Echo SRM 225 Parts Diagram Overview

In the world of outdoor power equipment, comprehending the arrangement of various components is essential for effective maintenance and repair. A clear visual representation can significantly aid in identifying each part’s function and location within the assembly, thereby enhancing the user’s ability to troubleshoot issues efficiently.

This overview provides insight into the intricate details of the machine’s construction, enabling operators to navigate their equipment with greater confidence. By studying the configuration of different elements, users can streamline their repair processes and ensure optimal performance during operation.

Furthermore, possessing knowledge of the assembly’s layout fosters a deeper understanding of how each component interacts with others. This awareness is crucial not only for effective repairs but also for preventing potential malfunctions, ultimately leading to a more reliable and efficient tool.

This section aims to provide a comprehensive understanding of a specific model within the realm of garden tools. The focus will be on its key components and their functions, which play a crucial role in ensuring optimal performance. By examining the assembly of this device, readers will gain insights into its design and operational efficiency.

| Component | Description |

|---|---|

| Engine | The heart of the machine, responsible for powering the tool and enabling its various functions. |

| Drive Shaft | This component transmits power from the engine to the cutting head, facilitating movement. |

| Cutting Head | The part that houses the blades or trimmer line, essential for executing cutting tasks. |

| Handle | Designed for user comfort, it allows for better control and maneuverability while operating the tool. |

| Throttle Trigger | This mechanism enables users to control the engine speed, providing flexibility based on the task. |

| Fuel Tank | A storage area for the mixture of fuel needed to power the engine, crucial for operation. |

| Air Filter | This component keeps contaminants from entering the engine, thereby maintaining its longevity. |

| Spark Plug | Plays a key role in igniting the fuel-air mixture, essential for starting and running the engine. |

| Guard | A safety feature that protects users from debris while cutting, ensuring a safer experience. |

| Gearbox | Helps in adjusting the rotational speed and torque, contributing to efficient cutting performance. |

| Starter Assembly | This mechanism initiates the engine, enabling users to start using the tool easily. |

Key Features of the Trimmer

This innovative gardening tool stands out for its exceptional performance and user-friendly design. It combines power with versatility, making it an ideal choice for both amateur gardeners and professional landscapers. The following attributes contribute to its efficiency and ease of use.

| Feature | Description |

|---|---|

| Lightweight Design | Ensures ease of handling, allowing for extended use without fatigue. |

| Powerful Engine | Delivers robust performance, making it suitable for tackling tough vegetation. |

| Adjustable Handle | Offers customizable height and angle for maximum comfort during operation. |

| Durable Cutting Head | Constructed from high-quality materials to withstand wear and tear. |

| Easy Start System | Facilitates quick ignition, reducing downtime and improving efficiency. |

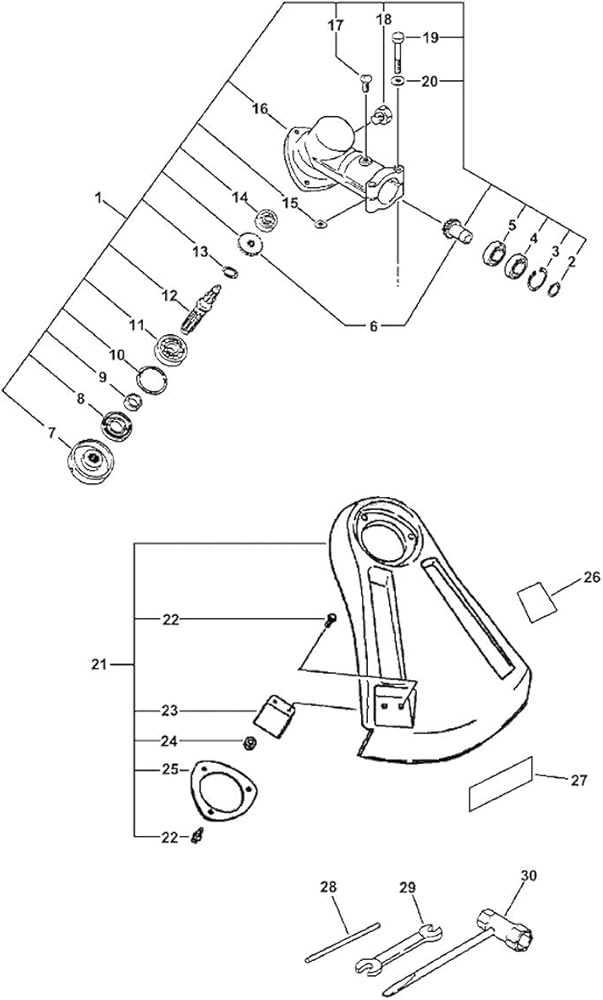

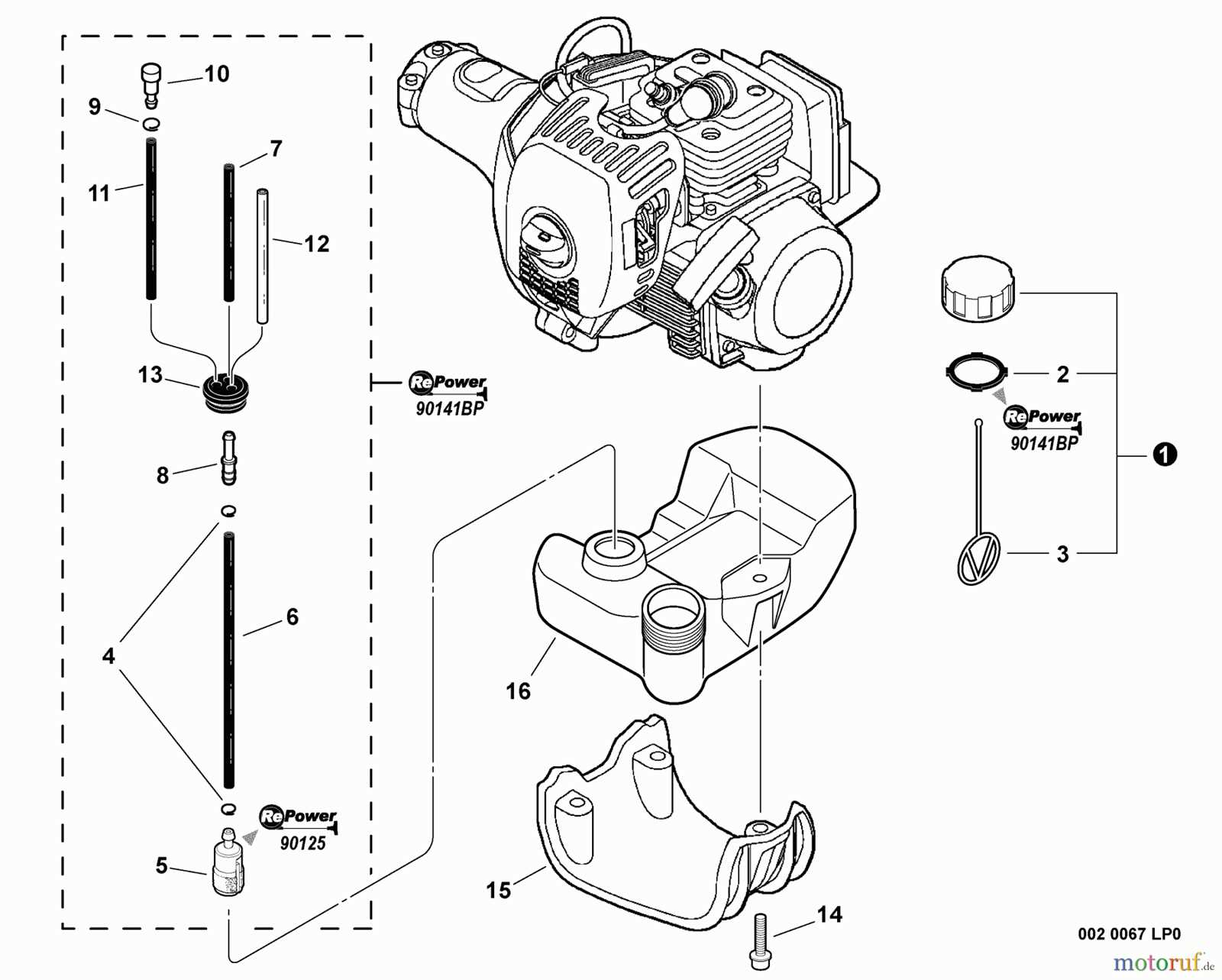

Understanding the Parts Diagram

The visual representation of components serves as an essential guide for users and technicians alike. This schematic layout highlights the various elements, providing clarity on how they interact and function within the overall system. Familiarity with this illustration enhances comprehension and facilitates maintenance tasks.

Each segment in the representation is meticulously labeled, allowing for easy identification. By referencing this illustration, individuals can effectively troubleshoot issues, ensuring the longevity of the equipment. It serves as a valuable resource, offering insights into assembly and disassembly procedures.

Moreover, grasping the relationships between different components aids in optimizing performance. Users can make informed decisions regarding replacements or upgrades, leading to improved functionality. Engaging with this informative guide empowers users to take charge of their equipment’s care and enhances their overall experience.

Essential Components Explained

This section provides an overview of vital elements commonly found in outdoor power equipment. Understanding these components is crucial for effective maintenance and optimal performance. Each element plays a significant role in the functionality and efficiency of the machinery.

The engine serves as the heart of the device, converting fuel into mechanical energy. It is essential to keep this part well-maintained to ensure reliable operation. The cutting mechanism, often made of durable materials, is responsible for executing precise cuts, making it vital for achieving the desired results.

Additionally, the fuel system plays a critical role in delivering energy to the engine, while the air filtration system protects the internal components from debris, ensuring longevity. Lastly, the handle and control systems provide the user with the necessary leverage and ease of operation, highlighting the importance of ergonomic design in enhancing user experience.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended lifespan of your equipment. Regular care not only enhances performance but also minimizes the likelihood of unexpected failures. Implementing a few straightforward strategies can lead to significant benefits over time.

- Regular Cleaning: Remove dirt, debris, and grass clippings from the unit after each use. This prevents buildup that can cause mechanical issues.

- Check and Replace Filters: Keep air and fuel filters clean and replace them as needed to maintain optimal airflow and performance.

- Inspect the Blades: Ensure that cutting blades are sharp and free of damage. Dull blades can strain the engine and reduce efficiency.

- Monitor Fuel Quality: Use fresh fuel and consider adding a stabilizer to prevent deterioration over time.

- Routine Lubrication: Lubricate moving parts regularly to reduce friction and wear, ensuring smooth operation.

- Store Properly: During off-seasons, store equipment in a dry, sheltered location to protect it from the elements.

By incorporating these practices into your maintenance routine, you can significantly enhance the durability and functionality of your equipment, leading to a more efficient and reliable performance.

Identifying Common Issues

When operating a string trimmer, users may encounter various problems that can affect performance and efficiency. Recognizing these issues early can save time and effort during maintenance. This section discusses some typical challenges and their potential causes.

Performance-Related Challenges

- Power Loss: A noticeable drop in power may be due to fuel quality or clogs in the air filter.

- Starting Difficulties: If the machine is hard to start, it might be a result of a drained battery or issues with the ignition system.

- Uneven Cutting: An inconsistent cutting performance can arise from dull blades or improper string length.

Maintenance-Related Problems

- Excessive Vibration: This may indicate loose components or misalignment in the cutting head.

- Overheating: An overheating engine could be a sign of insufficient lubrication or a blocked exhaust.

- Fuel Leaks: Leaks may occur from worn seals or damaged fuel lines, requiring immediate attention.

Replacement Parts Availability

Ensuring the accessibility of components for maintenance and repair is crucial for the longevity of any equipment. Users often seek reliable sources to procure necessary items that can restore functionality and enhance performance. A wide variety of options exists, catering to different needs and preferences.

Several avenues can be explored for acquiring these essential elements:

- Authorized Dealers: Official representatives provide authentic items, ensuring quality and compatibility.

- Online Retailers: Numerous e-commerce platforms offer a broad selection, often at competitive prices.

- Local Hardware Stores: Community outlets may carry popular replacements, allowing for immediate purchases.

- Manufacturer Websites: Direct purchases from the producer can guarantee the best options tailored for specific models.

When considering the procurement of components, it’s advisable to evaluate the following:

- Compatibility with the specific equipment model.

- Warranty and return policies for peace of mind.

- Customer reviews and ratings to ensure product reliability.

By exploring these options, users can effectively find the right solutions to maintain their tools and equipment.

Tools Required for Repairs

When undertaking maintenance tasks on outdoor power equipment, having the right tools at your disposal is crucial for effective and efficient repairs. Proper instruments not only facilitate smoother operations but also enhance safety during the repair process.

Essential tools typically include various wrenches, screwdrivers, and pliers. These items allow for the disassembly and reassembly of components with ease. Additionally, specialized equipment such as torque wrenches and impact drivers may be necessary to ensure that parts are secured to the manufacturer’s specifications.

Furthermore, having a reliable set of diagnostic tools can significantly aid in troubleshooting issues, enabling quicker identification of problems. Overall, being well-equipped is key to achieving successful maintenance outcomes.

Step-by-Step Assembly Guide

This section provides a comprehensive guide for assembling your equipment efficiently. By following these systematic steps, you can ensure that all components are fitted correctly and function optimally. Proper assembly is crucial for achieving the best performance and longevity from your tool.

Gather Necessary Tools

Before you begin, make sure you have all the required tools on hand. Having the right instruments not only makes the process smoother but also minimizes the risk of damage to any parts. Essential tools typically include screwdrivers, wrenches, and pliers.

Follow the Assembly Instructions

Carefully follow the assembly instructions provided with your unit. Start by identifying each component and its corresponding position. Pay attention to details such as orientation and alignment, as these are critical for the functionality of the equipment. Take your time to double-check your work at each step to avoid mistakes that could lead to performance issues.

Safety Precautions When Repairing

When undertaking maintenance or repairs on any equipment, it is essential to prioritize safety to prevent accidents and ensure a successful outcome. Awareness of potential hazards and adherence to recommended practices can significantly reduce the risk of injury. This section outlines key safety measures that should be observed during the repair process.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is crucial. This includes safety goggles to protect your eyes from debris, gloves to shield your hands from sharp edges, and sturdy footwear to prevent injuries from falling objects. Always ensure that your PPE is in good condition and suitable for the specific task at hand.

Work Environment Safety

Maintaining a clean and organized workspace is vital for minimizing risks. Keep tools and components stored properly to avoid tripping hazards. Ensure adequate lighting is available, as poor visibility can lead to mistakes and accidents. Additionally, always work in a well-ventilated area to prevent inhalation of harmful fumes or dust particles.

Frequently Asked Questions

This section addresses common inquiries regarding the maintenance and assembly of outdoor power tools. It aims to provide clear and concise answers to help users better understand their equipment and ensure optimal performance.

What should I do if I can’t find a specific component for my tool?

If you’re having difficulty locating a particular piece, consider checking with authorized retailers or online marketplaces that specialize in outdoor equipment. Additionally, consulting the manufacturer’s website can provide valuable resources and information.

How can I ensure that I am using the correct components?

To guarantee compatibility, refer to the user manual that came with your device. It typically includes specifications and recommendations for all necessary components, ensuring you select the right ones for your tool.

Is it advisable to use generic parts instead of original ones?

While generic parts may seem like a cost-effective solution, they may not always meet the quality standards of the original equipment. Using genuine components ensures reliability and longevity of your device.

How often should I inspect my tool for wear and tear?

Regular inspections are crucial. It is recommended to check your equipment before each use, paying close attention to signs of wear. This practice helps prevent issues during operation and extends the lifespan of your tool.

Additional Resources and References

This section aims to provide readers with valuable materials and sources to enhance their understanding of the topic at hand. By exploring supplementary literature, individuals can gain deeper insights and practical knowledge about the subject, facilitating more informed decisions and effective problem-solving.

Recommended Literature

For those seeking comprehensive guides, various manuals and instructional books offer in-depth information. These publications often include troubleshooting tips, maintenance advice, and operational guidance that are essential for optimal use and care of the equipment.

Online Communities and Forums

Participating in online forums and community discussions can be incredibly beneficial. Engaging with other users allows for the sharing of experiences and solutions, creating a collaborative environment where individuals can seek advice and learn from one another. Websites dedicated to outdoor equipment often host these discussions, fostering a supportive network of enthusiasts.