Understanding the Components of a Clothes Dryer Through Diagrams

In the world of household machines, a comprehensive understanding of their inner workings is essential for effective maintenance and troubleshooting. Familiarizing oneself with the various elements that contribute to the functionality of these devices can ultimately lead to more efficient operation and longevity.

Every machine consists of a series of interconnected components that work together seamlessly. Each element plays a crucial role, and recognizing how they interact can empower users to diagnose issues with greater ease and precision.

This guide aims to delve into the essential components of these appliances, providing clarity on their arrangement and function. By breaking down each element, users will gain valuable insights that enhance their overall knowledge and confidence in managing these household essentials.

Understanding Clothes Dryer Components

In the realm of laundry appliances, each unit comprises several essential elements that work harmoniously to ensure optimal performance. Familiarity with these components can significantly enhance maintenance and troubleshooting efforts, leading to efficient operation and longevity of the equipment.

Key Functional Elements

Among the critical elements are the heating mechanisms and airflow systems. The heating unit generates warmth necessary for effective moisture removal, while the airflow channels facilitate the movement of hot air throughout the interior, ensuring uniform drying. Understanding these functions aids users in recognizing potential issues, such as insufficient drying or overheating.

Maintenance and Care

Regular upkeep of these integral components is vital for maintaining efficiency. For instance, cleaning lint filters and inspecting venting systems can prevent blockages that hinder airflow, leading to improved performance and safety. Knowledge of these components empowers users to carry out basic maintenance, enhancing the overall lifespan of the appliance.

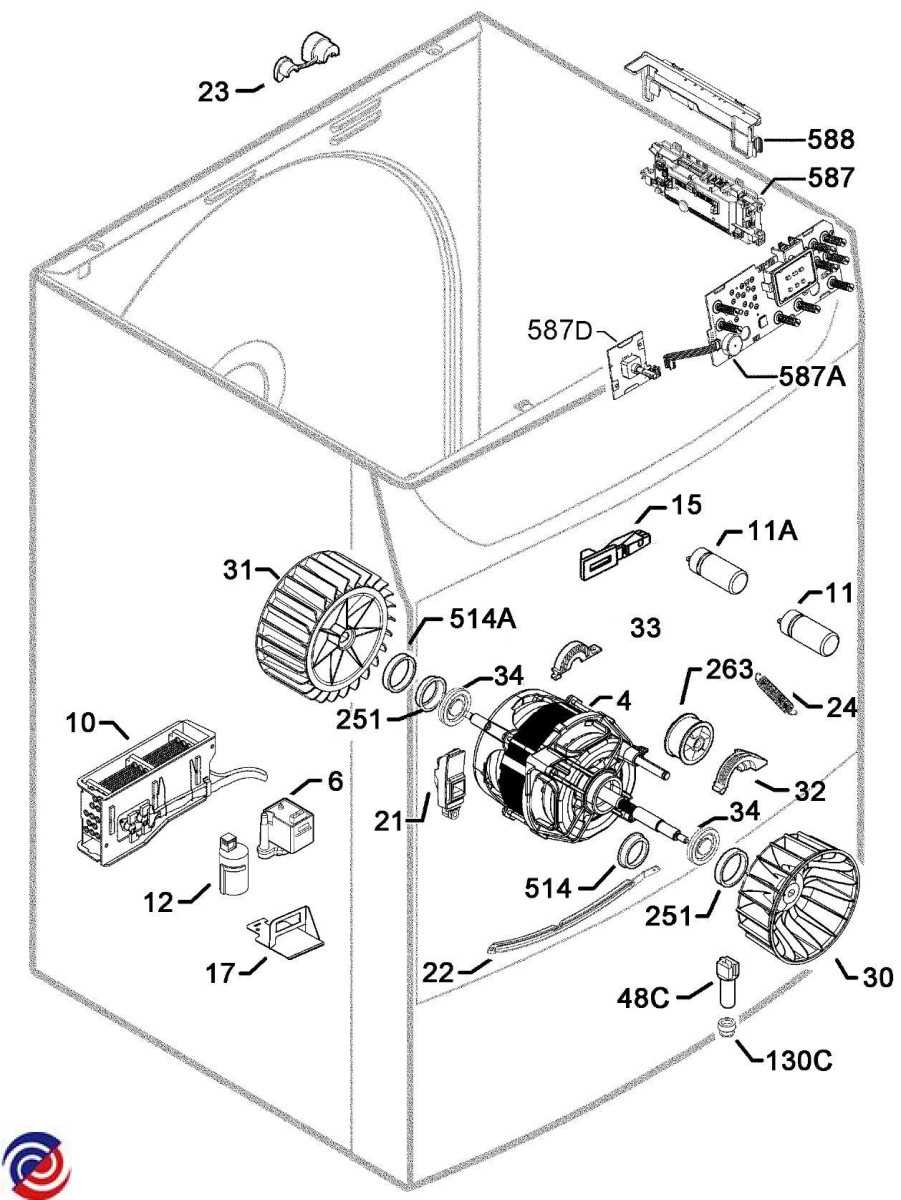

Key Parts of a Dryer

Understanding the various components of a heat-based appliance used for drying fabrics can help identify issues and enhance efficiency. Each element plays a crucial role in the machine’s operation, working together to provide effective and uniform drying.

- Heating Element: This component generates the warmth necessary for moisture evaporation, ensuring the garments are dried evenly.

- Drum: The rotating chamber where fabrics are placed for drying. It ensures consistent movement, which aids in efficient moisture removal.

- Blower: Responsible for circulating hot air inside the unit, helping to distribute warmth evenly across the load.

- Thermostat: Regulates temperature levels, preventing overheating and ensuring optimal drying conditions.

- Lint Filter: Collects fibers and debris that separate from the fabrics during the process, helping to maintain proper airflow.

- Control Panel: Allows users to select different settings and customize the drying process based on fabric type or drying preference.

Function of the Heating Element

The heating element plays a critical role in maintaining the internal temperature required for proper operation. It is designed to convert electrical energy into heat, which is then distributed to ensure efficient functioning of the entire system. Without this component, the process would be incomplete, and temperature control would not be possible.

How the Heating Element Works

This component functions by generating heat through electrical resistance. As current flows through, the element heats up, providing the necessary warmth. This heat is circulated by a fan or similar mechanism, ensuring even distribution and consistent performance.

Maintaining Optimal Performance

Over time, the heating element may degrade or become less effective due to wear. Regular inspection and timely replacement are essential to maintain consistent temperature levels and ensure the system operates at its best.

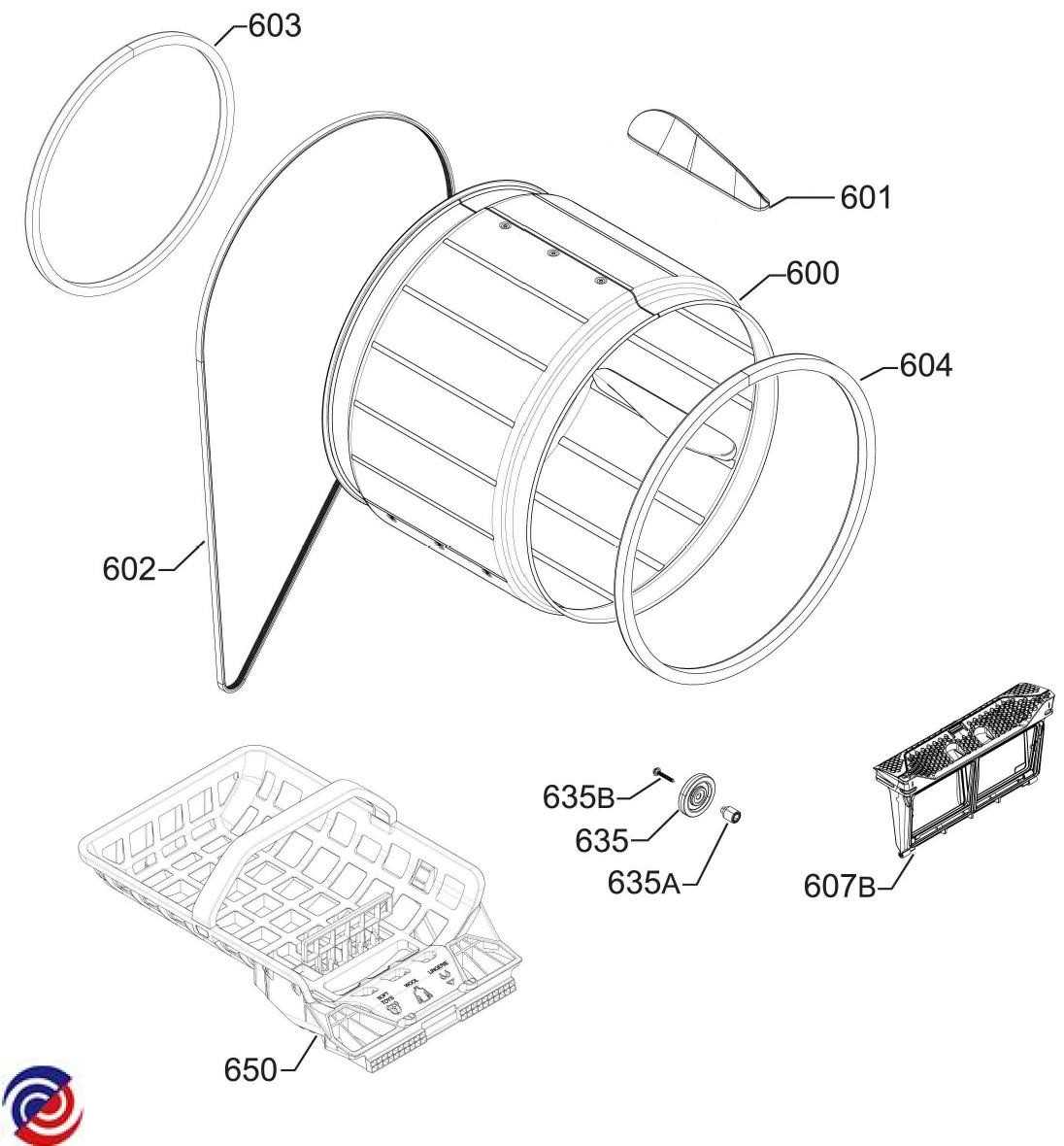

Importance of the Drum Assembly

The rotating enclosure plays a critical role in ensuring the efficient operation of the overall system. It serves as the central component responsible for holding and moving items during the drying process. Without a functioning drum, the entire mechanism would fail to perform its essential task of evenly circulating heated air, which is necessary for thorough and quick drying.

Key Functions of the Drum

- Uniform Airflow Distribution: The drum ensures that hot air reaches every surface of the fabrics inside, contributing to even drying results.

- Rotation Mechanism: It keeps the items in constant motion, preventing them from clumping together, which allows for better air penetration.

- Protection and Durability: A robust drum protects delicate items from damage, ensuring they are treated gently throughout the cycle.

Impact of Drum Maintenance

- Longevity: Regular inspection and cleaning of the drum extend the lifespan of the appliance, as it prevents excessive wear.

- Efficiency: Proper care minimizes energy consumption by allowing the system to operate at peak performance.

- Safety: A well-maintained drum reduces the risk of overheating and potential hazards.

Role of the Control Panel

The control interface plays a crucial part in managing the overall functionality of the machine. It acts as the primary point of interaction between the user and the internal mechanisms, allowing precise control over various operational settings. This section explores the significance of this component and how it influences performance and ease of use.

Core Functions

The control interface is responsible for regulating the machine’s operations. Through its buttons and dials, users can select specific settings such as temperature, cycle duration, and special features. This flexibility allows for tailored experiences, catering to different types of fabrics and drying preferences. Without this component, customizing these settings would be nearly impossible.

Enhancing User Experience

Another critical role of the interface is to enhance the user’s experience by simplifying complex operations. The clear display of information, combined with user-friendly navigation, helps reduce errors and ensures that the correct settings are applied. Its intuitive design improves accessibility, making the process seamless and efficient.

How the Vent System Works

The vent system is crucial for maintaining optimal performance and safety of your appliance. Its primary role is to facilitate the efficient removal of moisture and heat generated during the drying process. Proper ventilation ensures that air circulates effectively, preventing potential hazards and enhancing energy efficiency.

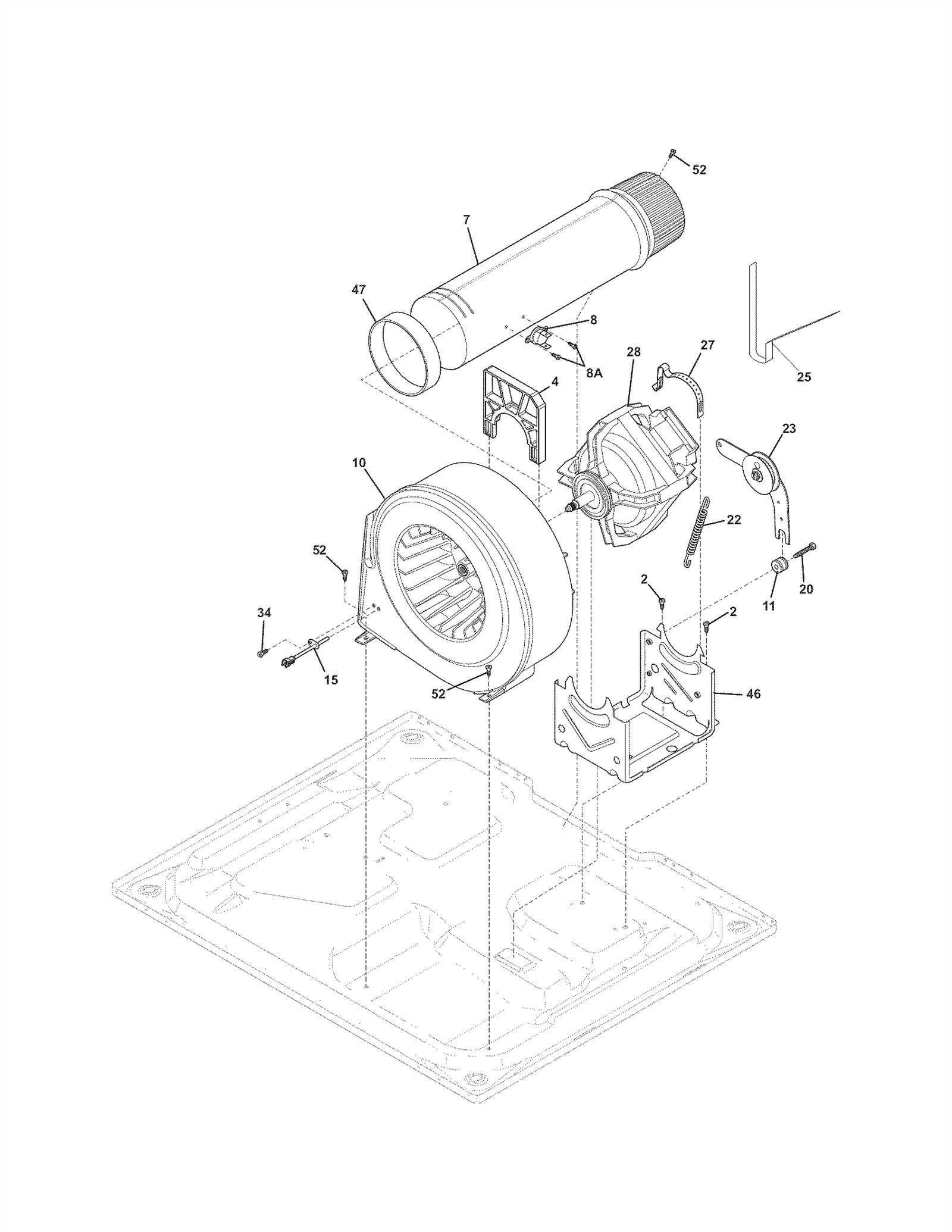

Components of the Vent System

- Venting Duct: A tube that channels moist air outside, usually made of metal or flexible plastic.

- External Vent Cap: A cover that prevents backdrafts and protects the duct from debris and pests.

- Fan Assembly: A component that helps to push air through the system, ensuring continuous airflow.

Functionality and Importance

The functionality of the vent system relies on a few key principles:

- Airflow: Fresh air is drawn in, while warm, humid air is expelled, creating a cycle that promotes drying.

- Moisture Control: Efficient removal of moisture helps to prevent mildew and mold growth, protecting both the appliance and your home.

- Energy Efficiency: A well-functioning vent system reduces energy consumption by allowing the appliance to operate effectively.

Regular maintenance and inspection of the vent system are essential to ensure it remains unobstructed and functions optimally, ultimately prolonging the life of your appliance and enhancing safety.

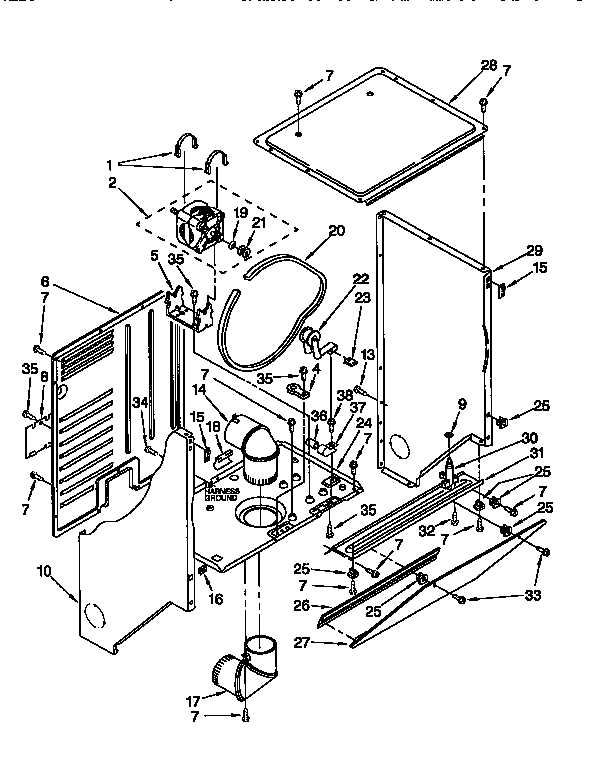

Identifying the Belt Mechanism

The belt mechanism is a crucial component that ensures the efficient operation of your appliance. Understanding its structure and function can significantly enhance your ability to troubleshoot and maintain your device.

Here are key aspects to identify the belt mechanism:

- Location: Typically found near the motor and drum.

- Appearance: Usually a flat, rubber component, often with a ribbed design.

- Function: Connects the motor to the drum, facilitating rotation.

To further delve into its identification, consider these steps:

- Remove the outer casing to access internal components.

- Locate the motor; the belt will be connected here.

- Check for tension and wear; a loose or frayed belt may indicate a need for replacement.

Recognizing these features will help you effectively manage maintenance tasks and ensure the ultimate performance of your appliance.

Significance of the Thermostat

The thermostat plays a crucial role in regulating temperature within the appliance, ensuring optimal performance and safety. By monitoring heat levels, it prevents overheating and maintains efficiency during operation.

| Function | Description |

|---|---|

| Temperature Regulation | Maintains a consistent heat level to protect fabrics and enhance drying efficiency. |

| Safety Mechanism | Shuts off the system if temperatures exceed safe limits, preventing potential hazards. |

| Energy Efficiency | Helps reduce energy consumption by optimizing drying cycles based on fabric type. |

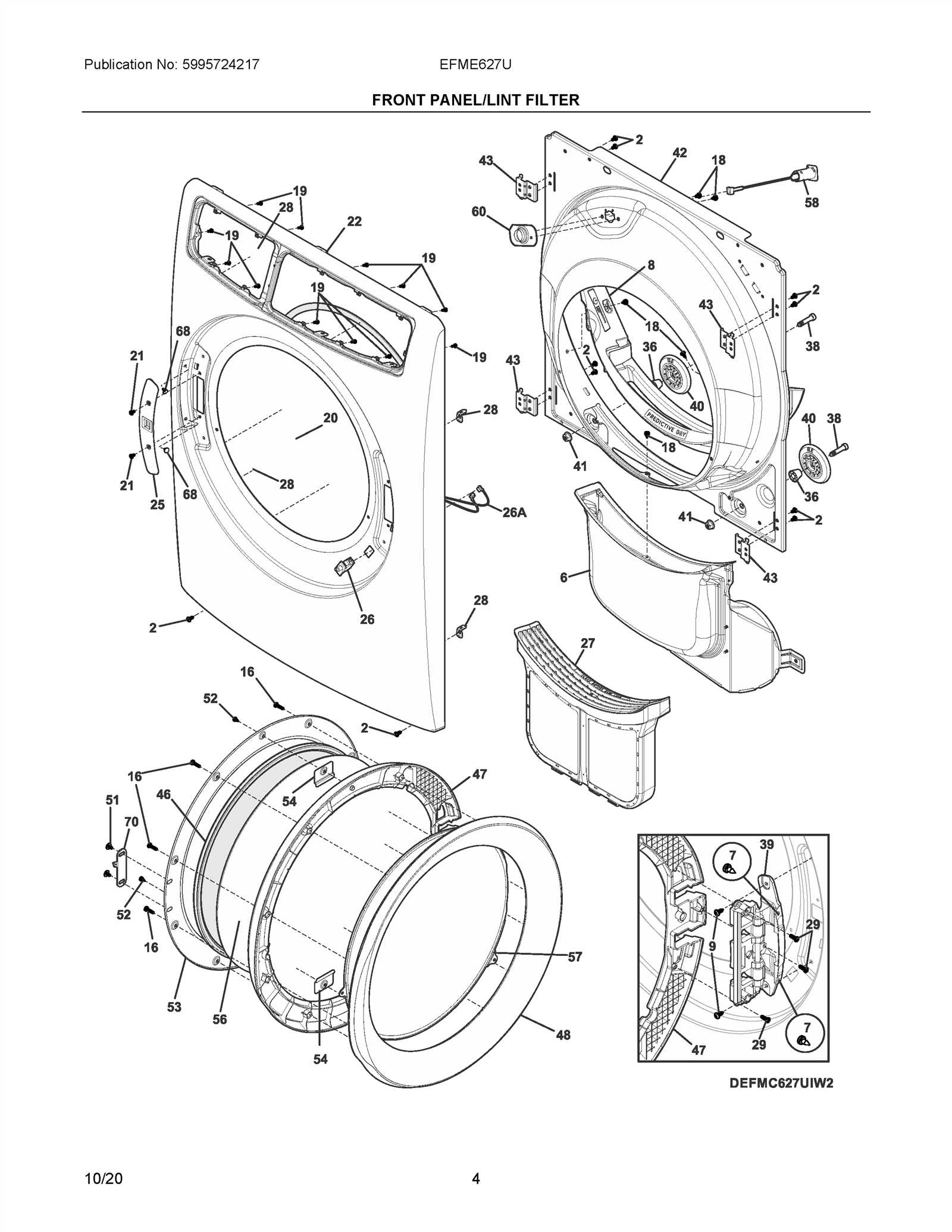

Exploring the Lint Filter System

The lint filtration mechanism plays a crucial role in maintaining efficiency and safety in textile drying appliances. This system is designed to capture fibers and debris, preventing them from circulating back into the environment or clogging internal components.

Understanding its components is essential for optimal performance. The primary element is the filter itself, which is typically located near the door or access panel. Regular cleaning of this component ensures unobstructed airflow, enhancing the drying process.

Additionally, the lint filter system contributes to energy efficiency by reducing the amount of time required for drying. By preventing blockages, it allows the appliance to operate at its ultimate capacity, saving time and resources.

Overall, maintaining this system is vital for prolonging the lifespan of the appliance and ensuring safe operation.

Understanding the Idler Pulley

The idler pulley plays a crucial role in the efficiency and functionality of a particular appliance. It is an essential component that assists in maintaining the tension within the belt system, ensuring optimal performance. This small yet significant piece aids in the smooth operation of moving parts, contributing to the overall effectiveness of the machinery.

Functionality: The primary function of the idler pulley is to adjust the tension of the drive belt, preventing slippage and ensuring that the components operate seamlessly. When this mechanism is functioning correctly, it minimizes wear and tear, extending the life of the appliance.

Importance: A malfunctioning idler pulley can lead to various issues, including noise, reduced efficiency, and potential damage to other parts. Understanding its role helps in troubleshooting and maintaining the appliance, ultimately leading to better performance and longevity.

Impact of the Door Switch

The functionality of household appliances heavily relies on various components that work in harmony. One such critical element is the mechanism responsible for detecting whether the access point is closed or open. Its role is essential in ensuring safety and efficiency during operation.

When the door is closed, the system engages, allowing the device to commence its functions. Conversely, if the entryway is ajar, this mechanism prevents activation, thus avoiding potential hazards. This safety feature protects users and the appliance itself from damage.

Additionally, a malfunctioning switch can lead to operational issues, such as the appliance failing to start or shutting down unexpectedly. Regular inspection and maintenance of this component are vital for optimal performance and longevity of the equipment.

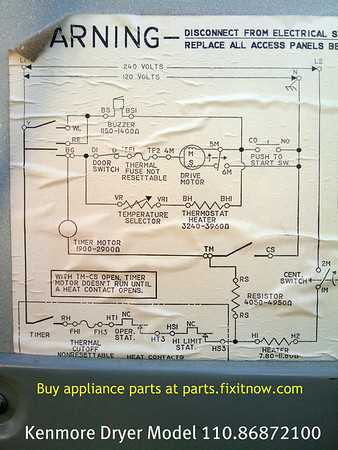

Overview of Electrical Connections

This section delves into the intricacies of electrical connections crucial for the functionality of household appliances. Understanding these components is essential for troubleshooting and ensuring optimal performance.

Electrical systems in appliances typically involve various elements that work together. Here are the main aspects to consider:

- Power Source: The initial input of electricity from the outlet.

- Wiring: Conductors that facilitate the flow of electricity throughout the device.

- Connectors: Junctions where wires meet, ensuring secure and efficient transmission.

- Control Board: The brain of the appliance, managing operations and settings.

- Heating Element: A crucial component responsible for generating heat, powered through the electrical system.

Proper maintenance of these connections is vital for safety and efficiency. Regular checks can prevent potential hazards and enhance the longevity of the appliance.