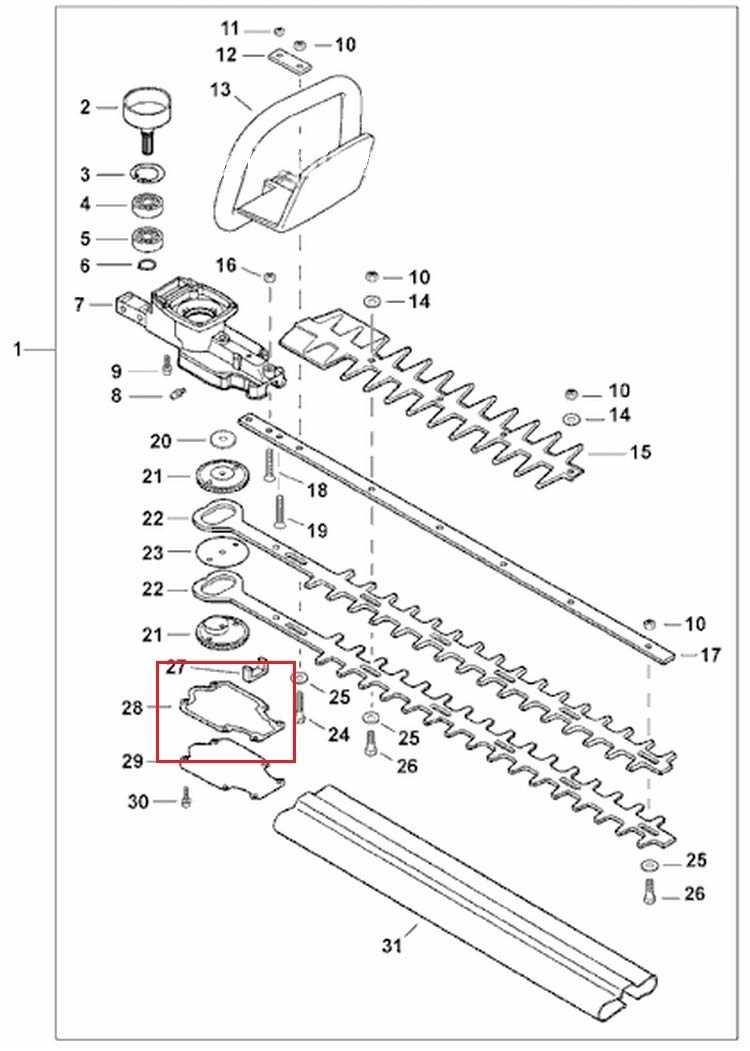

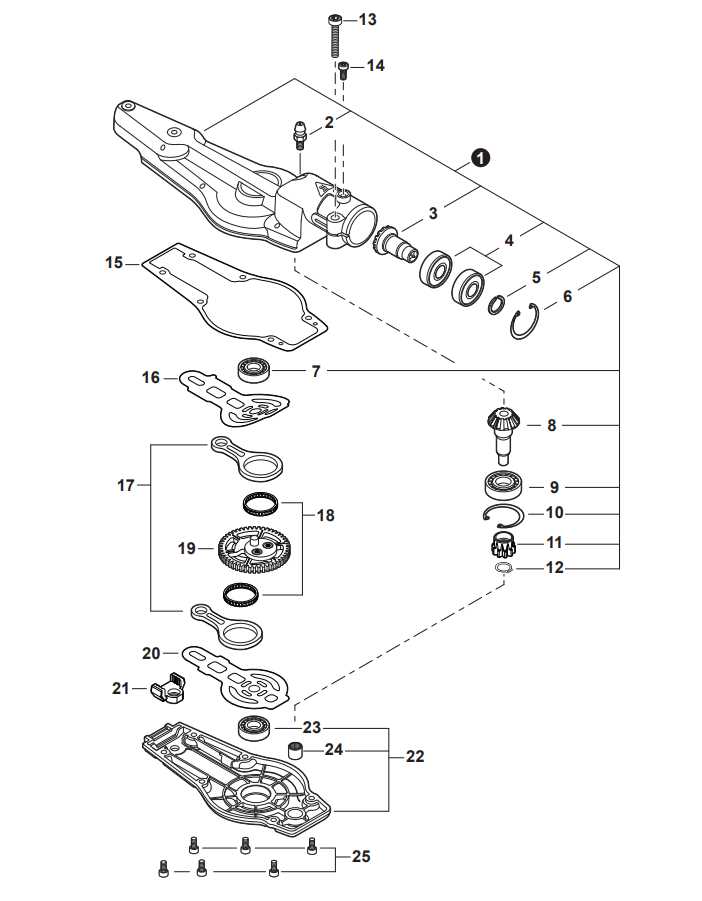

Understanding the Echo HC-152 Parts Diagram for Effective Repairs

In the realm of machinery and tools, comprehending the intricate network of elements is crucial for optimal functionality. Each device is composed of numerous individual pieces that work in harmony to deliver performance and reliability. A thorough grasp of these components not only aids in effective maintenance but also enhances the ability to troubleshoot issues as they arise.

Exploring the structure of a specific model unveils the relationships between various elements, shedding light on their roles and significance. Recognizing how each part contributes to the overall operation can empower users to make informed decisions regarding repairs and upgrades. This knowledge fosters a deeper appreciation for the engineering behind the equipment.

In this discussion, we will delve into the configuration of a well-known machine, providing insights into its assembly and operational mechanics. By examining the layout and interaction of its components, readers will gain valuable information that can be applied in practical scenarios, ensuring better care and longevity of their tools.

Understanding Echo HC-152 Components

Grasping the various elements of a specific device is essential for effective operation and maintenance. Each component plays a vital role in ensuring that the equipment functions seamlessly, and a clear understanding of these parts can greatly enhance user experience and longevity.

Components can typically be categorized into several key groups:

- Mechanical Parts: These include structural elements that provide support and stability. Common examples are housings, frames, and mounts.

- Electrical Elements: This group encompasses wiring, connectors, and circuit boards that facilitate power distribution and control mechanisms.

- Operational Accessories: Items such as handles, levers, and knobs are crucial for user interaction and control of the equipment.

- Maintenance Components: Spare parts and consumables, like filters and belts, ensure the device operates efficiently over time.

Understanding the function and interrelation of these categories is crucial. Each component not only serves its purpose but also interacts with others, contributing to the overall efficiency and performance of the unit.

When troubleshooting or upgrading, knowing the layout and functionality of these elements can lead to informed decisions and better results. Familiarity with each part’s role can also facilitate quicker repairs and maintenance, ultimately enhancing the user’s experience.

Benefits of Using Parts Diagrams

Utilizing visual representations of components offers significant advantages for both professionals and enthusiasts. These illustrations serve as valuable tools that simplify complex systems, enabling users to quickly identify and understand individual elements. This clarity enhances the efficiency of maintenance and repairs, minimizing downtime and errors.

Improved Efficiency: By providing a clear overview of each component’s location and function, these visuals streamline the repair process. Technicians can swiftly locate necessary items, leading to faster diagnostics and resolutions.

Enhanced Communication: Visual aids foster better communication among team members. When discussing specific elements, having a shared reference helps eliminate misunderstandings and ensures everyone is on the same page.

Informed Decision-Making: Access to detailed visual guides allows users to assess wear and tear or potential issues more effectively. This knowledge empowers individuals to make informed choices regarding replacements and upgrades, ultimately extending the lifespan of equipment.

Learning Aid: For newcomers, these illustrations serve as excellent educational resources. They break down complex machinery into understandable segments, facilitating a smoother learning curve and building confidence in handling various tasks.

In summary, leveraging visual representations of components greatly enhances efficiency, communication, decision-making, and learning, making them indispensable tools in maintenance and repair contexts.

Common Issues with Echo HC-152

When operating any outdoor power equipment, users may encounter various challenges that can hinder performance. Understanding these common difficulties is essential for maintaining efficiency and ensuring longevity. This section highlights prevalent problems, offering insights into identification and potential solutions.

Performance Problems

One of the frequent concerns involves a noticeable drop in power output. This can stem from various factors, including fuel quality, air filter blockages, or issues with the spark plug. Regular maintenance is crucial; checking these components can often resolve the issue and restore functionality.

Starting Difficulties

Another typical challenge is difficulty in starting the machine. Users might find that it won’t start or requires multiple attempts. This issue can often be traced back to the fuel system or ignition components. Ensuring that the fuel is fresh and that the carburetor is clean can significantly improve starting performance.

How to Identify Component Names

Understanding the names and functions of various elements in machinery is essential for effective maintenance and repairs. Identifying these components can streamline the troubleshooting process and enhance overall efficiency.

To accurately recognize the names of different parts, consider the following approaches:

- Refer to Manuals: Instructional guides often provide comprehensive lists of components, along with diagrams and descriptions.

- Utilize Online Resources: Numerous websites and forums are dedicated to specific equipment, offering detailed information and discussions about individual parts.

- Labeling Systems: Many manufacturers use standardized codes or labels that can help in quickly identifying components.

Moreover, familiarize yourself with common terminology used in the industry. Here are some tips for enhancing your vocabulary:

- Study Technical Glossaries: These resources define terms and provide context for their use.

- Join Workshops or Training Sessions: Engaging with experts can deepen your understanding and provide practical insights.

- Engage with Community Groups: Networking with peers can lead to shared knowledge and experiences that clarify component names.

By employing these methods, you will be better equipped to identify the names and functions of various elements in your equipment, making repairs and maintenance more manageable.

Repairing Your Echo HC-152 Effectively

Maintaining and restoring your garden tool is essential for ensuring its longevity and optimal performance. Understanding the common issues and knowing how to address them can save both time and money. This guide will provide you with the necessary steps to effectively troubleshoot and repair your equipment, ensuring it operates smoothly for years to come.

Identify Common Issues

Before diving into repairs, it is crucial to recognize frequent problems that may arise during usage. These can include engine starting difficulties, poor cutting performance, or unusual noises. Observing these symptoms closely will help you determine the specific areas that require attention.

Gather Necessary Tools

Equipping yourself with the right tools is vital for any repair task. A basic toolkit should include screwdrivers, wrenches, and pliers. Additionally, specialized tools may be needed depending on the specific repairs you plan to undertake. Having everything organized will streamline the process and prevent unnecessary delays.

Follow a Systematic Approach

When approaching repairs, it’s beneficial to follow a systematic method. Start by consulting the user manual for guidance on disassembly and assembly procedures. Take notes or photos during the process to aid in reassembly. This organized approach reduces the risk of missing components or reassembling incorrectly.

Replace Worn Components

As with any machinery, certain components may wear out over time. Identifying these parts and replacing them promptly is essential for maintaining performance. Consider using high-quality replacements to ensure durability and reliability.

Test Thoroughly After Repairs

After completing the repairs, conduct thorough testing to confirm everything is functioning as expected. Start the engine and observe its performance, checking for any unusual sounds or issues. Make necessary adjustments to ensure optimal operation.

Regular Maintenance

Finally, adopting a routine maintenance schedule will significantly reduce the likelihood of future problems. Regularly cleaning, inspecting, and servicing your equipment will keep it in top condition, making repairs less frequent and easier when they do arise.

Where to Find Replacement Parts

Locating suitable components for your equipment is crucial for maintaining its functionality and extending its lifespan. Whether you need a specific piece or an accessory, several avenues can be explored to acquire what you need efficiently.

Authorized dealers and specialized retailers often have a comprehensive inventory, ensuring that you receive genuine items that meet the original specifications. Additionally, online marketplaces provide a broader selection, often featuring competitive prices and user reviews that can guide your purchasing decisions.

Consider also checking with local repair shops, as they may have the required items in stock or can order them for you. Furthermore, community forums and social media groups dedicated to enthusiasts of similar equipment can be valuable resources for recommendations and second-hand options.

| Source | Description |

|---|---|

| Authorized Dealers | Offer genuine components with warranty and support. |

| Online Marketplaces | Wide selection, competitive prices, and customer reviews. |

| Local Repair Shops | Potential stock and ordering capabilities for specific needs. |

| Community Forums | Recommendations and second-hand options from fellow enthusiasts. |

Comparing OEM and Aftermarket Parts

When it comes to maintaining or repairing equipment, choosing between original components and alternatives can significantly impact performance and longevity. Understanding the distinctions between these options is crucial for making informed decisions that align with both quality expectations and budget constraints.

| Criteria | Original Components | Alternative Components |

|---|---|---|

| Quality | Typically higher, meeting strict manufacturer standards | Varies widely; some can match quality, while others may fall short |

| Cost | Generally more expensive due to brand reputation and assurance | Often more affordable, appealing to budget-conscious consumers |

| Availability | May be limited to specific retailers or the manufacturer’s website | Usually widely available across various stores and online platforms |

| Warranty | Often comes with a warranty that guarantees performance | Warranties can be less comprehensive or non-existent |

| Compatibility | Designed specifically for optimal compatibility with the equipment | Can vary; some alternatives may not fit or function as intended |

Ultimately, the choice between these two options depends on individual preferences and specific needs, weighing the importance of quality against cost savings.

Tools Needed for Maintenance Tasks

Proper upkeep of equipment requires a set of essential implements that facilitate efficient service and repair. Having the right tools on hand not only enhances the quality of maintenance work but also ensures safety and prolongs the lifespan of the machinery. Below is a guide to the necessary equipment for performing routine tasks effectively.

Essential Hand Tools

A variety of hand tools is crucial for tackling different maintenance challenges. Basic implements such as screwdrivers, wrenches, and pliers should be part of every toolkit. These tools assist in loosening and tightening various components, making adjustments, and replacing worn parts. It is also advisable to have a good-quality socket set to handle specific fasteners that may not be accessible with standard tools.

Safety Gear and Accessories

In addition to hand tools, safety gear is paramount when engaging in maintenance activities. Protective eyewear, gloves, and hearing protection help mitigate risks associated with potential hazards. Keeping a first aid kit nearby is also prudent, ensuring that any minor injuries can be addressed immediately. Finally, a reliable workbench or maintenance platform can provide a stable workspace, further enhancing safety and efficiency.

Tips for Safe Equipment Handling

Proper handling of machinery and tools is essential for ensuring both personal safety and the longevity of the equipment. By adhering to specific guidelines, users can minimize risks and enhance their efficiency while working. This section outlines key practices to follow when engaging with various types of machinery.

| Tip | Description |

|---|---|

| Wear Protective Gear | Always use appropriate personal protective equipment such as gloves, goggles, and ear protection to shield against potential hazards. |

| Read the Manual | Familiarize yourself with the user manual to understand the equipment’s features, functions, and safety instructions. |

| Inspect Before Use | Conduct a thorough inspection of the machinery to check for any damage or wear before starting operation. |

| Maintain Cleanliness | Keep the work area clean and organized to prevent accidents caused by clutter or misplaced tools. |

| Stay Focused | Avoid distractions while operating machinery to ensure full attention is dedicated to the task at hand. |

| Follow Safety Protocols | Adhere to established safety procedures and protocols specific to the equipment being used. |

By implementing these recommendations, users can promote a safer working environment and extend the life of their tools and machines.

Maintenance Schedule for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of any machinery. Establishing a systematic maintenance schedule not only enhances performance but also helps in identifying potential issues before they escalate. Adhering to a consistent routine ensures that all components function seamlessly, thereby minimizing downtime and repair costs.

Key Maintenance Tasks

To maintain peak functionality, consider the following essential tasks:

| Task | Frequency |

|---|---|

| Check oil levels | Every 10 operating hours |

| Inspect air filter | Weekly |

| Clean spark plug | Every 20 operating hours |

| Examine fuel lines | Monthly |

| Sharpen blades or cutting edges | Every 25 operating hours |

| Check and tighten bolts | Every 50 operating hours |

Conclusion

Following a structured maintenance plan is crucial for maximizing the efficiency and reliability of your equipment. By performing regular inspections and necessary adjustments, you can significantly extend the lifespan of your machine and ensure it operates at its best, providing you with optimal performance throughout its service life.

Frequently Asked Questions about Repairs

This section addresses common inquiries regarding maintenance and restoration tasks. Understanding the intricacies of repair work can enhance your overall experience and efficiency. Here, we aim to clarify typical concerns and provide guidance for successful troubleshooting.

What tools are necessary for basic repairs?

Having the right tools is crucial for effective repair tasks. Basic tools may include wrenches, screwdrivers, pliers, and a multimeter. Depending on the complexity of the job, specialized equipment might also be needed.

How can I determine if a component needs replacement?

Assessing whether a part requires replacement can often be done by inspecting for visible damage, unusual noises during operation, or performance issues. If in doubt, consulting a manual or seeking expert advice can be beneficial.

Are there common signs of wear and tear?

Yes, frequent indicators of deterioration include reduced performance, leaks, and unusual vibrations. Regular inspections can help identify these signs early, preventing more extensive damage.

Can I perform repairs myself, or should I seek professional help?

Many repairs can be handled independently if you have the necessary skills and tools. However, for complex issues or if you’re uncertain, enlisting the help of a qualified technician is advisable.

Where can I find replacement components?

Replacement parts can typically be sourced from authorized dealers, online retailers, or specialized shops. Ensuring that you obtain compatible components is essential for successful repairs.