation and preventing unnecessary strain on the mechanism.

Types of Latching Systems for Storm Doors

Latching mechanisms come in various styles, offering different levels of security and ease of use. These systems ensure that panels are properly secured, preventing unwanted access and maintaining the structure’s integrity. The choice of a latching solution often depends on the material, design preferences, and specific functional needs.

Manual Latches

Manual latching systems require the user to physically engage or disengage the lock. They are often simple in design and highly reliable, making them a popular option for those who prefer direct control over securing the entryway.

Automatic Latches

Automatic latches operate without direct user input once the panel is closed. These systems typically engage by themselves, providing added convenience for frequent use and ensuring consistent closure without additional effort.

Materials Commonly Used in Handle Parts

Various materials are utilized in manufacturing components, each selected for its specific properties. These materials are chosen to provide durability, strength, and aesthetic appeal, depending on the functional requirements and design preferences.

Metals

- Stainless Steel: Known for its corrosion resistance and strength, this material is commonly used in environments where exposure to moisture is frequent.

- Aluminum: Lightweight and resistant to rust, aluminum is often selected for its ease of handling and affordability.

- Brass: Valued for its attractive appearance and resistance to tarnishing, brass is frequently chosen for decorative purposes.

Non-Metallic Materials

- Plastic: Popular for its versatility, plastic is lightweight, cost-effective, and can be molded into various shapes.

- Wood: Often selected for its natural aesthetic, wood provides a unique texture and warmth, though

Replacing the Lock Cylinder

The process of changing a lock cylinder can be done with basic tools, ensuring improved security and functionality. It involves carefully removing the current mechanism and installing a new one without damaging the surrounding elements.

Begin by unscrewing the outer faceplate to access the internal components. This may require a standard screwdriver or a specific tool depending on the model. After removing the plate, you can reach the cylinder and loosen it from its position.

Once the cylinder is exposed, gently slide it out while making sure to keep the surrounding parts intact. When installing the new piece, ensure it fits securely before reattaching the faceplate and tightening all screws.

Steps to Fix a Broken Lever

If the lever mechanism becomes faulty, it is crucial to address the issue promptly to restore functionality. Following these steps can help you repair the lever with minimal tools and ensure it operates smoothly again.

- Identify the problem: Start by assessing the lever’s movement. Check if it’s loose, stuck, or not responding properly. This will help you determine the exact issue before proceeding.

- Disassemble the lever: Carefully remove the screws or fasteners holding the lever in place. Keep track of all the components as you dismantle the mechanism.

- Inspect for damage: Look for any worn-out or broken parts within the mechanism. Pay special attention to springs, pins, or latches that may need replacement.

- Replace faulty components: If any internal elements are damaged, replace them with new ones. Ensure the replacements are compatible with the original design.

- Reassemble the mechanism: Once the necessary repairs are made, carefully put the lever back together, ensuring all parts ar

Compatibility of Storm Door Handles with Locks

Understanding how various types of locking mechanisms integrate with external fixtures is crucial for ensuring security and ease of use. The correct alignment of these components guarantees both functionality and durability.

Key Factors in Matching Locking Systems

When selecting a locking system, it is important to consider several factors such as the type of locking mechanism, its dimensions, and the materials used. Compatibility between the fixture and the lock ensures that they work smoothly together.

- Type of locking mechanism (deadbolt, latch, etc.)

- Material of the external fixture and lock

- Size and installation method

Common Issues with Incompatible Combinations

Using mismatched components can lead to difficulties such as improper alignment or weakened security. Ensuring compatibility during installation helps avoid these common problems.

- Misalignment affecting the locking system’s performance

- Increased wear and tear due to poor fit

- Compromised security if components do not match

Handle Styles and Their Applications

Choosing the right type of grip can enhance both functionality and aesthetics in various setups. Different designs serve unique purposes, offering tailored solutions depending on the environment and user needs. Understanding the available options helps in selecting the most efficient and stylish choice for any scenario.

- Classic Lever Grips: Known for their simplicity and ease of use, these are perfect for settings where accessibility and quick action are crucial.

- Modern Pull Grips: Featuring sleek lines and minimalist designs, these grips suit contemporary environments, providing a clean look without sacrificing practicality.

- Rotary Grips: Often utilized in specialized applications, rotary grips combine precision with versatility, allowing for a smooth operation in tighter spaces.

Each style offers distinct benefits, making them suitable for different functional and decorative needs. Care

Signs of Wear on Handle Parts

Over time, frequent use and environmental factors can lead to noticeable deterioration in various components of a mechanism. Understanding the early indications of wear helps prevent more serious malfunctions and ensures longevity.

Visible Scratches and Discoloration

One of the first signs of aging is the appearance of fine scratches on the surface. In addition, color changes, such as fading or darkening, may occur due to exposure to sunlight or moisture.

Loosening or Unstable Movement

When mechanisms begin to feel loose or shift unexpectedly, it can indicate internal damage. This may stem from worn-out fasteners or internal components losing their integrity.

| Wear Sign |

Potential Cause |

| Scratches |

Frequent friction or improper cleaning |

| Discoloration |

Sunlight or humidity

Differences Between Standard and Heavy-Duty Handles

The choice between standard and heavy-duty models is crucial for ensuring long-lasting performance and durability. Each type offers unique characteristics that cater to different needs and situations. Understanding these distinctions will help you make an informed decision based on your requirements.

Material and Build Quality

- Standard models are typically made from lightweight materials, which makes them suitable for less demanding conditions.

- Heavy-duty options are built with reinforced components, offering greater resistance to wear and tear over time.

Performance and Usage

Another significant difference lies in the functionality. Heavy-duty variants are engineered for frequent use and tougher environments, while standard versions are better suited for regular but less intensive conditions.

- Heavy-duty models provide enhanced stability and endurance.

- Standard designs focus more on ease of use and simplicity.

How to Adjust Handle Tightness

Ensuring the proper grip of your entry mechanism is essential for smooth functionality and longevity. Over time, adjustments may be necessary to maintain an ideal fit and ease of use.

To begin, locate the securing mechanism, typically found beneath or adjacent to the lever. Using the appropriate tool, gently loosen the screws or fasteners that hold the assembly in place. Be cautious not to over loosen, as this may cause misalignment.

Next, carefully rotate or slide the lever to achieve the desired tightness. Once satisfied with the adjustment, re-tighten the screws securely while ensuring the assembly remains aligned. Finally, test the mechanism to confirm it operates smoothly without excessive resistance or looseness.

Common Issues with Handle Springs

Springs used in locking mechanisms often face a range of challenges that can impact their functionality. Understanding these common problems can help in maintaining the efficiency of the mechanism and ensuring proper operation.

Wear and Tear

Over time, the constant movement and pressure on springs can lead to fatigue and eventual failure. Frequent use may cause them to lose tension, affecting their ability to return to the original position. Regular inspection and timely replacement are crucial to prevent this issue.

Improper Installation

Another frequent issue arises from incorrect installation, which can lead to misalignment and uneven pressure on the springs. Ensure that the springs are installed according to the manufacturer’s guidelines to avoid complications that could hinder performance.

Tips for Installing New Handle Sets

When upgrading or replacing entryway fixtures, it’s essential to ensure a seamless installation process. Following these guidelines can help achieve a secure and functional fit, enhancing both aesthetics and usability.

Preparation Steps

- Gather all necessary tools, including a screwdriver, measuring tape, and a level.

- Read the manufacturer’s instructions thoroughly before starting the installation.

- Ensure the new fixtures are compatible with existing fittings.

Installation Process

- Remove the old fixture by unscrewing any fasteners holding it in place.

- Clean the area where the new components will be mounted to ensure a secure fit.

- Position the new set carefully, aligning it with pre-drilled holes if applicable.

- Secure the fixture using the provided screws, ensuring it is level and properly aligned.

- Test the functionality before completing the process to confirm a successful installation.

By following these tips, you can ensure a smooth upgrade, providing enhanced security and ease of use for years to come.

|