Comprehensive Guide to Echo SRM 210 Parts Diagram

When it comes to maintaining your outdoor equipment, comprehending the intricate assembly of its elements is essential for optimal performance. This section delves into the various components that make up a specific model of a trimmer, providing insights into their functions and interrelations. Familiarity with these parts not only aids in effective repairs but also enhances overall efficiency during use.

Each individual component plays a critical role in the seamless operation of the machine. From the motor to the cutting mechanism, understanding how these pieces interact can lead to better maintenance practices. This knowledge empowers users to troubleshoot issues and make informed decisions about repairs and upgrades.

In addition, recognizing the significance of each element allows for a deeper appreciation of the technology behind these devices. Whether you are a seasoned user or a newcomer, grasping the layout and function of the various parts will enhance your experience and ensure your equipment remains in prime condition for years to come.

Understanding Echo SRM 210 Components

Exploring the various elements that make up a specific gardening tool enhances our appreciation of its functionality and efficiency. Each component plays a vital role in ensuring the overall performance, contributing to a seamless experience for users. By examining these pieces, we can gain insights into maintenance and potential upgrades.

Key Functional Elements

Crucial parts include the engine, which provides power, and the cutting mechanism that ensures precision. Additionally, the housing protects internal components, while the handle offers user control and comfort. Understanding these functions helps users optimize their equipment.

Maintenance Considerations

Regular checks on wear-prone parts such as blades and filters are essential for longevity. Being aware of how each element interacts can guide effective maintenance practices, ensuring that the tool remains reliable over time. Proper care maximizes efficiency and enhances performance.

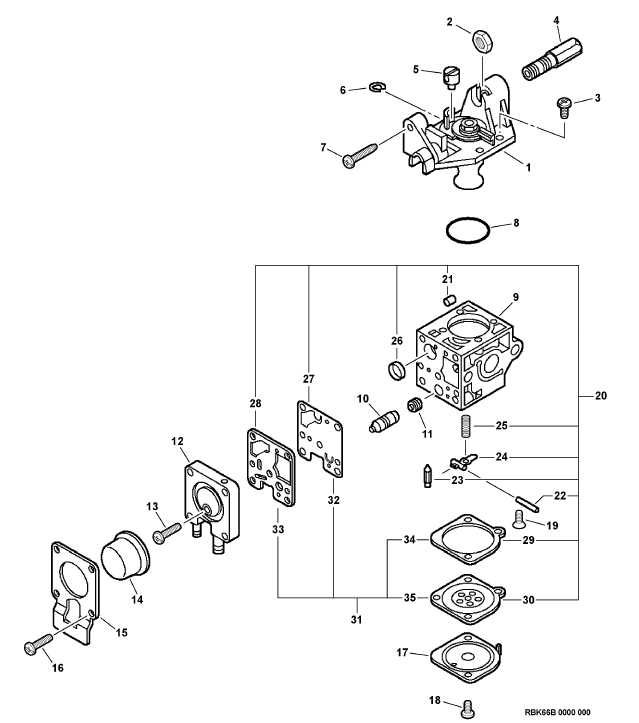

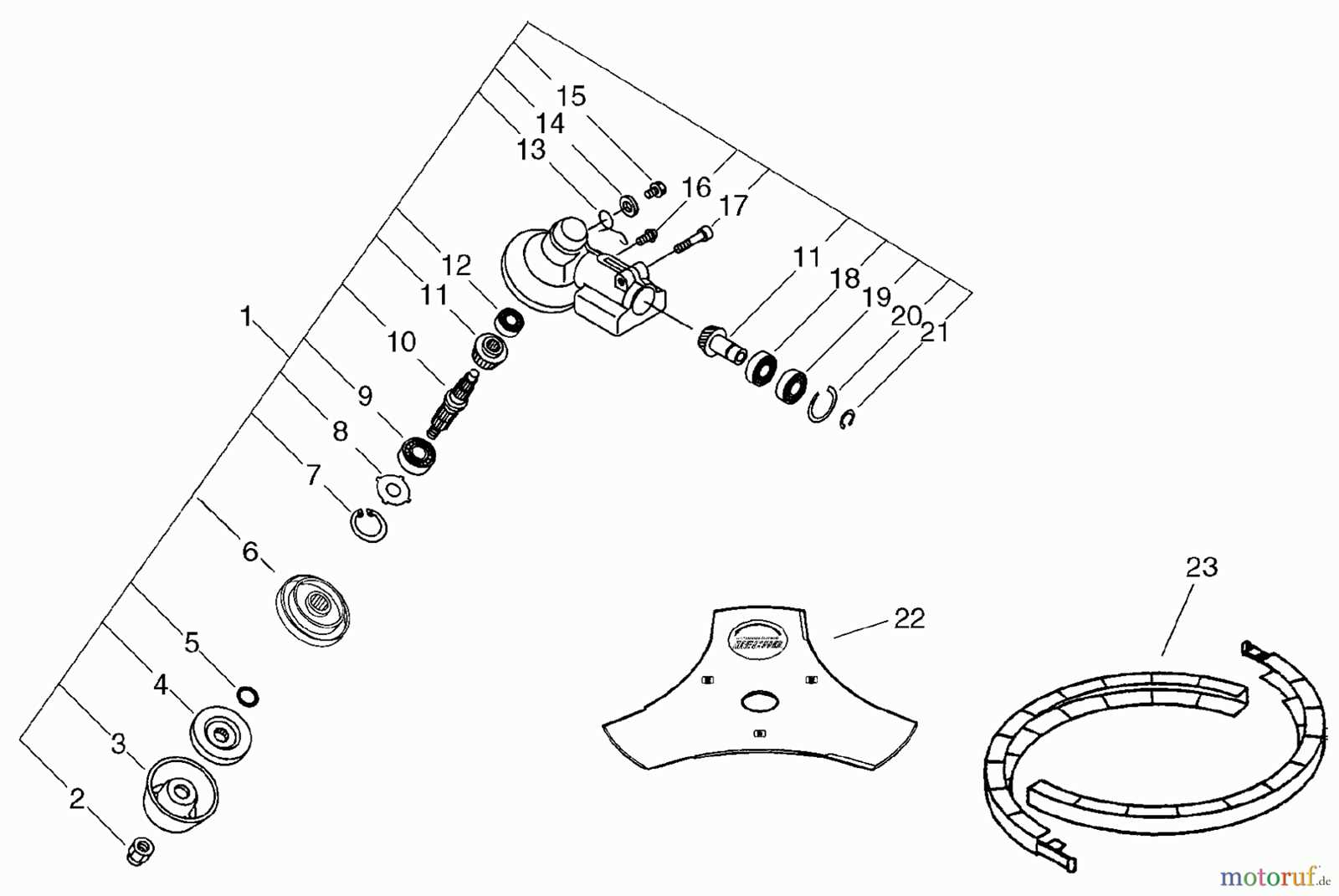

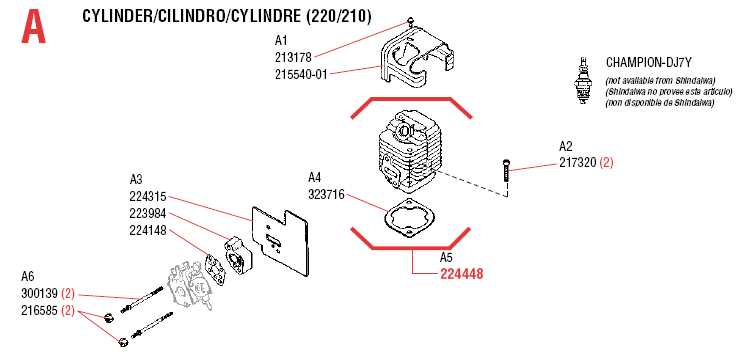

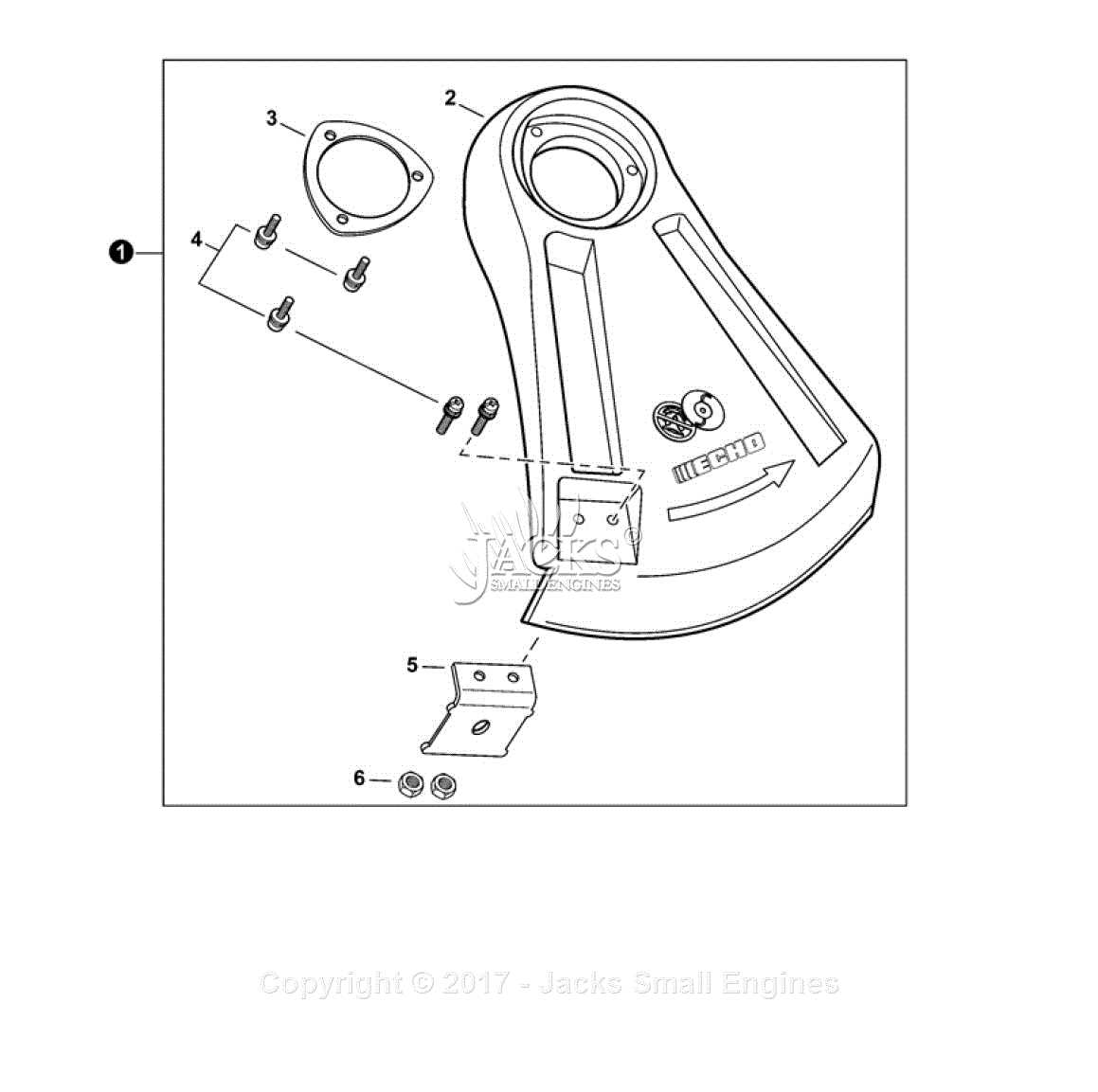

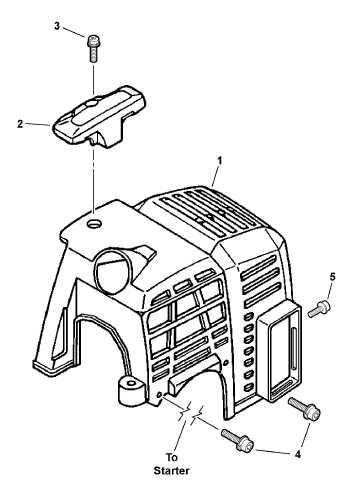

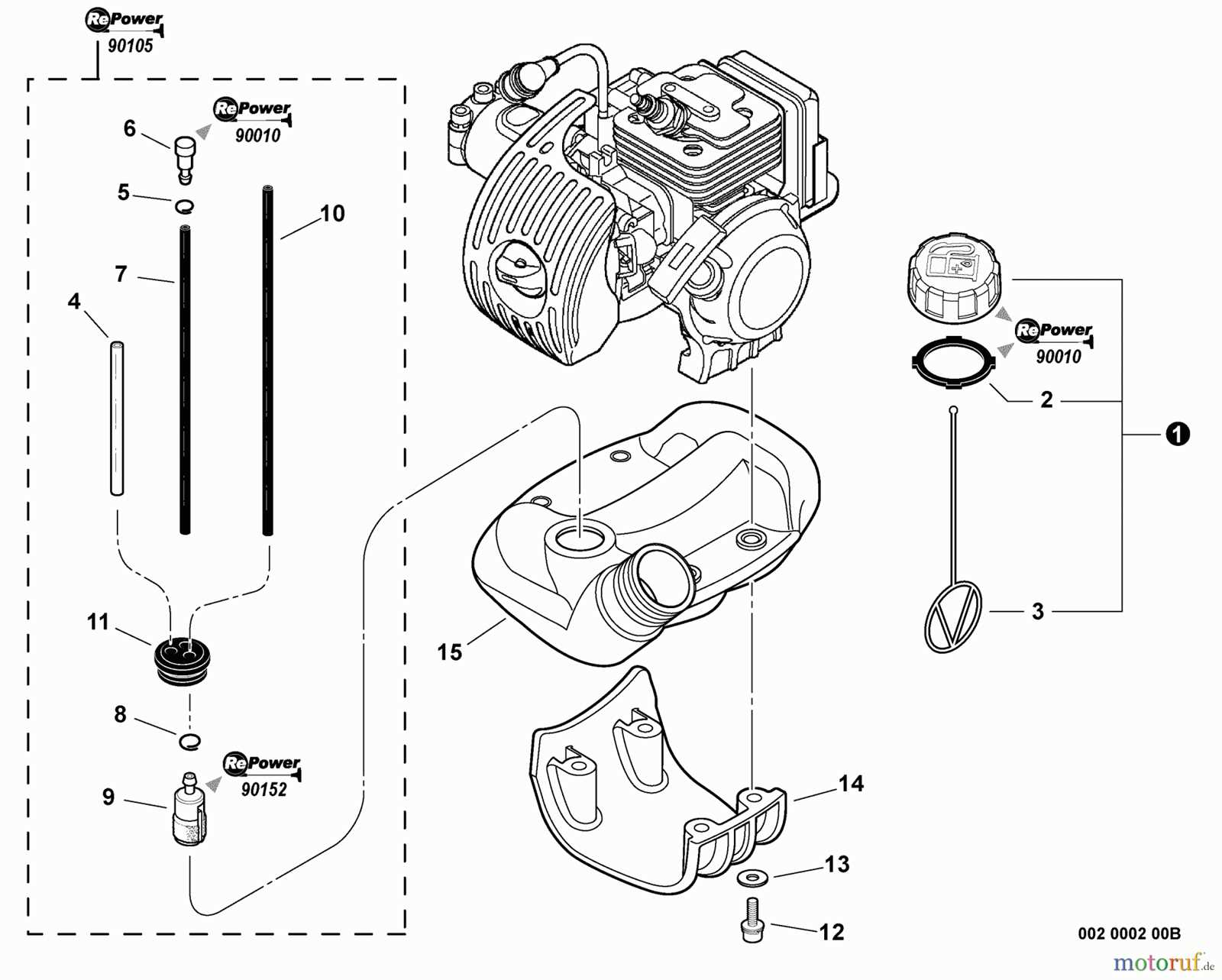

Overview of Parts Diagram

The representation of components within a machine is crucial for understanding its structure and functionality. A visual breakdown allows users to identify each element, facilitating maintenance and repairs. Such illustrations serve as a valuable resource, particularly for those unfamiliar with the intricacies of the equipment.

Importance of Understanding Components

Grasping the layout of individual parts is essential for effective troubleshooting and performance optimization. Users can pinpoint specific sections that may require attention, thereby enhancing the longevity of the device. A clear depiction aids in recognizing compatible replacements and accessories, streamlining the repair process.

Utilization in Maintenance and Repair

Employing a detailed visual guide simplifies the task of reassembly after servicing. By following the outlined structure, users can ensure that every component is correctly positioned, minimizing the risk of malfunctions. Furthermore, this approach fosters a deeper comprehension of the machinery’s operation, empowering users to tackle issues with confidence.

Key Features of Echo SRM 210

This lightweight cutting tool stands out due to its exceptional performance and user-friendly design. Crafted for both professional landscapers and gardening enthusiasts, it offers a blend of power and efficiency, making yard maintenance tasks easier and more enjoyable.

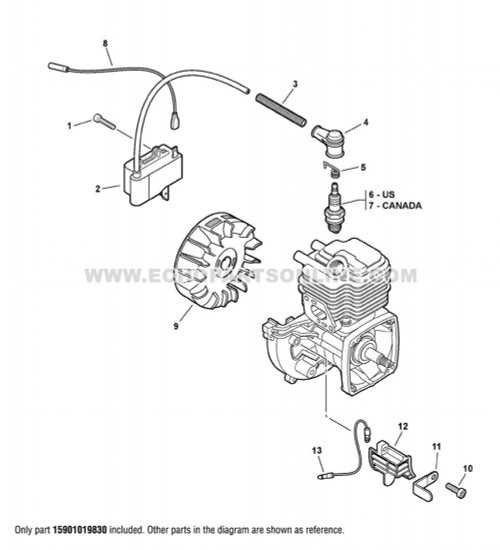

Powerful Engine Performance

Equipped with a robust engine, this device delivers impressive cutting speed and efficiency. The high-performance motor ensures that even the toughest vegetation can be tackled effortlessly. Users benefit from reduced vibration and smooth operation, enhancing comfort during extended use.

Ergonomic Design

The thoughtfully designed handle and lightweight structure provide excellent maneuverability. The intuitive controls allow for quick adjustments, ensuring that users can focus on their work without unnecessary distractions. Additionally, the balanced weight distribution minimizes fatigue, making it suitable for prolonged tasks.

Durability is a key aspect, as the materials used in construction ensure longevity and reliability. This makes it a valuable addition to any toolkit, ready to handle various challenges in outdoor maintenance.

In summary, this cutting tool combines power, comfort, and durability, making it an ideal choice for anyone looking to enhance their gardening experience.

Importance of Using Genuine Parts

Utilizing authentic components is crucial for maintaining the performance and longevity of equipment. When original items are used, they ensure compatibility and reliability, which is essential for optimal operation. Imitation alternatives may seem appealing due to lower costs, but they often lead to inefficiencies and can compromise overall functionality.

Quality Assurance

Authentic components undergo rigorous testing to meet stringent standards, ensuring they can withstand the demands of rigorous use. By choosing genuine items, users can be confident in their quality and performance.

Long-Term Savings

While the initial investment in original items may be higher, the long-term benefits include reduced maintenance costs and fewer replacements. Investing in quality leads to greater reliability, ultimately saving time and money in the future.

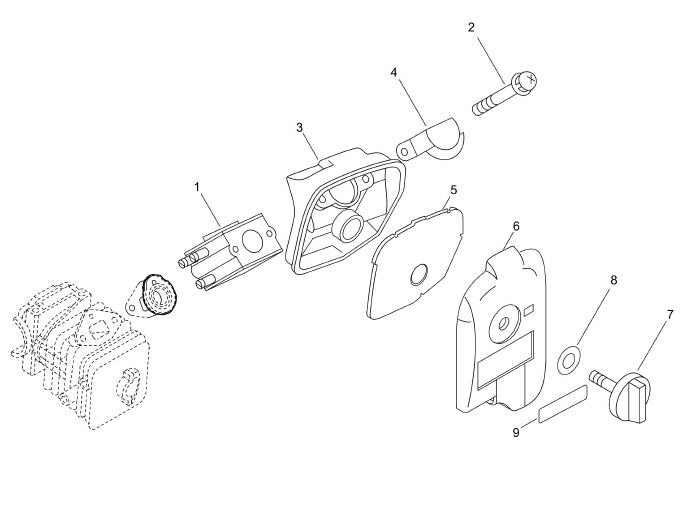

Common Repairs and Maintenance Tips

Regular upkeep and timely fixes are essential for ensuring optimal performance and longevity of outdoor power tools. By implementing a few straightforward practices, users can prevent major issues and enhance efficiency.

- Always check and replace the air filter regularly to maintain proper airflow.

- Inspect the spark plug for wear and replace it as needed to ensure reliable starting.

- Keep the cutting head clean and free of debris to prevent clogs and reduce wear.

Additionally, consider these maintenance steps:

- Lubricate moving parts to reduce friction and enhance performance.

- Sharpen blades frequently to ensure clean cuts and reduce strain on the engine.

- Store the tool in a dry place to prevent rust and corrosion.

By following these guidelines, users can enjoy a smoother operation and extend the life of their equipment.

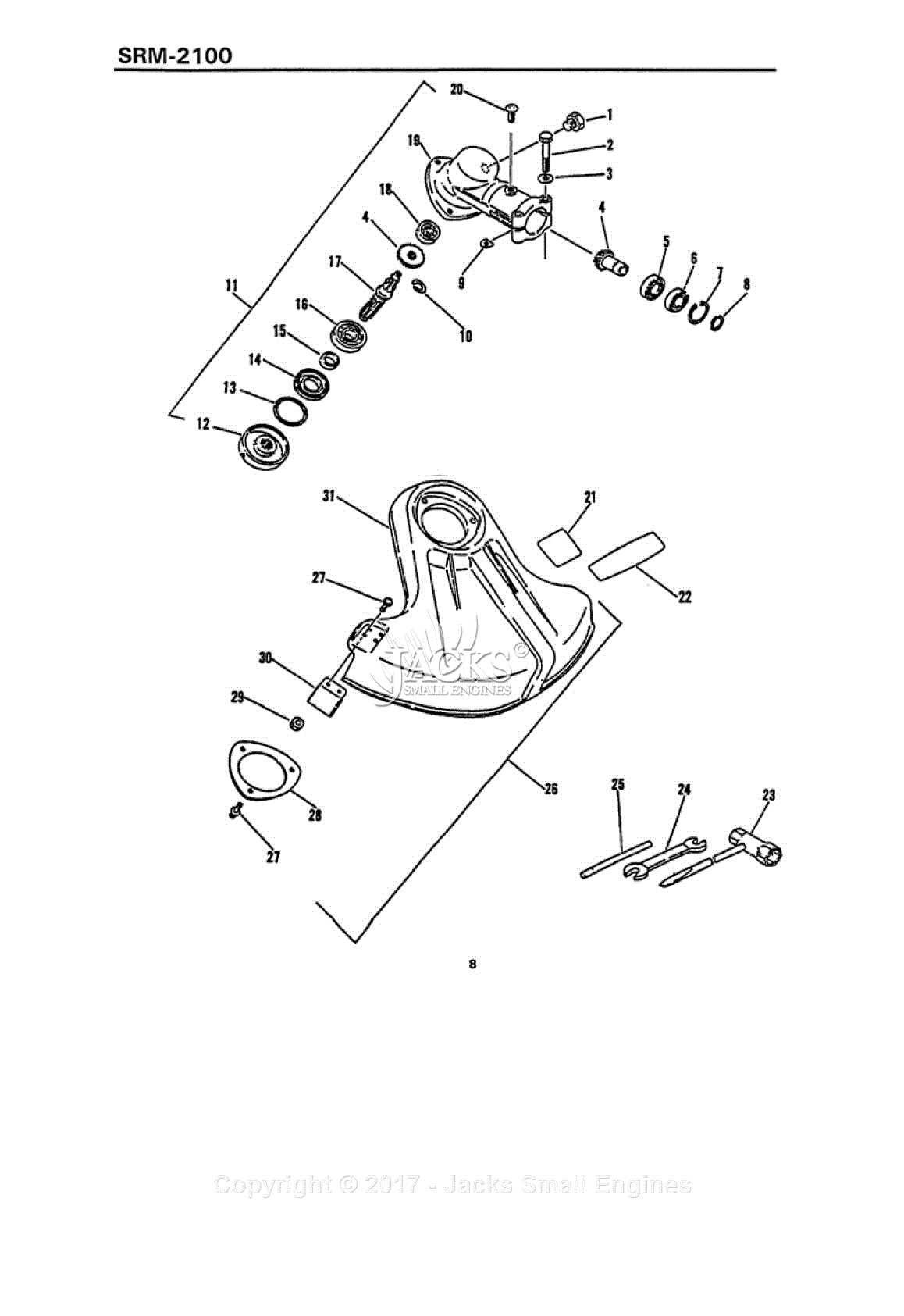

Tools Needed for Disassembly

Proper disassembly of equipment requires a specific set of tools to ensure efficiency and safety. Using the right instruments not only speeds up the process but also minimizes the risk of damage to components. Below is a list of essential tools that will facilitate a smooth dismantling procedure.

- Wrenches: Adjustable and fixed wrenches are vital for loosening and tightening various bolts and nuts.

- Screwdrivers: A set of flathead and Phillips screwdrivers is necessary for removing screws of different types.

- Pliers: Needle-nose and slip-joint pliers can help grip and manipulate small parts effectively.

- Socket Set: A socket wrench set provides versatility for tackling fasteners in tight spaces.

- Torque Wrench: Ensures that bolts are tightened to the correct specifications, preventing damage.

- Hammer: A rubber or plastic hammer can assist in loosening stuck components without causing harm.

- Utility Knife: Useful for cutting through any seals or straps that may be present.

Having these tools ready will greatly enhance the disassembly process, making it easier to handle each part carefully and methodically.

Interpreting the Parts Diagram

Understanding a technical illustration of components can be essential for effective maintenance and repair. These visual representations serve as a valuable guide, allowing users to identify various elements and their interconnections within a complex assembly. By comprehending the layout and symbolism utilized in these depictions, one can facilitate troubleshooting and enhance overall efficiency in working with equipment.

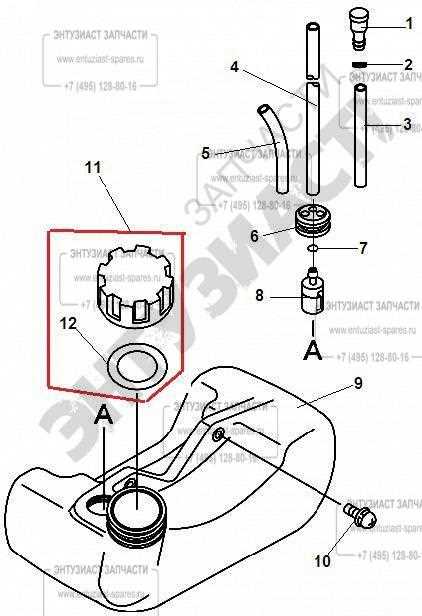

Components and Their Functions

Each item in the illustration typically corresponds to a specific function or role within the system. Recognizing what each component does can greatly simplify the repair process. Users should familiarize themselves with the key parts, noting their positions and relationships to one another.

Decoding Symbols and Notations

Many illustrations employ unique symbols or annotations to convey additional information. Understanding these notations is crucial for accurate interpretation. It is advisable to refer to any accompanying legends or keys that clarify these symbols, ensuring that the reader gains a comprehensive grasp of the content.

Order of Assembly

Another critical aspect of these visuals is the sequence in which components are assembled or disassembled. By following the depicted order, users can avoid potential pitfalls and ensure that the equipment is reassembled correctly. This systematic approach minimizes the risk of errors and enhances operational reliability.

In conclusion, a thorough understanding of these visual guides not only aids in repairs but also fosters a deeper appreciation for the intricacies of mechanical design. By investing time in interpreting these representations, users can become more proficient and confident in their maintenance tasks.

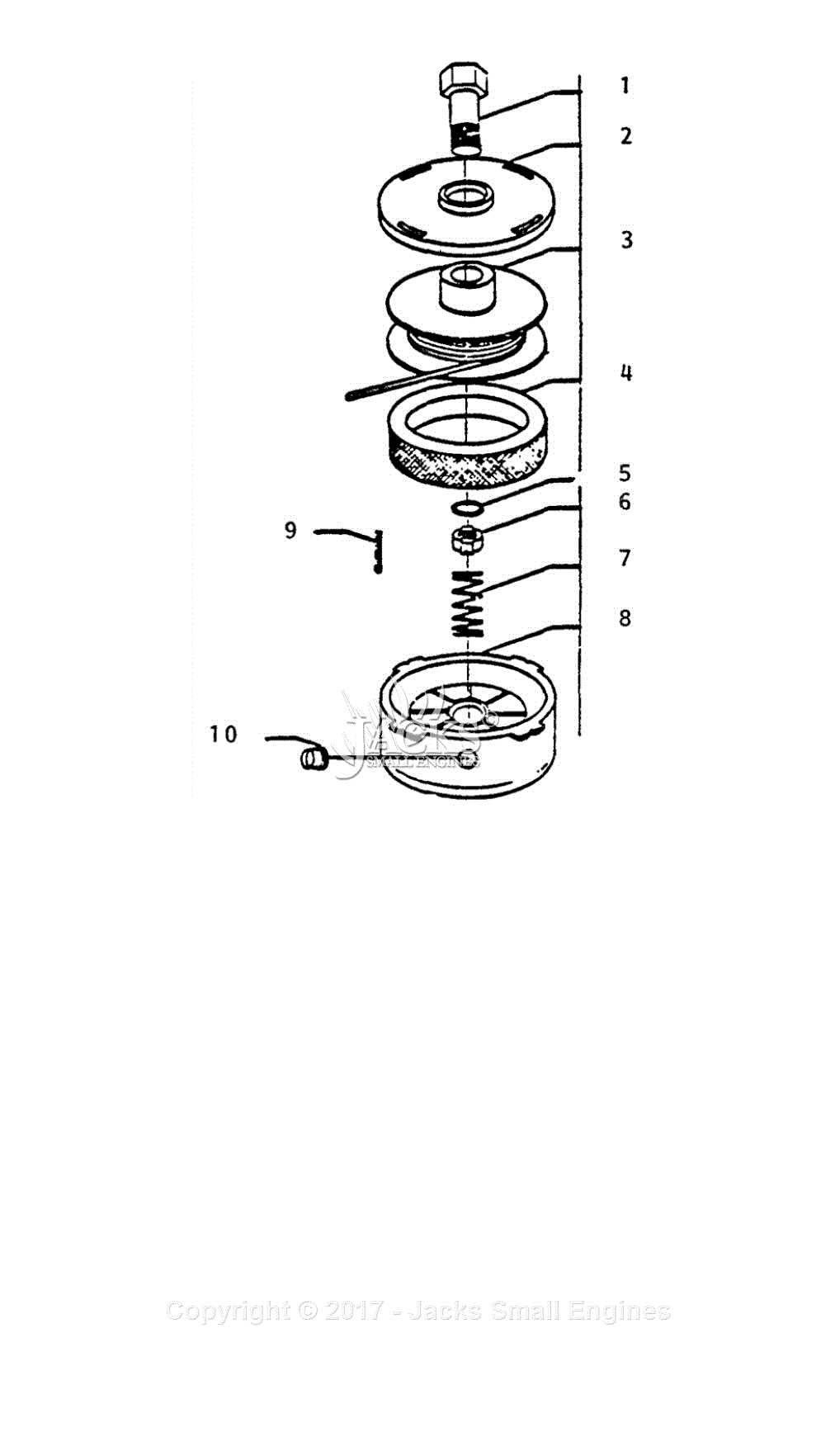

Frequently Replaced Components

In any machine, certain elements tend to wear out or require replacement more frequently due to regular use. Understanding which components are commonly replaced can enhance maintenance efficiency and prolong the life of the equipment.

Common Wear Parts

Parts such as cutting edges, spark plugs, and filters are often among the first to show signs of deterioration. Regular inspection of these elements can prevent performance issues and ensure optimal operation.

Maintenance Essentials

Additionally, components like fuel lines and ignition systems are critical for functionality. Keeping these parts in good condition is vital for reliable performance and efficiency.

Where to Find Replacement Parts

When seeking components for your equipment, there are several avenues to explore. First, consider checking authorized dealers who specialize in your brand, as they typically offer a comprehensive selection of genuine items. Online marketplaces also provide a vast array of options, allowing you to compare prices and availability.

Local hardware stores can be a convenient source, especially if you need something quickly. Additionally, you may find useful resources in specialized forums or community groups, where fellow enthusiasts share their experiences and recommendations for sourcing materials.

Don’t overlook manufacturer websites, which often feature detailed catalogs and ordering options. By delving into these resources, you can ensure you find the right components to keep your machinery running smoothly.

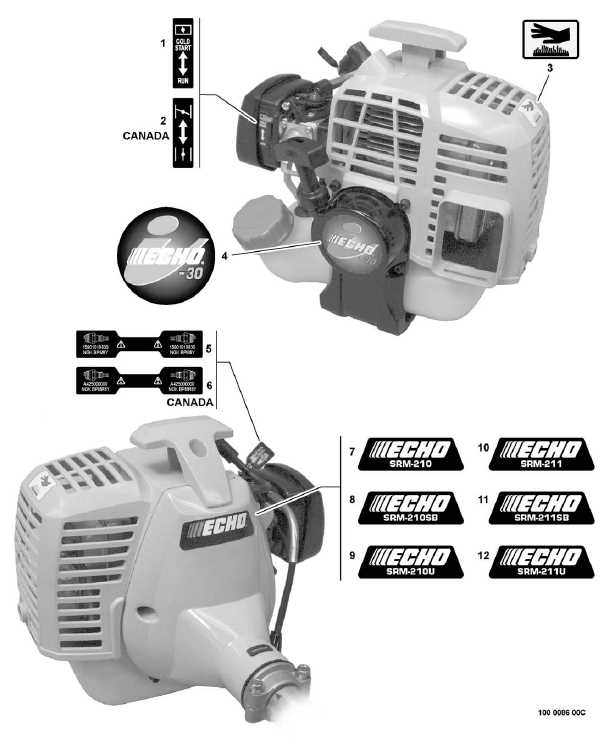

Comparing Models in the Echo Range

The variety of models available in this product line showcases distinct features and capabilities, catering to different user needs. By examining these options, one can identify which variant excels in specific applications and provides the best performance for various tasks.

Performance varies significantly among the selections, with some designed for light-duty tasks while others are engineered for heavy-duty use. Understanding these differences helps in making an informed choice based on individual requirements.

Moreover, the ergonomics of each model are tailored to enhance user experience, making some versions more comfortable for extended usage. This aspect is crucial for professionals who spend long hours on the job.

Additionally, comparing accessories and compatibility features can lead to better customization options, enabling users to adapt their tools for specific tasks. Exploring these elements provides insights into maximizing efficiency and effectiveness.

Upgrades and Enhancements Available

In the world of outdoor equipment, optimizing performance and extending the lifespan of your tools is crucial. Various enhancements can significantly improve efficiency, comfort, and functionality. These modifications often include upgraded components designed to withstand more rigorous use, as well as ergonomic features that enhance user experience.

Below is a table summarizing some common upgrades and enhancements that can be applied:

| Upgrade Type | Description |

|---|---|

| Enhanced Cutting Head | Improves cutting efficiency and reduces wear on the line. |

| Fuel System Optimization | Increases fuel efficiency and reduces emissions. |

| Vibration Dampening Handle | Reduces operator fatigue and enhances comfort during prolonged use. |

| Performance Exhaust | Improves engine efficiency and enhances power output. |

| Upgraded Starter Mechanism | Makes starting easier and more reliable in various conditions. |

By investing in these enhancements, users can ensure their equipment performs at its best, providing a more enjoyable and efficient experience in the field.

Safety Precautions During Repair

When undertaking maintenance or repair tasks, it is essential to prioritize safety to prevent accidents and injuries. Proper precautions can significantly reduce the risk of harm while ensuring that the work is completed efficiently and effectively.

First and foremost, always wear appropriate personal protective equipment (PPE). This may include gloves, safety goggles, and sturdy footwear to safeguard against potential hazards. Additionally, ensure that the workspace is well-lit and organized to minimize the chances of mishaps.

Before beginning any repair, disconnect the equipment from its power source. This step is crucial to avoid accidental starts that could lead to injuries. Furthermore, familiarize yourself with the specific components and mechanisms involved in the repair process to enhance your understanding and confidence.

Keep tools and materials within reach, but organized in a way that reduces clutter. Using the right tools for each task is vital; using incorrect tools can lead to damage or personal injury. Always inspect tools for any signs of wear or damage before use.

Lastly, if you are unsure about any aspect of the repair, seek assistance or consult the manufacturer’s guidelines. Taking the time to ensure safety can prevent accidents and enhance the overall repair experience.