Understanding the Components of a DC Electric Motor Diagram

The intricate world of direct current drives encompasses a variety of essential elements that work harmoniously to convert electrical energy into mechanical motion. A comprehensive examination of these components reveals how each plays a crucial role in ensuring the efficient operation of the system.

By delving into the specific functions and interactions of these key elements, one can gain valuable insights into the underlying mechanics that govern performance and reliability. Each component contributes uniquely to the overall functionality, highlighting the importance of their precise arrangement and synergy.

Furthermore, recognizing the significance of these individual pieces allows for a deeper understanding of troubleshooting and maintenance practices. This knowledge empowers users to optimize performance and prolong the lifespan of the entire assembly.

Understanding DC Electric Motors

Devices powered by direct current have become integral in numerous applications due to their efficiency and reliability. These systems convert electrical energy into mechanical energy, enabling a wide range of functions, from simple household appliances to complex industrial machinery.

Key components contribute to the operation and performance of these devices:

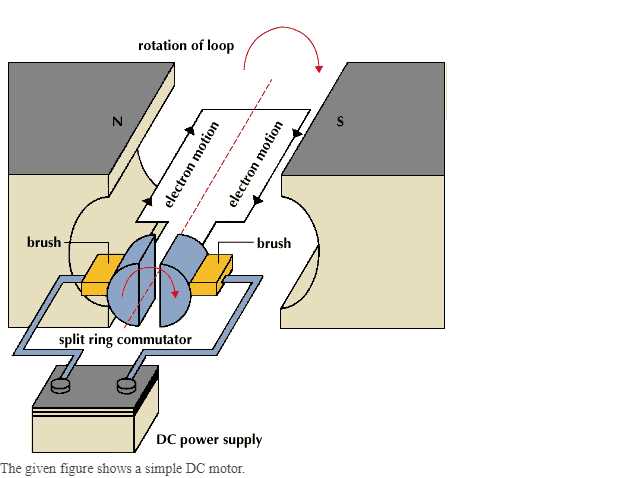

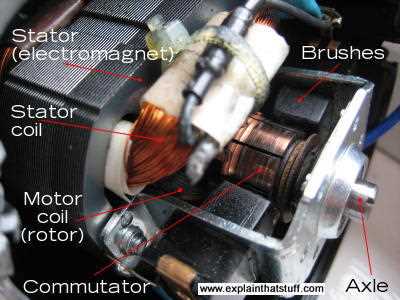

- Armature: This rotating element is crucial for transforming electrical energy into motion.

- Field Windings: These create a magnetic field that interacts with the armature, facilitating rotation.

- Commutator: This component ensures the flow of current is directed properly, allowing for consistent motion.

- Brushes: These maintain electrical contact with the commutator, providing necessary current for the armature.

The interaction between these components defines the performance characteristics, such as speed and torque. Understanding the functions and relationships among them is essential for optimizing and troubleshooting these systems.

Applications of direct current systems are vast, including:

- Automotive systems for propulsion and accessory power.

- Home appliances like vacuum cleaners and fans.

- Industrial tools for manufacturing processes.

- Renewable energy solutions such as solar panel systems.

In conclusion, a thorough grasp of the various components and their roles enhances the ability to utilize and innovate within this essential technology.

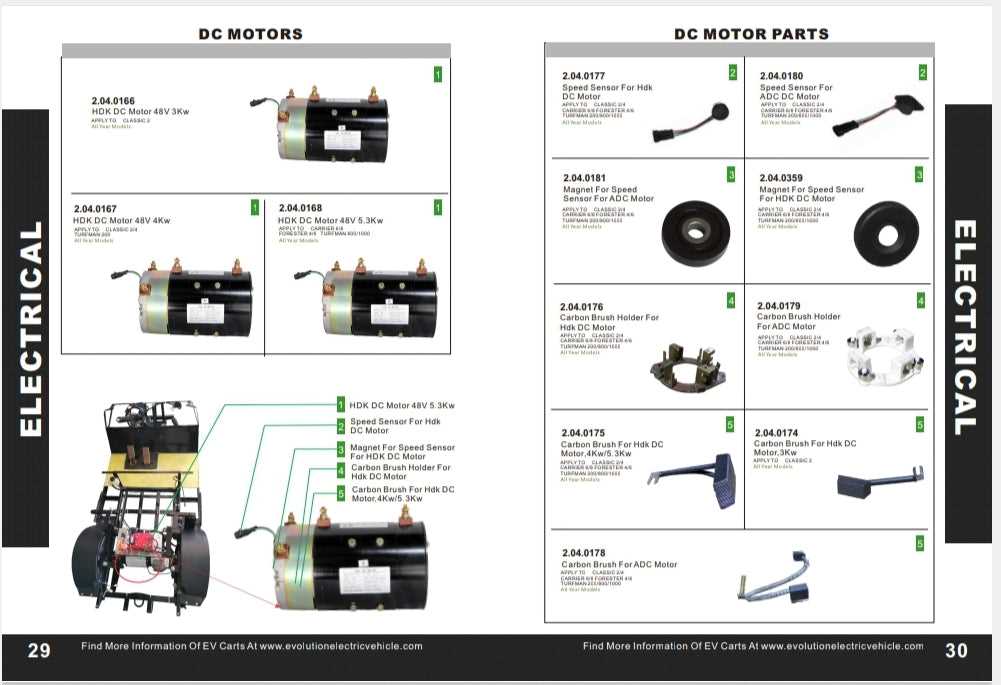

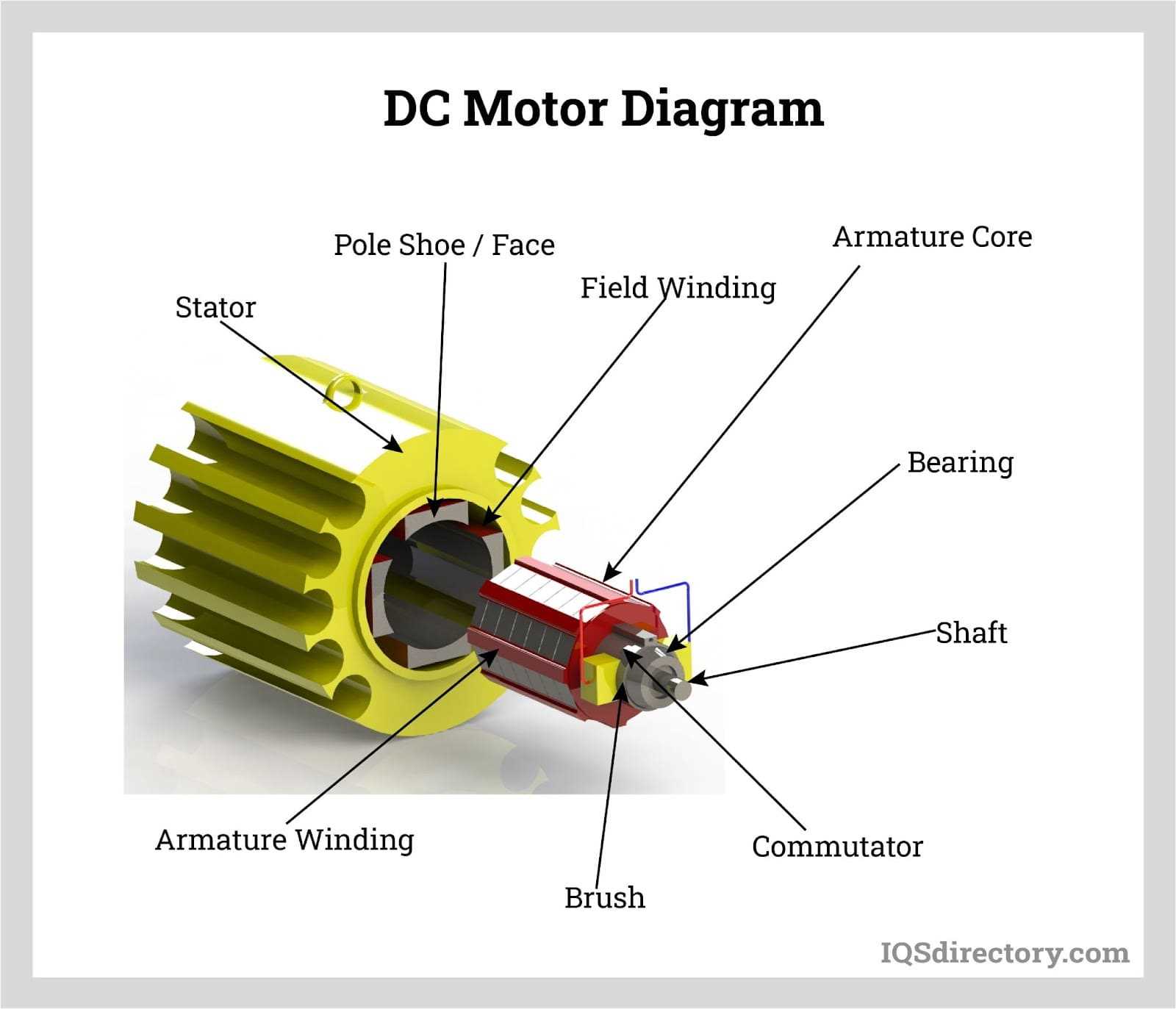

Key Components of DC Motors

Understanding the essential elements that make up these devices is crucial for grasping their functionality and efficiency. Each component plays a vital role in the overall operation, influencing performance and reliability.

Armature: The core part responsible for converting electrical energy into mechanical motion, usually consisting of a winding that rotates within a magnetic field.

Commutator: A segmented switch that ensures the current flows in the correct direction, facilitating continuous rotation by reversing the current as the armature turns.

Field Windings: Coils of wire that generate a magnetic field when energized, crucial for establishing the interaction between the armature and the magnetic field.

Brushes: Conductive elements that maintain electrical contact with the commutator, allowing current to flow to the armature while compensating for its rotation.

Shaft: A mechanical element that transmits the rotational motion generated by the armature to external loads, playing a key role in power delivery.

These components work in harmony to deliver the ultimate performance, enabling various applications across industries.

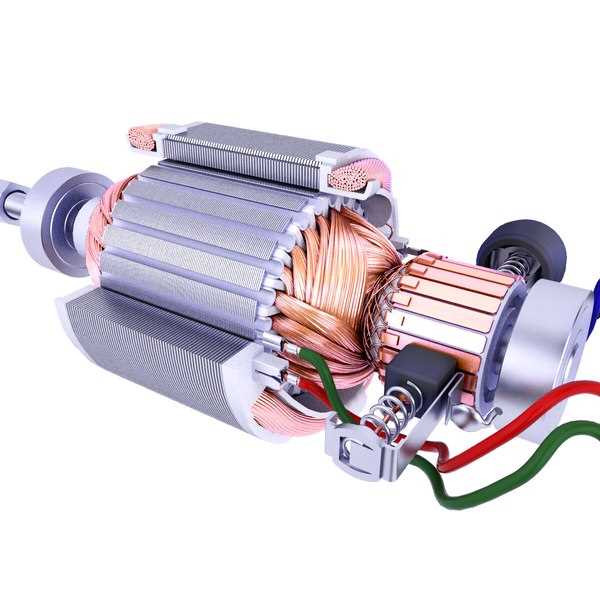

Function of the Armature

The armature plays a crucial role in the operation of a machine by facilitating the conversion of energy. It serves as the core component that interacts with magnetic fields, ultimately generating motion. This element is vital for achieving the desired performance and efficiency of the system.

Energy Conversion

When current flows through the windings of the armature, it creates a magnetic field that interacts with the stationary magnets. This interaction leads to torque generation, causing the armature to rotate. The ability to transform electrical energy into mechanical work is fundamental to the effectiveness of the apparatus.

Components and Design

The design of the armature is optimized to enhance its functionality. It typically consists of a core made from ferromagnetic materials, which improves magnetic flux. Additionally, the winding configuration is engineered to maximize the electromagnetic forces at play, ensuring the system operates at its ultimate potential.

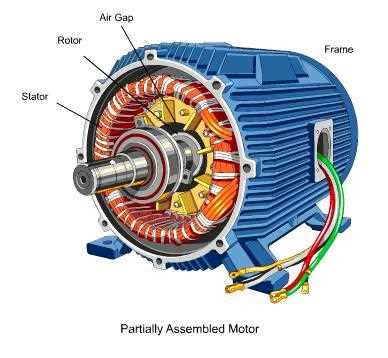

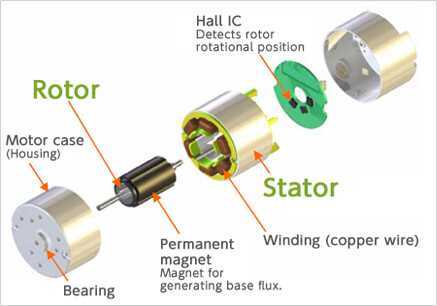

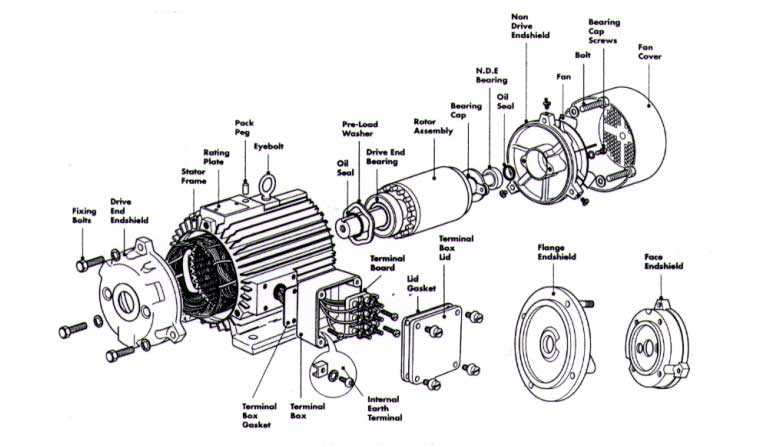

The Role of the Stator

The stator serves a crucial function in the operation of rotating machinery, providing stability and structure while facilitating the generation of magnetic fields. This component is essential for transforming electrical energy into mechanical motion, acting as the anchor that allows other elements to perform their roles effectively.

Typically composed of a series of windings and laminated cores, the stator interacts with rotating parts to create the necessary magnetic fields. These fields are fundamental for inducing motion and ensuring efficient performance. The quality and design of the stator directly influence the efficiency and reliability of the overall system.

| Feature | Description |

|---|---|

| Magnetic Field Generation | Creates a stable magnetic environment essential for operation. |

| Structural Support | Holds other components in place, ensuring alignment and durability. |

| Energy Efficiency | A well-designed stator enhances performance and reduces energy loss. |

| Heat Dissipation | Helps manage thermal conditions to prevent overheating. |

In summary, the stator is a vital element that underpins the effectiveness of rotating systems. Its design and function are integral to achieving optimal performance and longevity.

Importance of Brushes and Commutators

The elements responsible for transferring energy within a rotating device are crucial for its optimal functioning. These components ensure that the flow of current remains steady and allows for effective performance across various applications.

Brushes play a significant role in maintaining electrical contact while the device operates. They are designed to withstand wear and tear, ensuring longevity and reliability. Conversely, commutators are pivotal in reversing the direction of current, enabling consistent torque and efficiency.

| Component | Function | Importance |

|---|---|---|

| Brushes | Maintain contact with the rotating part | Ensure consistent current flow |

| Commutators | Reverse current direction | Enable effective torque generation |

Understanding these components allows for better maintenance and troubleshooting, ultimately enhancing performance and extending the life of the system.

Power Supply Connections Explained

The connection of power sources is crucial for the efficient operation of various devices. Understanding how these connections function can significantly impact performance and reliability. Properly aligning voltage and current requirements ensures optimal efficiency and longevity of the system.

Direct connections typically provide a steady flow of energy, while indirect connections, such as those involving transformers or converters, modify the input to suit specific needs. Each type of connection serves a unique purpose, addressing varying demands for power levels.

When establishing connections, polarity plays a vital role. Incorrect polarity can lead to malfunctions or damage. It is essential to verify the configuration to maintain the integrity of the setup.

Additionally, the use of fuses or circuit breakers is recommended to safeguard against overloads. These protective components help manage excess current and prevent potential hazards.

Ultimately, understanding these connections allows for enhanced performance and safety, making it a fundamental aspect of device operation.

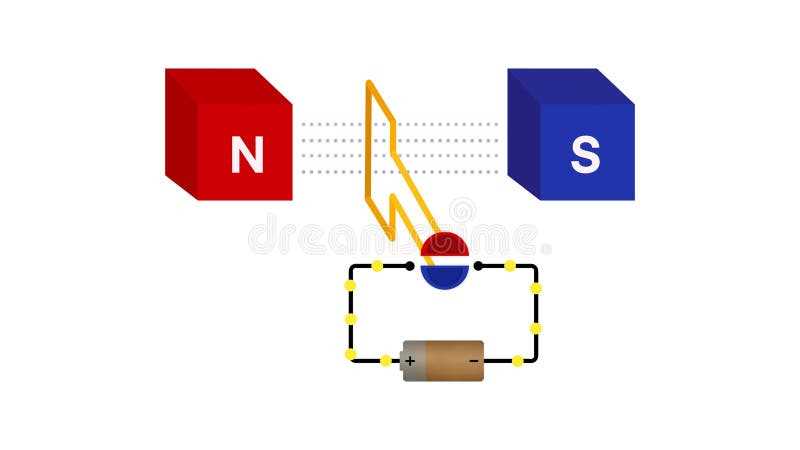

Magnetic Field Creation Mechanism

The generation of a magnetic field is a fundamental process that underpins many technologies. Understanding this mechanism is essential for grasping how various devices operate efficiently.

- Current Flow: The movement of charged particles creates a magnetic field around the conductor.

- Electromagnetism: The interaction between electricity and magnetism facilitates the creation of a magnetic field.

- Field Direction: The right-hand rule helps determine the orientation of the generated field based on the direction of the current.

Various components contribute to the effectiveness of this process:

- Coils: Wrapping conductors into coils enhances the strength of the generated field.

- Core Materials: Utilizing ferromagnetic materials within coils intensifies the magnetic field.

- Power Source: The intensity of the flow significantly impacts the strength of the resultant field.

In summary, the intricate interplay of current, materials, and design ultimately determines the efficiency of magnetic field generation.

Types of DC Motor Configurations

Understanding the various arrangements of direct current machines is essential for selecting the right design for specific applications. Each configuration offers unique characteristics and benefits, making them suitable for different operational needs. This section explores the prominent types and their distinctive features.

1. Series Configuration

In this setup, the winding is connected in series with the armature. This arrangement has several implications for performance:

- High starting torque, ideal for applications requiring significant initial power.

- Speed varies inversely with load; as load increases, speed decreases.

- Commonly used in applications like cranes and electric traction systems.

2. Shunt Configuration

The shunt configuration features the winding connected in parallel with the armature. This design is known for its unique attributes:

- Maintains relatively constant speed under varying loads.

- Provides lower starting torque compared to the series arrangement.

- Typically found in applications like fans and blowers where consistent speed is essential.

Each configuration serves distinct operational roles, influencing the overall efficiency and effectiveness of the system. Understanding these types aids in making informed decisions for specific industrial and commercial requirements.

Winding Types and Their Functions

In the realm of electromagnetic devices, the arrangement of conductive materials plays a pivotal role in their operation. Different configurations of coils influence performance characteristics, efficiency, and overall functionality. Understanding these variations is essential for optimizing the design and application of such systems.

Types of Windings

- Lap Winding: This configuration allows for higher current capacity and is commonly used in high-power applications.

- Wave Winding: With a more distributed coil layout, this type is ideal for reducing harmonics and improving smooth operation.

- Spiral Winding: Often utilized for compact designs, spiral arrangements enhance space efficiency while maintaining performance.

Functions of Different Winding Types

- Magnetic Field Generation: The arrangement of coils determines the strength and direction of the magnetic field produced.

- Torque Production: Different winding types influence how torque is developed, affecting the response and dynamics of the system.

- Efficiency Optimization: The design of the winding can minimize losses, leading to better energy utilization and performance.

Thermal Management in Motor Design

Effective thermal regulation is crucial for ensuring optimal performance and longevity of machinery. Excessive heat can lead to inefficiencies, reduced output, and potential failures, highlighting the necessity for robust temperature control strategies.

Key Considerations

- Heat Generation: Understanding sources of thermal energy is essential for effective management.

- Material Selection: Choosing materials with appropriate thermal conductivity can enhance heat dissipation.

- Cooling Techniques: Implementing various cooling methods, such as forced air or liquid cooling, can mitigate overheating.

Strategies for Effective Management

- Designing for airflow: Ensuring proper ventilation within the structure allows for better heat exchange.

- Incorporating heat sinks: Using these devices can help draw heat away from critical components.

- Utilizing thermal insulation: Properly insulating certain areas can prevent unwanted heat transfer.

Applications of DC Electric Motors

These devices play a crucial role in various fields, providing efficiency and reliability in numerous applications. Their versatility allows them to be utilized in both simple and complex systems, enhancing functionality across different sectors.

- Automotive Industry

- Robotics and Automation

- Consumer Appliances

- Medical Equipment

- Industrial Machinery

In the automotive sector, they are employed in features such as window lifts and seat adjustments. In robotics, they enable precise movements and control. Household items like vacuum cleaners and blenders utilize them for effective operation. Medical devices rely on their reliability for critical functions. Finally, in industry, they drive conveyors and tools, ensuring productivity.

Maintenance Tips for Longevity

Ensuring the durability of your machinery requires consistent care and attention. Implementing regular check-ups and maintenance routines can significantly enhance performance and lifespan. By following a few key practices, you can prevent unexpected breakdowns and extend functionality.

1. Regular Cleaning: Keep the components free from dust and debris. Accumulation can lead to overheating and reduced efficiency. Use a soft brush or cloth to gently wipe surfaces.

2. Lubrication: Apply appropriate lubricants to moving elements to minimize friction. This practice not only improves efficiency but also prevents wear and tear over time.

3. Inspect Connections: Regularly examine all electrical connections and wiring. Ensure that they are secure and free from corrosion, as this can lead to malfunctions.

4. Monitor Performance: Pay attention to any unusual sounds or changes in operation. Early detection of issues can save time and resources in the long run.

5. Store Properly: When not in use, ensure that your equipment is stored in a dry and stable environment to prevent damage from moisture and extreme temperatures.

By adhering to these practices, you can delve into a realm of optimal performance, ensuring your machinery remains reliable for years to come.