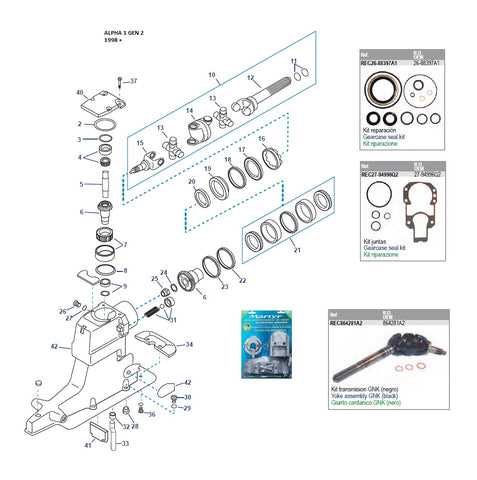

Alpha 1 Outdrive Parts Diagram Explained

The intricate world of marine propulsion systems plays a crucial role in enhancing the performance and efficiency of watercraft. A thorough comprehension of these mechanisms is essential for both enthusiasts and professionals alike. This section aims to provide a detailed overview of the essential elements that constitute these systems, focusing on their interconnections and functionalities.

Delving into the specifics, we explore various segments that contribute to the overall operation of marine drives. Understanding these elements not only facilitates better maintenance practices but also aids in troubleshooting potential issues that may arise during operation. By familiarizing oneself with the structural intricacies, one can ensure optimal performance and longevity of the equipment.

In this examination, we will highlight key features, common wear points, and best practices for care and maintenance. Each component plays a significant role in the drive’s efficiency, and knowing their functions will empower users to make informed decisions regarding repairs and upgrades. Through this exploration, we invite readers to enhance their knowledge and appreciation of these essential marine systems.

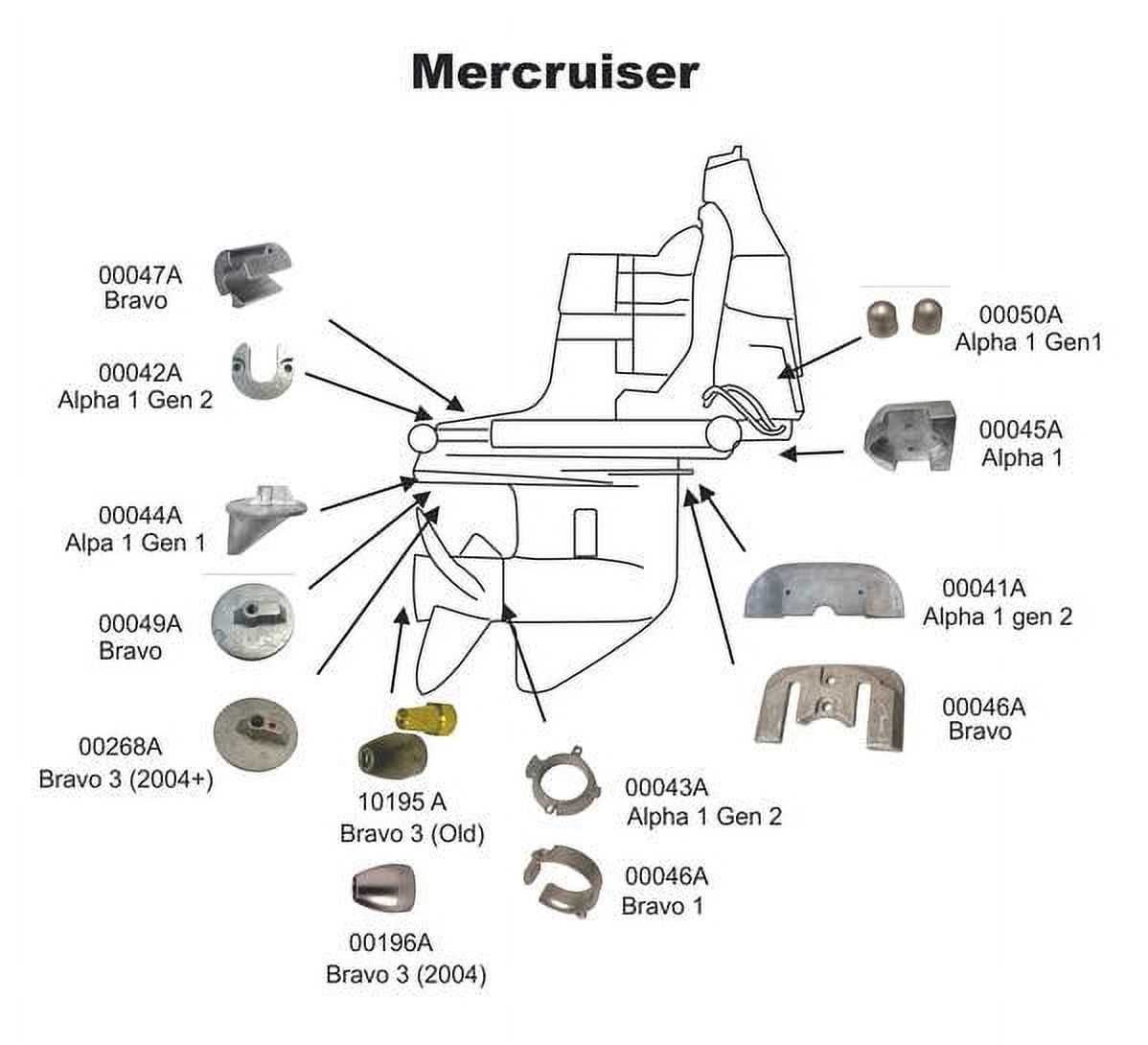

Overview of Alpha 1 Outdrive Components

This section provides a comprehensive look at the various elements that constitute a key marine propulsion system, ensuring effective performance and reliability on the water. Understanding these components is essential for proper maintenance and troubleshooting, allowing boat enthusiasts and technicians alike to optimize their vessel’s functionality.

Key Elements of the Marine Propulsion System

Each component plays a crucial role in the overall operation, contributing to the smooth transition of power from the engine to the water. Familiarity with these parts helps in identifying issues and implementing timely repairs.

Component Specifications

| Component | Description | Function |

|---|---|---|

| Gear Case | Houses the gears and other internal mechanisms. | Transmits power from the engine to the propeller. |

| Propeller | Rotating blade assembly. | Generates thrust to propel the vessel forward. |

| Trim Cylinder | Hydraulic cylinder that adjusts the angle of the drive. | Enhances performance and fuel efficiency by optimizing the water flow. |

| Drive Shaft | Connects the engine to the gear case. | Transfers rotational force from the engine to the gears. |

| Seal Kit | Collection of seals and gaskets. | Prevents leaks and protects internal components from water ingress. |

Main Gear Housing Functionality

The main gear housing plays a crucial role in the overall performance and efficiency of marine propulsion systems. This component serves as the central structure that houses various mechanical parts, ensuring smooth operation and effective power transmission from the engine to the propeller. Its design is engineered to withstand harsh marine conditions while providing the necessary support for the gear assembly.

One of the primary functions of the main gear housing is to protect internal components from water intrusion and debris. This protective feature is essential for maintaining the integrity of the gears and bearings, which are vital for reliable operation. Additionally, the housing is designed to facilitate the alignment and engagement of gears, minimizing wear and enhancing longevity.

Moreover, the main gear housing contributes to the efficient dissipation of heat generated during operation. Proper heat management is critical for preventing damage to internal components and ensuring optimal performance. By maintaining appropriate operating temperatures, the housing supports the overall reliability and functionality of the propulsion system.

Propeller Shaft and Its Role

The propeller shaft is a crucial component in the propulsion system of marine vessels, transmitting power from the engine to the propeller. This element plays a significant role in converting rotational energy into thrust, enabling the craft to move efficiently through the water. Understanding its function and structure is essential for maintaining optimal performance and ensuring the longevity of the propulsion system.

Functionality of the Propeller Shaft

At its core, the propeller shaft serves several key purposes:

- Power Transmission: It effectively transfers torque from the engine to the propeller.

- Alignment: Ensures proper alignment between the engine and the propeller, minimizing wear and tear.

- Vibration Reduction: Helps in dampening vibrations that may arise during operation, contributing to a smoother ride.

Components of the Propeller Shaft Assembly

The assembly typically includes various elements that work together to facilitate its operation:

- Universal Joints: Allow for flexibility and adaptability in movement.

- Couplings: Connect different segments of the shaft, ensuring a secure fit.

- Bearings: Support the shaft and reduce friction during rotation.

Understanding the roles of these components is vital for troubleshooting and ensuring efficient operation. Regular maintenance of the propeller shaft assembly can prevent potential issues and enhance overall performance.

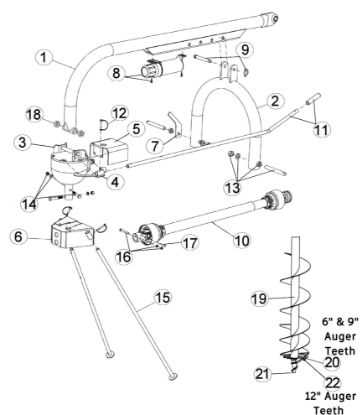

Water Pump Placement and Importance

The positioning of the water pump is crucial for the efficient operation of marine propulsion systems. Proper placement ensures optimal cooling and prevents overheating of engine components. Additionally, the strategic location allows for effective water circulation, which is vital for maintaining the system’s performance and longevity.

Significance of Proper Placement

The correct positioning of the pump minimizes the risk of air pockets forming within the cooling system. These pockets can disrupt the flow of water, leading to inadequate cooling. A well-placed pump facilitates smooth water intake, enhancing the overall efficiency of the engine.

Factors to Consider

When determining the optimal placement, several factors should be taken into account. The pump must be situated in a location that provides easy access for maintenance and inspection. Additionally, it should be positioned to prevent debris from obstructing the intake, ensuring uninterrupted water flow.

Conclusion

In summary, the placement of the water pump is a critical aspect of marine systems that directly impacts performance and reliability. Ensuring it is correctly positioned not only enhances cooling efficiency but also contributes to the overall durability of the propulsion system.

Pinion Gear Structure in Alpha 1

The pinion gear is a crucial component in the transmission system, playing a significant role in the overall functionality and efficiency of the drive mechanism. Understanding its structure helps in grasping how power is transferred and controlled within the system. The design of the pinion gear is essential for maintaining smooth operation and durability under various conditions.

This component typically consists of several key elements that contribute to its performance:

| Component | Description |

|---|---|

| Gear Teeth | These interlocking features ensure effective torque transmission and alignment with the mating gears. |

| Body | The main structure providing strength and stability, usually made from high-strength materials to withstand wear. |

| Hub | The central part where the pinion gear is mounted, allowing for precise rotation and connection to the drive shaft. |

| Coating | A protective layer that reduces friction and enhances durability, prolonging the component’s lifespan. |

Overall, the effective design and functionality of the pinion gear contribute significantly to the reliability and efficiency of the entire transmission system, ensuring optimal performance in various operating conditions.

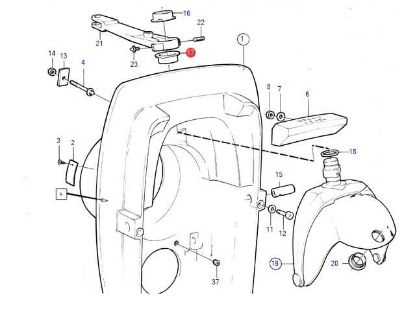

Gimbal Ring and Its Operation

The gimbal ring plays a crucial role in ensuring the smooth functioning of marine propulsion systems by allowing for controlled movement and stability. This component is designed to support various mechanisms while accommodating the dynamic motion experienced in aquatic environments.

Key functions of the gimbal ring include:

- Providing a pivot point that enables rotational movement.

- Allowing for the alignment of the propulsion unit with the boat’s orientation.

- Minimizing vibrations and enhancing stability during operation.

The operation of the gimbal ring involves several important aspects:

- Mounting: The gimbal ring is securely attached to the vessel’s transom, serving as the anchor point for the propulsion unit.

- Articulation: It permits the propulsion unit to tilt and rotate, enabling maneuverability in various water conditions.

- Load Distribution: The design of the gimbal ring helps to evenly distribute forces, reducing wear on connected components.

Regular maintenance and inspection of the gimbal ring are essential to ensure optimal performance and longevity. Proper lubrication and checking for wear can prevent potential failures, safeguarding both the vessel and its passengers.

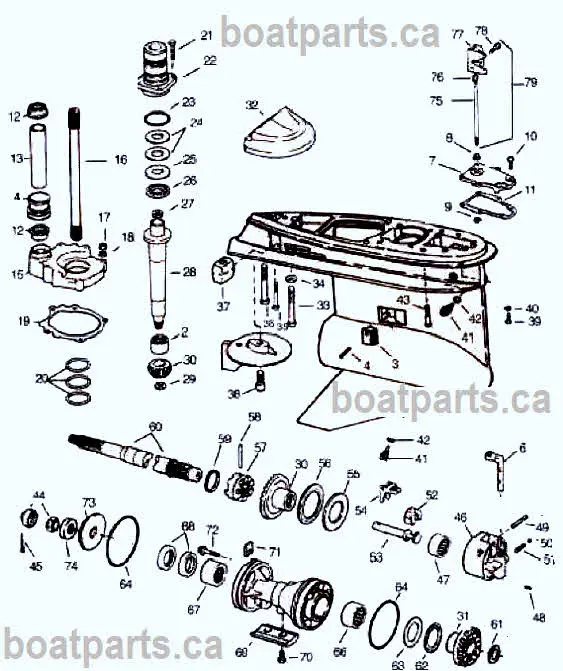

Driveshaft Components in Alpha 1 Outdrive

The assembly that transmits power from the engine to the propulsion unit consists of several crucial elements. Understanding the function and interaction of these components is essential for maintaining optimal performance and ensuring a smooth operation. Each part plays a specific role in facilitating the connection between the motor and the propeller, ultimately influencing the overall efficiency of the vessel.

Main Elements of the Driveshaft Assembly

The primary constituents of this assembly include the shaft itself, universal joints, and couplings. The driveshaft is a cylindrical component that transmits rotational energy, while the universal joints allow for flexibility in movement, accommodating the changes in angle during navigation. Couplings serve as connectors, linking the various sections of the system and ensuring a secure fit.

Maintenance and Importance

Regular inspection of these components is vital to prevent failures and ensure reliability. Wear and tear can lead to misalignment or failure of the assembly, which can result in significant performance issues. Understanding the role of each part not only aids in effective troubleshooting but also enhances the longevity of the entire propulsion system.

Upper Gear Assembly Breakdown

The upper gear assembly is a crucial component of the propulsion system, playing a vital role in transferring power from the engine to the propeller. Understanding its structure and functionality is essential for effective maintenance and troubleshooting.

Key Components

- Gear Housing: Encloses and protects the gears, providing structural integrity.

- Drive Gear: Engages with the engine’s output to initiate movement.

- Driven Gear: Connects to the propeller, translating rotational force for propulsion.

- Bearings: Reduce friction and support the rotating elements within the assembly.

- Seals: Prevent leakage of lubricants, ensuring optimal operation and longevity.

Assembly Overview

- Disassemble the gear housing carefully to access internal components.

- Inspect the drive and driven gears for wear and damage.

- Check bearings for smooth operation and replace if necessary.

- Ensure all seals are intact to prevent fluid leaks.

- Reassemble the unit in reverse order, ensuring all components are properly aligned.

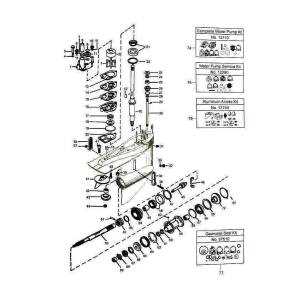

Lower Unit Elements and Their Purpose

The lower unit of a marine propulsion system plays a critical role in the overall functionality of the vessel. It houses various components that work in harmony to ensure optimal performance and reliability. Understanding these elements and their respective functions is essential for maintaining and troubleshooting the system effectively.

Key Components of the Lower Unit

- Gearcase: This component contains the gears that transfer power from the engine to the propeller, enabling efficient movement through water.

- Propeller Shaft: A vital element that connects the gearcase to the propeller, transmitting rotational force.

- Water Pump: Responsible for drawing water from the surrounding environment to cool the engine and lubricate internal components.

- Trim Tab: A small adjustable fin that helps stabilize the vessel by influencing its position in the water, improving handling and fuel efficiency.

- Oil Seal: This component prevents lubricants from leaking out of the gearcase, ensuring that the internal parts remain properly lubricated.

Functions of Each Element

- The gearcase is crucial for converting engine speed into the necessary thrust required for propulsion.

- The propeller shaft facilitates the transfer of rotational power, enabling the propeller to generate forward motion.

- The water pump maintains engine temperature and prevents overheating by circulating coolant.

- By adjusting the trim tab, operators can optimize the vessel’s performance in various water conditions.

- Oil seals are essential for maintaining the integrity of the lubricating system, contributing to the longevity of the entire assembly.

Seals and Bearings Overview

In the realm of marine propulsion systems, effective components play a crucial role in ensuring smooth operation and longevity. This section delves into the essential elements that contribute to the reliability and efficiency of these mechanisms, focusing on their significance, types, and maintenance practices.

Importance of Seals and Bearings

Seals and bearings are fundamental in reducing friction, preventing leaks, and safeguarding critical internal components. Their proper functioning ensures that power is transmitted efficiently while protecting against external contaminants that could compromise performance.

Types of Seals and Bearings

- Seals:

- Rotary seals

- Mechanical seals

- O-rings

- Bearings:

- Ball bearings

- Roller bearings

- Thrust bearings

Understanding the various types of seals and bearings is vital for ensuring optimal performance. Each type serves a unique purpose and is designed to withstand specific operational conditions.

Maintenance and Replacement

Regular inspection and timely replacement of these components are essential for maintaining system integrity. Signs of wear, such as leaks or increased friction, should prompt immediate attention to prevent further damage.

In conclusion, seals and bearings are integral to the functionality of marine propulsion systems. Their proper maintenance not only enhances performance but also extends the lifespan of the equipment.

Throttle Linkage and Control Mechanism

The throttle linkage and control system play a vital role in regulating the engine’s power output, enabling smooth acceleration and deceleration. This assembly consists of several components that interact seamlessly to translate driver inputs into precise adjustments in engine speed. By understanding how this mechanism functions, users can better appreciate the intricacies of their marine propulsion systems.

Components of the Throttle Linkage

At the heart of the control assembly is the throttle cable, which connects the accelerator pedal to the engine. As the driver presses the pedal, the cable pulls a lever on the engine, increasing the throttle opening. This simple yet effective design ensures that engine response is immediate and proportional to the driver’s commands.

Control Mechanism Functionality

The control system’s effectiveness relies on the proper functioning of various elements, including the throttle plate and its actuator. When the driver accelerates, the throttle plate pivots open, allowing air to flow into the engine. This action is complemented by an electronic control unit (ECU) that fine-tunes the fuel injection, optimizing performance and efficiency.

Regular maintenance of the throttle linkage and control system is essential for ensuring reliability and responsiveness. Proper lubrication of moving parts, inspection for wear, and adjustment of cable tension can prevent potential issues that may arise from a neglected system.