Understanding the Parts Diagram of GE Electric Dryers

When it comes to maintaining home appliances, having a clear visual representation of their internal mechanisms can be invaluable. This overview aims to provide insights into the intricate elements that contribute to the functionality of your household device. By familiarizing yourself with these components, you can enhance your troubleshooting skills and ensure your appliance operates smoothly.

Each appliance consists of various essential elements that work in harmony to deliver optimal performance. Understanding these critical components not only aids in identifying potential issues but also empowers users to make informed decisions regarding repairs or replacements. This guide will explore the layout of these integral parts, highlighting their roles and significance.

By delving into the structure and arrangement of these mechanisms, users can gain a better appreciation for the engineering behind their appliances. Whether you’re a seasoned technician or a curious homeowner, this information will enhance your knowledge and confidence in managing your household equipment.

Understanding GE Electric Dryer Components

Maintaining and troubleshooting home appliances can be a daunting task, especially when it comes to understanding their internal workings. GE appliances, known for their reliability, incorporate a variety of elements that contribute to their efficient operation. Familiarity with these components not only aids in effective maintenance but also enhances the overall user experience.

Each appliance consists of a unique assembly of mechanisms that play specific roles in the drying process. From heating elements to control systems, these parts work in harmony to ensure optimal performance. Recognizing how each component functions can empower users to address minor issues independently, saving time and potentially costly repairs.

Moreover, knowing the layout and interconnections of these components can simplify the process of part replacement. When users are equipped with knowledge about which parts correspond to specific functions, they can make informed decisions about repairs and upgrades. This understanding ultimately leads to improved longevity and efficiency of the appliance.

Importance of Knowing Dryer Parts

Understanding the components of your laundry appliance is essential for effective maintenance and troubleshooting. Familiarity with these elements can help users ensure optimal performance and longevity of the equipment.

Here are several reasons why this knowledge is crucial:

- Improved Maintenance: Recognizing the key elements allows for timely servicing, preventing potential breakdowns.

- Informed Troubleshooting: When issues arise, knowing what each component does can help identify the root cause more quickly.

- Cost Efficiency: By understanding the system, users can perform minor repairs themselves, saving on service costs.

- Safety Awareness: Being aware of which parts are electrical or mechanical can enhance safety during operation and maintenance.

- Enhanced Performance: Regular checks of specific components can lead to better efficiency and effectiveness in drying clothes.

Ultimately, being knowledgeable about the inner workings of your appliance empowers you to maintain it properly and make informed decisions when problems occur.

Common Issues with Electric Dryers

Household appliances often face a range of problems that can affect their performance and efficiency. Understanding these common challenges can help users troubleshoot issues effectively and maintain their equipment in optimal condition.

Typical Problems Encountered

Several factors can contribute to malfunctions in these devices, leading to decreased functionality or complete failure. Users may notice that their unit is not heating, not spinning, or experiencing unusual noises during operation.

| Issue | Possible Cause | Suggested Solution |

|---|---|---|

| No heat | Faulty heating element | Inspect and replace the heating element if necessary. |

| Not spinning | Belt malfunction | Check the belt for wear and replace if broken. |

| Unusual noises | Loose or damaged components | Tighten or replace the affected parts. |

Maintenance Tips

Regular maintenance can prevent many common issues. Cleaning lint traps, checking hoses for blockages, and ensuring proper ventilation can significantly enhance the lifespan and performance of these appliances.

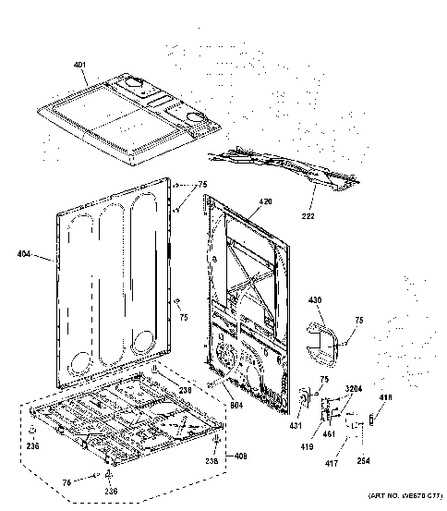

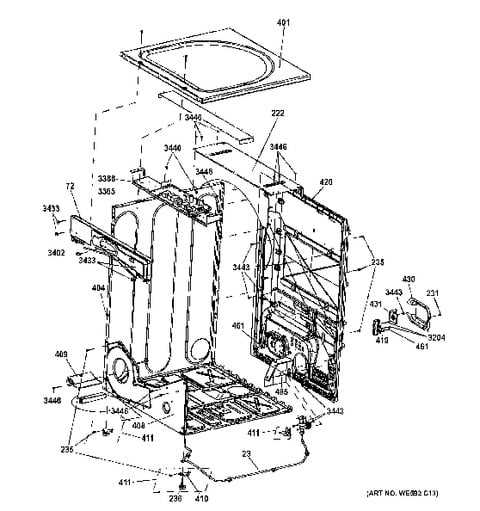

Overview of Dryer Parts Diagram

This section provides a comprehensive look at the essential components involved in a typical drying appliance. Understanding these elements is crucial for troubleshooting and maintenance, ensuring optimal performance and longevity of the unit. By familiarizing oneself with the various sections and their functions, users can make informed decisions regarding repairs and replacements.

Key Components

Among the various elements, several play pivotal roles in the overall functionality. The heating mechanism generates warmth necessary for moisture removal, while the drum facilitates the tumbling action that helps in evenly distributing heat and airflow. Additional features, such as lint filters and exhaust systems, contribute to both efficiency and safety, preventing potential hazards.

Importance of Familiarity

Acquaintance with these components empowers users to identify issues more quickly and accurately. Routine inspections can prevent minor problems from escalating, thus saving time and costs associated with repairs. Furthermore, understanding the layout and relationship between these sections enhances troubleshooting skills, making maintenance tasks simpler and more effective.

Key Components of GE Dryers

Understanding the essential elements of GE appliances is crucial for efficient operation and maintenance. Each component plays a vital role in ensuring optimal performance and longevity, contributing to a seamless user experience. Familiarity with these parts can aid in troubleshooting and enhance overall functionality.

Heating Elements

Heating elements are responsible for generating the warmth necessary for drying. These components ensure that the air circulated within the unit reaches the desired temperature, allowing fabrics to dry thoroughly and effectively. Regular checks and maintenance can prevent issues related to inadequate heating.

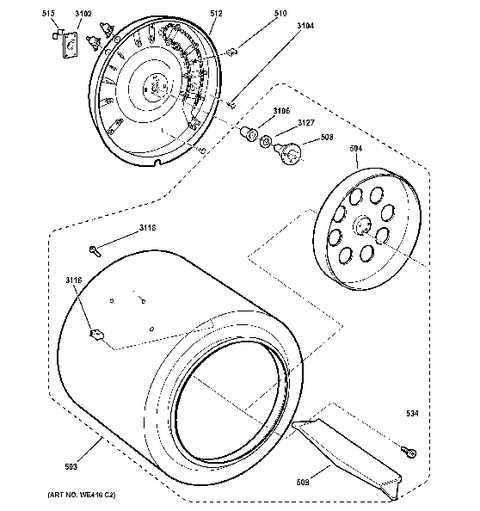

Drum and Agitator

The drum serves as the main chamber where items are placed for drying. Its design allows for efficient movement and distribution of air. An agitator, when present, enhances the tumbling action, ensuring that fabrics are evenly exposed to heat. This combination is crucial for achieving consistent results with each load.

Identifying the Heating Element

Recognizing the key component responsible for generating warmth is crucial for ensuring optimal performance of your appliance. This element plays a vital role in transforming electrical energy into heat, enabling effective drying of fabrics. Understanding how to locate and identify this component will help you troubleshoot issues and maintain your device.

To pinpoint the heating element, follow these steps:

- Unplug the appliance to ensure safety.

- Access the rear panel or the bottom cover, depending on your model.

- Look for a metal coil or rod, typically encased in a protective shield.

Here are some characteristics to help you identify it:

- Color: Often a metallic gray or silver.

- Shape: Generally cylindrical or coiled.

- Size: Varies, but typically spans several inches in length.

If you encounter any difficulty, consult the user manual for specific guidance on your appliance’s configuration. Proper identification is essential for effective repairs and ensuring longevity.

Function of the Drum Roller

The drum roller plays a crucial role in the efficient operation of a household appliance designed for drying textiles. This component ensures smooth and seamless movement of the drum, which is essential for optimal performance. A well-functioning roller minimizes friction and wear, contributing to the longevity of the appliance and enhancing the drying process.

| Function | Description |

|---|---|

| Support | The roller supports the weight of the drum, allowing it to rotate freely during operation. |

| Stability | By providing a stable base, the roller helps prevent excessive vibrations that can lead to noise and mechanical issues. |

| Friction Reduction | It reduces friction between the drum and the appliance’s frame, promoting efficient movement and energy use. |

| Durability | A durable roller can withstand repeated use, ensuring long-term functionality of the appliance. |

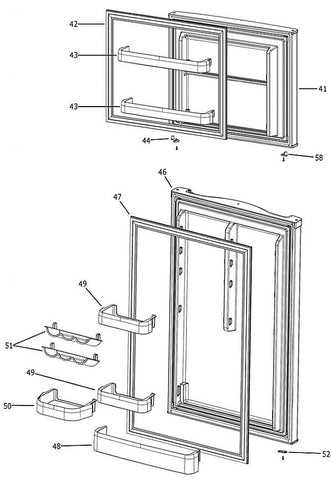

Role of the Door Switch

The door switch is a crucial component in the operation of a household appliance, ensuring safety and functionality. It plays a vital role in controlling the appliance’s power supply, preventing accidents and malfunctions. By detecting whether the door is open or closed, it helps maintain the integrity of the drying process.

Functionality of the Door Switch

This component serves multiple purposes that enhance user experience and appliance efficiency. When the door is closed, the switch allows the device to operate; when opened, it interrupts the cycle. This mechanism not only safeguards against potential hazards but also conserves energy by halting operation when access is needed.

Common Issues and Maintenance

Like any mechanical element, the door switch may encounter problems over time. Issues such as wear and tear or electrical faults can hinder its performance. Regular inspection and maintenance can help identify these issues early, ensuring safe and efficient operation.

| Issue | Symptoms | Solution |

|---|---|---|

| Faulty Switch | Device won’t start | Replace the switch |

| Worn Wiring | Intermittent operation | Inspect and repair wiring |

| Dirt and Debris | Door not sealing properly | Clean the switch area |

Understanding the Belt System

The belt mechanism plays a crucial role in the operation of many household appliances, providing the necessary movement to ensure proper functioning. This system consists of several components that work together harmoniously, allowing for the smooth transfer of energy from the motor to the various elements within the machine.

The main component of this system is the belt itself, which is typically made from durable materials designed to withstand wear and tear over time. It is responsible for connecting the motor to the drum or other moving parts, facilitating their rotation during operation.

Maintenance of the belt system is essential for optimal performance. Regular checks can help identify signs of wear, such as fraying or stretching, which may lead to inefficiency or even malfunction. Addressing these issues promptly can prolong the life of the appliance and enhance its effectiveness.

Understanding how this mechanism functions allows users to troubleshoot potential problems effectively. Knowledge of the belt’s role and its condition can empower individuals to take action before minor issues escalate into significant repairs.

Exploring the Control Panel Layout

The control panel serves as the command center for managing various functions and settings of the appliance. Understanding its arrangement and features is crucial for effective operation and maintenance. Each element is strategically placed to provide intuitive access and enhance user experience.

Typically, the interface includes a selection of dials, buttons, and digital displays, each designed for specific tasks. The controls may vary in style, ranging from simple rotary knobs to modern touch-sensitive screens. Familiarizing oneself with these components can significantly streamline the process of adjusting cycles, temperatures, and other settings.

Moreover, the layout often incorporates indicators and status lights that provide real-time feedback on the machine’s performance. Recognizing these signals is essential for troubleshooting issues and ensuring optimal functionality. Overall, a well-organized control panel not only simplifies operation but also enhances the overall efficiency of the device.

Significance of the Thermostat

The thermostat plays a crucial role in regulating temperature, ensuring optimal performance and safety in various appliances. By monitoring heat levels, it maintains a consistent environment, preventing overheating and enhancing efficiency.

One of the primary functions of this component is to control the heating element. When temperatures reach a predetermined threshold, the thermostat activates or deactivates the heat source, creating a balanced cycle. This not only preserves the integrity of items being dried but also contributes to energy conservation.

Furthermore, a malfunctioning thermostat can lead to numerous issues, including inadequate drying or potential damage to the unit. Therefore, regular checks and timely replacements are essential for maintaining functionality and extending the lifespan of the appliance.

Maintenance Tips for Dryer Parts

Regular upkeep of your appliance is essential for optimal performance and longevity. By taking proactive steps, you can ensure that all components function smoothly, reducing the risk of malfunctions and enhancing efficiency. Here are some key strategies to maintain your equipment effectively.

1. Clean the Lint Filter: Always remove lint from the filter after each use. A clogged filter can lead to reduced airflow, increasing drying time and potentially causing overheating.

2. Inspect Ventilation Ducts: Periodically check the ventilation system for blockages. Dust and debris can accumulate, hindering airflow and risking safety hazards. Clear any obstructions to promote efficient operation.

3. Check Seals and Gaskets: Examine door seals for wear and tear. Damaged seals can lead to heat loss and inefficient drying cycles. Replace any compromised components to maintain optimal performance.

4. Clean the Interior: Every few months, wipe down the interior of your appliance to prevent buildup of dust and lint. This simple step can enhance airflow and reduce odors.

5. Schedule Professional Servicing: Consider having your appliance serviced by a professional annually. They can identify potential issues before they escalate, ensuring your unit remains in top condition.

6. Monitor Performance: Pay attention to any changes in drying efficiency or unusual noises. Addressing these concerns early can prevent larger problems down the line.

By implementing these maintenance tips, you can enhance the performance of your appliance, ensuring it serves you well for years to come.

How to Source Replacement Parts

Finding components for home appliances can be a daunting task, but with the right approach, it can become a straightforward process. Understanding where to look and what to consider can save time and money while ensuring your equipment runs efficiently. Whether you need a specific item or just want to explore options, there are several strategies to follow.

Utilize Online Resources

One of the most effective ways to locate the necessary components is through online platforms. Numerous websites specialize in appliance repair supplies, offering detailed listings and often including customer reviews. Search by model number or description to narrow down your options. Websites like e-commerce giants and dedicated repair shops provide comprehensive databases that can aid in your search.

Consult Local Repair Shops

Another valuable avenue is to reach out to local service centers. Many repair professionals maintain inventories of common items or can order specific components for you. Building a relationship with these experts can also provide insights into the best quality options available, along with guidance on installation or troubleshooting.

In summary, sourcing components requires a blend of online research and local expertise. By leveraging these resources, you can ensure your appliance remains in optimal condition.