Comprehensive Guide to Mercruiser Alpha One Gen 2 Outdrive Parts Diagram

The intricate workings of marine propulsion systems are essential for optimal performance on the water. A thorough grasp of the individual elements that contribute to the overall functionality can significantly enhance maintenance and repair efforts. This section aims to shed light on the various components involved in these systems, offering insights into their design and interrelationships.

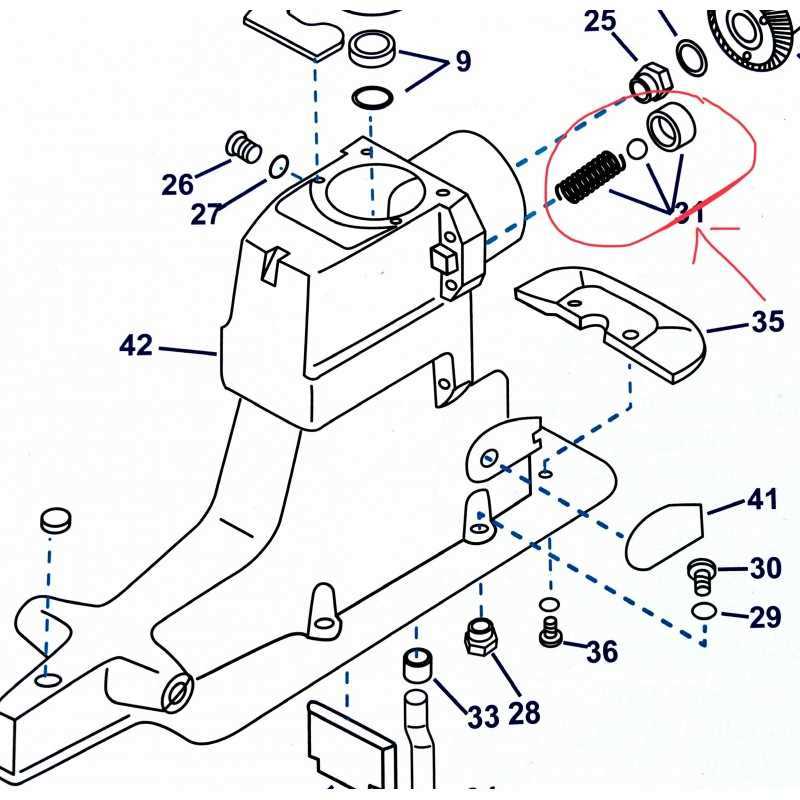

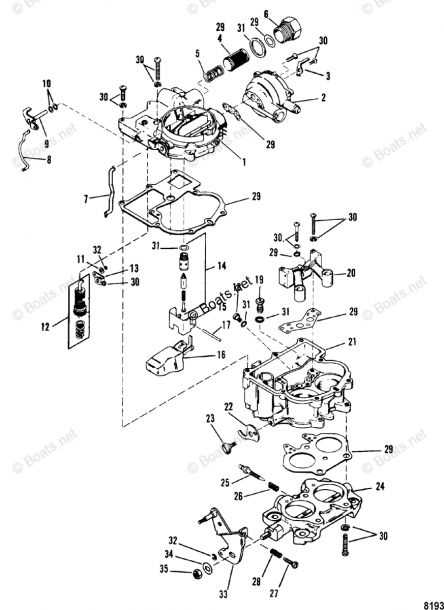

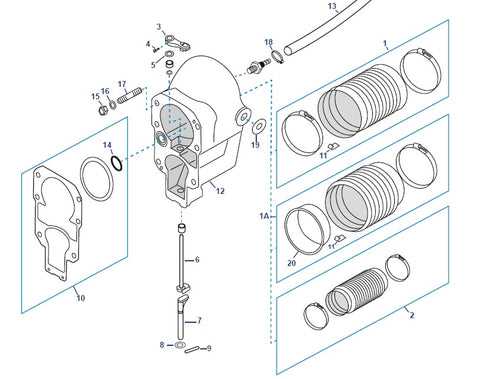

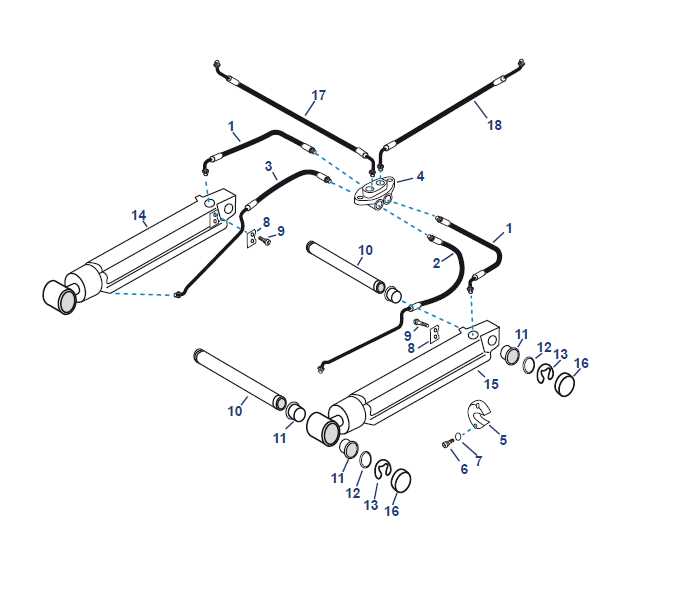

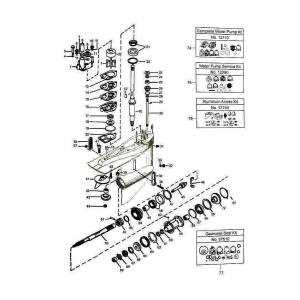

Visual aids, such as schematics, serve as invaluable tools for both novice and experienced technicians alike. They not only illustrate the assembly of the different components but also highlight the importance of each part in ensuring smooth operation. Recognizing the specific roles and connections of these elements is crucial for troubleshooting and effective upkeep.

By delving into the intricacies of marine drive assemblies, enthusiasts can cultivate a deeper appreciation for their mechanics. Whether for routine maintenance or complex repairs, understanding the layout and function of each piece can lead to more informed decisions and better performance on the water.

Understanding Mercruiser Alpha One Gen 2

This section provides a comprehensive overview of a crucial component in marine propulsion systems. Understanding its design and functionality can significantly enhance performance and maintenance. The assembly is designed to ensure smooth operation and durability in various water conditions.

Components and Functionality

The system consists of several key elements that work in unison. Each component plays a vital role in transferring power from the engine to the propeller. A thorough grasp of how these parts interact can lead to better upkeep and longevity.

Maintenance Tips

Regular inspections and timely replacements are essential for optimal performance. Pay attention to wear and tear, as well as fluid levels, to prevent potential issues. Keeping everything in check will ensure a reliable experience on the water.

Overview of Outdrive Components

This section explores the essential elements that contribute to the functionality and performance of marine propulsion systems. Understanding these components is crucial for maintaining efficiency and ensuring smooth operation on the water.

Key Elements of Marine Propulsion

Each component plays a vital role in the overall mechanism. From the propulsion unit to the connecting parts, each piece must work in harmony to achieve optimal results.

Component Breakdown

| Component | Description |

|---|---|

| Drive Shaft | Transmits power from the engine to the propeller. |

| Gear Assembly | Modulates rotational speed and torque. |

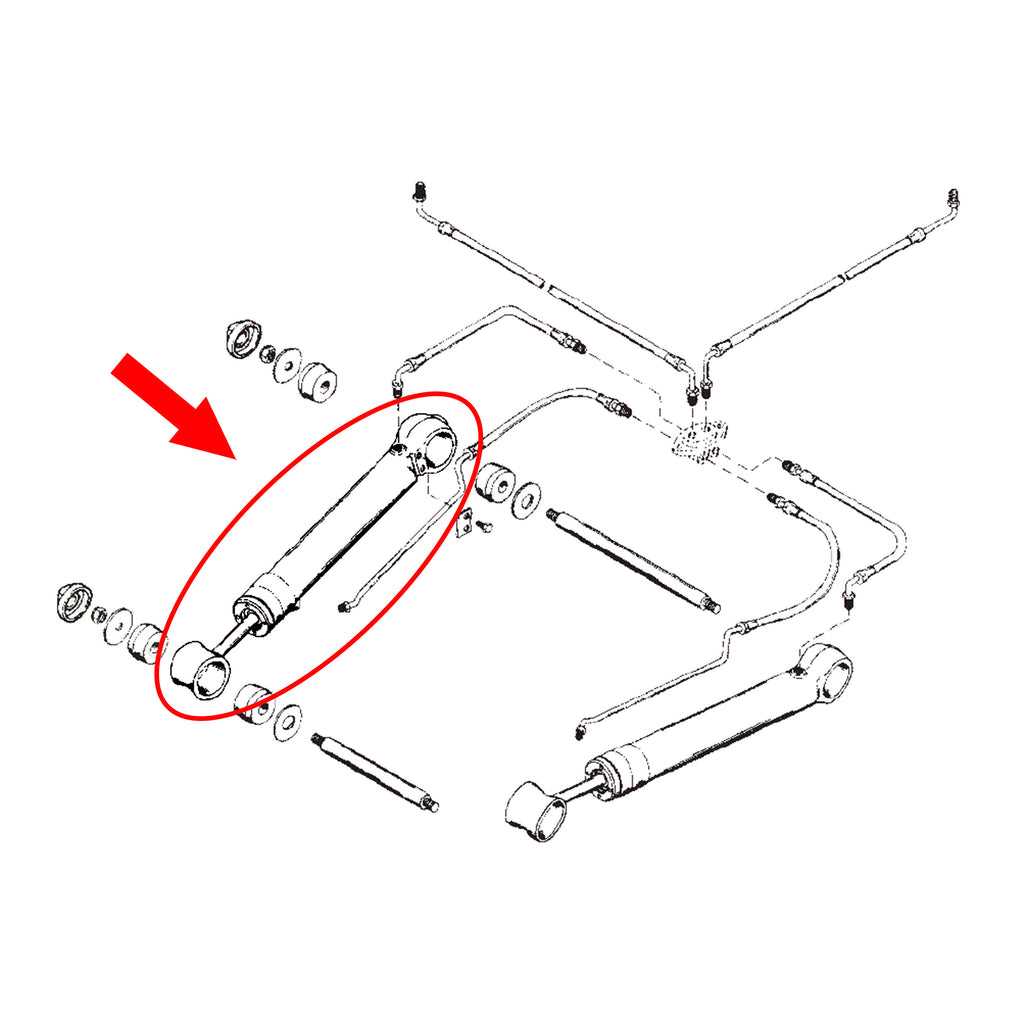

| Trim Cylinder | Adjusts the angle of the propulsion unit for optimal performance. |

| Propeller | Converts rotational energy into thrust. |

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding complex machinery. They provide clarity and enhance the user’s ability to identify various elements within a system, making it easier to comprehend how everything fits together. By utilizing these illustrations, one can effectively troubleshoot issues and plan maintenance more efficiently.

Moreover, these visuals serve as invaluable resources for both novice and experienced technicians. They facilitate communication between parties, ensuring that everyone involved has a shared understanding of the components in question. This common language helps to streamline repairs and replacements, ultimately leading to better performance and longevity of the equipment.

Additionally, detailed schematics can assist in sourcing the correct replacements, reducing the likelihood of errors during assembly or disassembly. Understanding the layout of parts fosters confidence in handling repairs, contributing to a more proficient approach to upkeep.

Common Issues with Alpha One Outdrive

When dealing with marine propulsion systems, several challenges can arise that may affect performance and reliability. Understanding these frequent problems can help boat owners take preventive measures and ensure smooth operation.

1. Gear and Shaft Wear

One of the primary concerns is the wear and tear on gears and shafts, which can lead to noise and operational inefficiencies. This can result from:

- Insufficient lubrication

- Corrosion from saltwater exposure

- Improper alignment during installation

2. Seal and Gasket Failures

Another common issue involves the seals and gaskets, which can deteriorate over time. Signs of this problem include:

- Leaking fluids

- Increased maintenance needs

- Potential for further damage to internal components

Regular inspections and timely maintenance can significantly mitigate these problems, ensuring optimal performance and longevity of the propulsion system.

Key Parts in the Outdrive Assembly

Understanding the essential components of a propulsion unit is crucial for effective maintenance and operation. Each element plays a significant role in ensuring optimal performance and longevity.

- Gear Housing: This encasement protects the internal mechanisms while housing vital gears.

- Propeller: The rotating blade that generates thrust, translating engine power into movement.

- Drive Shaft: Transfers rotational force from the engine to the propeller.

- Trim Tab: Adjusts the angle of the unit, enhancing steering and stability.

- Upper and Lower Units: House the gears and bearings, facilitating smooth operation.

Familiarity with these components will ultimately aid in troubleshooting and repairs, ensuring reliable operation of your marine equipment.

Identifying Replacement Components

When it comes to maintaining marine propulsion systems, recognizing the right components for replacement is crucial for optimal performance and longevity. Understanding the various elements involved and their interconnections will ensure efficient troubleshooting and repairs.

Key Components to Consider

Several vital elements play a role in the overall functionality of the system. These include the drive unit, housing, seals, and gaskets. Each component must be examined for wear and tear, as they contribute to the smooth operation of the entire mechanism. Familiarity with these parts will aid in selecting appropriate replacements.

Utilizing Resources for Identification

Accessing reliable resources such as service manuals, online forums, and component catalogs can significantly enhance your ability to identify the necessary pieces. These tools often provide detailed information, including specifications and compatibility, ensuring that the correct items are sourced for replacement. Leveraging these resources will streamline the repair process and improve the performance of your vessel.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and performance of marine propulsion systems. Adopting a systematic approach to maintenance can significantly extend the life of your equipment and enhance its efficiency. This section outlines key strategies to keep your machinery in optimal condition.

Start by conducting routine inspections. Check for signs of wear, corrosion, and leaks in seals and connections. Addressing minor issues promptly can prevent more significant problems down the line. Additionally, ensure that all fasteners are secure and that components are properly aligned to avoid unnecessary strain during operation.

Regularly change lubricants and fluids according to manufacturer recommendations. Clean and replace filters as needed to maintain smooth operation and prevent contaminants from causing damage. Using high-quality products tailored for marine environments will provide additional protection against the harsh conditions encountered on the water.

Storage is another crucial aspect of maintenance. When not in use, ensure that your equipment is stored in a dry, sheltered area to protect it from the elements. Covering your machinery with protective tarps can help minimize exposure to moisture and UV rays, both of which can lead to deterioration over time.

Finally, consider scheduling professional evaluations periodically. Experienced technicians can identify potential issues that may go unnoticed during routine checks. Investing in expert assessments can save you money in the long run by avoiding costly repairs and extending the lifespan of your equipment.

Tools Needed for Repairing Outdrive

Effective maintenance of marine propulsion systems requires specific instruments to ensure efficiency and safety. Having the right tools at your disposal not only simplifies the repair process but also enhances overall performance.

Essential Tools

- Socket set

- Wrenches

- Screwdrivers

- Pliers

- Torque wrench

Specialized Equipment

- Grease gun

- Oil pump

- Propeller puller

- Multimeter

- Alignment tool

Having these tools readily available will help ensure that your repairs are conducted efficiently and effectively, ultimately leading to better performance on the water.

Where to Find Genuine Parts

Locating authentic components for marine propulsion systems is essential for maintaining performance and longevity. Reliable sources ensure that you obtain the correct elements needed for optimal functionality, avoiding potential issues caused by counterfeit products.

Authorized Dealers

One of the best ways to ensure you are getting genuine components is to purchase them from authorized dealers. These retailers are certified to sell original products and often provide warranties, further guaranteeing your investment.

Online Marketplaces

Reputable online platforms also offer a wide selection of authentic components. It’s important to verify seller ratings and reviews to ensure that you’re buying from a trustworthy source.

| Source Type | Benefits |

|---|---|

| Authorized Dealers | Certified products, warranties |

| Online Marketplaces | Wide selection, competitive pricing |

Step-by-Step Disassembly Process

Disassembling mechanical components requires a careful approach to ensure all pieces are safely removed and organized. This section outlines a systematic method to break down the assembly, emphasizing precision and attention to detail.

Preparation and Safety

Before beginning, gather necessary tools such as wrenches, screwdrivers, and pliers. Wear safety goggles and gloves to protect yourself from potential hazards. Ensure the work area is clean and well-lit, allowing for a smooth workflow.

Disassembly Steps

Start by disconnecting any electrical connections and fluids to avoid spills. Next, remove fasteners in a logical sequence, marking their locations for easy reassembly. As you delve deeper into the assembly, take note of the orientation and position of each part. Place all components in labeled containers to maintain organization. The ultimate goal is to complete the process without damaging any elements, facilitating a seamless reassembly later.

Reassembly Guidelines for Optimal Performance

Reassembling marine propulsion components requires meticulous attention to detail and a systematic approach to ensure peak efficiency and longevity. Following the right procedures not only enhances functionality but also reduces the risk of future malfunctions. Adhering to best practices during the reassembly process will help maintain the integrity of the system and ensure a smooth operation on the water.

Preparation and Inspection

Before beginning the reassembly, it is crucial to thoroughly inspect all components for wear, damage, or contamination. Cleaning each part with appropriate solvents and tools will remove any debris or residue. This preparatory step sets the foundation for successful reassembly. Additionally, consulting the manufacturer’s guidelines or service manuals can provide valuable insights into specific requirements and torque specifications.

Assembly Techniques

During assembly, use proper techniques to avoid misalignment and ensure correct fitting. Employ thread sealants and lubricants where necessary to prevent leaks and facilitate smooth movement. It’s advisable to work in a clean, organized space, keeping all components sorted and labeled. Take your time to verify that each part is secured to the correct torque level, as this is essential for the overall performance and reliability of the system.

Upgrades for Enhanced Functionality

Improving the performance and efficiency of your marine propulsion system can significantly enhance your boating experience. Upgrades can address various aspects such as speed, fuel consumption, and overall reliability, ensuring that your vessel operates at its best.

Performance Enhancements

Installing high-performance propellers can provide better thrust and efficiency, enabling quicker acceleration and smoother cruising. Additionally, considering a shift to stainless steel components may offer increased durability and resistance to corrosion.

Electrical System Improvements

Upgrading to a more efficient electrical system can enhance functionality by providing better power management. High-capacity batteries and modern charging systems can ensure your onboard equipment runs seamlessly, reducing the risk of failure during critical moments.

FAQs about Alpha One Gen 2 Parts

This section aims to address common inquiries regarding components associated with a specific marine propulsion system. Understanding these elements can enhance performance and facilitate maintenance, making it easier for enthusiasts and professionals alike to navigate their options.

What are the most common issues with this system?

Common problems include wear on seals, corrosion of components, and performance inconsistencies. Regular inspection can help mitigate these issues.

Where can I find replacement components?

Replacement items can be sourced from specialized marine retailers, online marketplaces, or authorized dealers that focus on marine equipment.

Are there aftermarket alternatives available?

Yes, various aftermarket options exist, often providing competitive pricing and unique features, but it’s essential to ensure compatibility and quality.

How do I identify specific components?

Identification can typically be achieved by consulting the owner’s manual or using online resources that detail the specifications and functions of each element.

What maintenance tips should I follow?

Regularly check fluid levels, inspect for wear and tear, and follow manufacturer guidelines for seasonal maintenance to keep everything running smoothly.