Alpha One Outdrive Parts Diagram and Overview

Understanding the intricacies of marine propulsion systems is essential for anyone involved in boating or marine maintenance. This section delves into the essential elements that contribute to the efficient operation of a particular type of drive mechanism. By examining each component’s role and function, readers can gain valuable insights into maintaining and troubleshooting their vessels.

Knowledge of each element is crucial for achieving optimal performance. A well-functioning propulsion system relies on various interconnected parts that must work harmoniously. Familiarity with these components allows boaters to recognize signs of wear and potential failures, leading to timely interventions and repairs.

In this guide, we will explore the key features of the assembly, outlining their interrelations and functionalities. Whether you are a seasoned marine technician or a novice boat owner, understanding these aspects will enhance your confidence in managing your vessel’s performance and longevity.

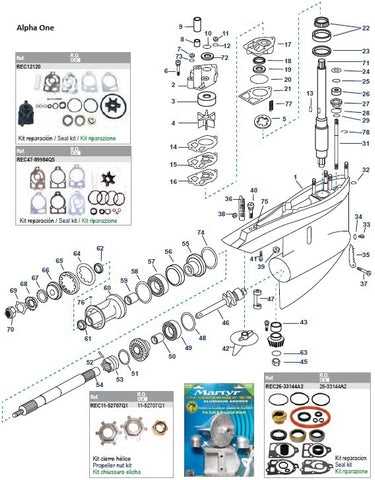

Understanding Alpha One Outdrive Components

Grasping the essential elements of a marine propulsion system is crucial for optimal performance and maintenance. This segment delves into the various components that comprise this assembly, each playing a pivotal role in ensuring smooth operation and longevity.

Transmission Housing: The outer shell protects internal mechanisms while housing the gear assembly. It serves as a sturdy foundation that withstands the harsh marine environment.

Drive Shaft: This component transfers power from the engine to the propeller. Its efficient functioning is vital for propulsion, directly impacting speed and maneuverability.

Propeller: Often regarded as the heart of the system, the propeller converts mechanical energy into thrust. The design and pitch of the blades are critical in determining the vessel’s speed and efficiency.

Trim Tab: This small yet significant element aids in stabilizing the vessel during operation. By adjusting the angle of the assembly, it helps maintain optimal performance in varying water conditions.

Seal and Bearing Assembly: These components ensure smooth rotation and reduce friction. Their integrity is crucial for preventing leaks and ensuring the longevity of the entire system.

Understanding these vital components is essential for anyone looking to maintain or repair a marine propulsion system effectively. Regular inspections and maintenance of these elements can significantly enhance performance and reliability.

Essential Parts of Alpha One Outdrive

Understanding the fundamental components of marine propulsion systems is crucial for efficient operation and maintenance. Each element plays a significant role in ensuring smooth performance and longevity, allowing vessels to navigate waters with ease. Familiarity with these key components can lead to better care and timely repairs, ultimately enhancing the overall boating experience.

Key Components and Their Functions

Among the critical elements are the gear housing, which protects and supports the internal mechanisms, and the drive shaft that transmits power from the engine to the propeller. The housing also houses essential gears that regulate speed and torque, providing the necessary force to propel the vessel forward. Additionally, the trim cylinder allows for the adjustment of the drive angle, enhancing maneuverability and efficiency.

Maintenance Considerations

Regular inspection and maintenance of these components are vital for preventing issues that may lead to costly repairs. Proper lubrication of moving parts minimizes wear and tear, while checking for any signs of corrosion can help maintain the integrity of the system. Staying informed about the functionalities of each component can aid in identifying potential problems early, ensuring reliable performance on the water.

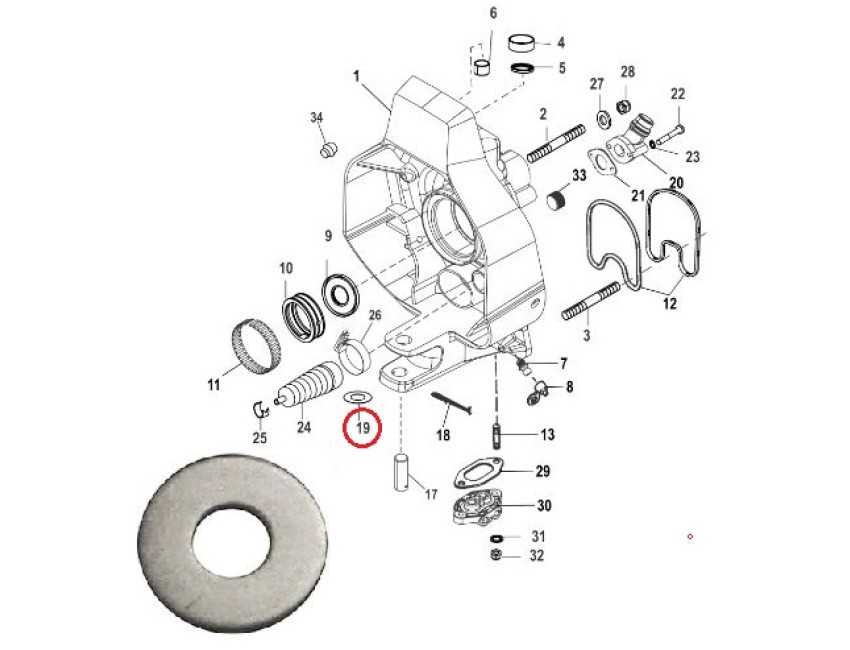

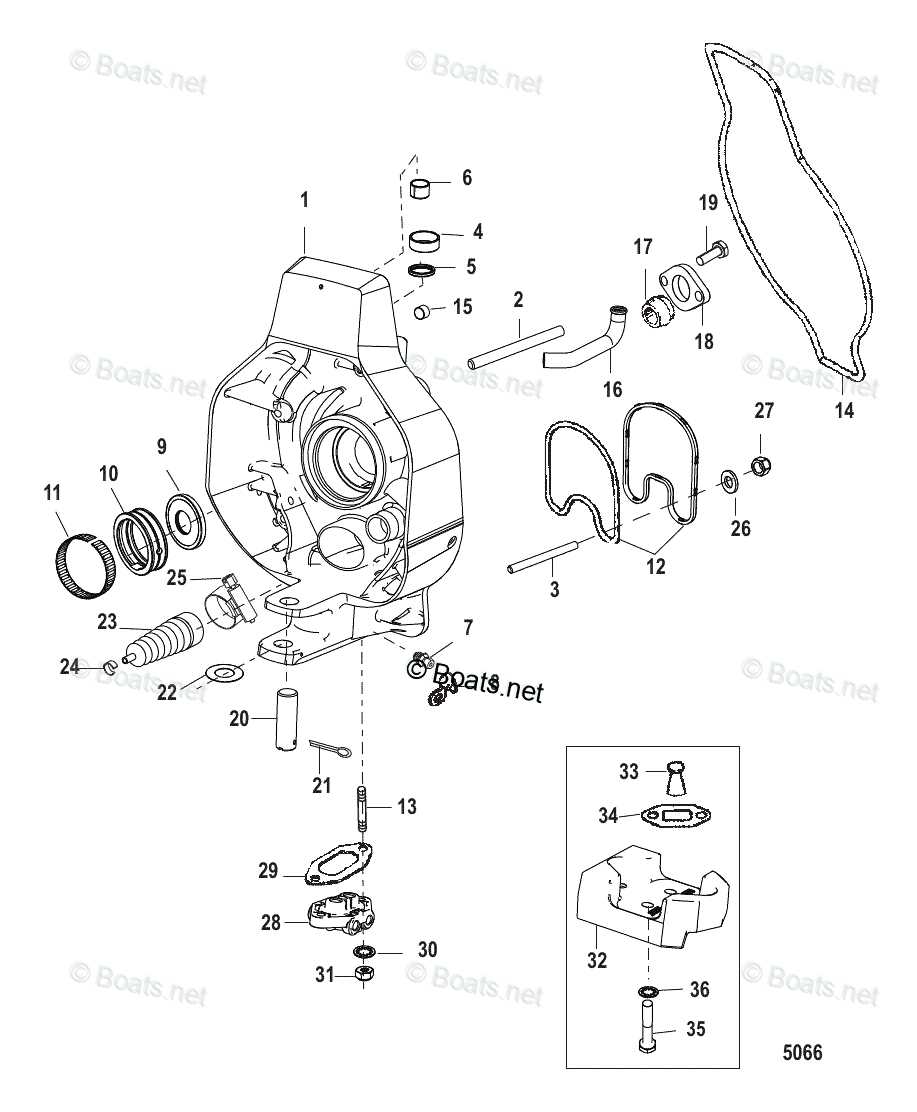

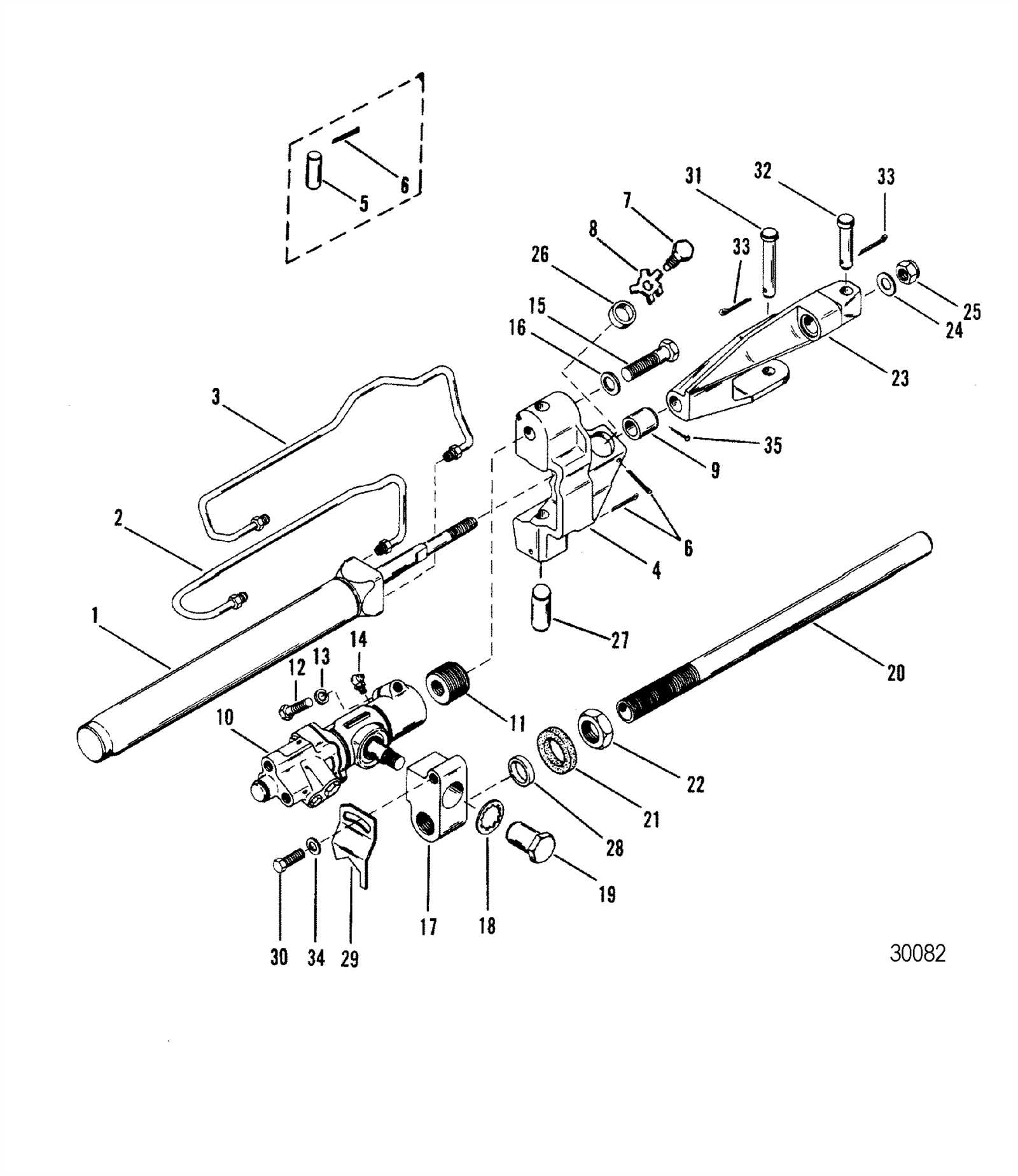

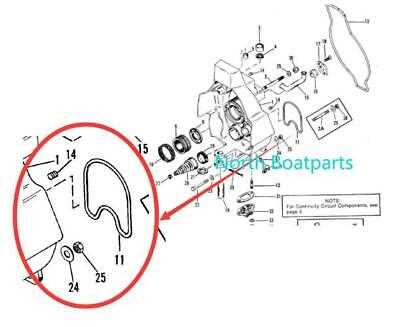

Visual Guide to Outdrive Assembly

This section provides a comprehensive overview of the components and their interconnections necessary for assembling the marine propulsion system. Understanding the arrangement and functionality of each element is crucial for maintaining optimal performance and ensuring longevity.

Component Overview: The assembly consists of several key elements, including the gear housing, drive shaft, and propeller. Each piece plays a vital role in the overall operation, contributing to the efficient transfer of power from the engine to the water.

Assembly Process: Begin by aligning the gear housing with the drive shaft, ensuring that all securing mechanisms are properly engaged. Following this, attach the propeller to the end of the drive shaft, making certain that it rotates freely without obstruction.

Final Checks: Once the assembly is complete, conduct a thorough inspection to confirm that all components are securely fastened and functioning as intended. Regular maintenance and checks will enhance the durability of the system, minimizing the risk of mechanical failure.

Common Issues with Alpha One Parts

In the realm of marine propulsion systems, several components may present challenges that can affect overall performance and reliability. Understanding these common problems is crucial for maintenance and ensuring longevity. Below are frequent issues that users may encounter with these mechanical assemblies.

1. Wear and Tear

One of the most prevalent concerns is the natural deterioration of components over time. Factors contributing to this include:

- Frequent exposure to water and marine environments

- Inadequate lubrication leading to friction

- Corrosion from saltwater

2. Misalignment

Improper installation can lead to misalignment, which can cause various complications. Key indicators include:

- Unusual vibrations during operation

- Increased wear on bearings and seals

- Difficulty in steering or responsiveness

Addressing these issues proactively can greatly enhance the performance and reliability of your marine system. Regular inspections and maintenance are essential in mitigating these problems.

Maintenance Tips for Outdrive Longevity

Proper upkeep of your marine propulsion system is crucial for ensuring its efficiency and extending its lifespan. Regular maintenance not only prevents unexpected breakdowns but also enhances overall performance, allowing for smoother and more reliable operation on the water.

One key aspect of maintaining your system is routine inspections. Check for any signs of wear and tear, such as corrosion or leaks, which can indicate underlying issues. Addressing these problems early can prevent costly repairs later on.

Another important practice is ensuring proper lubrication of all moving components. Using the correct type of lubricant at recommended intervals helps reduce friction and wear, thereby prolonging the life of the system. Regularly replacing old lubricant with fresh oil also helps keep the mechanism running smoothly.

Cleaning is equally essential. Remove any debris, algae, or buildup that may accumulate around the system. This not only enhances performance but also prevents potential damage from obstructions that can affect functionality.

Lastly, always consult the manufacturer’s guidelines for specific maintenance recommendations tailored to your system. Following these guidelines ensures you are taking the right steps to maintain efficiency and longevity, keeping your equipment in top condition for years to come.

Upgrading Your Alpha One Outdrive

Enhancing your marine propulsion system can significantly improve performance, efficiency, and overall enjoyment on the water. By carefully selecting and upgrading essential components, you can ensure your vessel operates at its best. This section explores the benefits and considerations of upgrading your marine drive system.

Benefits of Upgrading

Upgrading your propulsion assembly can lead to various advantages, including improved fuel efficiency, increased horsepower, and enhanced maneuverability. Additionally, modern components often incorporate advanced technologies that provide greater reliability and durability, reducing maintenance costs and downtime.

Key Components to Consider

When planning an upgrade, it’s essential to focus on the following key components:

| Component | Description | Benefits |

|---|---|---|

| Propeller | The device that converts engine power into thrust. | Improved speed and handling. |

| Transmission | Regulates power distribution from the engine to the propeller. | Smoother shifting and better torque management. |

| Exhaust System | Manages exhaust flow from the engine. | Reduced emissions and enhanced performance. |

Upgrading these components can dramatically enhance your vessel’s performance and longevity. Consider consulting with a professional to identify the best upgrades suited for your specific needs and preferences.

Finding Replacement Parts Efficiently

When it comes to maintaining and repairing marine propulsion systems, sourcing components can often be a challenge. Understanding how to navigate the market for these essentials can save both time and money. This section explores effective strategies for locating the necessary items quickly and efficiently.

Utilizing Online Resources

The internet has revolutionized the way individuals acquire components. Here are some effective methods to leverage online platforms:

- Manufacturer Websites: Start by visiting the official sites of manufacturers. They often provide detailed catalogs and specifications.

- Online Marketplaces: Platforms like eBay, Amazon, or specialized marine supply websites frequently list a variety of components.

- Forums and Community Groups: Engaging with online forums dedicated to marine mechanics can lead to recommendations for reputable suppliers.

Local Suppliers and Salvage Yards

While online options are convenient, local resources should not be overlooked. Consider the following:

- Marine Supply Stores: These establishments often stock essential components and can provide expert advice.

- Salvage Yards: For those seeking budget-friendly alternatives, salvage yards can be a goldmine for hard-to-find items.

- Networking with Local Technicians: Building relationships with local repair professionals can yield insights into reliable sources for components.

By employing these strategies, you can streamline the process of finding the necessary components for your marine propulsion system, ensuring you spend less time searching and more time enjoying your vessel.

Importance of Regular Inspections

Conducting frequent assessments of marine propulsion systems is crucial for maintaining optimal performance and preventing unexpected failures. Regular evaluations help identify wear and tear on components, ensuring that potential issues are addressed before they escalate into costly repairs or safety hazards.

Enhancing Performance

Routine checks not only extend the lifespan of mechanical systems but also enhance overall efficiency. By monitoring critical elements, operators can ensure smooth operation, which contributes to better fuel economy and improved handling in various conditions.

Preventing Accidents

Implementing a proactive approach to maintenance significantly reduces the likelihood of accidents. Identifying and rectifying minor issues early on can prevent severe mechanical failures that could lead to hazardous situations on the water.

Performance Enhancements for Outdrive

Improving the efficiency and power of marine propulsion systems is essential for achieving optimal performance on the water. By implementing various modifications and upgrades, boat enthusiasts can enhance acceleration, speed, and overall handling. These enhancements not only contribute to a more exhilarating experience but also improve fuel efficiency and prolong the lifespan of the equipment.

One effective method for boosting performance is through the optimization of the gear ratio. Selecting a higher or lower ratio can significantly affect torque and top speed, allowing for tailored performance based on specific boating needs. Additionally, upgrading to high-performance propellers can improve thrust and reduce cavitation, resulting in smoother operation and increased responsiveness.

Another avenue for enhancement involves fine-tuning the engine’s power output. This can be achieved by installing performance exhaust systems or upgrading the ignition components. Such modifications help in maximizing engine efficiency, translating to better acceleration and increased horsepower.

Regular maintenance and inspection play a crucial role in sustaining high performance. Ensuring that all components are functioning correctly, free of corrosion, and properly lubricated can prevent unnecessary wear and tear, thus maintaining the efficiency of the entire system.

Ultimately, the pursuit of enhanced performance is a multifaceted approach involving various upgrades and regular upkeep. By focusing on key areas of improvement, boat owners can achieve a significant boost in performance, leading to an enjoyable and efficient boating experience.

Tools Needed for Outdrive Repairs

When undertaking maintenance or restoration tasks on marine propulsion systems, having the right tools is crucial for efficiency and safety. Proper equipment not only streamlines the repair process but also ensures that all components are handled correctly and efficiently, reducing the risk of damage.

Essential Tools

- Wrenches: Various sizes are needed for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips are necessary for different fasteners.

- Socket Set: A complete set allows for easy access to hard-to-reach areas.

- Pliers: Useful for gripping and bending components as needed.

- Torque Wrench: Ensures bolts are tightened to the manufacturer’s specifications.

Additional Equipment

- Sealant: Important for preventing leaks when reassembling parts.

- Lubricant: Reduces friction and wear on moving components.

- Cleaning Supplies: Solvents and brushes for cleaning parts before assembly.

- Safety Gear: Gloves and goggles to protect against debris and chemicals.

- Work Light: Enhances visibility in tight spaces for precise work.

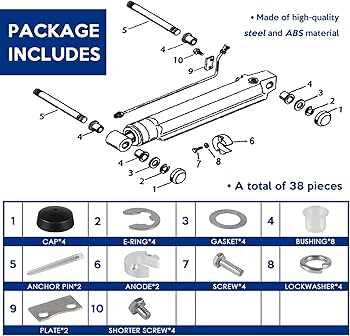

Identifying Genuine Alpha One Parts

Recognizing authentic components for your marine propulsion system is crucial for optimal performance and longevity. Using counterfeit or substandard items can lead to malfunction and increased repair costs. This section will guide you through the essential characteristics to distinguish genuine elements from replicas.

When assessing the authenticity of these components, consider the following factors:

- Brand Markings: Genuine items often have distinctive logos or part numbers stamped or printed on them. Check for clarity and correct placement.

- Material Quality: Authentic elements are typically made from high-quality materials. Inspect for weight and texture; inferior items may feel lighter or have a different finish.

- Packaging: The original packaging is often designed for protection and branding. Examine it for tampering, inconsistencies, or missing information.

- Price Point: If the price seems too good to be true, it likely is. Research typical costs for these items to avoid unexpected surprises.

By being vigilant and informed, you can ensure that your marine system remains reliable and effective. Regularly consult reputable sources and authorized dealers to enhance your purchasing decisions.

Expert Recommendations for Outdrive Care

Maintaining the performance and longevity of your marine propulsion system is crucial for ensuring a smooth and enjoyable experience on the water. Proper care and attention can significantly reduce the likelihood of costly repairs and downtime, ultimately enhancing your vessel’s overall efficiency.

Regular Inspection and Maintenance

It is essential to conduct routine checks on critical components to identify any signs of wear or damage early on. Inspect seals, bearings, and other vital elements for leaks, corrosion, or deterioration. Regular maintenance, including fluid changes and component lubrication, will ensure optimal functioning and prevent potential issues.

Storage and Environmental Considerations

When not in use, proper storage practices are vital. Ensure that the unit is protected from harsh weather conditions and moisture, which can lead to corrosion and other damage. Using a quality cover or storing the vessel in a dry, controlled environment will help preserve the integrity of all components.

Following these guidelines will not only enhance performance but also extend the lifespan of your marine system, ensuring a safe and reliable journey on the water.