Understanding the Parts of Echo HC-1500

In the realm of outdoor equipment, comprehending the various elements that contribute to a machine’s functionality is essential for effective maintenance and repair. Each unit consists of a collection of intricate parts, all working in harmony to ensure optimal performance. This section aims to illuminate the essential components, allowing users to navigate the intricacies of their devices with greater confidence.

By gaining insight into the assembly and arrangement of these elements, operators can troubleshoot issues more efficiently and perform necessary upgrades. A well-rounded understanding not only enhances the user experience but also extends the lifespan of the equipment. Through careful examination of the internal configurations, one can appreciate the design and engineering that go into crafting such specialized machinery.

Moreover, recognizing the specific functions of each component can lead to more informed decisions regarding repairs and replacements. This knowledge empowers users to take charge of their tools, fostering a sense of independence and capability. As we delve deeper into the specifics, a clearer picture of how these components interact will emerge, paving the way for more effective use and maintenance.

This section delves into the essential elements that constitute the functionality and efficiency of the machinery. Understanding these components is crucial for proper maintenance, optimal performance, and effective troubleshooting.

| Component | Description |

|---|---|

| Engine | The heart of the equipment, providing the necessary power for operation. |

| Fuel System | Responsible for delivering fuel to the engine, ensuring smooth performance. |

| Air Filter | Prevents dust and debris from entering the engine, prolonging its life. |

| Starter | Facilitates the initial ignition of the engine, enabling the machine to start. |

| Control Handle | Allows the operator to manipulate the equipment with ease and precision. |

| Exhaust System | Manages the release of gases produced during combustion, maintaining safety and efficiency. |

Functionality of Each Part

This section delves into the various components of the equipment, highlighting their specific roles and contributions to the overall performance. Understanding the function of each element is crucial for effective operation and maintenance, ensuring optimal efficiency and longevity.

Main Components Overview

- Engine: Provides the necessary power to drive the entire system, converting fuel into mechanical energy.

- Throttle Control: Regulates the engine’s power output, allowing the operator to adjust speed and performance based on tasks.

- Fuel Tank: Stores the required fuel, ensuring a steady supply for the engine to function effectively.

- Air Filter: Protects the engine from debris and contaminants, maintaining air quality for efficient combustion.

Supporting Elements

- Exhaust System: Directs harmful gases away from the engine, enhancing safety and efficiency.

- Ignition System: Initiates the combustion process by creating a spark, crucial for starting the engine.

- Drive Mechanism: Transmits power from the engine to the operational components, ensuring smooth functionality.

- Control Panel: Allows the operator to monitor and adjust settings, facilitating user-friendly operation.

Importance of Regular Maintenance

Consistent upkeep is essential for ensuring the longevity and optimal performance of equipment. Regular attention helps identify potential issues before they escalate, allowing for timely interventions that can save both time and resources. By committing to a maintenance schedule, users can enhance efficiency and reliability, ultimately extending the lifespan of their tools.

Benefits of Routine Care

- Prevention of Major Failures: Regular check-ups can prevent minor problems from developing into significant failures, reducing downtime.

- Cost Savings: Addressing small issues early can lead to significant savings on repairs and replacements in the long run.

- Enhanced Safety: Well-maintained equipment reduces the risk of accidents and injuries, ensuring a safer working environment.

- Improved Efficiency: Routine maintenance ensures that tools operate at peak efficiency, leading to better overall performance.

Key Maintenance Practices

- Regular Cleaning: Keeping equipment clean prevents the buildup of dirt and debris, which can hinder performance.

- Inspection: Frequent visual checks help identify wear and tear, allowing for early intervention.

- Lubrication: Ensuring moving parts are adequately lubricated reduces friction and wear, promoting smoother operation.

- Replacement of Worn Components: Timely replacement of worn-out parts is crucial for maintaining functionality.

Common Issues and Solutions

In the realm of outdoor power equipment, users often encounter various challenges that can hinder performance. Understanding these frequent complications and their remedies can enhance the longevity and effectiveness of your tools. Below are some prevalent concerns along with practical solutions.

Frequent Challenges

- Difficulty starting the engine

- Inefficient fuel consumption

- Unusual noise during operation

- Power loss during use

Practical Solutions

-

Starting Issues:

- Check the fuel level and quality.

- Inspect the spark plug for wear or damage.

- Ensure the air filter is clean and unobstructed.

-

Ineffective Fuel Use:

- Adjust the carburetor settings as needed.

- Use fresh, high-quality fuel.

- Regularly clean the fuel filter to prevent blockages.

-

Unusual Noise:

- Examine for loose or damaged components.

- Ensure proper lubrication of moving parts.

- Inspect the exhaust system for leaks.

-

Power Loss:

- Check for clogs in the air intake system.

- Assess the condition of the spark plug and replace if necessary.

- Evaluate the overall maintenance schedule and adhere to it.

Replacement Parts Availability

Access to essential components for machinery maintenance is crucial for ensuring optimal performance and longevity. This section highlights the options available for sourcing these necessary items, making it easier for users to keep their equipment running smoothly. Whether for routine upkeep or unexpected repairs, having reliable access to quality replacements is vital.

Sources for Components

Numerous suppliers offer a wide selection of components to meet various needs. Online retailers, specialized stores, and local dealers typically carry a range of items suitable for different models. It’s advisable to compare prices and availability across multiple platforms to find the best options. Additionally, checking manufacturer websites can provide insights into recommended retailers and authorized distributors.

Aftermarket Options

In addition to original equipment, aftermarket alternatives can often provide cost-effective solutions. Many manufacturers produce compatible components that meet or exceed the performance of the originals. However, it is essential to verify the quality and compatibility of these alternatives before making a purchase, as this can impact the overall functionality of the equipment.

How to Identify Genuine Parts

Ensuring the authenticity of components is crucial for maintaining the functionality and longevity of your equipment. Distinguishing between original and counterfeit items can greatly affect performance and reliability. Here are some effective strategies to recognize authentic replacements.

Check Packaging and Labels

Authentic items typically come in high-quality packaging with clear branding and product information. Look for inconsistencies in fonts, colors, or logos. Genuine products often include unique identifiers such as serial numbers or barcodes that can be verified through the manufacturer’s website.

Research Authorized Dealers

Purchasing from verified retailers is essential. Authorized vendors not only guarantee authenticity but also provide access to proper documentation and support. Avoid buying from unknown sources or unverified online marketplaces, as these may offer imitation goods.

Trust Your Instincts: If a deal seems too good to be true, it likely is. Prioritize quality and authenticity over price to ensure your equipment operates at its best.

Step-by-Step Disassembly Guide

This guide provides a comprehensive approach to carefully taking apart a specific equipment model. Following these detailed steps will help ensure a smooth disassembly process while minimizing the risk of damaging any components. It is important to work methodically, keeping track of each piece as it is removed.

Preparation for Disassembly

Before starting the disassembly process, gather all necessary tools, including screwdrivers and pliers. Make sure to have a clean workspace to organize the components as you remove them. Disconnect any power sources to ensure safety while handling the equipment.

Removing the Exterior Housing

Begin by loosening the screws securing the outer casing. Carefully lift off the housing, being mindful of any attached cables or connectors. As you progress, note the arrangement of parts to facilitate reassembly later. Take your time to avoid unnecessary force that could lead to breakage.

Tools Required for Repairs

When undertaking maintenance or restoration tasks, having the right instruments is crucial for achieving optimal results. A well-equipped toolkit not only enhances efficiency but also ensures safety and precision during the repair process.

Below is a list of essential tools that will aid in various repair activities:

| Tool | Description |

|---|---|

| Wrench Set | Useful for loosening or tightening bolts and nuts. |

| Screwdriver Set | Essential for removing and securing screws of different sizes and types. |

| Pliers | Handy for gripping, twisting, and cutting wires or components. |

| Torque Wrench | Ensures that fasteners are tightened to the correct specifications. |

| Multimeter | Helps in measuring electrical values and diagnosing issues. |

| Safety Goggles | Protects eyes from debris and chemicals during repairs. |

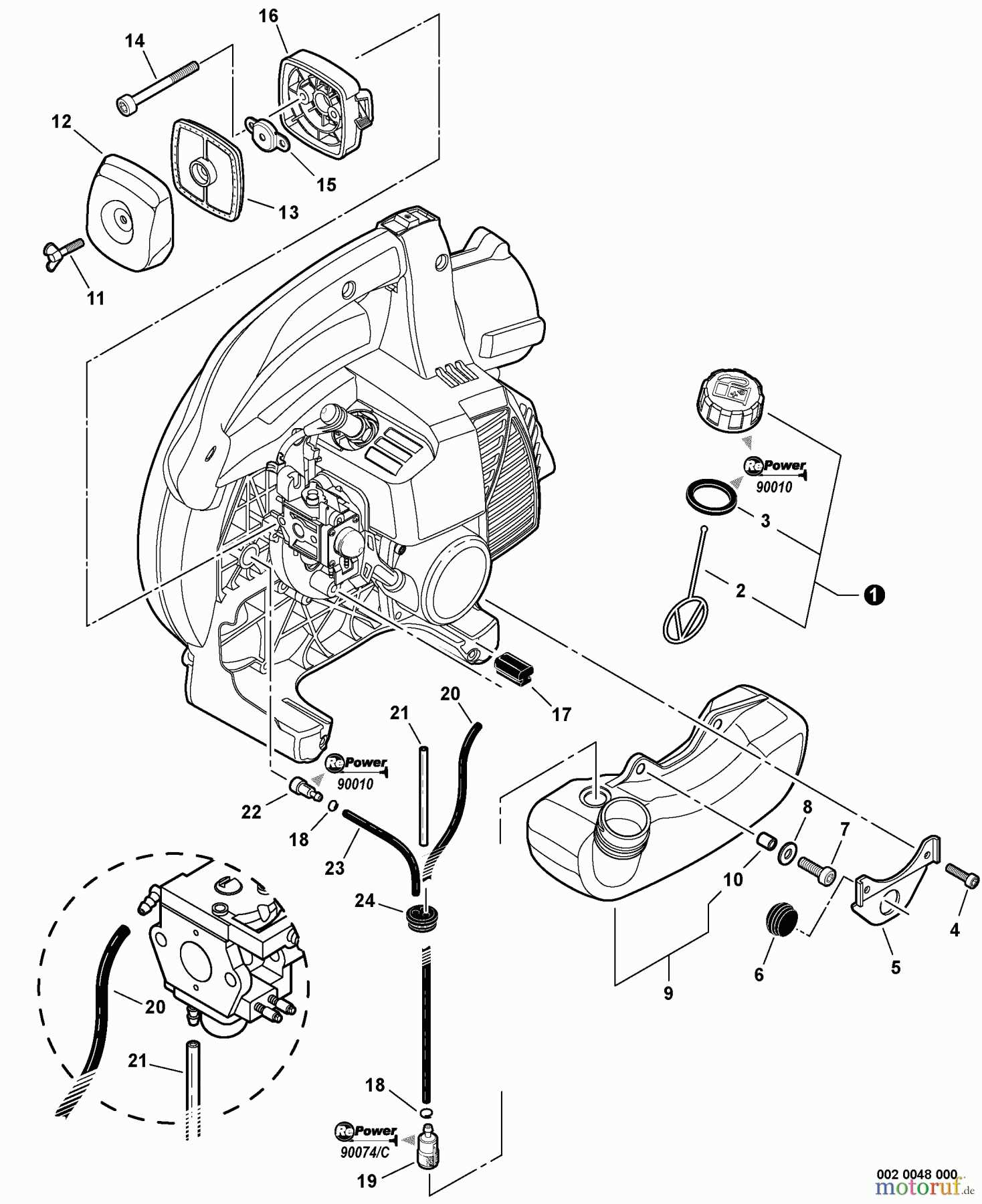

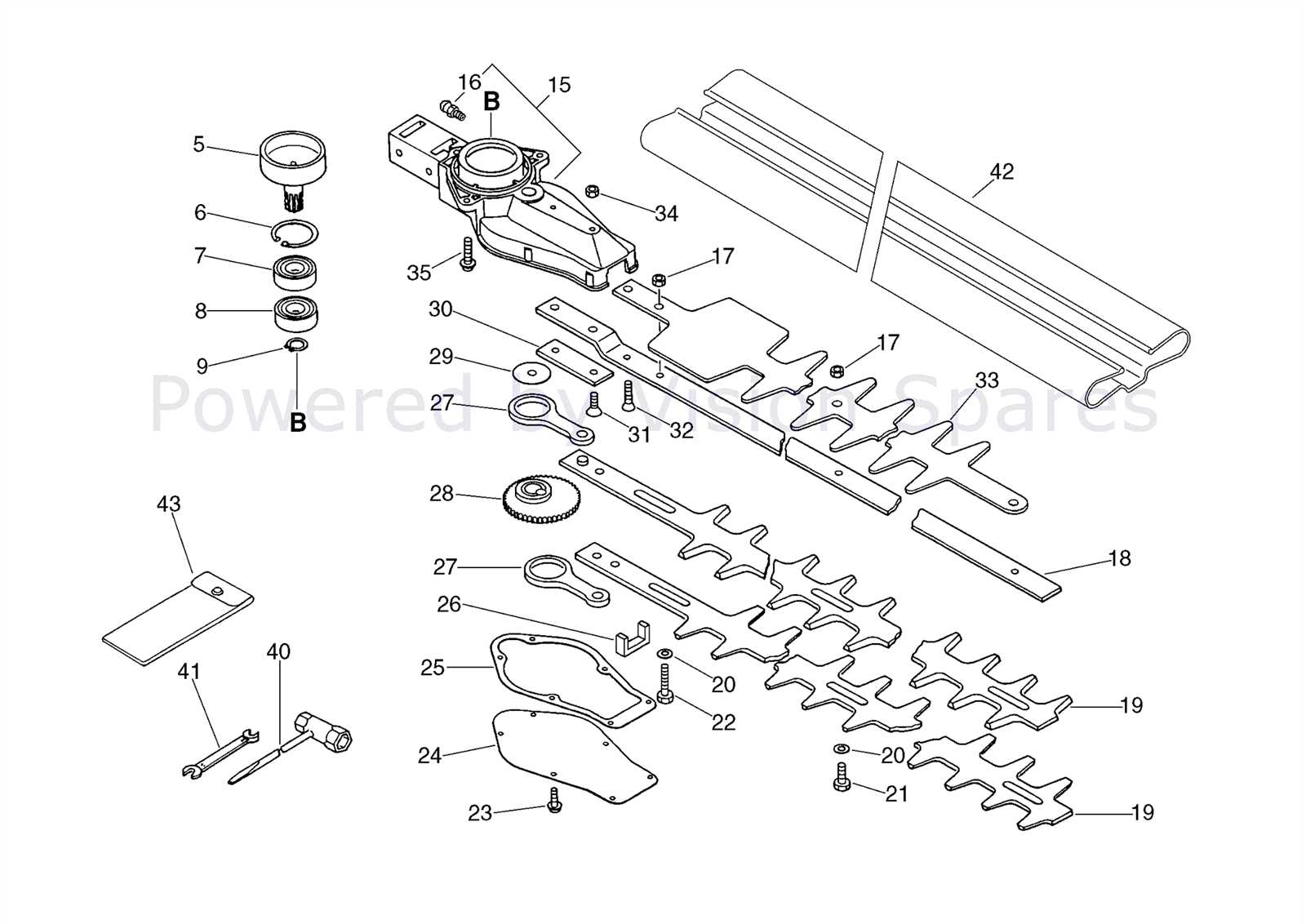

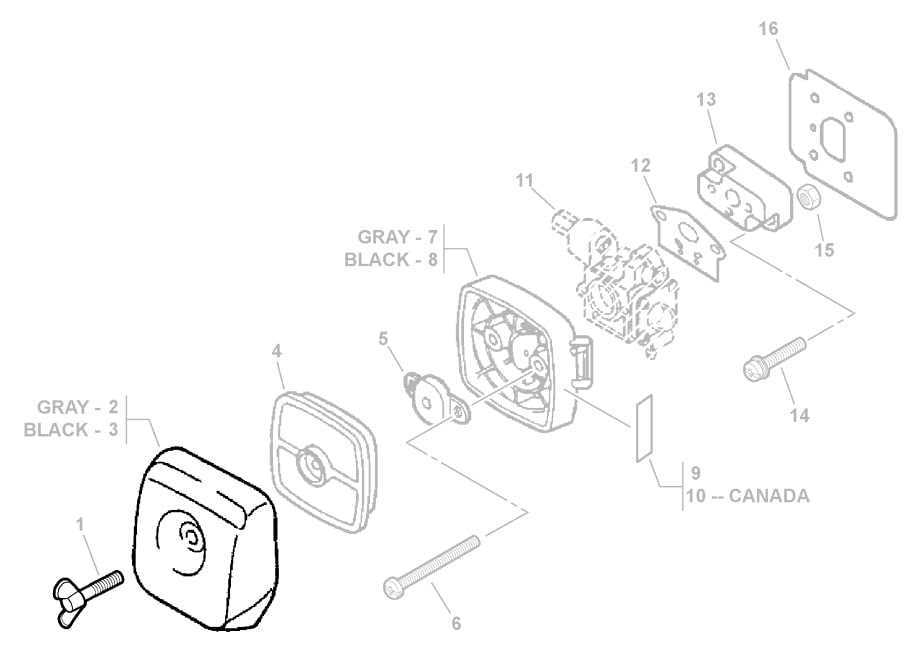

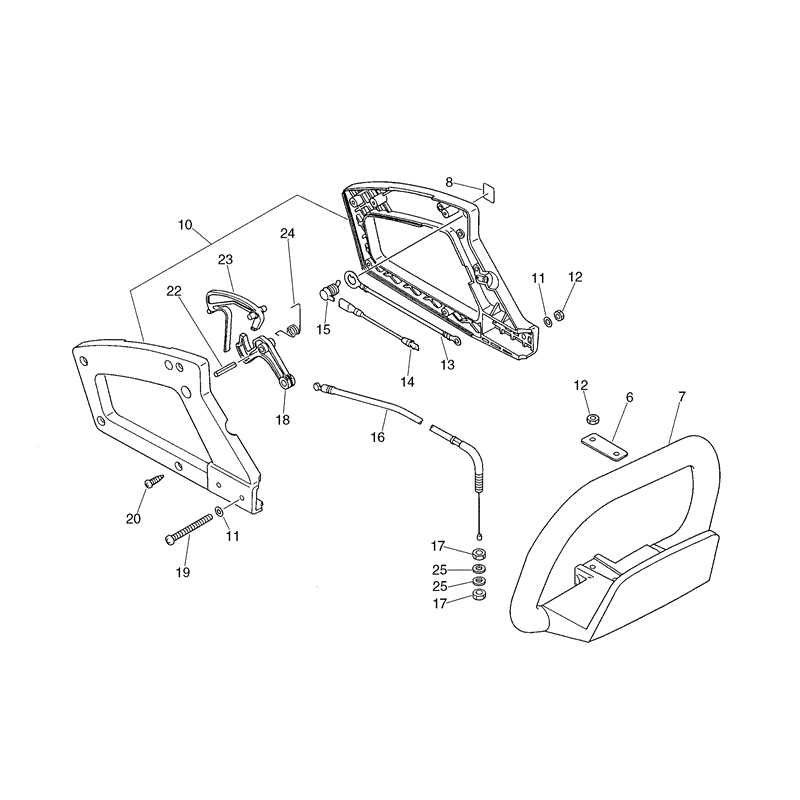

Visual Reference for Assembly

In the process of reassembling equipment, having a clear visual guide is essential for ensuring that each component is correctly positioned and securely fitted. This section aims to provide a comprehensive overview that will assist in identifying individual elements and their respective placements, making the assembly process more efficient and straightforward.

Component Overview

Understanding the various components involved is crucial for a successful reassembly. Below is a detailed table highlighting the key elements and their functions within the assembly. This reference will aid in recognizing each part’s role and location during the reassembly process.

| Component Name | Function |

|---|---|

| Base Unit | Serves as the main support structure for other parts. |

| Motor Assembly | Powers the device, enabling it to function effectively. |

| Control Panel | Facilitates user interaction, allowing for adjustments and settings. |

| Safety Guard | Protects users from potential hazards during operation. |

| Fasteners | Secure various components together, ensuring structural integrity. |

Assembly Tips

For optimal results, follow these tips during the assembly process. Begin by organizing all components to streamline the workflow. Refer to the visual guide frequently to confirm the correct positioning of each part. Ensure that all fasteners are tightened adequately to prevent any future issues. Finally, conduct a thorough inspection once assembly is complete to verify that everything is in its rightful place.

Upgrades for Enhanced Performance

Improving the efficiency and effectiveness of outdoor power equipment can significantly enhance its overall functionality. By considering various enhancements, users can achieve optimal performance and prolong the lifespan of their tools. Below are some recommended upgrades that can make a noticeable difference.

Engine Enhancements

- Performance Carburetor: Upgrading to a high-performance carburetor can improve fuel delivery and increase power output.

- Exhaust System: Installing a performance exhaust system can enhance airflow, leading to better combustion and increased horsepower.

- Ignition System: A high-efficiency ignition module can provide stronger spark and improved engine response.

Accessory Improvements

- Cutting Blades: Using specialized cutting blades designed for specific tasks can enhance cutting efficiency and reduce wear.

- Fuel Filter: A high-quality fuel filter ensures cleaner fuel reaches the engine, optimizing performance.

- Handle Grips: Upgrading to ergonomic handle grips can enhance comfort and control during operation.

Implementing these enhancements can lead to improved performance, increased reliability, and a more enjoyable user experience. Each upgrade contributes to a more effective and efficient tool, ensuring it meets the demands of various tasks.

Resources for Further Assistance

When seeking support for equipment maintenance or troubleshooting, various resources can provide valuable information. These materials are designed to guide users in understanding their devices and resolving common issues effectively.

Online Communities: Engaging with online forums and user groups can be an excellent way to connect with fellow enthusiasts. Members often share experiences, tips, and solutions that can enhance your knowledge and troubleshooting skills.

Official Documentation: Accessing manufacturer-provided manuals and guides can ensure you have accurate information about your device’s features and functions. These documents often include troubleshooting sections that address frequent concerns.

Video Tutorials: Platforms like YouTube host a wealth of instructional videos created by users. These visual aids can help clarify complex processes and demonstrate step-by-step solutions for various challenges.

Local Experts: Consulting with local repair professionals or service centers can provide personalized assistance. They possess hands-on experience and may offer insights that are not readily available in online resources.

By utilizing these resources, you can enhance your understanding and effectively address any concerns that may arise with your equipment.