Comprehensive Guide to Echo PB-770H Parts Diagram

In the realm of outdoor tools, maintaining optimal performance hinges on understanding their intricate structures. A detailed exploration of the various elements that compose these machines is essential for effective upkeep and troubleshooting. Recognizing how each part functions together not only enhances the user experience but also extends the lifespan of the equipment.

To facilitate maintenance and repairs, visual representations serve as invaluable resources. These illustrations provide a clear overview of the assembly, allowing users to identify specific components quickly. By dissecting the construction of these devices, enthusiasts can navigate issues with confidence and clarity.

Furthermore, being familiar with the individual elements empowers users to make informed decisions regarding replacements and upgrades. Whether you are a seasoned professional or a weekend warrior, a comprehensive understanding of your machinery’s layout is crucial for achieving the best results in your outdoor endeavors.

Understanding Echo PB-770H Components

When working with outdoor power equipment, grasping the various elements that make up the machine is crucial for effective operation and maintenance. Each component plays a specific role, contributing to the overall functionality and performance of the tool. By familiarizing oneself with these parts, users can enhance their understanding of how to best care for and utilize the equipment.

Key Elements of the Machinery

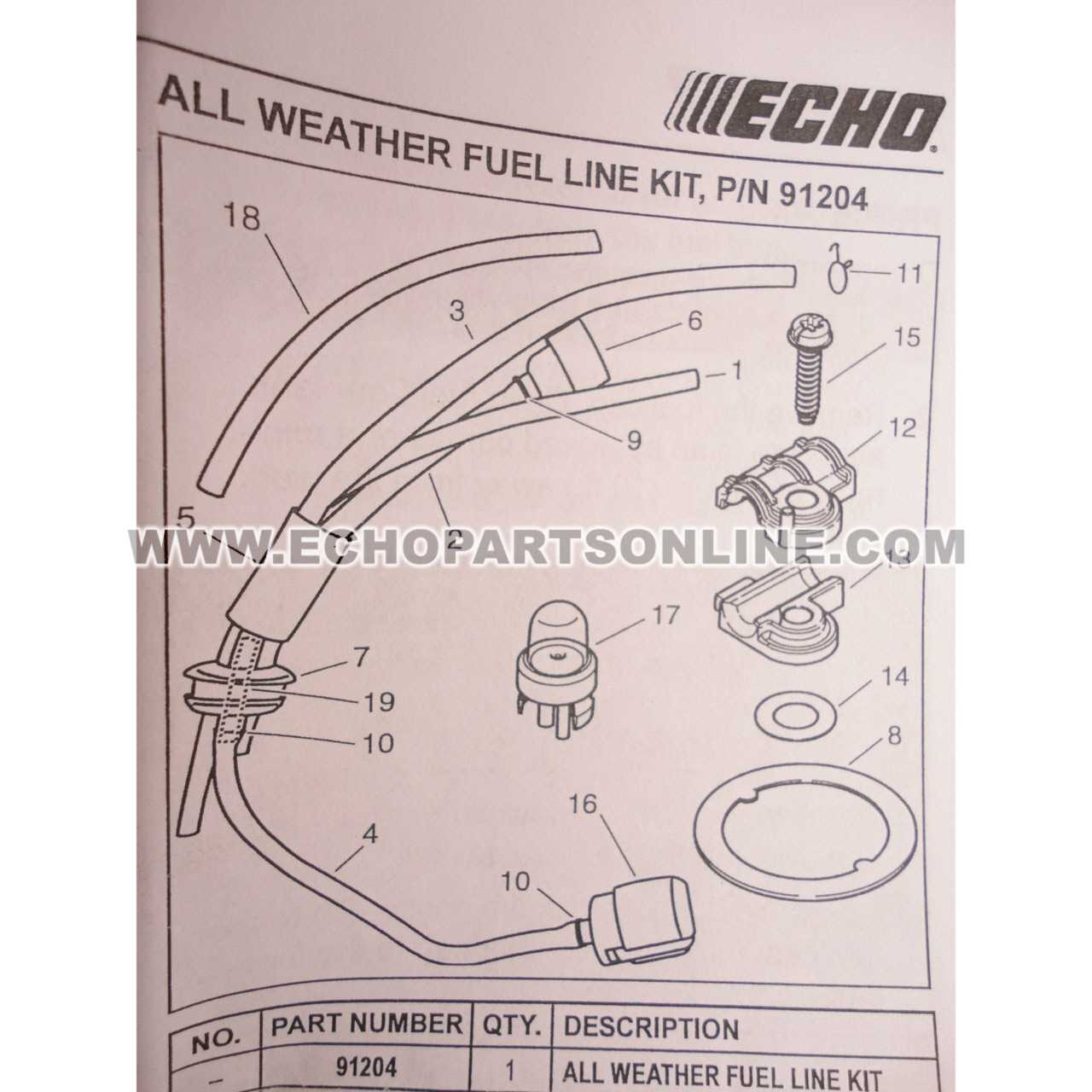

At the heart of any powerful device lies its engine, which is responsible for generating the necessary power. Additionally, the fuel system ensures a steady supply of energy, while the ignition system is vital for starting the engine smoothly. Each of these sections must work in harmony to achieve optimal results.

Maintenance and Care

Proper upkeep is essential to prolong the lifespan of the machine. Regularly inspecting elements like the air filter, spark plug, and fuel lines can prevent malfunctions and ensure efficient operation. Understanding these components not only aids in troubleshooting but also empowers users to perform necessary repairs, making the entire experience more rewarding and efficient.

Importance of Parts Diagrams

Understanding the intricacies of machinery is essential for effective maintenance and repair. Visual representations of components serve as vital tools that enhance the efficiency of both professionals and enthusiasts. These illustrations simplify the complex structures of devices, allowing users to identify each element and its function with clarity.

Such visual aids play a crucial role in troubleshooting, as they enable quick identification of faulty or worn-out components. By having a clear reference, users can streamline their repair processes, minimizing downtime and ensuring optimal performance of equipment. Furthermore, they facilitate communication between technicians and customers, making it easier to explain necessary repairs or replacements.

| Benefits | Description |

|---|---|

| Enhanced Clarity | Visual aids help in easily identifying and understanding each component’s role. |

| Improved Troubleshooting | Quickly pinpoint issues within complex systems, reducing repair time. |

| Effective Communication | Facilitates discussions regarding repairs and maintenance between technicians and clients. |

| Inventory Management | Aids in tracking necessary parts for replacements and ensuring adequate stock. |

In summary, the utilization of visual representations in the context of machinery maintenance is indispensable. They not only enhance understanding but also contribute significantly to operational efficiency and effective communication within the repair process.

Common Issues with the PB-770H Backpack Blower

In the realm of outdoor equipment for debris management, certain recurrent challenges can affect the performance and reliability of the PB-770H backpack blower. Understanding these issues is crucial for effective maintenance and optimal usage.

Performance Challenges

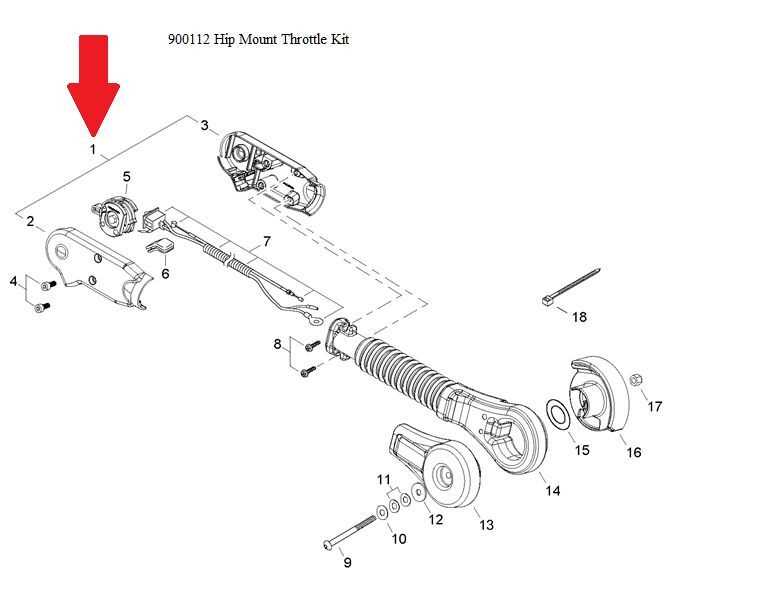

One of the primary concerns encountered by users relates to operational performance. Users have reported issues with airflow consistency, which impacts debris clearing efficiency. Additionally, throttle responsiveness has been noted as inconsistent, affecting the blower’s overall usability.

Maintenance and Durability

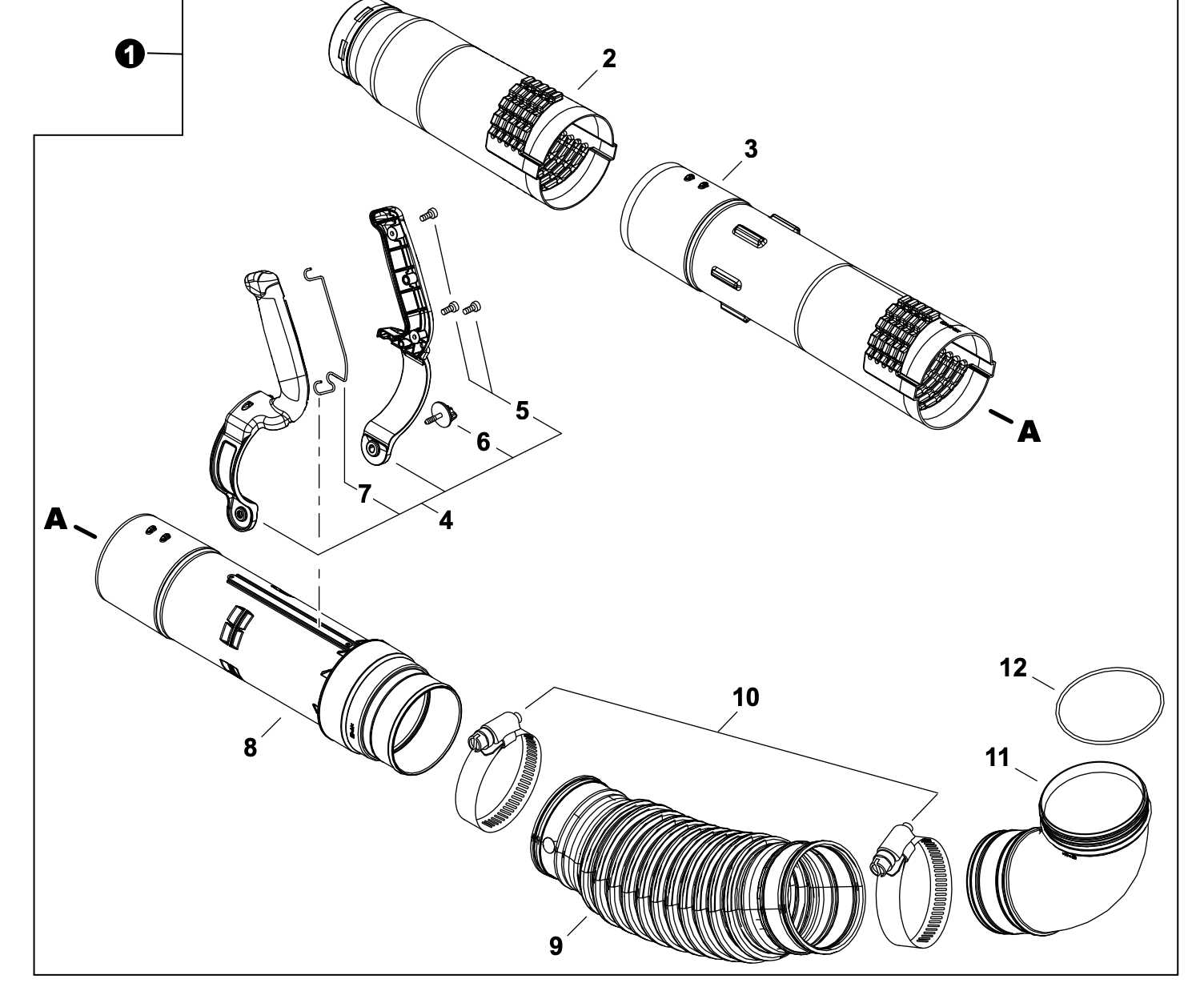

Another significant area of concern revolves around maintenance requirements and durability over time. Users have observed premature wear in critical components, such as the engine housing and intake system, leading to reduced lifespan and increased repair costs. Routine maintenance, including proper air filter cleaning and fuel system checks, is essential to mitigate these issues.

| Issue Category | Specific Concerns |

|---|---|

| Performance | Inconsistent airflow, throttle response |

| Maintenance | Premature component wear, increased repair costs |

Step-by-Step Maintenance Guide

In this comprehensive guide, we walk through the essential steps for maintaining and caring for your outdoor power equipment. Explore a detailed breakdown of the procedures involved in keeping your machinery in optimal condition, ensuring longevity and efficient operation.

Begin with a thorough inspection to identify any signs of wear or damage, addressing these early to prevent further issues down the line. Regular upkeep involves cleaning, lubricating, and inspecting various components, ensuring they function smoothly and reliably.

Next, focus on the engine and fuel system, performing routine checks such as changing oil, replacing filters, and inspecting fuel lines for leaks or blockages. Periodically examine the spark plugs and ignition system to maintain optimal performance.

Ensure the blades or cutting mechanisms are sharpened and balanced to enhance cutting efficiency and reduce strain on the engine. Inspect and tighten any loose bolts or fittings, securing parts as needed to maintain safety and functionality.

Conclude your maintenance with a final inspection, testing the equipment to confirm proper operation. Store your equipment in a clean, dry environment, protecting it from the elements to extend its lifespan and maintain performance for seasons to come.

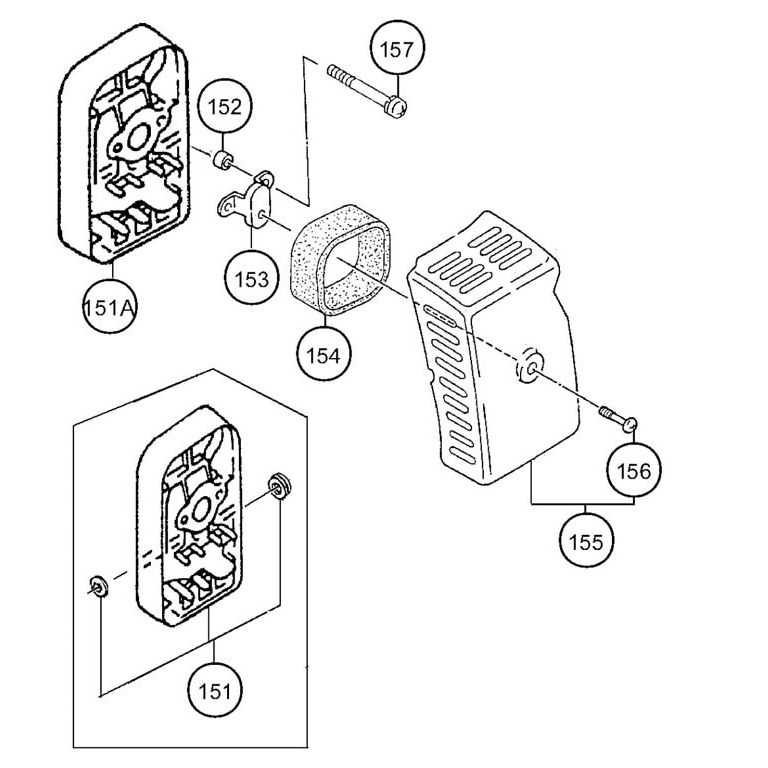

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repairs. These visual representations provide crucial information about components, their arrangement, and functionality within a larger assembly. By mastering the skill of interpreting these visuals, you can enhance your troubleshooting and repair processes.

Here are key steps to help you decode these technical visuals:

-

Familiarize Yourself with Symbols:

- Each illustration uses specific symbols to represent various elements.

- Learn the meaning of common icons, which can vary by manufacturer.

-

Identify the Main Assembly:

- Locate the primary structure or system highlighted in the visual.

- This serves as your reference point for other components.

-

Trace Connections:

- Follow lines or arrows that indicate how parts are connected.

- Understanding these links can clarify how components interact.

-

Take Note of Labels:

- Labels often provide crucial details such as part numbers or specifications.

- Use this information to locate replacement items or additional resources.

-

Consult the Legend:

- Many illustrations include a legend that explains symbols and notations.

- Refer to it for any clarifications on markings you don’t understand.

By following these steps, you can confidently navigate technical visuals, making your maintenance tasks more efficient and informed.

Identifying Replacement Components

In order to efficiently locate and acquire the necessary components to maintain or repair your equipment, it is essential to accurately identify each part required. This process involves recognizing the specific elements that make up the machinery, ensuring compatibility with existing components and functionality.

Key Steps to Identification

- Examine the detailed breakdown of the machinery to pinpoint individual elements.

- Verify the characteristics and specifications of each part to ensure proper integration.

- Consult technical documentation or product manuals for comprehensive part descriptions.

By following these steps, you can streamline the process of identifying replacement components, facilitating timely repairs and optimal equipment performance.

Tools Needed for Repairs

When it comes to conducting maintenance on outdoor equipment, having the right instruments is essential for ensuring efficient and effective repairs. This section outlines the essential tools that will facilitate the process and help in achieving optimal performance.

Basic Hand Tools: A reliable set of hand tools, including screwdrivers, wrenches, and pliers, is crucial. These instruments allow for the disassembly and reassembly of components with ease. It’s important to have both flathead and Phillips screwdrivers in various sizes to accommodate different fasteners.

Power Tools: Depending on the complexity of the repairs, power tools such as drills and saws may be beneficial. These can significantly reduce the time required for tasks like cutting or drilling, making the job more efficient.

Safety Equipment: Always prioritize safety by equipping yourself with the necessary protective gear. This includes gloves, goggles, and ear protection. Ensuring safety while working can prevent accidents and injuries.

Cleaning Supplies: Keeping the work area and the tools clean is vital. Having brushes, rags, and appropriate cleaning solvents on hand will help maintain the condition of your equipment and tools, leading to better performance over time.

Specialized Tools: Depending on the specific tasks at hand, certain specialized tools may be required. These could include torque wrenches or spark plug sockets, designed for precise applications that general tools might not handle effectively.

With the proper selection of tools, tackling repairs becomes a straightforward and manageable task, ensuring your equipment remains in peak condition.

Comparing Echo Models and Parts

When assessing various models from a leading outdoor equipment manufacturer, it becomes essential to understand the distinct features and components that set each version apart. A comprehensive evaluation allows users to make informed choices based on their specific needs, whether for professional landscaping or personal gardening tasks.

Model specifications vary widely, affecting performance, durability, and ease of use. For instance, engine power, weight, and fuel efficiency are critical factors that can influence the overall effectiveness of the equipment. Furthermore, attachments and accessories play a significant role in enhancing versatility, catering to different tasks and environments.

Additionally, examining the compatibility of various elements across different models reveals insights into maintenance and upgrade possibilities. Users often seek models that share interchangeable parts, as this can lead to reduced downtime and lower repair costs. Understanding the intricacies of each option ensures that the choice made is not only suitable for current tasks but also adaptable for future needs.

Where to Purchase Parts

Finding components for your equipment can be a straightforward process if you know where to look. Numerous sources offer a variety of options, catering to different needs and preferences. Whether you’re seeking genuine items or compatible alternatives, understanding your purchasing options will help you make an informed decision.

Online Retailers

Many individuals turn to online platforms for convenience and a broader selection. Websites often provide detailed descriptions, customer reviews, and competitive pricing. Here are a few popular online vendors:

| Vendor | Website | Special Features |

|---|---|---|

| Amazon | www.amazon.com | Wide selection, customer reviews |

| eBay | www.ebay.com | New and used options, bidding |

| Home Depot | www.homedepot.com | In-store pickup, project guides |

Local Stores

Visiting local retailers can also be advantageous. This option allows for immediate purchase and the opportunity to consult with knowledgeable staff. Check out hardware stores, garden centers, and specialized shops in your area to find the necessary components.

Safety Tips for Maintenance

Proper upkeep of equipment is essential for ensuring optimal performance and longevity. However, maintaining machinery can pose certain risks if safety protocols are not followed. Adhering to recommended practices can significantly minimize hazards during maintenance tasks.

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and ear protection.

- Before starting any maintenance work, ensure that the equipment is turned off and disconnected from any power source.

- Familiarize yourself with the user manual and safety guidelines provided by the manufacturer.

In addition to personal safety, it is crucial to create a secure work environment. Consider the following precautions:

- Keep your workspace clean and free of clutter to prevent accidents.

- Use proper tools and equipment that are in good working condition to avoid mishaps.

- Ensure adequate lighting in the work area to see all components clearly.

Finally, when performing maintenance, always follow these best practices:

- Work with a partner whenever possible to enhance safety and provide assistance if needed.

- Take breaks to avoid fatigue, which can lead to errors and accidents.

- Dispose of waste materials and chemicals according to local regulations to prevent environmental hazards.

By implementing these safety tips, you can help ensure a safer and more effective maintenance experience.

FAQs About Echo PB-770H Repairs

This section addresses common inquiries related to the maintenance and troubleshooting of a specific outdoor power equipment model. Understanding the typical issues and solutions can greatly enhance the efficiency of your repair efforts.

What are the most frequent problems encountered?

Users often report issues such as difficulty starting, poor performance, or excessive noise. Regular maintenance can help prevent these complications. Identifying the root cause early can save time and reduce repair costs.

How can I find replacement components?

Replacement components can be sourced from authorized dealers or reputable online retailers. Ensure that the parts match the specifications of your equipment for optimal performance. Consulting the manual can also provide guidance on compatible alternatives.

Regular maintenance and prompt attention to issues can extend the life of your equipment and improve its functionality. Being informed about common repairs is crucial for efficient troubleshooting.