Understanding the Parts Diagram of a Dryer Drum

In every household, certain machines play a crucial role in maintaining efficiency and convenience. One of the key aspects of these devices is the internal configuration, which ensures smooth operation and optimal performance. Grasping the intricacies of these mechanisms is essential for effective troubleshooting and maintenance.

To truly appreciate how your machine functions, it’s important to explore its inner workings. Each element has a specific purpose and contributes to the overall efficiency. By familiarizing yourself with these components, you can enhance your understanding and take better care of your appliance.

In this section, we will delve into the essential components that contribute to the appliance’s functionality. This knowledge will empower you to identify potential issues and make informed decisions regarding repairs and maintenance.

Understanding Dryer Drum Components

Within the realm of laundry appliances, certain elements play a crucial role in the efficient operation of the system. Recognizing these essential components can enhance your understanding of how to maintain and troubleshoot the machine effectively.

The core component serves as the central chamber where items are placed for drying. Its design is pivotal for facilitating optimal airflow, which significantly affects the drying process. A well-constructed chamber ensures that heat is distributed evenly, leading to better results.

Another significant element is the rotational mechanism, responsible for the movement of the central chamber. This feature ensures that garments are evenly exposed to the heated air, preventing damp spots and promoting uniform drying. The reliability of this mechanism is vital for consistent performance.

Additionally, the support structure plays a key role in maintaining the stability of the entire assembly. It helps to bear the weight and provides a secure setting, allowing for smooth operation over time. Proper maintenance of this component is essential to avoid potential disruptions.

Finally, understanding the accessories that accompany the main chamber can further enhance performance. Features such as lint traps and air vents are designed to optimize airflow and prevent blockages, contributing to the efficiency of the entire system.

By familiarizing yourself with these components, you can ensure better care and longevity of your appliance, leading to improved functionality and satisfaction with the drying process.

Importance of Dryer Drum Parts

The functionality of a laundry appliance relies heavily on its internal components. Each element plays a crucial role in ensuring efficient operation, contributing to both performance and longevity. Understanding the significance of these components can lead to better maintenance practices and enhanced efficiency.

Key elements facilitate the movement and drying process, impacting how effectively garments are treated. Properly functioning components minimize wear and tear, reducing the likelihood of breakdowns. Awareness of their importance helps users recognize the need for timely repairs and replacements, ultimately improving overall usage experience.

Incorporating quality materials in these internal mechanisms enhances durability, providing reliable service over time. This attention to detail not only optimizes performance but also promotes energy efficiency, leading to lower utility costs. Investing in quality replacements ensures the longevity of the appliance and optimal performance, making it essential to prioritize these internal components.

Common Dryer Drum Issues

Various complications can arise within the rotating chamber of laundry appliances, affecting their efficiency and performance. Identifying these issues early can save time and resources, ensuring optimal operation and longevity of the machine.

Below are some frequent problems encountered in the internal component responsible for tumbling fabrics:

| Issue | Description | Potential Causes |

|---|---|---|

| Unusual Noises | Strange sounds during operation often indicate underlying issues. | Worn bearings, foreign objects, or misalignment. |

| Inconsistent Drying | Fabrics may remain damp despite multiple cycles. | Blocked vents, malfunctioning sensors, or heating element failure. |

| Drum Not Turning | The chamber may fail to rotate entirely, halting the drying process. | Broken drive belt, motor issues, or obstruction. |

| Overheating | Excessive heat can damage fabrics and the machine. | Clogged lint filter, blocked exhaust, or faulty thermostat. |

| Wear and Tear | Components may degrade over time, impacting efficiency. | Age, lack of maintenance, or excessive use. |

Regular maintenance and prompt attention to these issues can help maintain peak performance and extend the lifespan of your appliance.

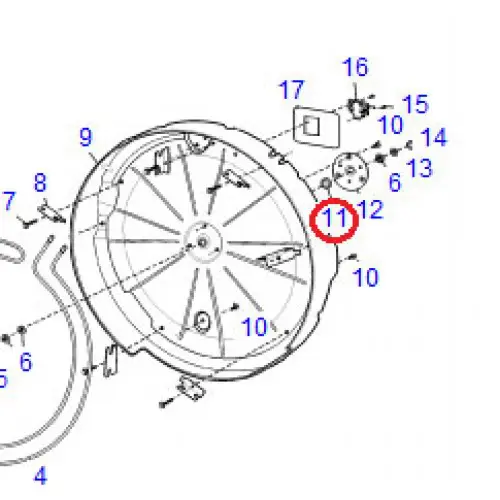

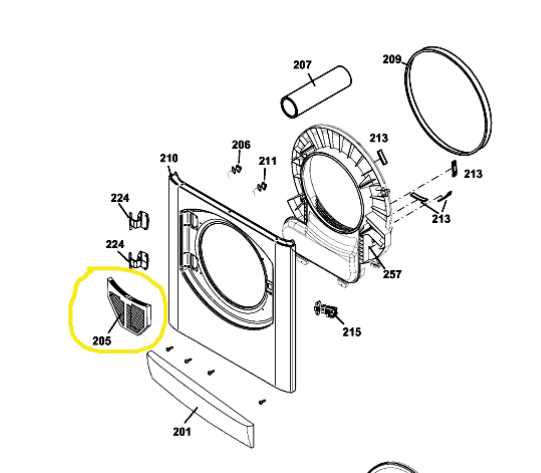

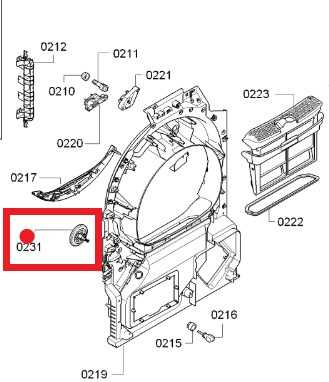

Identifying Each Drum Element

Understanding the components of a rotating chamber is essential for effective maintenance and troubleshooting. Each element plays a significant role in the overall functionality, contributing to efficient operation and optimal performance.

| Element | Function |

|---|---|

| Inner Cylinder | Holds the items being processed and allows airflow. |

| Lint Screen | Traps lint and debris to ensure smooth airflow. |

| Belt | Transfers power from the motor to facilitate rotation. |

| Drum Support Rollers | Ensure smooth and stable rotation of the inner cylinder. |

| Heating Element | Provides the necessary heat for drying items efficiently. |

How to Maintain Your Dryer

Regular upkeep of your appliance is essential for its efficiency and longevity. By implementing simple practices, you can ensure optimal performance and avoid costly repairs.

Cleaning and Inspection

Periodically remove lint buildup from the vent and filter. This not only improves airflow but also reduces fire hazards. Inspect the interior for any signs of wear or damage, addressing issues promptly to maintain functionality.

Routine Checkups

Schedule professional inspections to delve deeper into its workings. An ultimate assessment can uncover hidden problems and enhance the lifespan of your device. Always refer to the manufacturer’s guidelines for maintenance intervals.

Typical Dryer Drum Sizes

Understanding the common dimensions of these appliances is essential for both functionality and efficiency. Various models cater to different needs, influencing the overall capacity and performance.

Standard Dimensions

- Compact Models: Typically range from 3 to 4 cubic feet.

- Medium Models: Generally vary between 5 to 7 cubic feet.

- Large Models: Can exceed 7 cubic feet, accommodating larger loads.

Considerations for Selection

- Household Size: Smaller households may benefit from compact options.

- Load Frequency: Higher usage demands larger capacities.

- Space Constraints: Measure available area to ensure a proper fit.

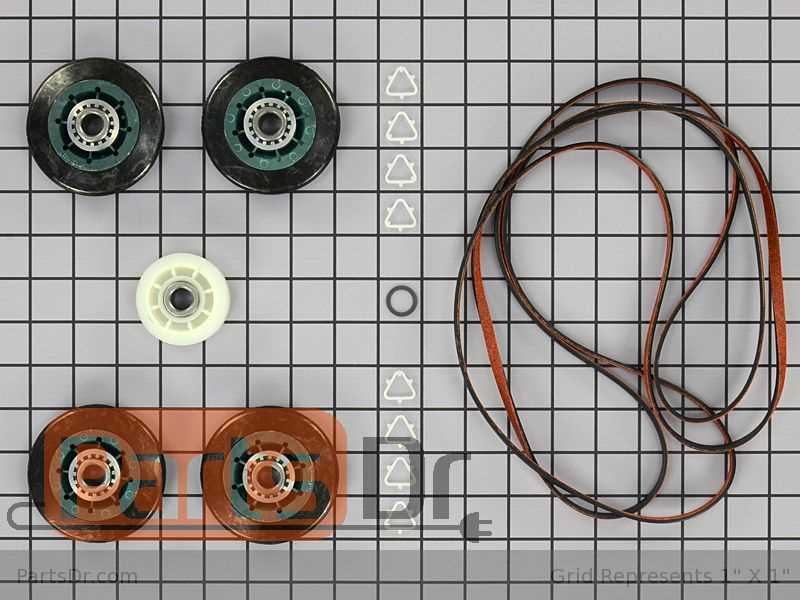

Replacement Parts Overview

This section explores the essential components that may require attention over time, ensuring optimal functionality and longevity of your appliance. Understanding these elements is crucial for effective maintenance and timely replacements.

Key Components

- Belt

- Motor

- Heating Element

- Rollers

- Bearings

Signs of Wear

- Unusual noises during operation

- Inconsistent drying performance

- Visible damage or wear

- Overheating issues

Tools for Drum Repairs

When it comes to maintaining and fixing essential appliances, having the right instruments is crucial for efficiency and effectiveness. Various tools can aid in diagnosing issues, facilitating repairs, and ensuring longevity. Understanding these implements can make the repair process smoother and more manageable.

Essential Instruments

Key implements include screwdrivers, wrenches, and pliers, which are fundamental for disassembling components. A well-equipped toolkit also often features torque wrenches to ensure that all fasteners are secured properly, preventing future malfunctions.

Diagnostic Tools

For effective troubleshooting, multimeters and voltage testers are invaluable. These devices help assess electrical components and verify that everything functions as intended. Additionally, having a good flashlight can significantly aid in inspecting hard-to-reach areas during the repair process.

Safety Tips for Repairing Dryers

When undertaking repairs on home appliances, prioritizing safety is essential. Proper precautions can prevent accidents and ensure a smooth maintenance process.

Preparation Steps

- Unplug the appliance before starting any work.

- Ensure your workspace is well-lit and free of clutter.

- Wear appropriate safety gear, including gloves and goggles.

During the Repair

- Use tools that are in good condition and designed for the task.

- Avoid wearing loose clothing that could get caught in moving parts.

- Keep children and pets away from the repair area.

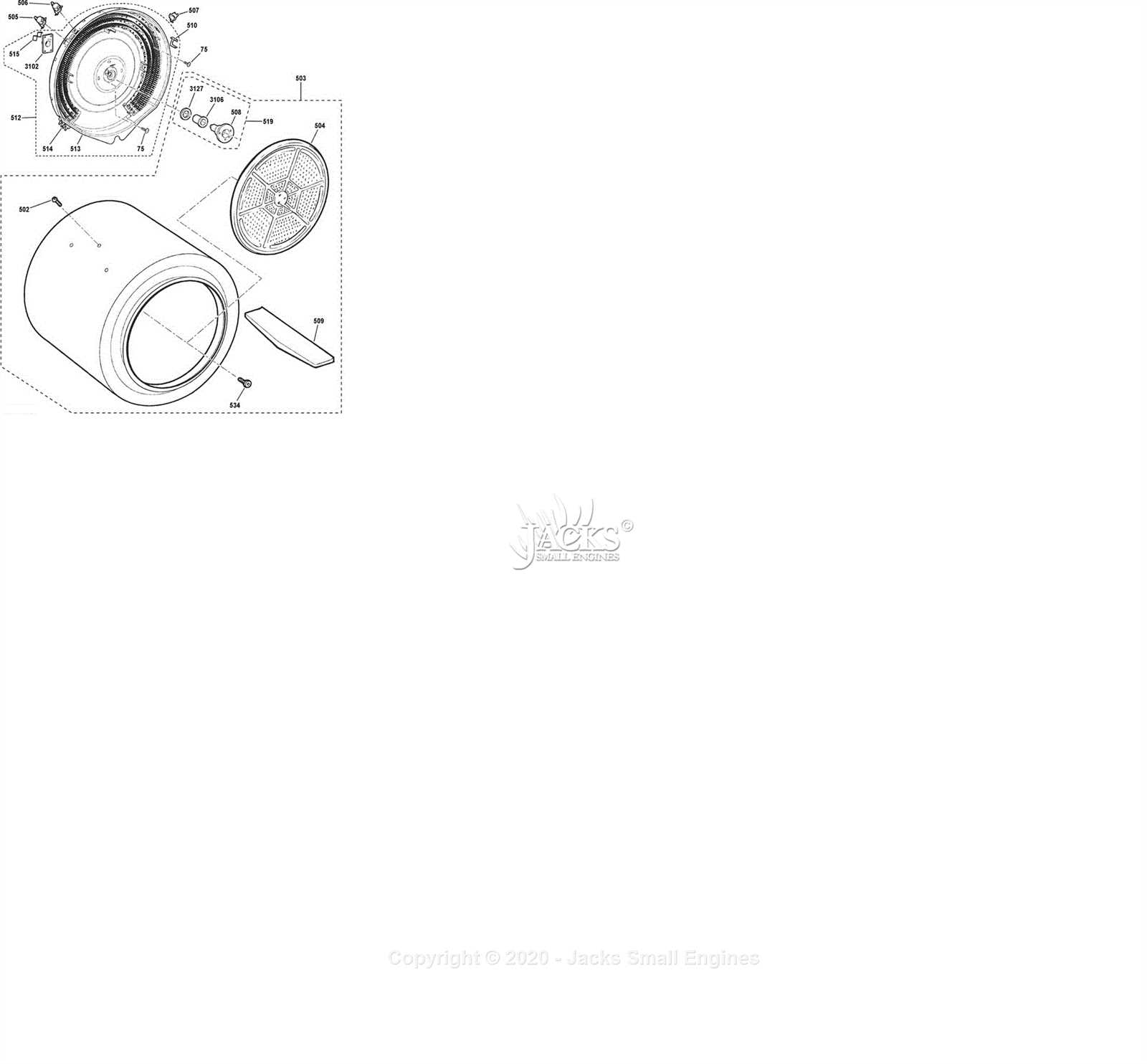

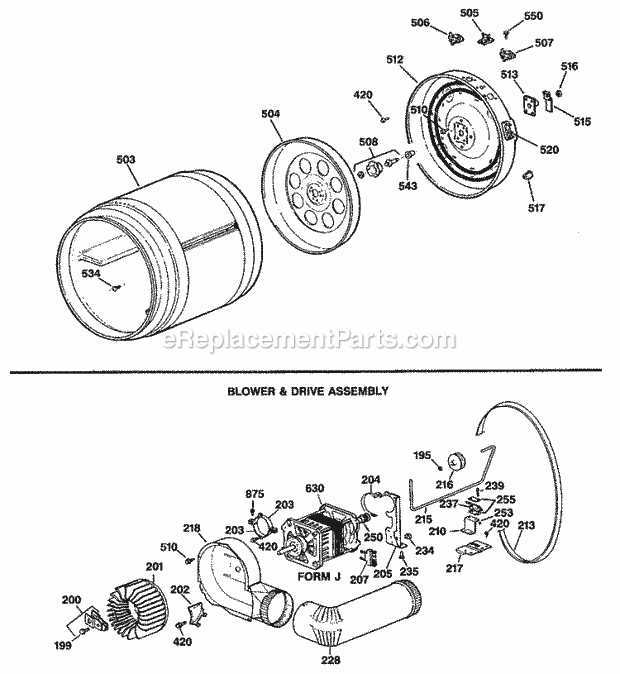

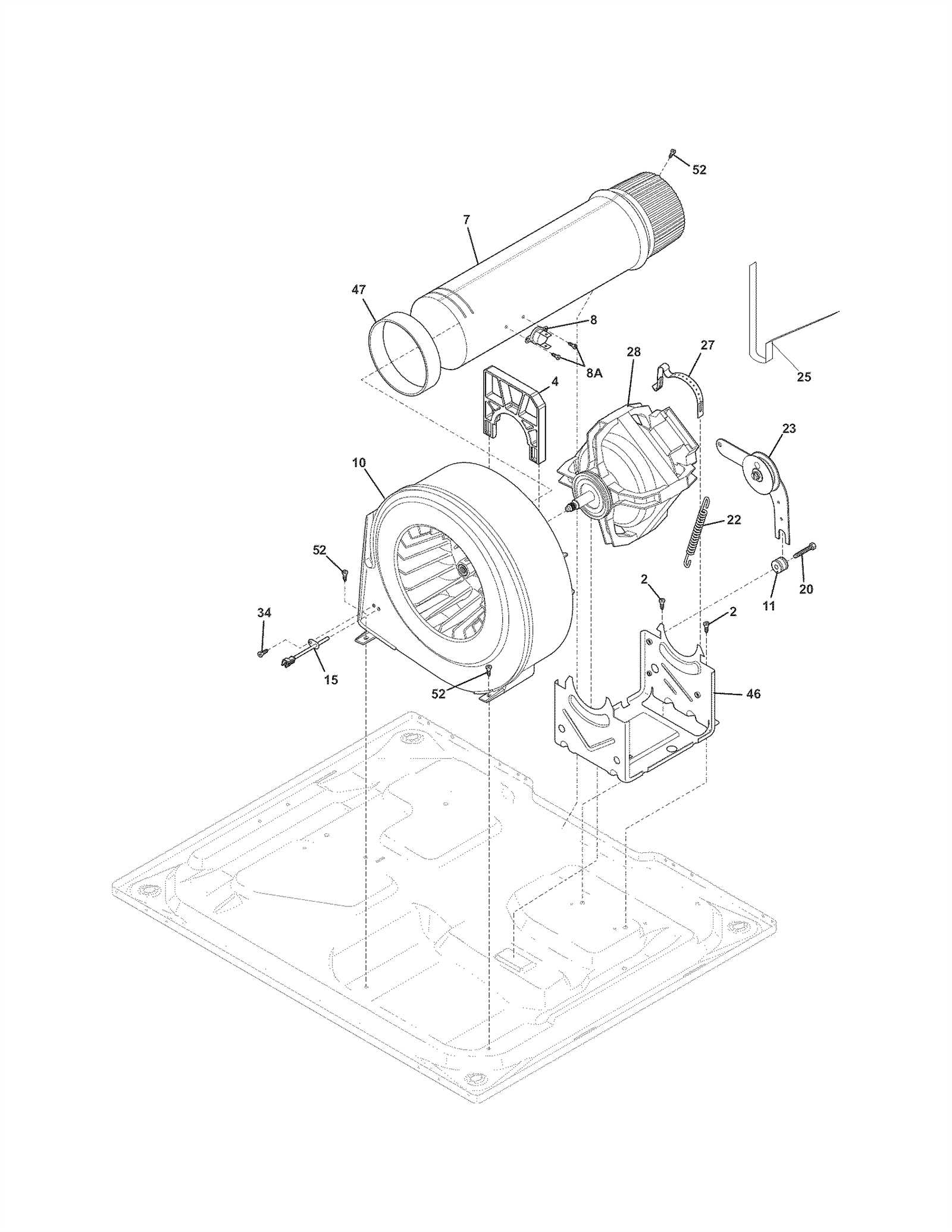

Diagram of a Dryer Drum

This section presents a visual representation of key components within a rotating cylinder used for fabric care. Understanding these elements is crucial for grasping how the entire system operates effectively and efficiently.

Essential Elements: The core structure consists of various integral components, each playing a unique role. For instance, the rotating mechanism is vital for ensuring even distribution and airflow, enhancing the overall drying process.

Maintenance Insights: Familiarity with these components aids in troubleshooting common issues and performing routine checks, which can extend the lifespan of the appliance.

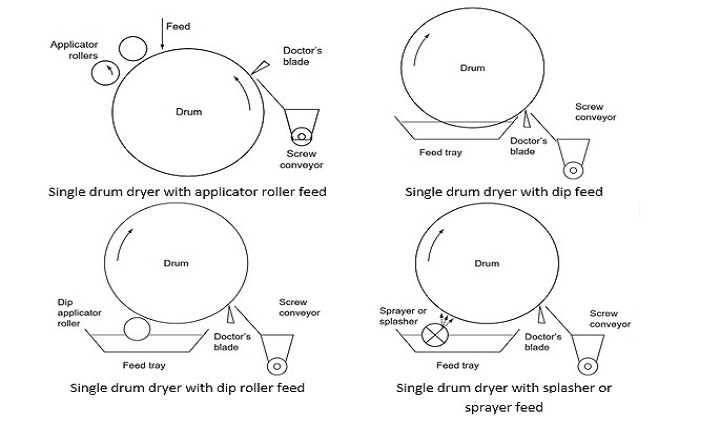

Differences in Drum Designs

The construction of cylindrical components varies significantly across different models, influencing performance, efficiency, and user experience. Understanding these distinctions can help consumers make informed choices when selecting equipment. Factors such as materials, size, and structural design play pivotal roles in how these elements function within a larger system.

Material Variations

One of the key aspects that differentiates cylindrical structures is the choice of materials. While some manufacturers opt for metal due to its durability and heat resistance, others may use high-quality plastics for lightweight and cost-effective solutions. Metallic components often provide better longevity and can withstand higher temperatures, while plastic alternatives may reduce overall weight and noise levels.

Structural Design Elements

The design layout can also greatly affect the efficiency of these elements. Some models feature a perforated design, allowing for improved air circulation, while others may have a solid configuration that can enhance heat retention. Additionally, variations in internal geometry can lead to differences in how evenly items are distributed and dried, ultimately impacting performance.

Signs of Worn Drum Parts

Identifying the symptoms of deterioration in key components is crucial for maintaining optimal functionality. Recognizing early indicators can prevent further damage and ensure efficient operation.

Unusual Noises: If you notice clanging, thumping, or grinding sounds during cycles, it may signal that certain elements have become loose or worn down.

Inefficient Performance: A noticeable decrease in drying efficiency can suggest that essential mechanisms are not functioning as they should. This may lead to longer drying times and increased energy consumption.

Visible Wear: Inspect for any signs of physical degradation, such as cracks, chips, or unusual discoloration. These can be clear indicators of wear and should be addressed promptly.

Excessive Vibration: If the appliance shakes more than usual, it might indicate imbalances or issues with internal components, which could compromise its overall stability.

Overheating: If the unit becomes excessively hot to the touch, it could point to problems with airflow or insulation, indicating that parts may need replacement to avoid overheating hazards.

Resources for DIY Repairs

For those who prefer to tackle home maintenance tasks themselves, accessing the right materials and guidance is essential. With an array of resources available, you can enhance your skills and efficiently resolve issues without professional assistance.

Online Platforms

- Video Tutorials: Websites like YouTube offer numerous step-by-step guides.

- DIY Blogs: Many bloggers share personal experiences and detailed instructions.

- Forums: Online communities provide a space for advice and troubleshooting tips.

Printed Resources

- User Manuals: Often available online, these documents offer manufacturer-specific information.

- Repair Guides: Books focused on home repairs can be found in libraries or bookstores.

- Trade Magazines: Subscriptions to relevant publications can keep you updated on techniques and tools.