Understanding the Unimac Dryer Parts Diagram for Better Maintenance

The efficient functioning of any machine relies heavily on the intricate network of its components. Each element plays a vital role, contributing to the overall performance and longevity of the equipment. Gaining insight into these pieces can greatly enhance your ability to troubleshoot and maintain your device effectively.

In this section, we will explore the essential features of a commonly used machine, focusing on how each component interacts with the others. Understanding these relationships will empower you to make informed decisions regarding repairs and upgrades.

By delving into the specifics of these mechanisms, you will uncover the ultimate path to enhancing your appliance’s efficiency. Whether you’re a novice or an experienced user, this knowledge is invaluable for ensuring optimal operation.

Understanding Unimac Dryers

This section aims to explore the essential components and functionality of industrial drying equipment. Understanding these elements is crucial for optimal performance and maintenance, ensuring longevity and efficiency in operations.

| Component | Function |

|---|---|

| Heating Element | Provides the necessary heat to evaporate moisture. |

| Drum | Houses items during the drying process and allows for even distribution of heat. |

| Blower | Circulates air to enhance moisture removal. |

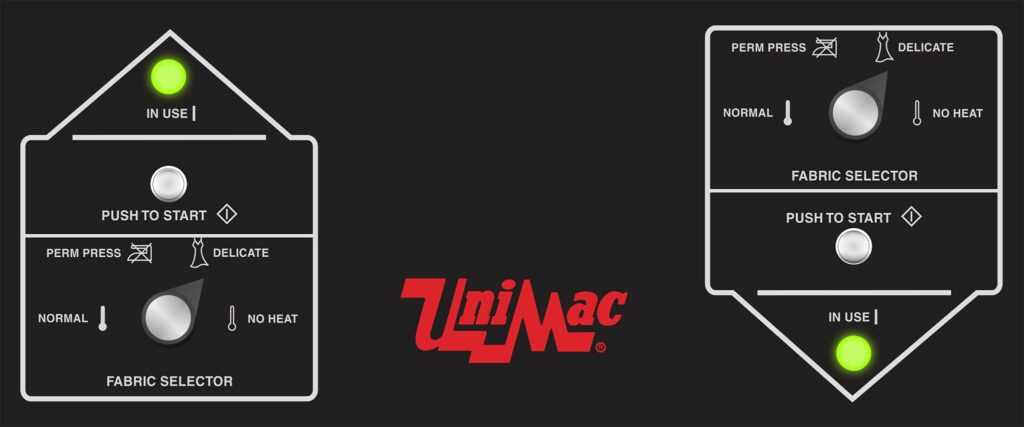

| Control Panel | Allows users to set and monitor drying parameters. |

| Filter | Catches lint and debris to maintain efficiency. |

Key Components of Unimac Dryers

Understanding the essential elements of a commercial drying machine is crucial for efficient operation and maintenance. Each component plays a significant role in ensuring optimal performance and longevity, making it important to recognize their functions and interconnections.

Essential Elements

- Drum: The primary chamber where materials are placed for drying. Its design impacts airflow and drying efficiency.

- Heating System: Provides the necessary heat to evaporate moisture. It can be electric or gas-powered.

- Motor: Powers the drum and often the fan, ensuring even distribution of air and consistent movement of materials.

- Control Panel: The interface for operators to set drying cycles, temperatures, and timings, facilitating user-friendly operation.

Supportive Components

- Fans: Enhance airflow throughout the system, improving drying efficiency.

- Exhaust System: Removes moist air from the machine, preventing buildup and ensuring effective drying.

- Belts and Pulleys: Enable movement of the drum and contribute to the overall functionality of the unit.

Each of these components must work harmoniously to achieve the best results, highlighting the importance of regular maintenance and timely replacements when necessary.

Importance of Dryer Maintenance

Regular upkeep of household appliances is crucial for ensuring their longevity and efficiency. Proper care not only enhances performance but also minimizes the risk of breakdowns. By investing time in routine checks and servicing, users can avoid costly repairs and extend the lifespan of their equipment.

Efficiency and Energy Savings

Maintaining appliances helps in optimizing their performance, leading to reduced energy consumption. When machines operate efficiently, they require less power, which translates into lower utility bills. Routine maintenance checks can identify issues that hinder performance, allowing for timely interventions that keep energy costs down.

Safety Considerations

Neglecting regular maintenance can pose safety hazards. Accumulated lint, for instance, can lead to fire risks, while malfunctioning components may result in electrical issues. Ensuring that appliances are in good working condition not only protects the equipment but also safeguards the home and its occupants from potential dangers.

Common Issues with Dryer Parts

Understanding the frequent challenges faced by components in a typical drying appliance is essential for maintaining optimal functionality. Many of these issues can lead to inefficiencies or complete failures, highlighting the importance of regular inspections and timely replacements.

Overheating Problems

One prevalent issue is overheating, often caused by blockages or malfunctioning sensors. Excessive heat can damage internal elements, resulting in a shortened lifespan or potential hazards. Regular cleaning and monitoring can help mitigate this risk.

Noisy Operation

Another common complaint is an unusual noise during operation, which may indicate wear and tear on moving parts. Loose belts or faulty bearings are typical culprits. Addressing these sounds early can prevent further damage and maintain performance.

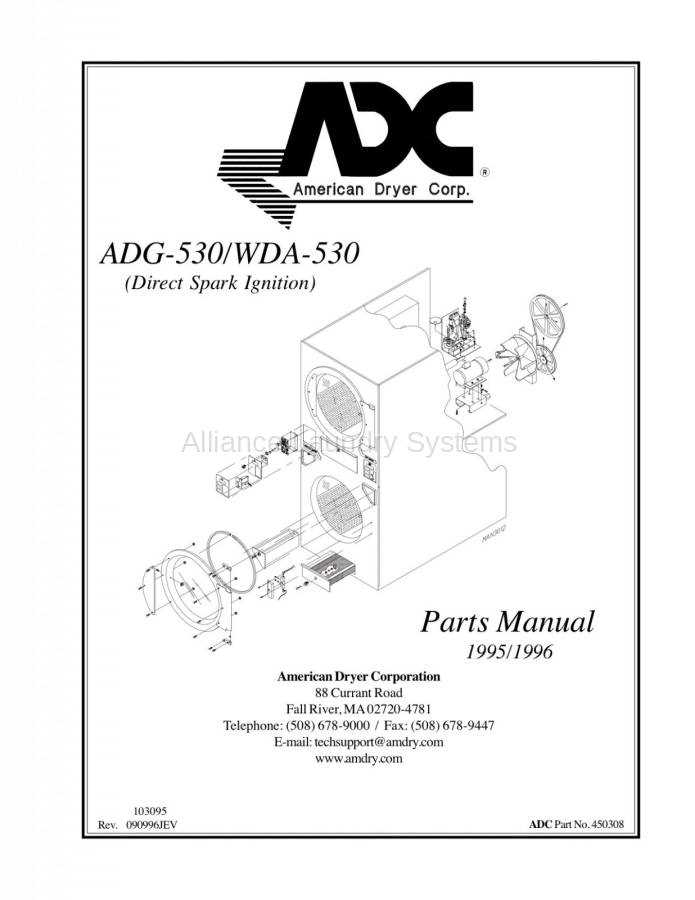

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repairs. These illustrations serve as valuable guides, helping users identify and locate specific elements within a system. Here’s how to interpret these visuals effectively.

- Familiarize Yourself with Symbols: Different icons represent various parts. Take time to learn what each symbol means.

- Identify the Layout: Examine the arrangement of components. Most illustrations follow a logical flow, making it easier to trace connections.

- Note the Labels: Each part usually has a corresponding label. Pay attention to these annotations, as they provide crucial information.

- Understand the Reference Numbers: Components are often assigned numbers for easy identification. Use these to cross-reference with lists or catalogs.

- Look for Color Codes: Colors can indicate different functionalities or categories of elements, aiding in quicker identification.

By mastering these techniques, you’ll enhance your ability to navigate visual guides, making repairs and replacements more straightforward and efficient.

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and troubleshooting. Proper tools not only enhance efficiency but also ensure safety during the repair process.

- Screwdrivers: Various sizes and types, including flathead and Phillips, are essential for removing and securing screws.

- Wrenches: Adjustable and socket wrenches help in loosening or tightening nuts and bolts.

- Pliers: Needle-nose and standard pliers are useful for gripping and manipulating small components.

- Multimeter: This tool is vital for testing electrical connections and diagnosing issues.

- Flashlight: A bright light source aids visibility in tight or dark spaces.

Equipping yourself with these fundamental tools can significantly ease the repair process and lead to successful outcomes.

Replacing Worn-Out Components

Over time, essential elements of your equipment may degrade, impacting performance and efficiency. Identifying and replacing these deteriorated components is crucial for maintaining optimal functionality. Regular inspection and timely intervention can extend the lifespan of the machine and prevent costly breakdowns.

Common Signs of Wear

Recognizing the indicators of wear is vital for prompt maintenance. Look for unusual noises, decreased efficiency, or visible damage. These symptoms often signal that specific components need attention.

Replacement Process

When replacing worn components, follow these steps to ensure a smooth process:

| Step | Description |

|---|---|

| 1 | Power off the equipment and unplug it to ensure safety. |

| 2 | Access the necessary areas by removing protective covers or panels. |

| 3 | Carefully detach the old components, noting their placement. |

| 4 | Install the new parts, ensuring they are securely fitted. |

| 5 | Reassemble the unit and restore power to test functionality. |

By following these guidelines, you can effectively replace outdated elements and ensure the machine operates efficiently for years to come.

Upgrading Dryer Efficiency

Enhancing the performance of a drying appliance can lead to significant energy savings and improved effectiveness. By focusing on key components and maintenance practices, one can optimize the functionality and lifespan of the equipment. Implementing strategic upgrades not only streamlines operations but also reduces overall costs associated with energy consumption.

Regularly inspecting and cleaning filters is crucial, as clogged filters can restrict airflow and diminish efficiency. Replacing worn-out or damaged elements can restore optimal performance, ensuring that the machine operates at peak capacity. Additionally, utilizing advanced technology such as moisture sensors can provide real-time feedback, allowing for more precise drying cycles and minimizing energy waste.

Another effective strategy is to consider insulation improvements. Properly insulating ductwork and the appliance itself can prevent heat loss, further enhancing energy efficiency. Investing in high-efficiency models or components designed with energy-saving features can also yield long-term benefits, making the drying process faster and more environmentally friendly.

Safety Tips During Repairs

When undertaking maintenance tasks, ensuring personal safety and equipment integrity is paramount. Proper precautions not only protect the individual but also prolong the lifespan of the machinery. Understanding basic safety measures can significantly reduce the risk of accidents and injuries.

Preparation and Precautions

Before starting any repair work, it’s essential to gather necessary tools and materials. Make sure to turn off power sources to prevent electric shocks. Wearing appropriate personal protective equipment, such as gloves and goggles, can provide an additional layer of safety.

Safe Working Environment

A well-organized workspace can prevent mishaps. Ensure the area is clean and free from clutter, which can be hazardous. Good lighting also aids in performing tasks accurately without strain or injury.

| Tip | Description |

|---|---|

| Disconnect Power | Always turn off power before starting repairs. |

| Use Proper Tools | Employ tools that are suited for the specific task. |

| Wear Safety Gear | Protective equipment is essential for personal safety. |

| Stay Focused | Avoid distractions to maintain concentration on the task. |

Where to Find Replacement Parts

When equipment malfunctions, locating the necessary components for repair becomes essential for restoring functionality. There are numerous avenues to explore, each offering a range of options tailored to your specific needs.

Online Retailers

Many online platforms specialize in offering a vast selection of components. These websites often feature user-friendly search functions, allowing you to quickly identify the items you need. Ensure you choose reputable sites with customer reviews to guarantee quality.

Local Supply Stores

Visiting nearby supply shops can provide immediate access to essential components. Local retailers often stock commonly needed items and may even assist with special orders. Building a relationship with store staff can enhance your search experience.

Expert Tips for Troubleshooting

Tackling issues with your equipment can be daunting, but with the right approach, you can identify and resolve common problems effectively. This section provides essential insights to help you navigate through challenges and ensure optimal performance.

- Understand the Basics: Familiarize yourself with the main components and their functions to streamline the troubleshooting process.

- Check Power Supply: Ensure that the unit is receiving adequate power; inspect cords and connections for damage.

- Listen for Unusual Sounds: Pay attention to any abnormal noises that may indicate mechanical failures or blockages.

- Inspect Filters and Vents: Regularly clean and check filters and ventilation systems to prevent overheating and inefficiency.

By following these guidelines, you can delve into the issues more confidently and work towards the ultimate solution.